Foam tool

A technology of tools and protrusions, which is applied in the field of foaming tools, can solve the problems of cost increase, liquid outlet wear, looseness, etc., and achieve the effects of increasing foaming volume and quality, prolonging service life, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

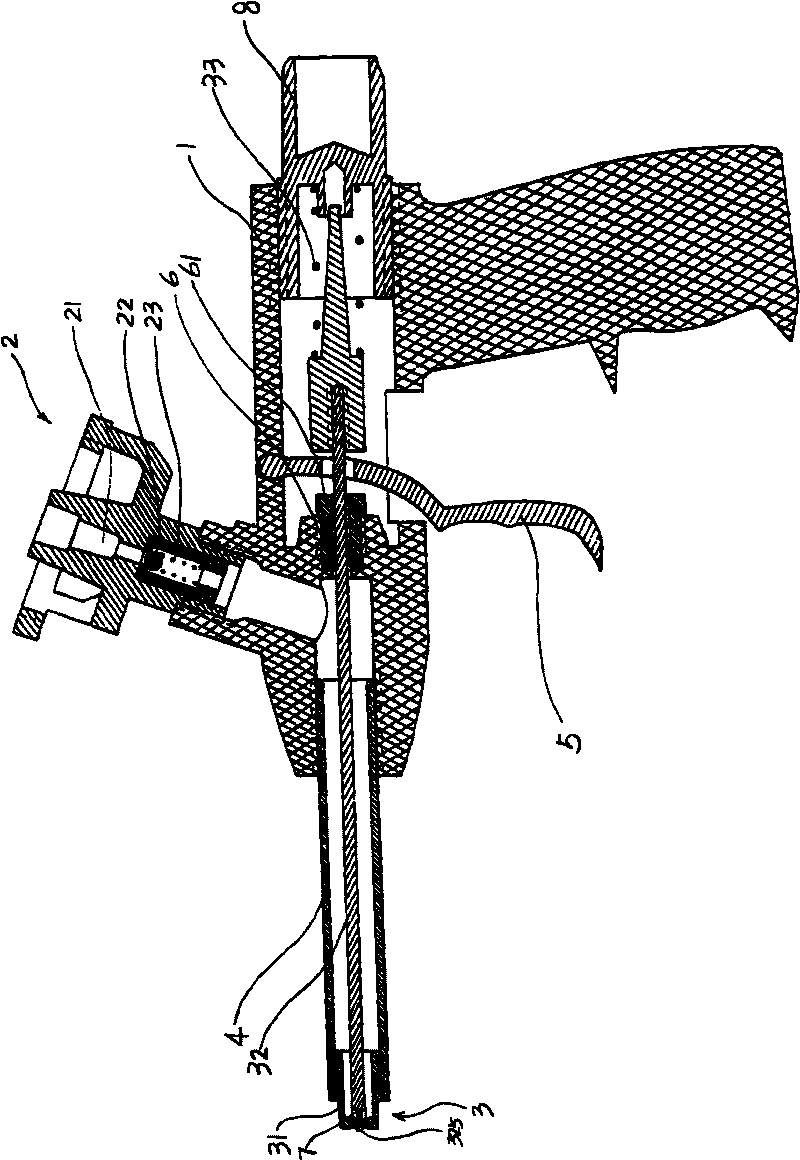

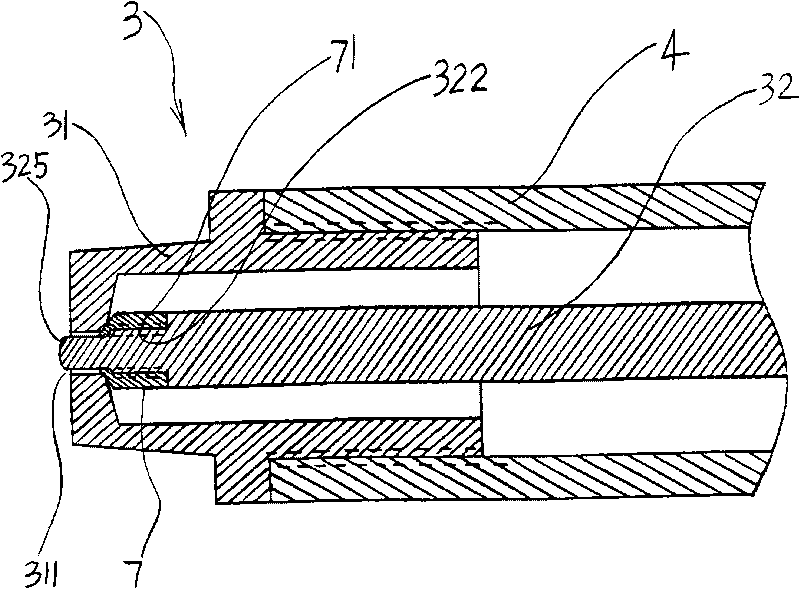

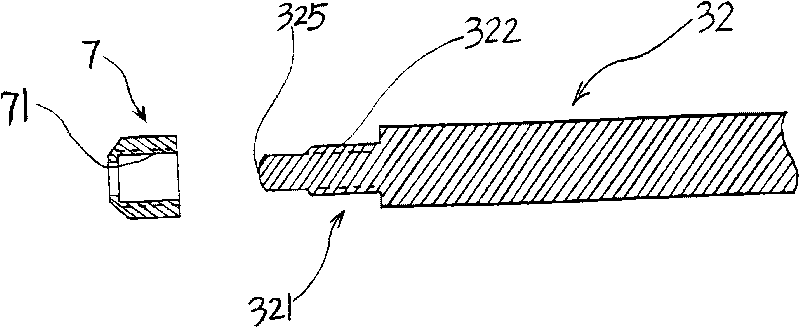

[0050] Foaming tool of the present invention, referring to all accompanying drawings, it comprises gun body 1, liquid inlet valve 2, liquid outlet valve 3, liquid outlet channel 4 and switching device 5, and liquid outlet valve 3 comprises the liquid outlet nozzle that has outlet 311 31. The valve core 32 and the return spring 33, the switch device 5 can make the liquid outlet valve 3 open or close, for example, the valve core 32 has at least a part of the inner channel extending out of the foaming tool, so that the switch device 5 can directly or indirectly act on the On the spool 32, the spool 32 is moved. The head of the spool 32 is provided with a screw thread 322 or a concave portion 323 or a convex portion 324, and also includes a sealing ring 7, which is connected with the screw thread provided at the head of the spool 32. 322 or the recessed part 323 or the convex part 324 are connected as one structure, and the sealing ring 7 connected as one body with the valve core 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com