Large aperture three-dimensional array structure

A three-dimensional array and large-aperture technology, which is applied in the direction of measuring devices, instruments, and radio wave measurement systems, can solve the problems of array element aperture size, limitation of the number of rods and array elements, suboptimal array performance, and unstable installation. , to achieve the effects of improving detection and positioning accuracy, expanding the lower limit of measurement frequency, and improving positioning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below with reference to the drawings and specific embodiments.

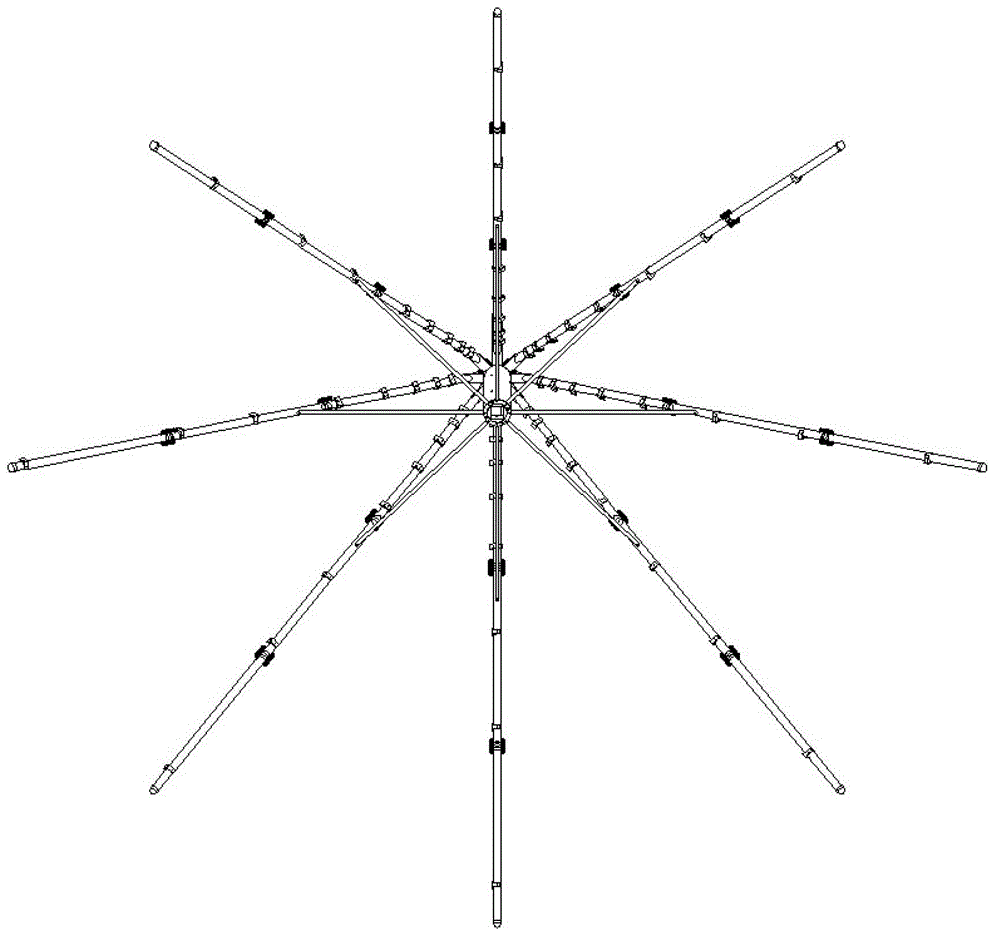

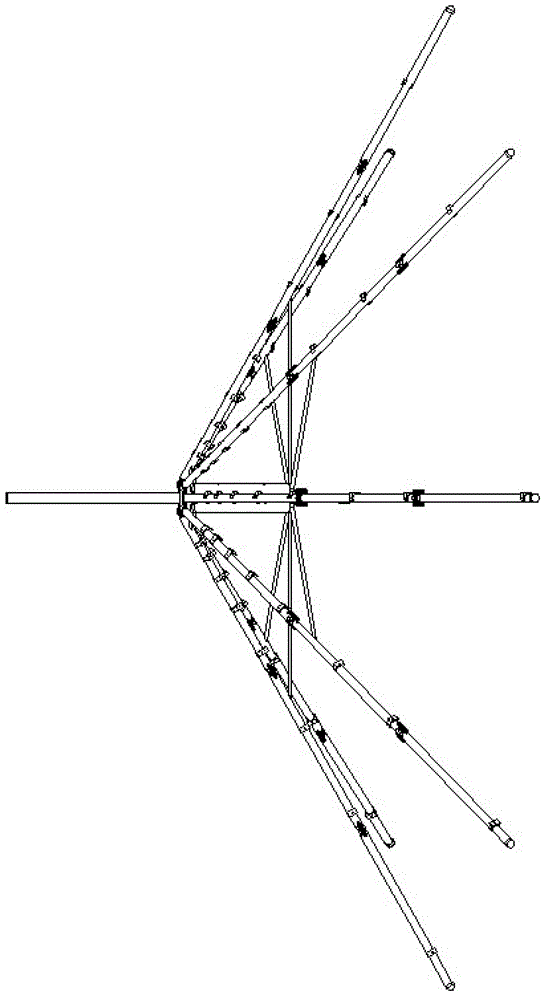

