Single-thread-inlet single-tube yarn feeder

A yarn feeder and single-tube technology, which is applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of unsteady yarn delivery, yarn breakage, and unstable tension, so as to ensure efficient operation, Compact structure and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific drawings and embodiments.

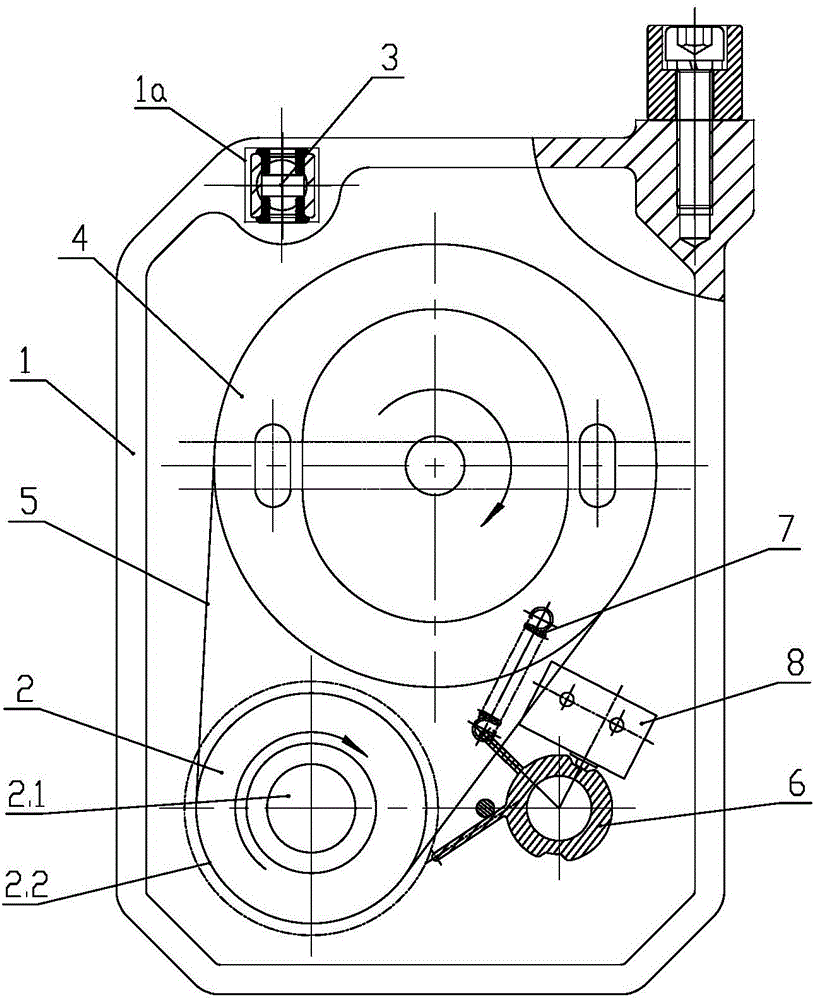

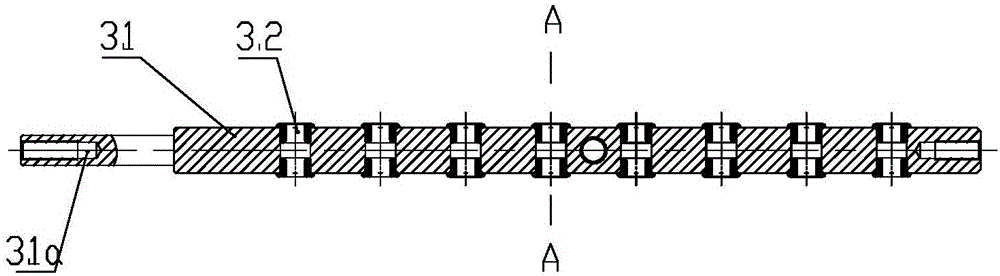

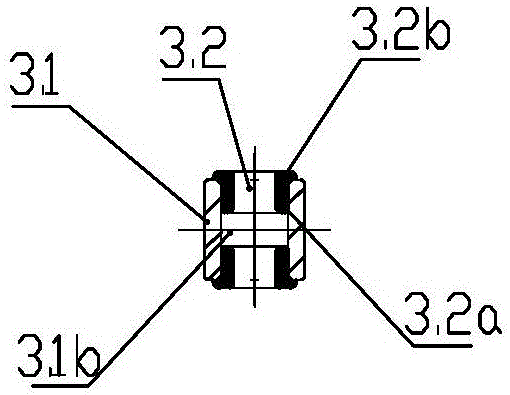

[0027] As shown in the figure: the single-entry single-tube yarn feeder in the embodiment is mainly composed of a single tube base 1, a roller roller 2, a yarn guide rod assembly 3, a driving mechanism and a yarn-breaking self-stop mechanism; the single tube base 1 It is square, and the upper left corner of the top of the single pipe seat 1 is provided with an incoming yarn guide rod mounting seat 1a, and a set of yarn guide rod assembly 3 is installed on the incoming thread guide rod mounting seat 1a; in the middle of the upper part of the single pipe seat 1 A motor shaft hole is provided, and the drive mechanism includes a motor, a drive pulley 4 and a transmission belt 5, and the motor is installed on the rear side wall of the single tube base 1, and the output shaft of the motor is connected from the motor shaft on the single tube base 1. The hole stretches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com