Polytetrafluoroethylene wave-proof sleeve assembly and preparation method thereof

A technology of polytetrafluoroethylene and wave-proof sleeves, which is applied in the direction of electrical components, circuit/collector parts, connecting parts, protective grounding/shielding devices, etc., and can solve the problems of heavy weight, poor corrosion resistance, aging resistance, and corrosion resistance. High and low temperature resistance and poor performance, to achieve the effect of light weight and excellent bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Specification of inner diameter as The PTFE straight pipe goes through the following steps:

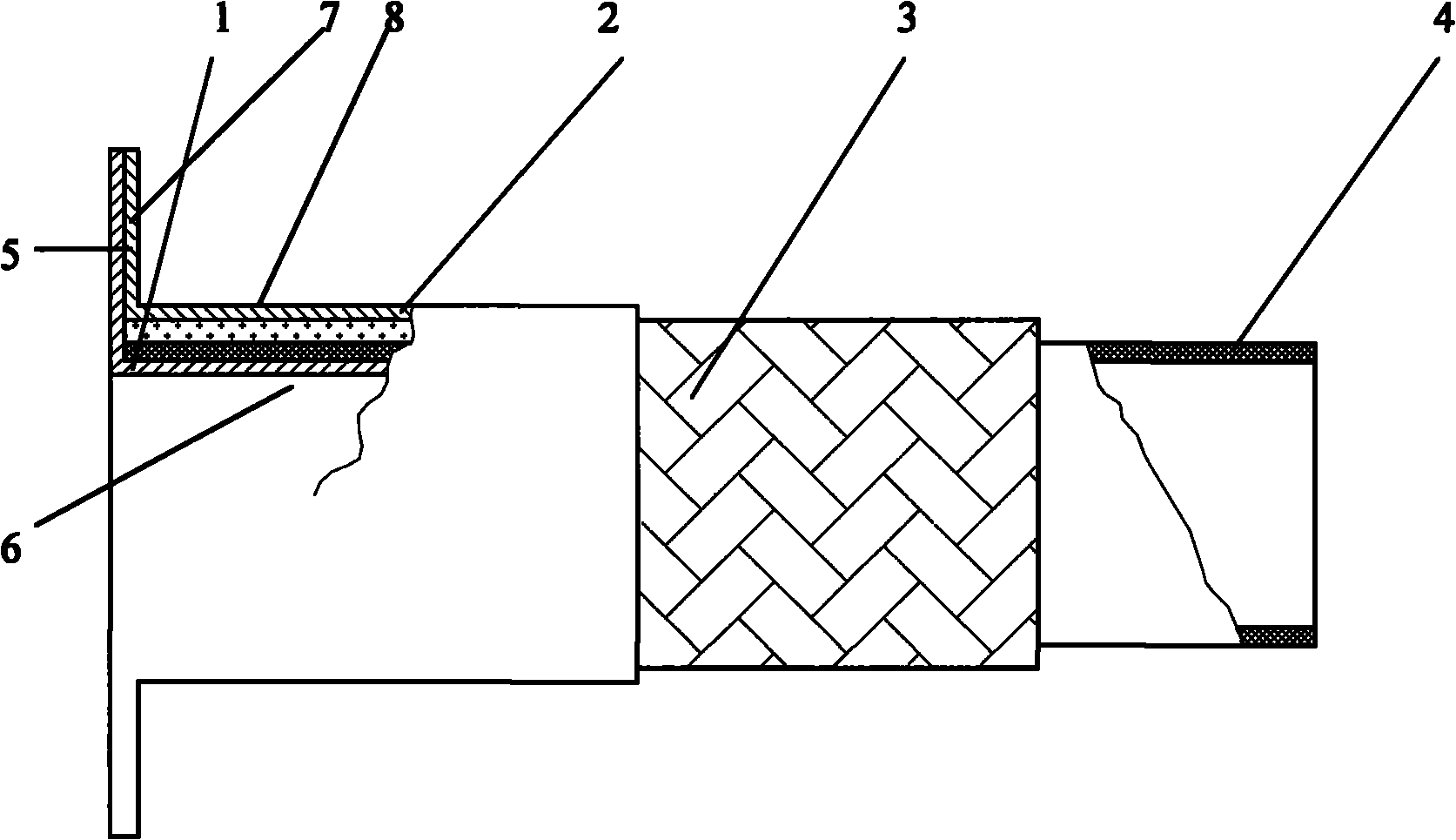

[0021] 1. Select inner diameter The polytetrafluoroethylene straight pipe is braided with stainless steel wire so that its outer wall is coated with a stainless steel wire braid layer 3 .

[0022] 2. Bind one end of the braided polytetrafluoroethylene straight pipe with lead wire, and place the second ring 8 of the outer bushing 2 of the metal connector outside the braided layer 3 of stainless steel wire.

