Touch panel and manufacturing method thereof

A technology of a touch panel and a manufacturing method, which is applied in the direction of instruments, electrical digital data processing, and input/output process of data processing, etc., can solve problems such as electrode layer disconnection and height difference, and achieve reduction of electrode layer disconnection and good The effect of production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

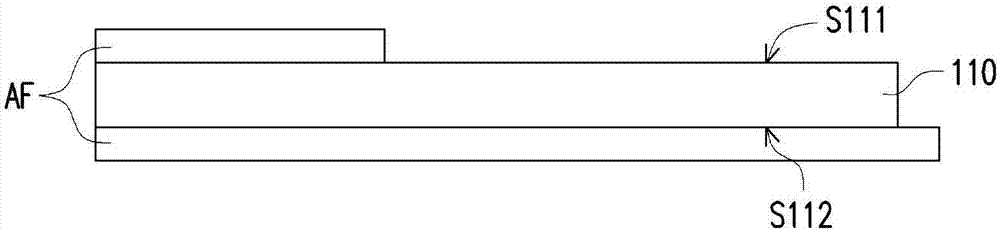

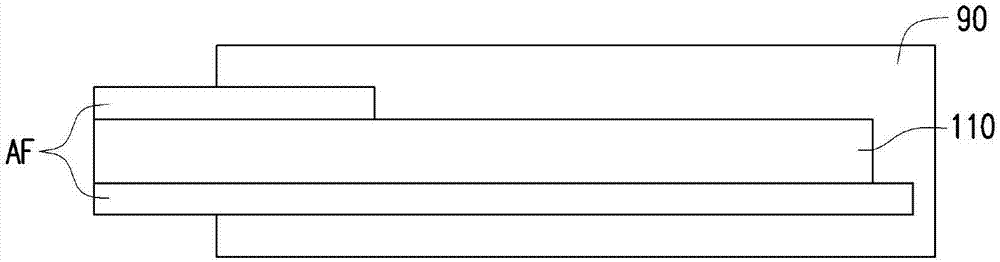

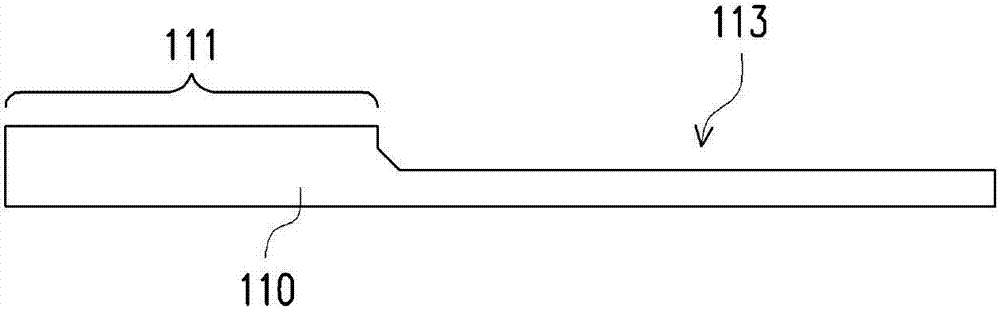

[0039] Figures 1A to 1F It is a schematic flowchart of the manufacturing method of the touch panel according to the first embodiment of the present invention. Figures 1A to 1F The cross-sectional structure diagrams of the touch panels are respectively shown. Figure 1G Yes Figure 1F Front view of the touch panel. First, a substrate 110 is provided, wherein the substrate 110 has a first surface S111 and a second surface S112 opposite to each other. In this embodiment, the substrate 110 is, for example, a glass substrate, but the invention is not limited thereto. In other embodiments, the material of the substrate 110 may be other light-transmitting materials. In addition, in this embodiment, the maximum thickness of the substrate 110 ranges from 700 μm to 1000 μm. It should be noted that the above-mentioned parameter ranges are only illustrative, and are not intended to limit the present invention. The thickness of the substrate 110 can be determined according to the des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com