Improved single-tube yarn feeder with pitch adjusting function

An improved yarn feeder technology, which is used in the transportation of filamentous materials, thin material handling, transportation and packaging, can solve the problems of yarn breakage, unsteady yarn delivery, unstable tension, etc. Compact structure, ensure efficient operation, and improve the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific drawings and embodiments.

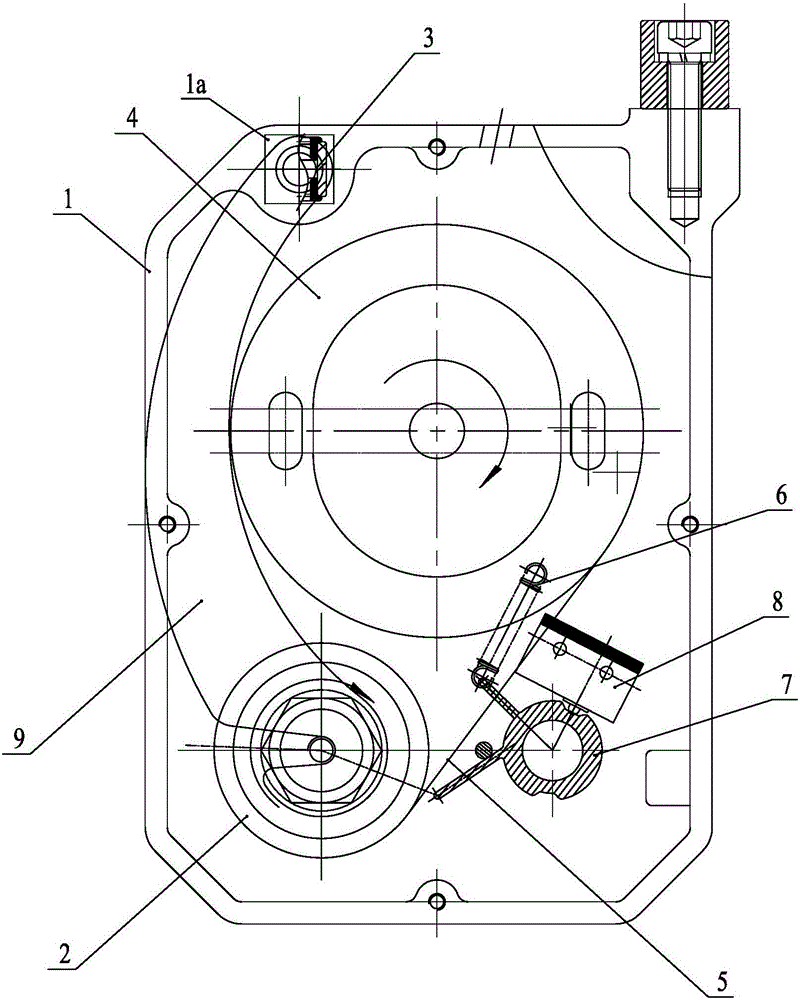

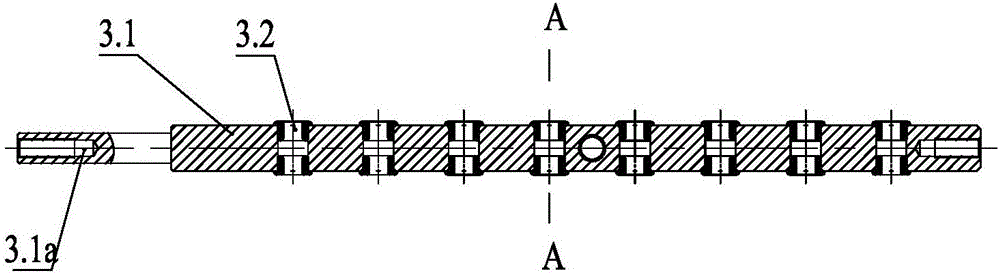

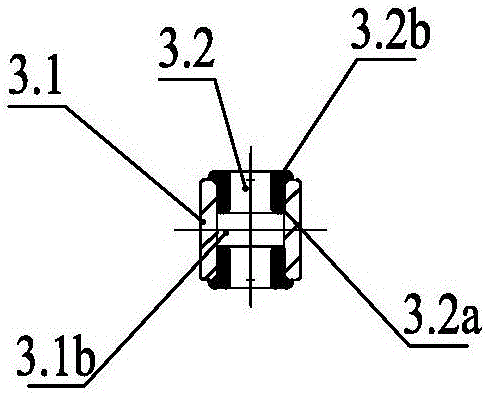

[0027] As shown in the figure: the improved single tube yarn feeder with distance adjustment function in the embodiment is mainly composed of single tube seat 1, roller roller 2, yarn guide rod assembly 3, distance adjustment connecting plate 9, driving mechanism and yarn breaking automatic The stop mechanism is composed of: the single pipe base 1 is square, and the upper left corner of the top of the single pipe base 1 is provided with an inlet yarn guide rod installation seat 1a, and a set of yarn guide rods is installed on the inlet yarn guide rod installation seat 1a Component 3; a motor shaft hole is provided in the middle of the upper part of the single tube base 1, the drive mechanism includes a motor, a drive pulley 4 and a transmission belt 5, the motor is installed on the rear side wall of the single tube base 1, and the output of the motor The shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com