[0023] 3. Insert the first circular ring 6 of the inner bushing 1 of the metal connector into the inner wall of one end of the PTFE straight pipe, and connect the annular plate 7 of the outer bushing 2 of the metal connector placed on the outer layer of the braided pipe with the metal The flat plate 5 of the inner bush 1 of the metal connector is combined to ensure that the braided layer of stainless steel wire 3 is located between the inner bush 1 of the metal connector...

Embodiment 2

[0030] Specification of inner diameter as The PTFE straight pipe goes through the following steps:

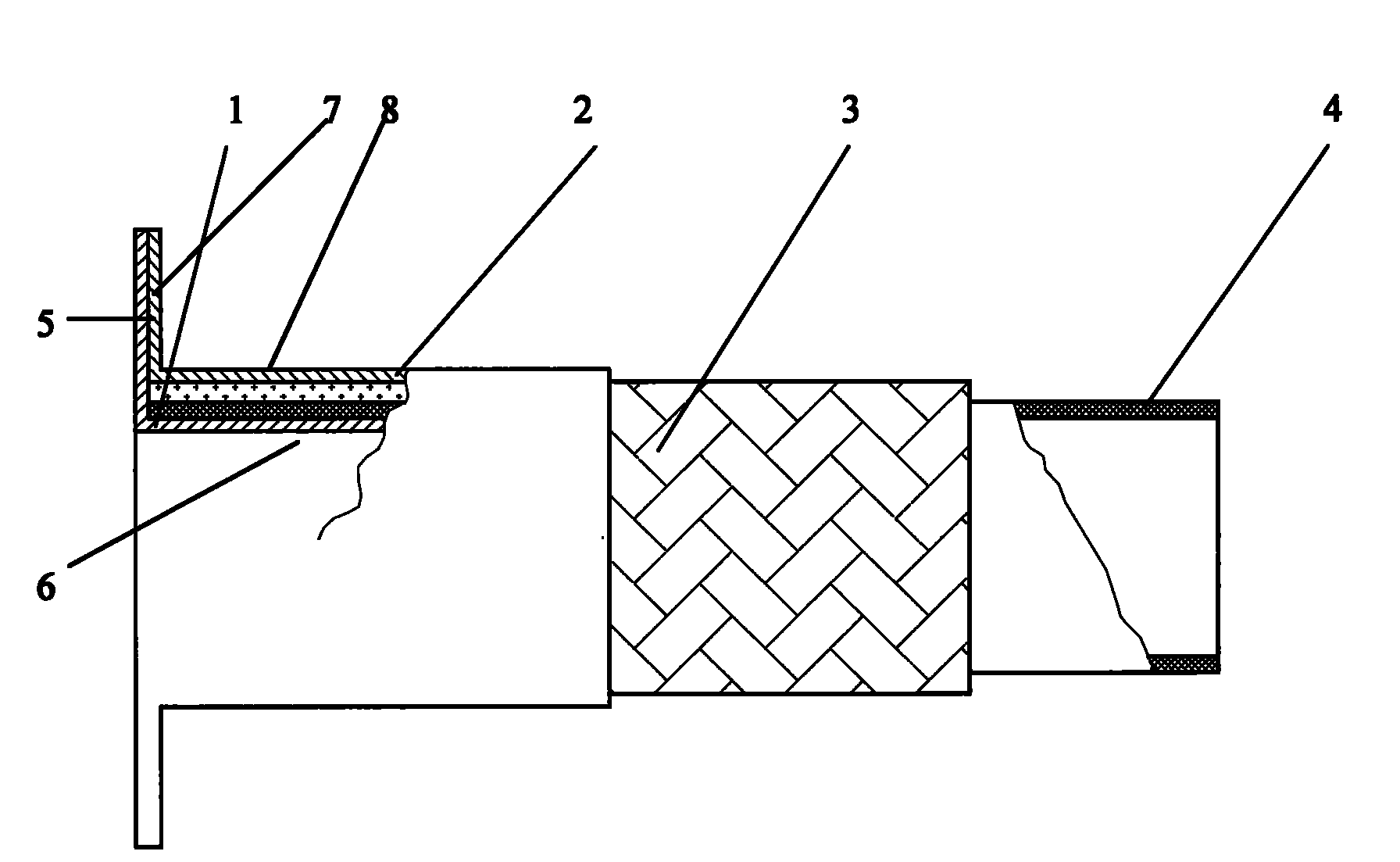

[0031] 1. Select inner diameter The polytetrafluoroethylene straight pipe is braided with stainless steel wire so that its outer wall is covered with a stainless steel wire braid layer 4 .

[0032] 2. Bind one end of the braided polytetrafluoroethylene straight pipe with lead wire, and place the second ring 8 of the outer bushing 3 of the metal connector outside the braided layer 4 of stainless steel wire.

[0033] 3. Insert the first ring 5 of the inner bushing 2 of the metal connector into the inner wall of one end of the PTFE straight pipe, and connect the annular plate 7 of the outer bushing 2 of the metal connector placed on the outer layer of the braided tube with the metal The flat plate 8 of the inner bush 2 of the metal connector is combined to ensure that the braided layer of stainless steel wire 3 is located between the inner bush 1 of the metal connector and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com