On-line width adjustment system for mold of slab continuous casting machine

A slab continuous casting machine and mold technology, applied in the field of slab continuous casting machine mold online width adjustment system, can solve the problems of wasting energy, affecting the production efficiency of continuous casting machine, mold running cone, etc., and improving production Efficiency, smooth continuous production operation, and effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

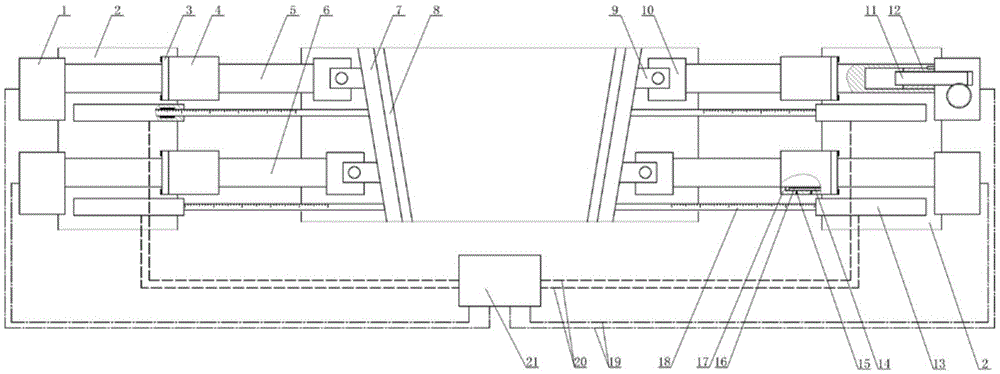

[0011] The on-line mold width adjustment system of the slab continuous casting machine includes a mold width adjustment controller 21 and a mold frame 2. The inner wall of the mold has two wide-side copper plates and two narrow-side copper plates 8, each The copper plates are all installed on the water-cooled water tank, forming an inverted cone shape, and the top and bottom are open metal containers. The two narrow-side copper plates are equipped with a mechanical transmission type crystallizer width adjustment device. The width adjustment device is driven by a screw rod 11 and a screw nut 12. There are two sets of transmission mechanisms on each side. The reduction motor 1 drives the screw rod to rotate, and the screw rod The nut is installed in the push rod, and the nut is connected with the push rod through the flat key. With the rotation of the screw rod, the nut and the push rod move horizontally along the axial direction of the screw rod. The head of each push rod has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com