Production technology for choline chloride

A choline chloride and production process technology, applied in the field of choline chloride production process, can solve problems such as harsh conditions, achieve the effects of increasing production capacity, ensuring product quality, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

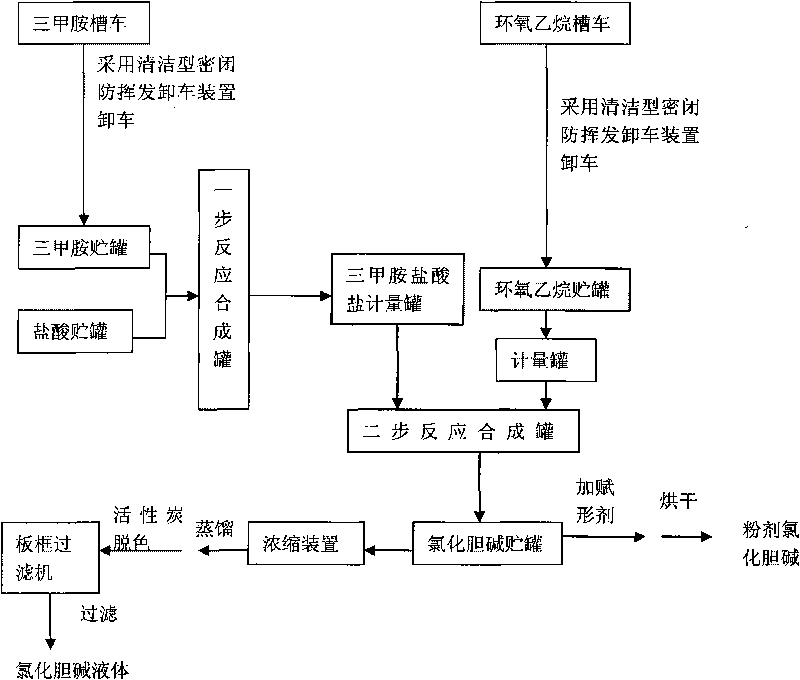

[0018] like figure 1 Shown, the choline chloride process embodiment of the present invention is:

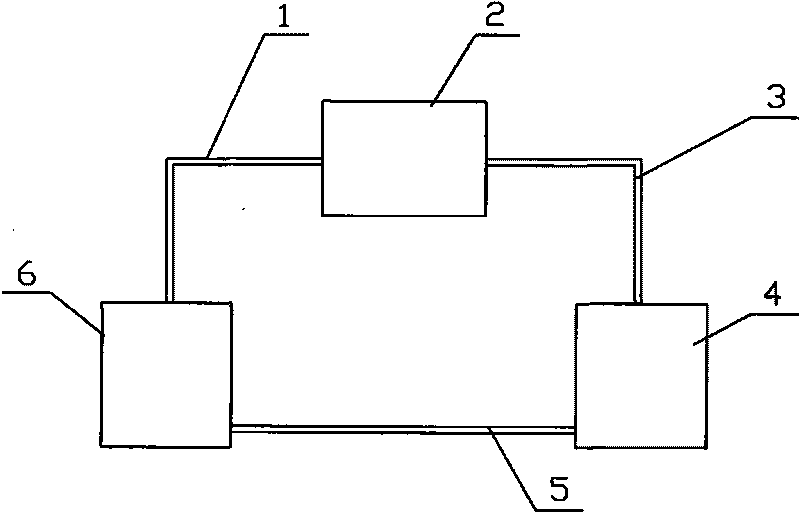

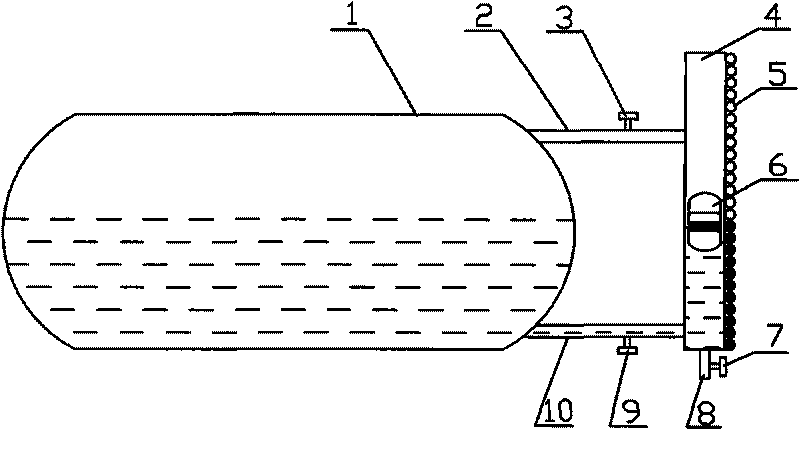

[0019] (1) Utilize raw material trimethylamine and oxirane figure 2 The shown clean airtight anti-volatile unloading device is respectively unloaded into such image 3 The shown trimethylamine storage tank and ethylene oxide storage tank with magnetic flap level display device;

[0020] (2) raw material trimethylamine and hydrochloric acid are respectively from trimethylamine storage tank and hydrochloric acid storage tank (such as image 3 As shown in the liquid level display device with magnetic flap) into the Figure 4 Carry out synthetic reaction in the one-step reaction synthetic tank that is suitable for choline chloride synthesis as shown and generate intermediate trimethylamine hydrochloride; The tank body of described one-step reaction synthetic tank is provided with such as Figure 7 The shown pressure balance device to prevent the pressure in the tank from exceedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com