Rotational flow ultralow NOX gas burner

A gas burner and burner technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of high nitrogen oxide emissions, insufficient combustion, complex structure, etc., to achieve stable combustion and prevent disturbance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

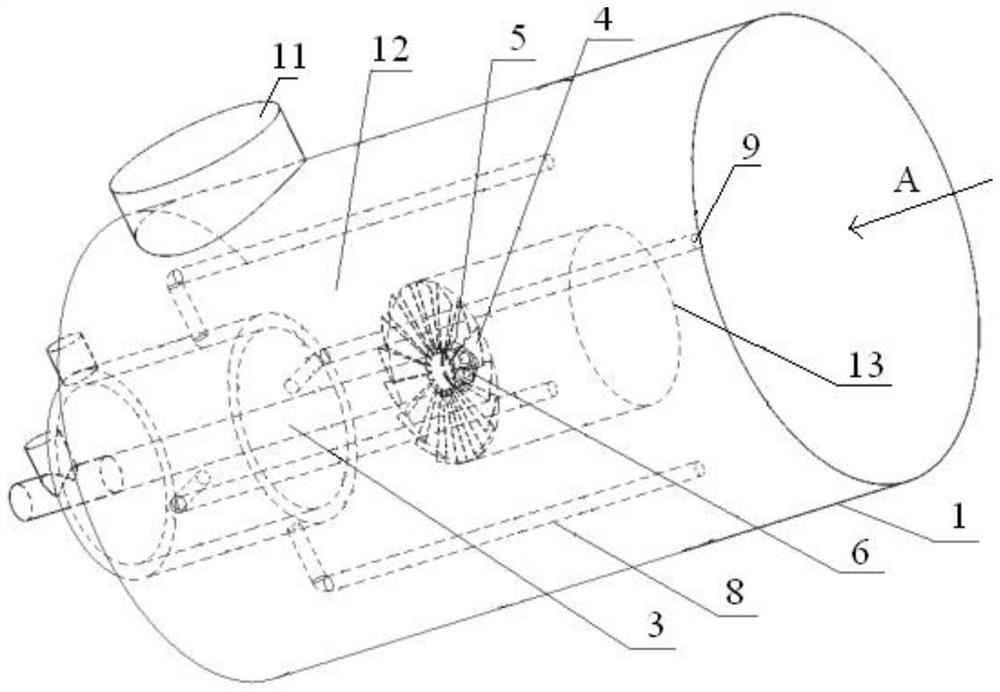

[0035] Example 1:

