Dynamic balance test method and device thereof

A detection method and detection device technology, applied in the direction of measuring device, static/dynamic balance test, machine/structural component test, etc., can solve the problems of increasing process and generating errors, so as to save process and improve detection and positioning accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

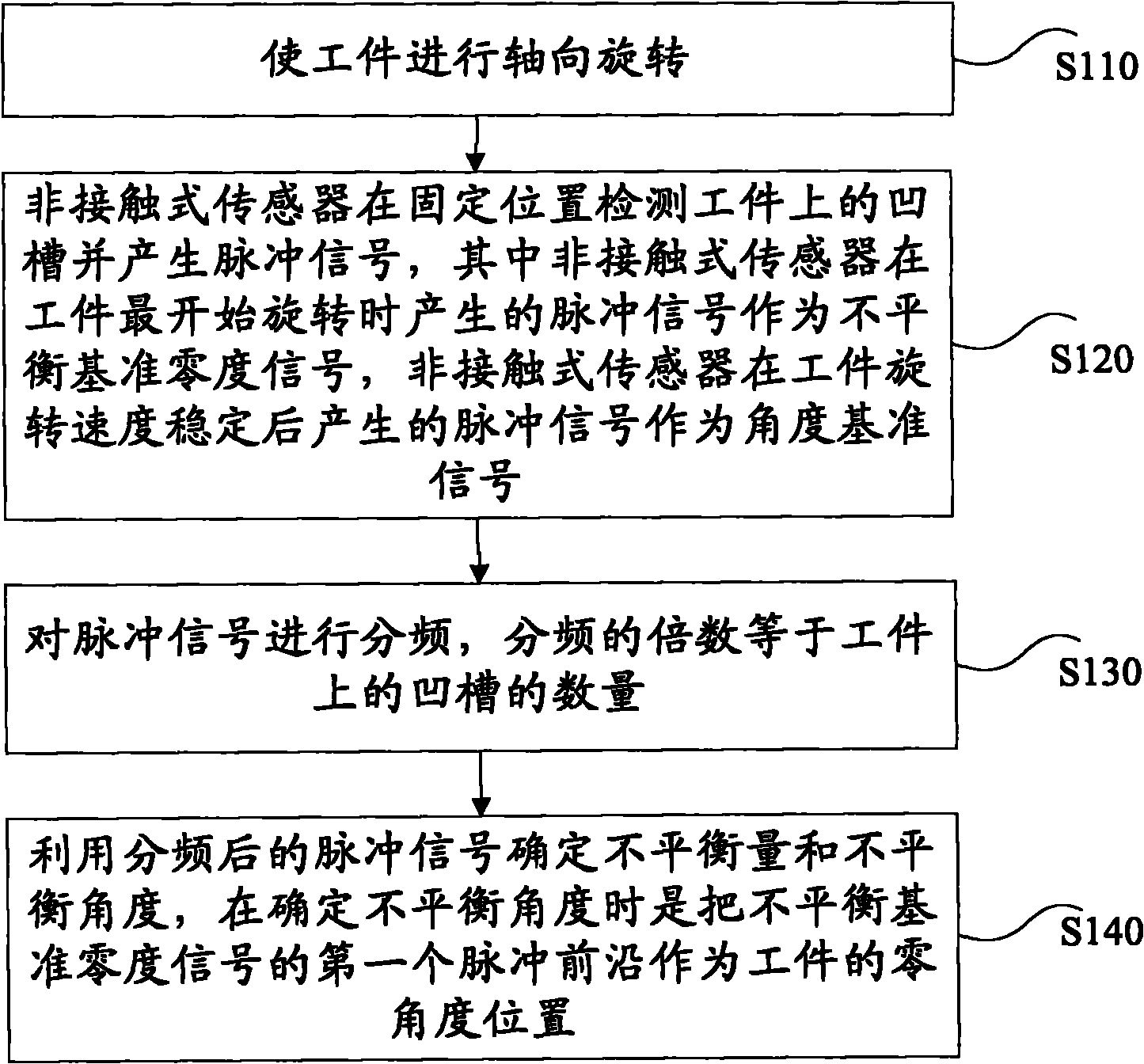

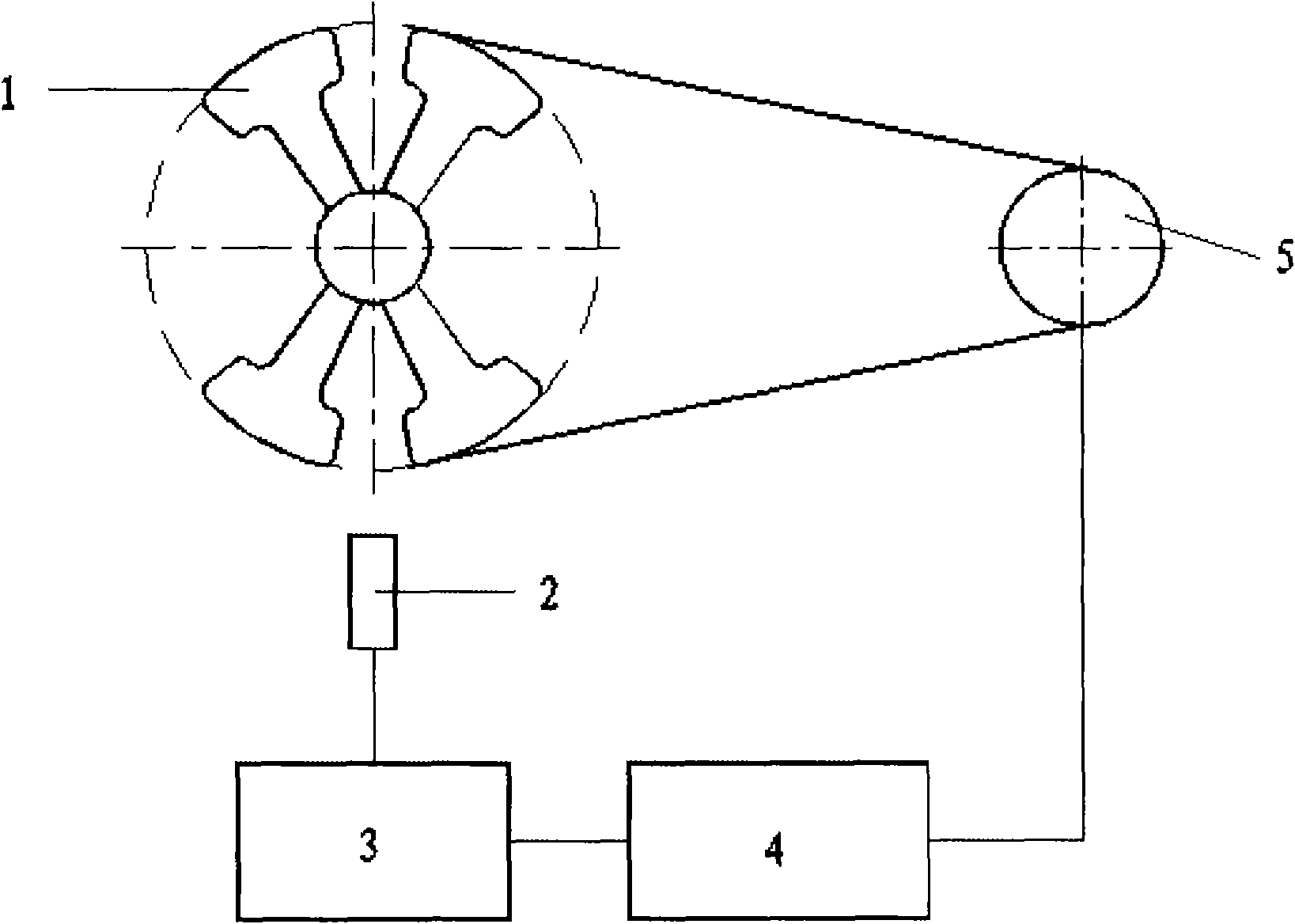

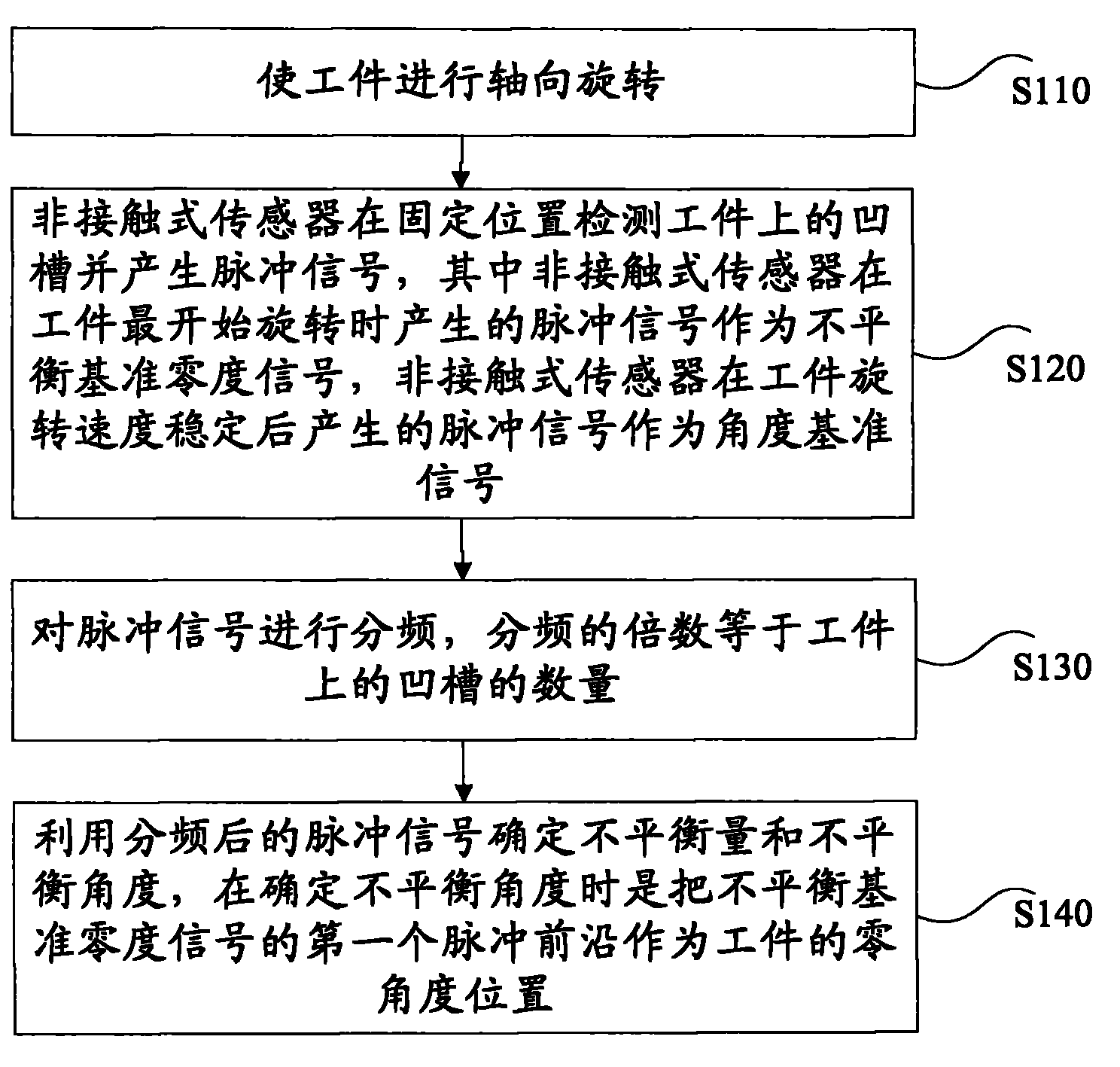

[0019] Such as figure 1 As shown, the dynamic balance detection method of this embodiment is used to detect the workpiece with grooves evenly distributed on the outer periphery, including the following steps: S110, the workpiece is rotated axially; S120, the non-contact sensor detects the groove on the workpiece at a fixed position. groove and generate a pulse signal, wherein the pulse signal generated by the non-contact sensor when the workpiece first rotates is used as the unbalanced reference zero-degree signal, and the pulse signal generated by the non-contact sensor after the workpiece rotation speed stabilizes is used as the angle reference signal; S130, Divide the frequency of the pulse signal, and the multiple of the frequency division is equal to the number of grooves on the workpiece; S140, use the pulse signal after frequency division to determine the unbalance amount and unbalance angle. When determining the unbalance angle, the unbalance reference zero degree signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com