Method and device for detecting printed material

A technology for printing materials and printed matter, applied in the direction of measuring devices, general parts of printing machinery, printing, etc., can solve problems such as difficulty in finding and removing printing quality and poor printing in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

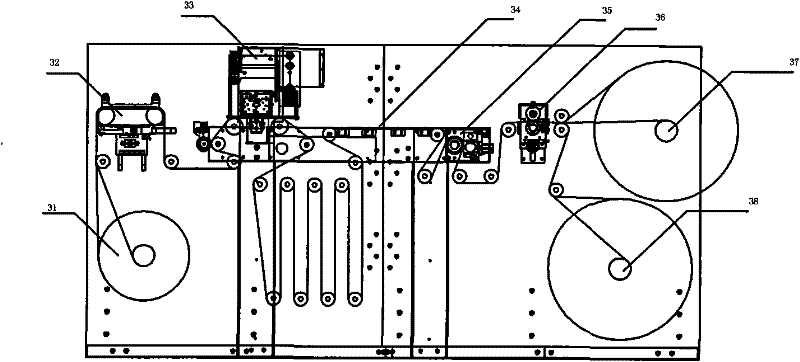

[0024] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

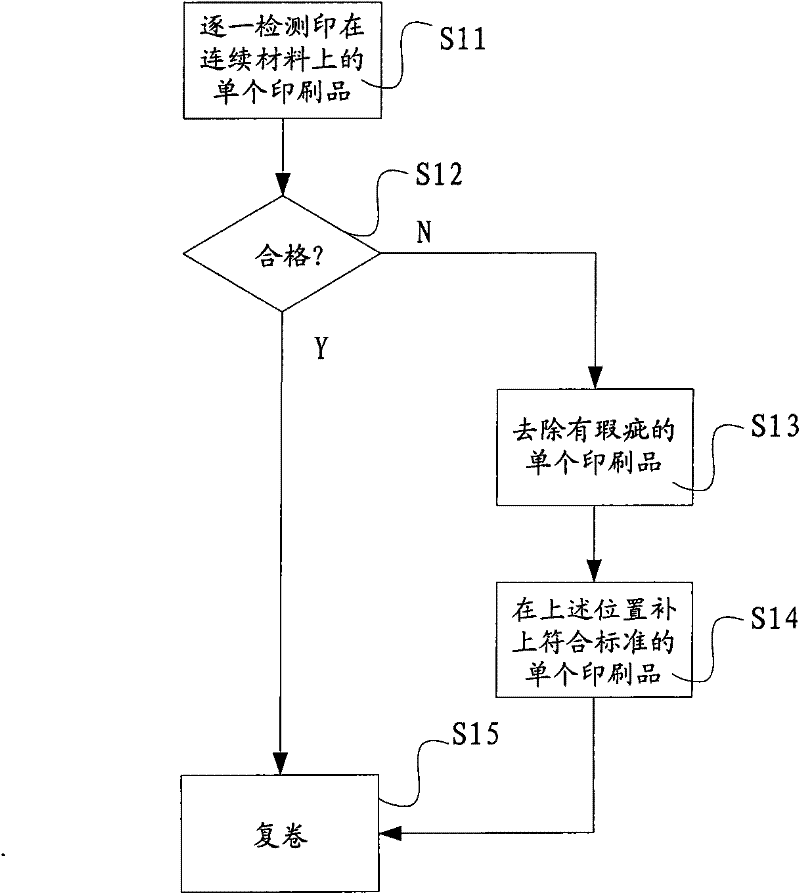

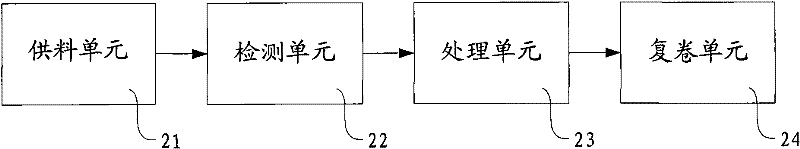

[0025] like figure 1 As shown, in the embodiment of the method and device for detecting printed materials in the present invention, the method includes the following steps:

[0026] Step S11 detects the individual printed matter printed on the continuous material one by one: in this embodiment, this step is to pass the printed and rolled material through the feeding unit, unfold it, and pass through the detection unit in sequence to detect The unit checks and judges the individual prints printed on the above materials. Since the printed material is continuous in this embodiment, there are multiple independent individual prints printed on the material that are actually the pattern for each product the material is used for, in other words, These single prints on a material are virtually all of that material for each product. Each roll of material mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com