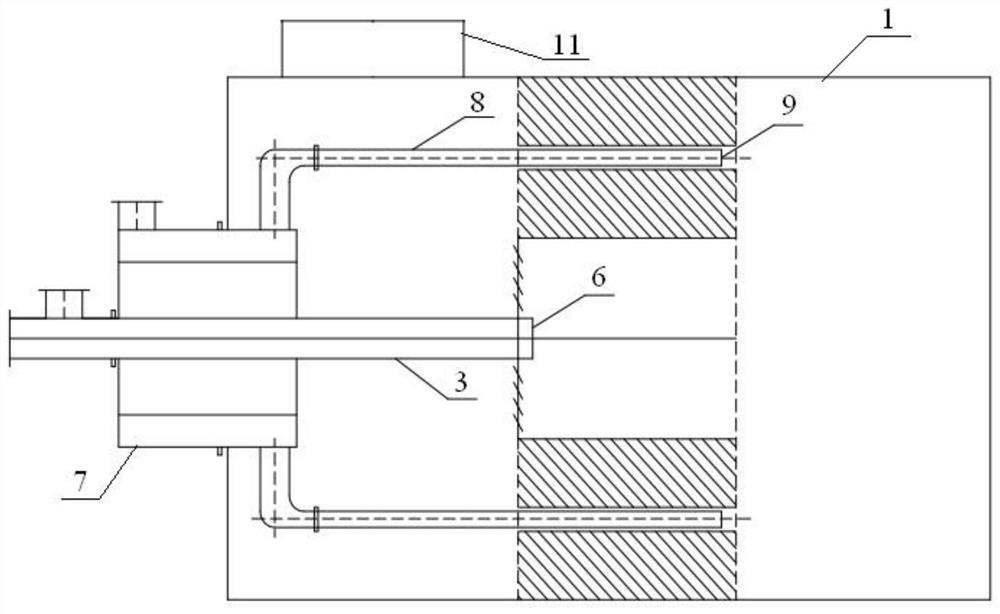

[0036] See Figure 1-4 , a swirl ultra-low NO X The gas burner comprises a burner shell 1, a primary air inlet part, a secondary air inlet part, a flue gas and air mixed air inlet part and an igniter 2, wherein the burner shell 1 has a cylindrical barrel structure, one end of which is a gas inlet and the other end is a gas outlet;

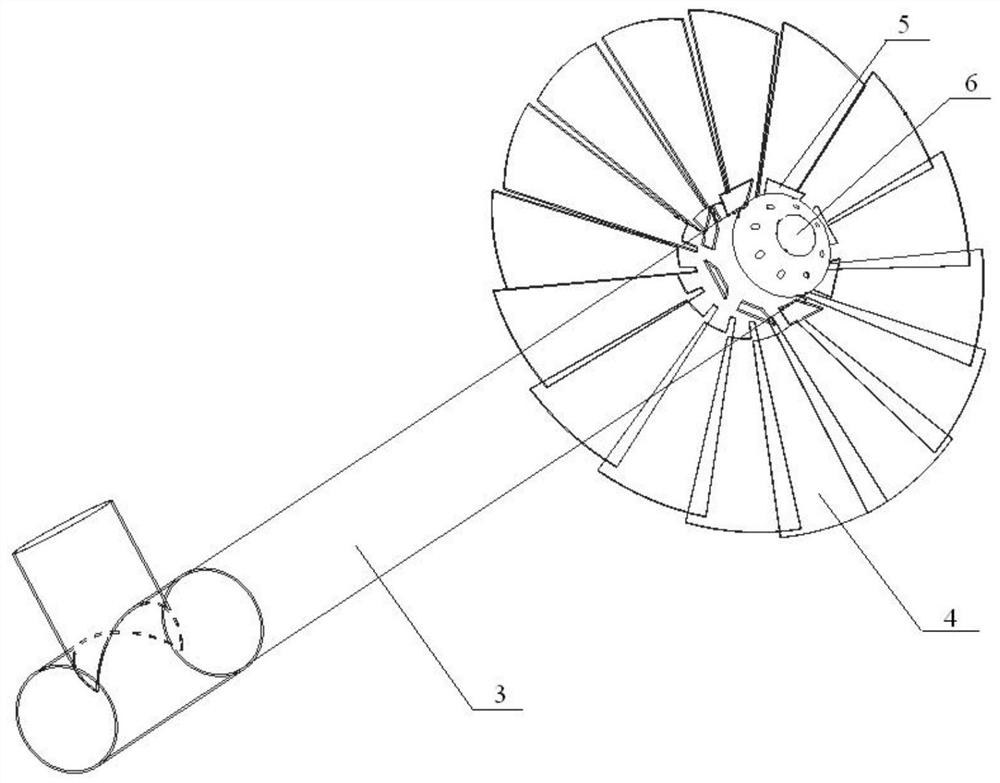

[0037] The primary gas inlet component comprises a primary gas pipeline 3 coaxially arranged with the combustor casing 1, a cyclone blade 4, a combustion-stabilizing baffle 5 and a primary gas nozzle 6 which are sequentially arranged on the primary gas pipeline 3 along the gas conveying direction, wherein one end of the primary gas pipeline 3 is provided with a primary gas inlet outside the combustor casing 1, and the other end is inserted into the combustor casing 1 from the gas inlet position. The number of the cyclone blades 4 and the combustion-stabilizing baffle plates 5 are multiple and are arranged obliquely along the outer si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com