Method of cutting ingot by wire-cutting mesh

A technology of splitting nets and ingots, which is applied in the direction of fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of affecting work efficiency, reducing production capacity, and unstable tension, so as to improve production efficiency and production capacity, improve The effect of reducing product yield and disconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

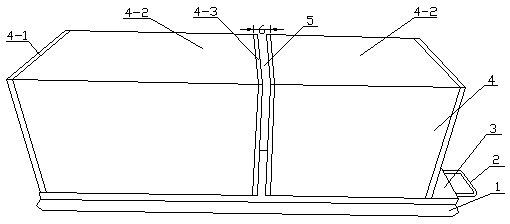

[0027] A method for cutting a crystal rod by a wire-dividing net, comprising the following steps (such as figure 1 shown):

[0028] 1) Band sawing process: the width of the bottom 4-1 of each silicon block 4 and the effective cutting length 4-2 of the silicon block are fixed values, and the top 4-3 of the two silicon blocks 4 are measured using a steel ruler , the area 4-1 at the bottom of the silicon block, and use a marker pen to mark the entry position of the band saw when cutting the silicon block, that is, the positions of the top 4-3 of the silicon block and the bottom 4-1 of the silicon block, each with a width of 2mm. Use Wuxi Shangji band saw machine tool for cutting (a band saw blade is installed on the band saw machine tool, the band saw blade rotates at high speed, the silicon block moves slowly with the worktable of the band saw machine tool, and the band saw blade cuts the silicon block).

[0029] 2) Bonding process: Before slicing, a bonding process is required...

Embodiment 2

[0038] The difference from Example 1 is that in step 1), the top 4-3 of the silicon block and the bottom 4-1 of the silicon block each retain a width of 3 mm; in step 2), a gap 5 with a width of 5 mm is left between the two silicon blocks 4 . Using the method improves the qualified rate of products, production efficiency and production capacity.

Embodiment 3

[0040] The difference from Example 1 is that in step 1), the top 4-3 of the silicon block and the bottom 4-1 of the silicon block each retain a width of 2.5 mm; in step 2), a gap 5 with a width of 4 mm is reserved between the two silicon blocks 4 . Using the method improves the qualified rate of products, production efficiency and production capacity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com