Wheel braking mechanism

A brake mechanism and wheel technology, applied in the direction of gear transmission mechanism, brake type, trolley, etc., can solve the problems of high local stress and low contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

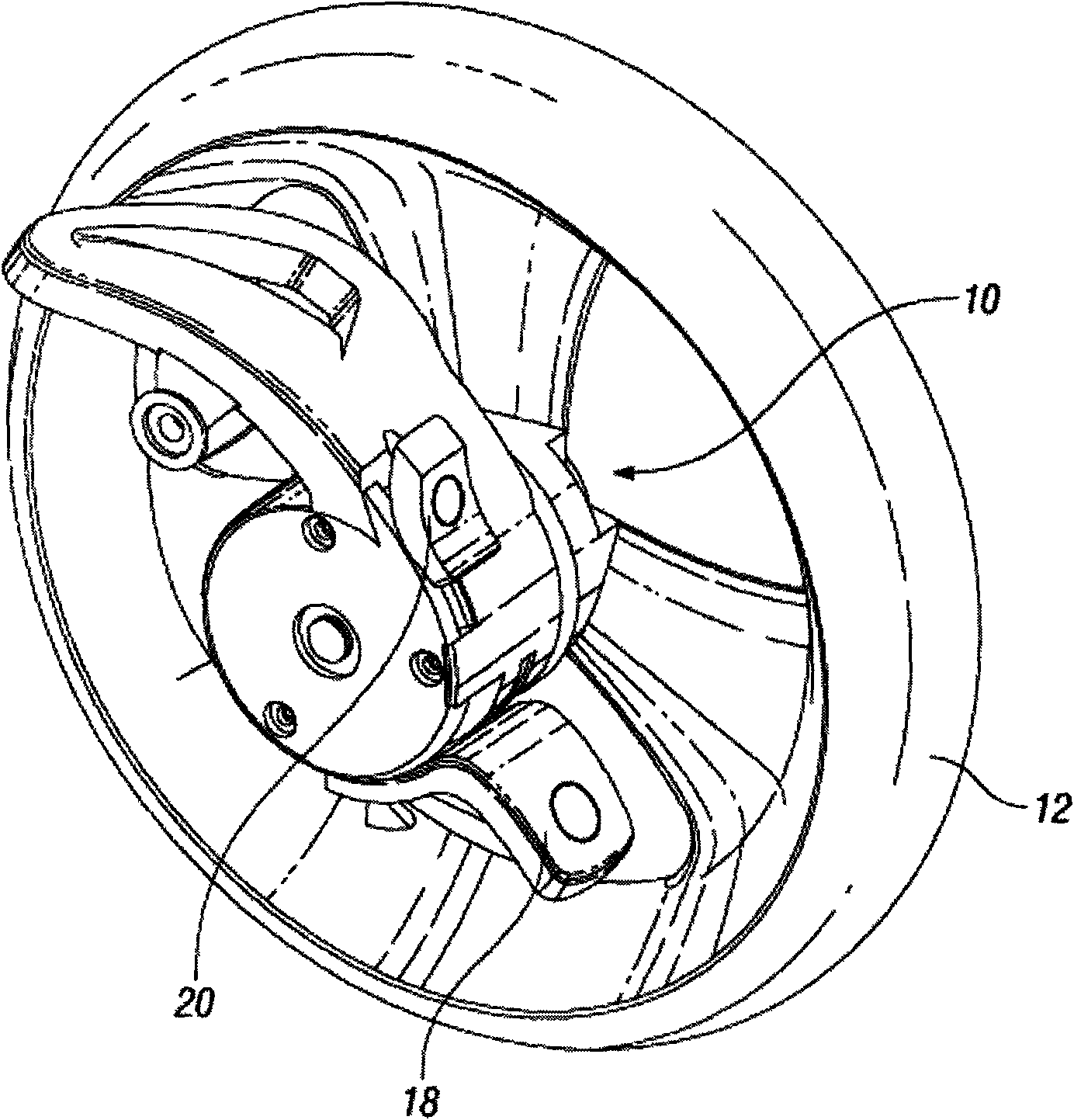

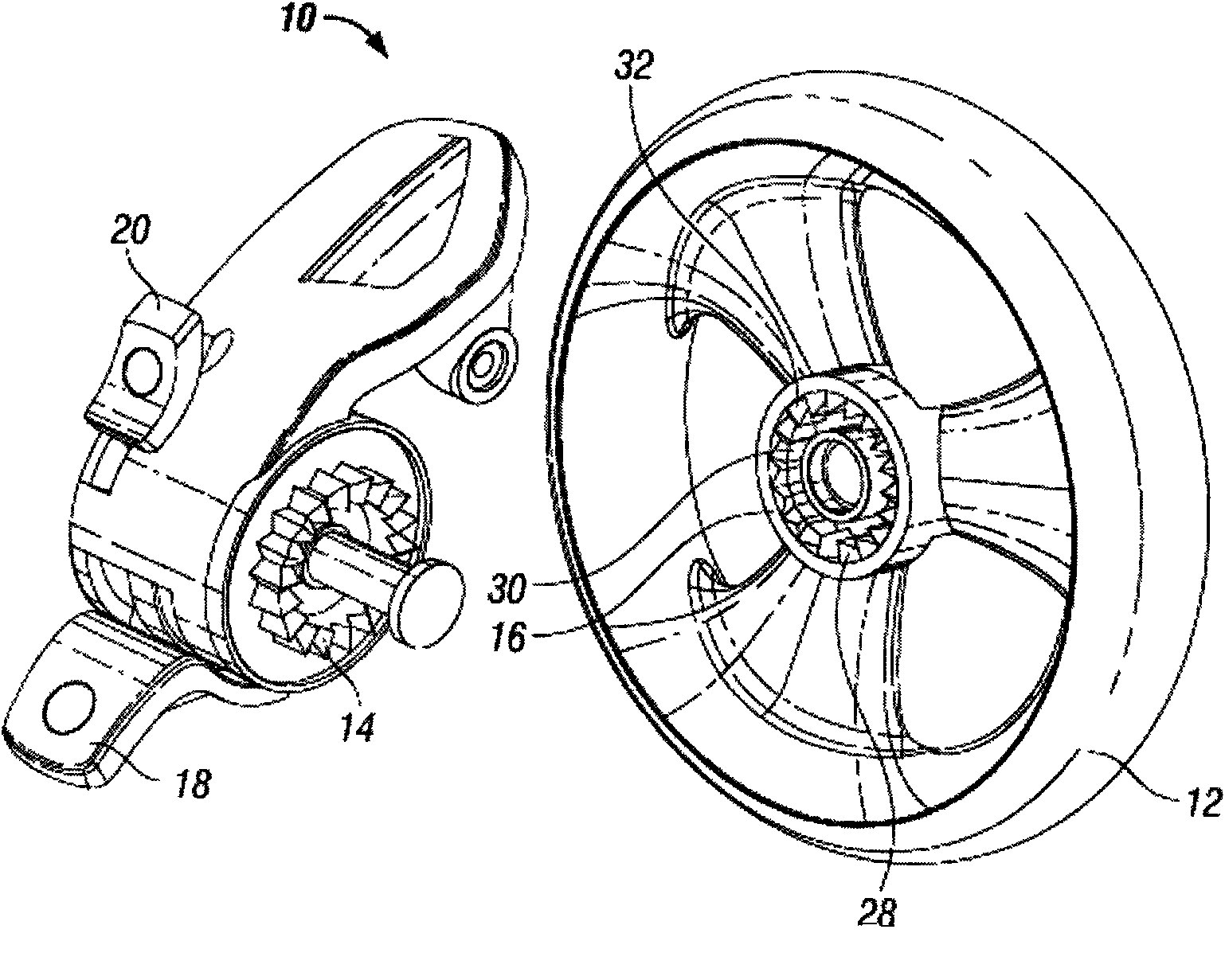

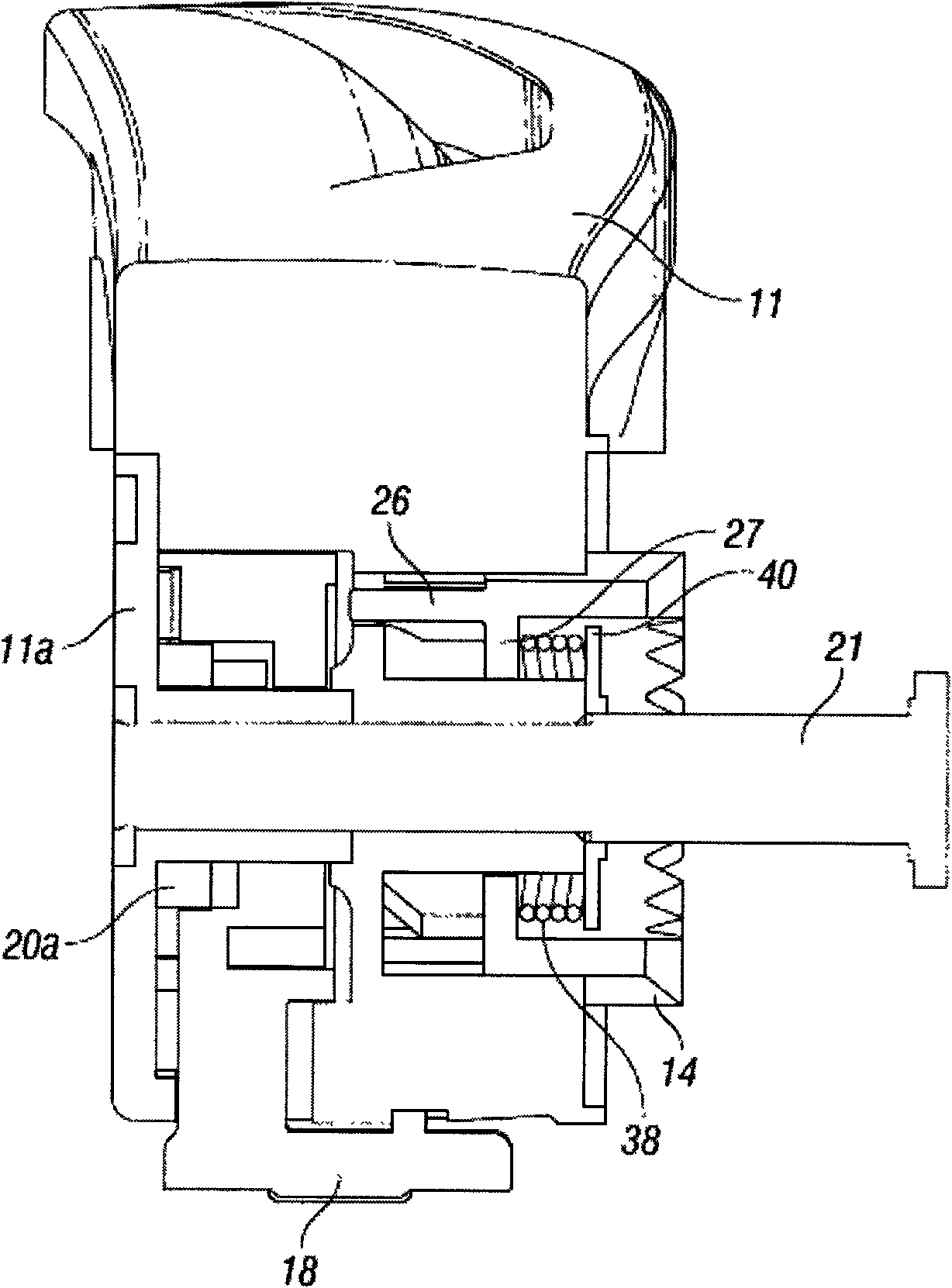

[0038] See figure 1 To 6, it shows the wheel brake mechanism 10 provided on the wheel 12 of the first embodiment of the present invention. The brake mechanism 10 includes a first brake element in the form of a brake shaft 14, a second brake element in the form of a brake drum 16, and a transmission device, including engagement (brake activation) pedal 18 and release (brake release) ) Pedal 20.

[0039] The brake shaft 14, the start pedal 18 and the release pedal 20 are provided in the brake box 11 and fixed on the center arm 21.

[0040] The brake shaft 14 has a plurality of first splines 22 provided in an adjacent series surrounding the outside of the brake shaft 14. The first splines 22 generally have a triangular cross-section, thereby giving each first spline 22 two engagement surfaces 22a, 22b. The first calibration element 24 is provided on top of each first spline (best see Fig. 6). The calibration elements 24 each have first and second opposing grooved calibration surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com