A method for detecting the overall additional tension of a multi-wire cutting machine

A multi-wire cutting machine and tension detection technology, applied in stone processing equipment, manufacturing tools, work accessories, etc., to achieve the effect of simple and convenient operation, low detection cost, and saving wiring network time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

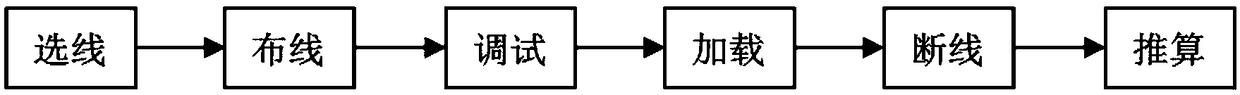

Method used

Image

Examples

Embodiment 1

[0041] Optimization of loading tension: The loading tension △F increases and decreases, and the final applied tension value Fd can be detected more accurately.

[0042] In this embodiment, a diamond wire with a stable busbar diameter of 80 μm is used, and the breaking tension Fj of the diamond wire measured by a tensile machine is 20.8N.

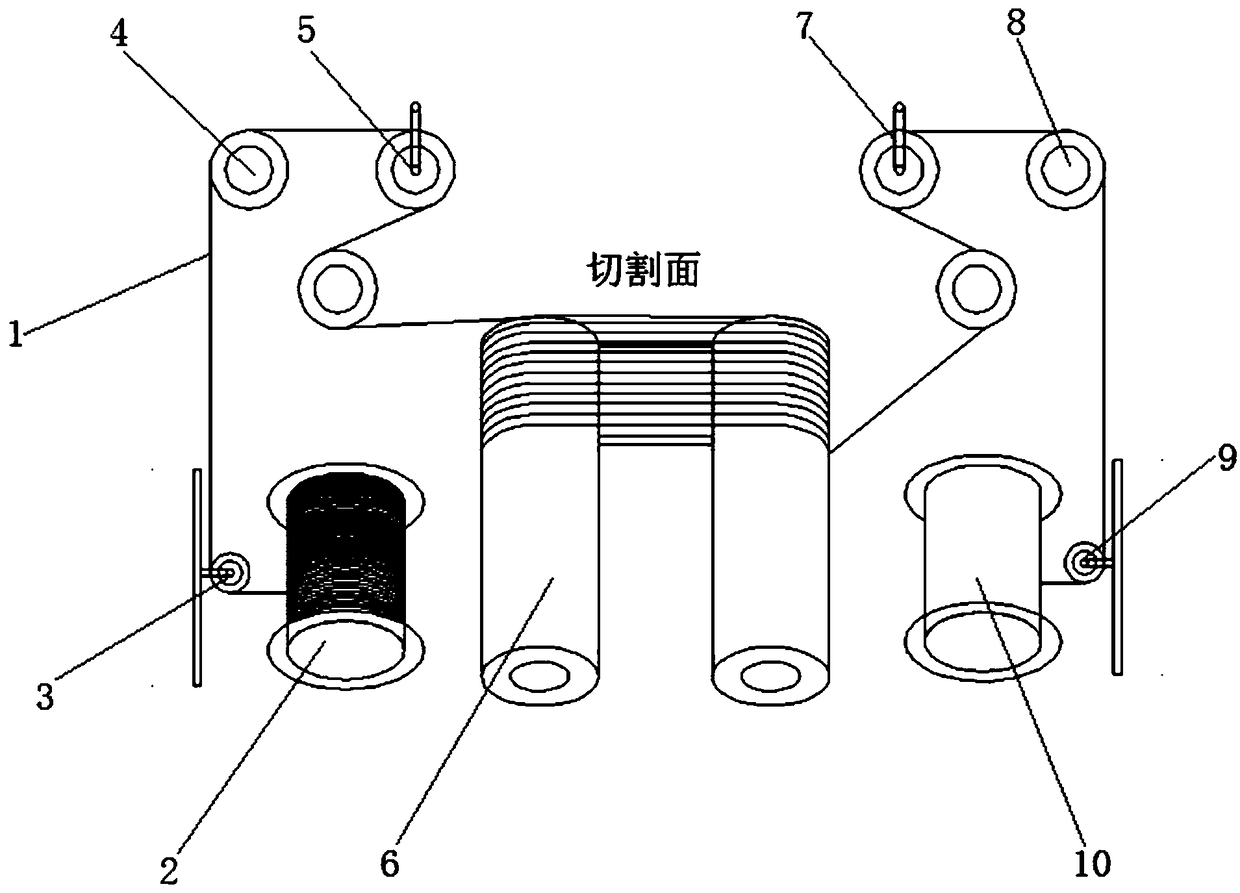

[0043] see figure 2 , the diamond wire 1 passes through the pay-off wheel 2, the wire-discharging wheel 3 at the pay-off end, the guide wheel 4 at the pay-off end, the tension arm 5 at the pay-off end, the main roller 6, the tension arm 7 at the take-up end, and the guide wheel 8 at the take-up end 1. Wiring is carried out by the line take-up wheel 9 and the line take-up wheel 10. During the wiring process, the initial tension is 10N, the line speed is 0.5m / min, and the width of the wiring network is 80mm. Start the cutting machine and run it in the non-cutting state. The line speed is 1000m / min, the acceleration and deceleration time is 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com