Processing method of steel wire reinforced polytetrafluoroethylene spiral tube component

A technology of polytetrafluoroethylene spiral and polytetrafluoroethylene, which is applied in the processing field of steel wire reinforced polytetrafluoroethylene spiral tube components, can solve the problems of poor bending performance, heavy weight, and restrictions, and achieve excellent bending performance, light weight effect

Active Publication Date: 2011-01-05

SHANGHAI PLASTICS RES INST CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the metal tube assembly has the characteristics of high and low temperature resistance, its shortcomings of heavy weight and non-distortion performance make its application limited. Similarly, PTFE hose assemblies have the disadvantages of heavy weight and poor bending performance.

Other engineering plastics, such as polyvinyl chloride, polyethylene and other hose components, are also subject to considerable restrictions in the aerospace field due to their poor performance in temperature resistance and aging resistance.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

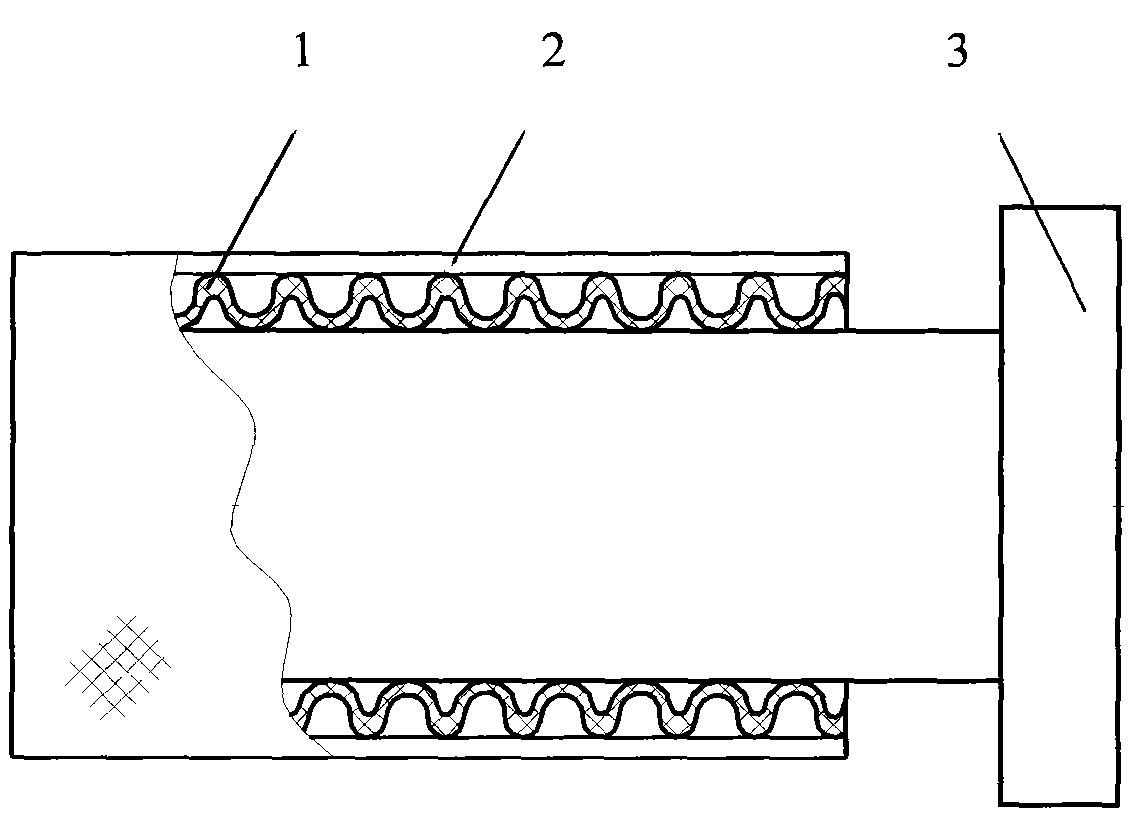

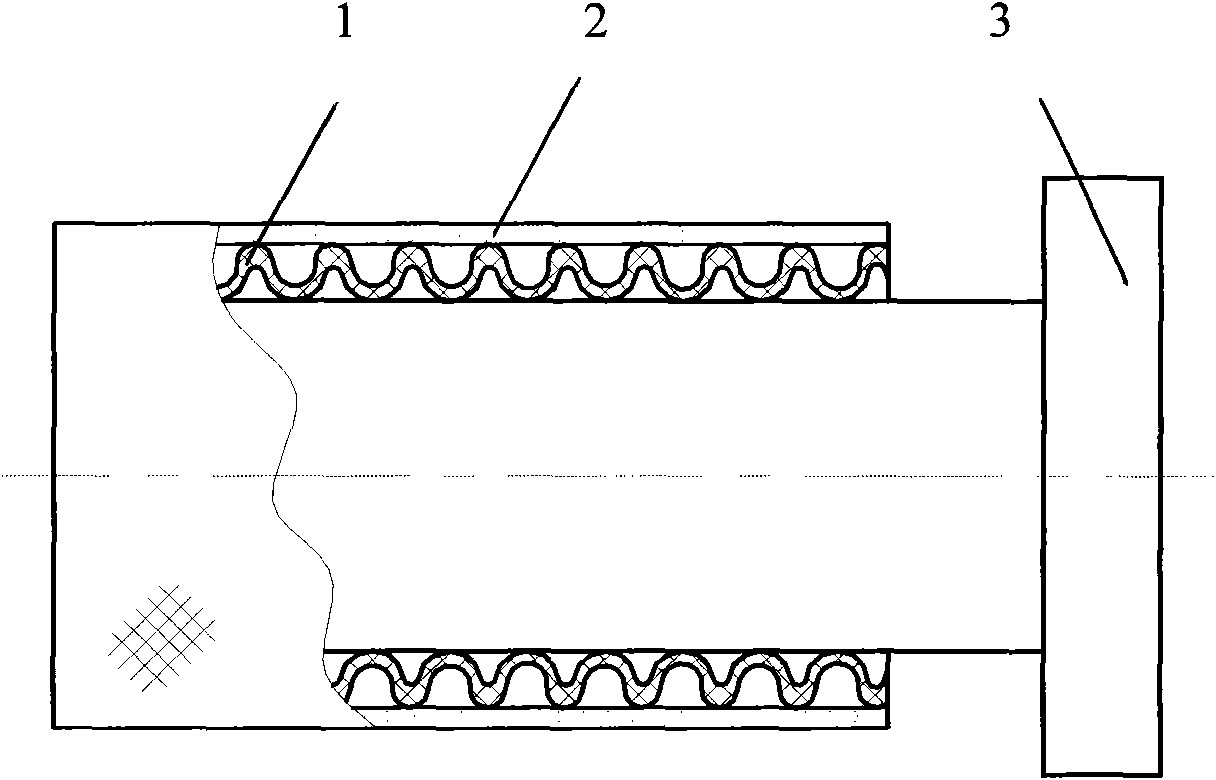

The invention relates to a polytetrafluoroethylene spiral tube component, in particular to a steel wire reinforced polytetrafluoroethylene spiral tube component and a processing method thereof. The polytetrafluoroethylene spiral tube component is formed by assembling stainless metal connecting pieces at two ends of a sinusoidal spiral tube, and wrapping a reinforced jacket of stainless steel wireat the outer layer. The preparation method comprises the following steps: the polytetrafluoroethylene resin is pushed, pressed and sintered into polytetrafluoroethylene