Reinforced compound pipe and manufacture device thereof

A technology for enhancing compounding and manufacturing devices, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of loss of resin liquid, increase in production cost, and inability to increase the content of feed particles, to prevent falling off, The effect of improving strength and suppressing shape deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

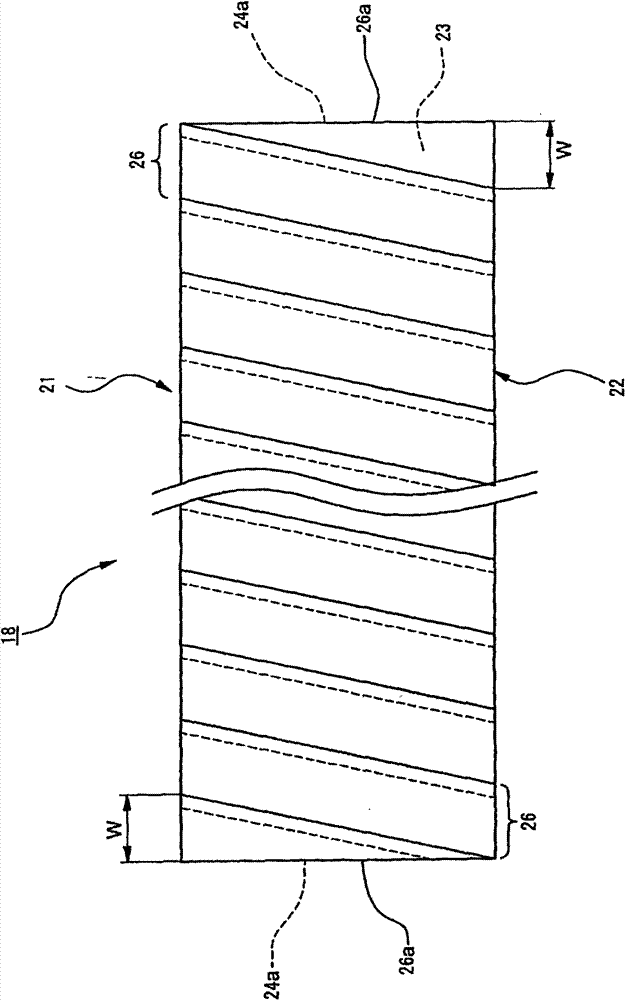

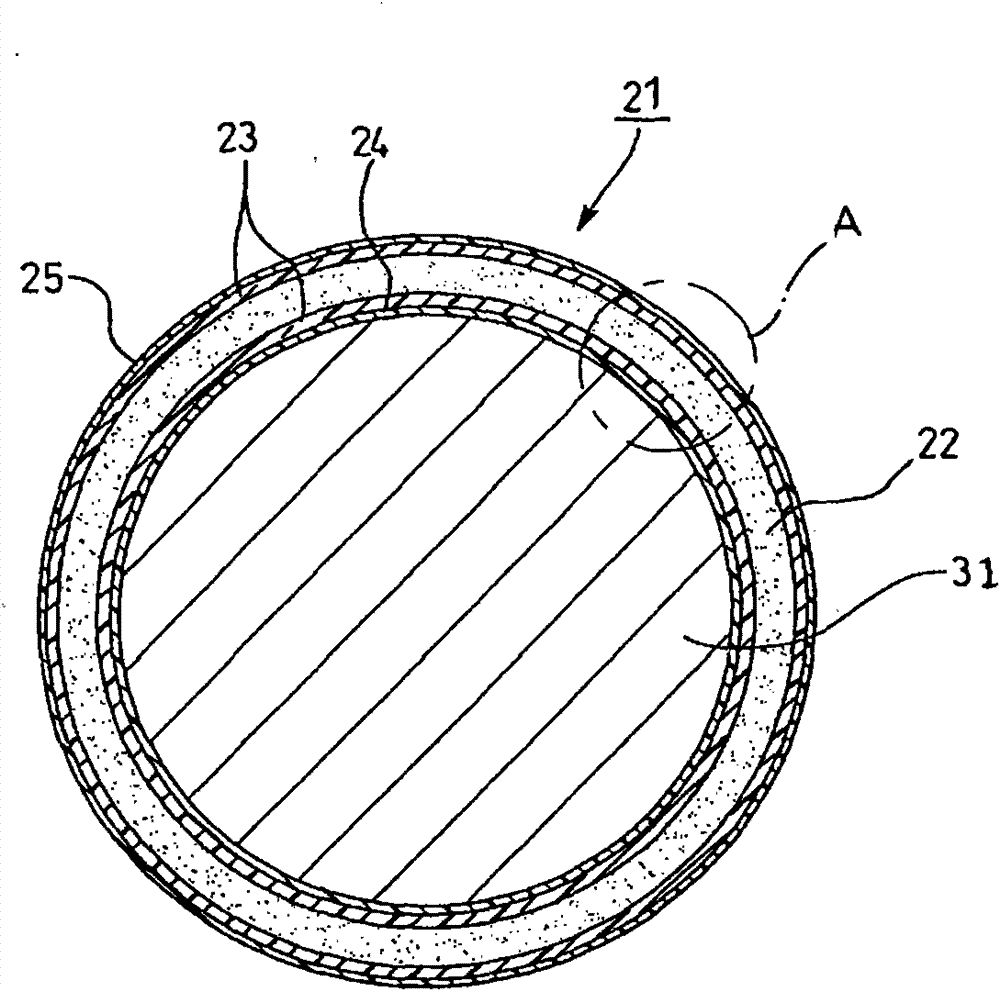

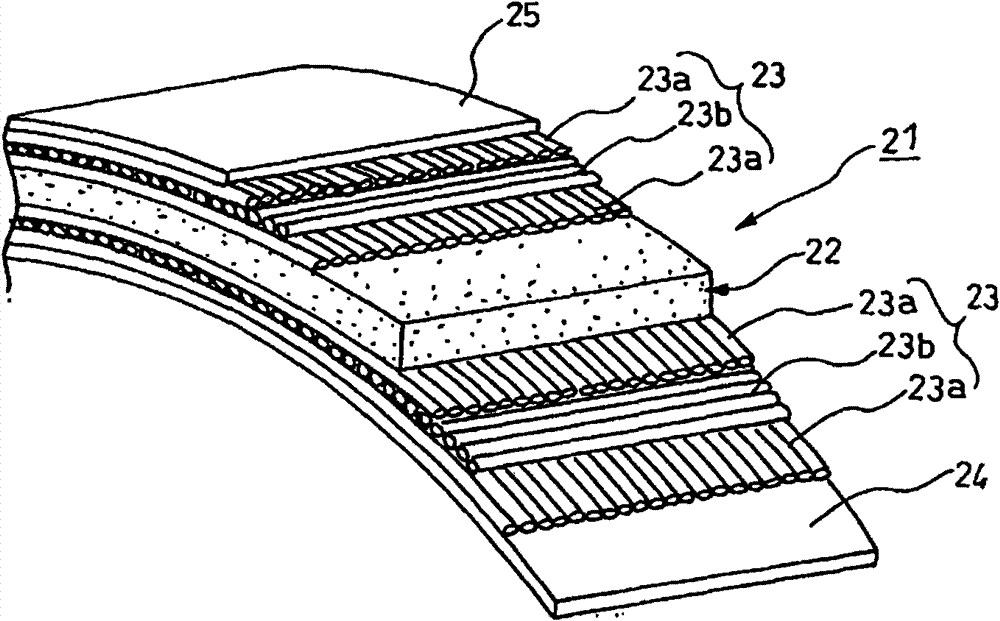

[0068] right Figure 1 to Figure 5 The structure of the reinforced composite pipe 21 shown in this embodiment 1 is illustrated. In the above-mentioned strip-shaped resin mortar body 26, the outer end edges 26a, 26a of the parts located at the side edges of the above-mentioned resin mortar layer 22 are gradually reduced in the width direction. The dimension W of the reinforced composite pipe 21 is shaped so that it coincides with the position 24a of the outer end edge of the above-mentioned inner surface protection layer 24 .

[0069] Therefore, this reinforced composite pipe 21 is constituted by winding the strip-shaped resin mortar body 26 in a spiral shape from above the inner surface protection layer 24 and the inner surface FRP layer 23 so that the edges 26a, 26a are formed on the reinforced composite pipe 21. In the direction of the tube axis, the neat winding is consistent throughout the entire circumferential area.

[0070] In addition, in the reinforced composite pipe...

Embodiment 2

[0125] Figure 6 to Figure 8 The reinforced composite pipe 121 and the manufacturing apparatus 130 of the reinforced composite pipe 121 according to the second embodiment of the present invention are shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com