Construction method for forming pile wall type retaining wall

A construction method and retaining wall technology, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as difficulty in ensuring water stop between piles, difficult construction, water leakage and quicksand, etc., and achieve simple and convenient construction , the effect of overall improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

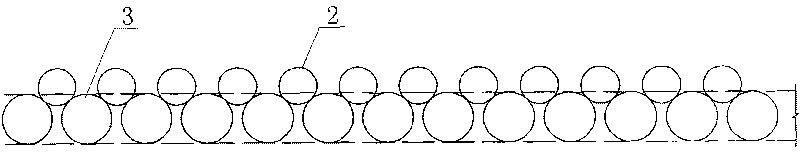

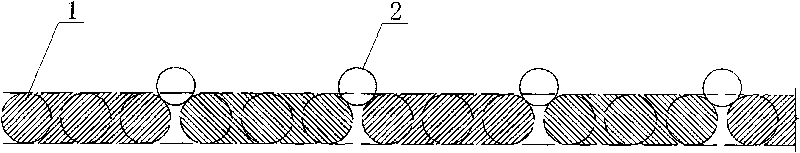

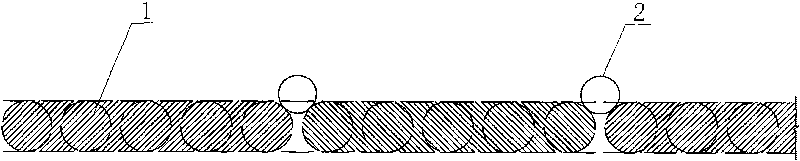

[0020] Such as figure 2 image 3 Shown, the forming construction method of a kind of pile wall type retaining wall of the present invention comprises the following steps:

[0021] (a) Construct multiple rows of bored or punched support piles along the direction of the enclosure structure;

[0022] (b) Use a square hammer to repair the soil between the pile holes to form a continuous slot;

[0023] (c) lowering the above-mentioned hole-forming support pile reinforcement cage in turn;

[0024] (d) down the conduit, and pour the underwater concrete of the above-mentioned hole-forming piles together to form a section of continuous wall;

[0025] (e) Construction of water-stop rotary grouting piles or deep cement mixing piles at the joints of the continuous walls of each section.

[0026] Among them, the number of drilled (punched) hole piles contained in each section of the above groove is determined according to geological conditions, construction capacity, mud pool capacity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com