Yarn guide rod assembly of single-tube yarn feeder

A yarn guide rod and yarn feeder technology, which is applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of unsteady yarn delivery, yarn breakage, and unstable tension, etc., to improve work efficiency and product quality, reduced yarn breakage, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific drawings and embodiments.

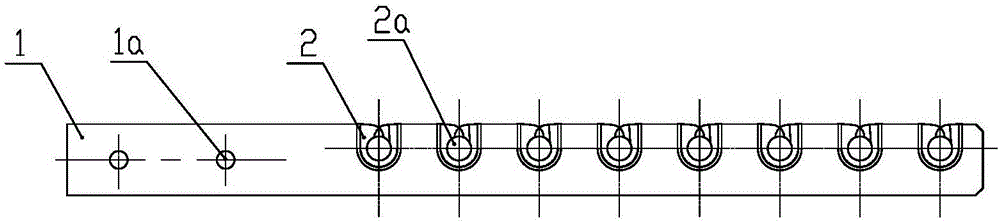

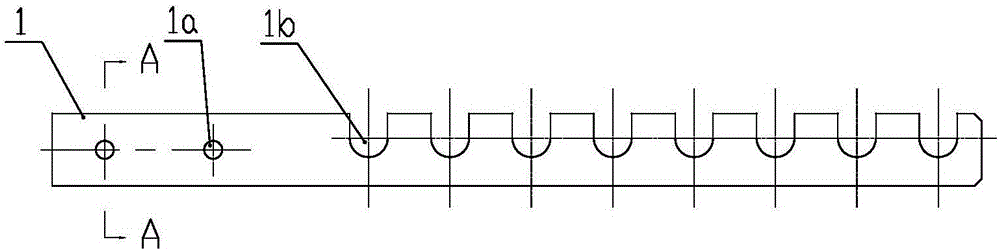

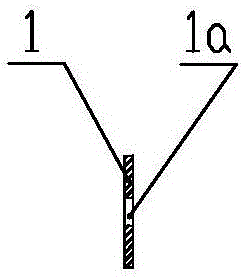

[0018] As shown in the figure: the yarn guide rod assembly of the single-tube yarn feeder in the embodiment is mainly composed of a yarn guide rod 1 and a yarn guide ring 2. There are installation holes 1a, and several yarn loop installation grooves 1b are evenly distributed along the length direction on the yarn guide rod 1; the yarn guide loop 2 is detachably assembled in the yarn loop installation groove 1b, and the center A yarn guide hole 2a is provided.

[0019] Such as Figure 1~Figure 5 As shown, in this embodiment, the yarn loop installation groove 1b is U-shaped, and the opening of the U-shaped yarn loop installation groove 1b is located on the upper side of the yarn guide rod 1, and the shape of the yarn guide loop 2 is U-shaped. The outer peripheral surface of the yarn coil 2 is provided with an inlaid clamping groove 2b matching with the side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com