straight blank tubes, and thenthe polytetrafluoroethylene straight blank tubes are prepared into the polytetrafluoroethylene spiral tube component through forming, end recovery, nesting cutting, wrapping the reinforced jacket of stainless steel wire and head assembly. The prepared polytetrafluoroethylene spiral tube component is characterized by high-temperature resistance and low-temperature resistance, corrosion resistance,ageing resistance, light weight, excellent bending performance and the like, and is an ideal protective tube for wires and cables used for aero-spacecrafts and aircrafts.

Description

Processing method of steel wire reinforced polytetrafluoroethylene spiral pipe assembly technical field The invention relates to a polytetrafluoroethylene spiral pipe assembly, in particular to a processing method for a steel wire reinforced polytetrafluoroethylene spiral pipe assembly. Background technique At present, metal pipe assemblies, polytetrafluoroethylene or other engineering plastic hose assemblies have been used for connecting and protecting pipelines of lines such as electric wires and cables. As a protective pipeline for aerospace and aviation aircraft wires and cables, it should have the characteristics of high and low temperature resistance, corrosion resistance, aging resistance, light weight and excellent bending performance. Although the metal tube assembly has the characteristics of high and low temperature resistance, its shortcomings of heavy weight and non-distortion performance make its application limited. Similarly, PTFE hose assemblies have the d...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F16L11/115

Inventor 邵漫江

Owner SHANGHAI PLASTICS RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com