[0038] Such as figure 1 with figure 2 As shown, the large-aperture three-dimensional array element structure of this embodiment includes: a central support platform and a number of round rods 11, and the number of round rods 11 and the central support platform are fixedly assembled; wherein the round rod 11 can be made of plastic or aluminum. Made of alloy, stainless steel, glass fiber reinforced plastic and other materials, the signal line of the array element conceals the inside of the cylinder to ensure clean and concise wiring and no line breaks due to mistakes.

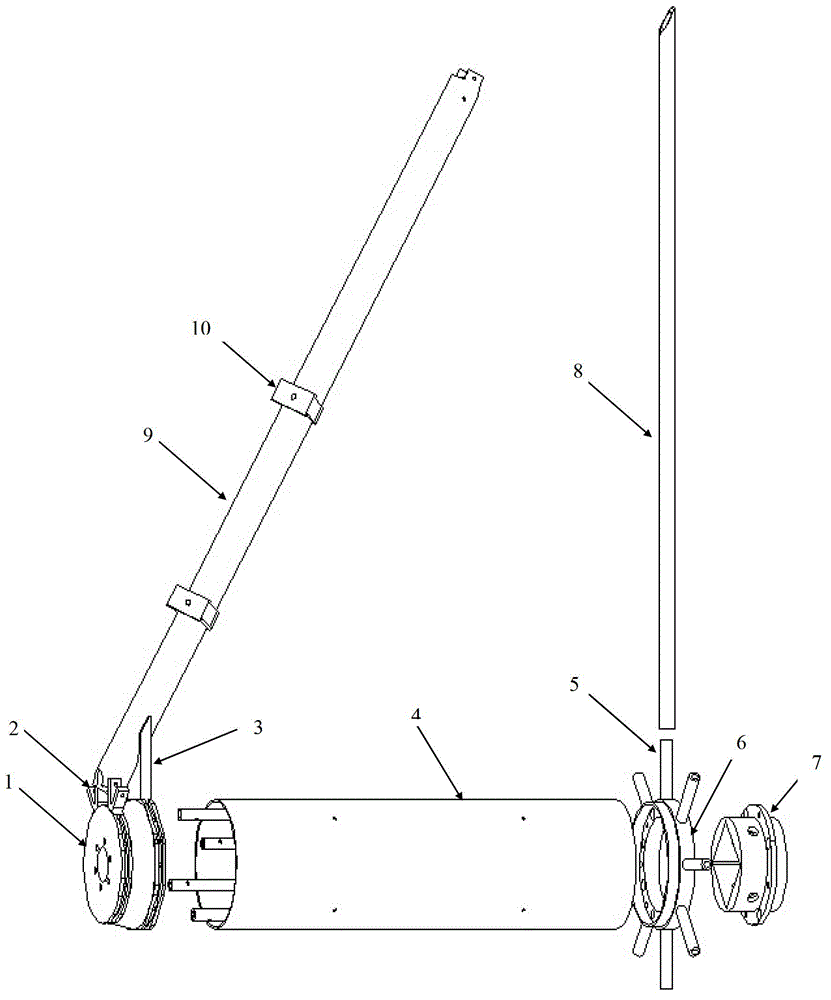

[0039] Such as image 3 As shown, the connection assembly relationship between the support platform and the round rod 11, the first short rod of the round rod 11 is connected to the platform installation base 1 through the round rod connector 2, and the round rod 11 and the support platform are ensur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com