Combustor for fuel oil heater supplied with oil at multiple points

A technology of fuel oil heater and burner, which is applied in the direction of burner, combustion type, combustion method, etc., to achieve the effects of less carbon deposition, improved economy, and low thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

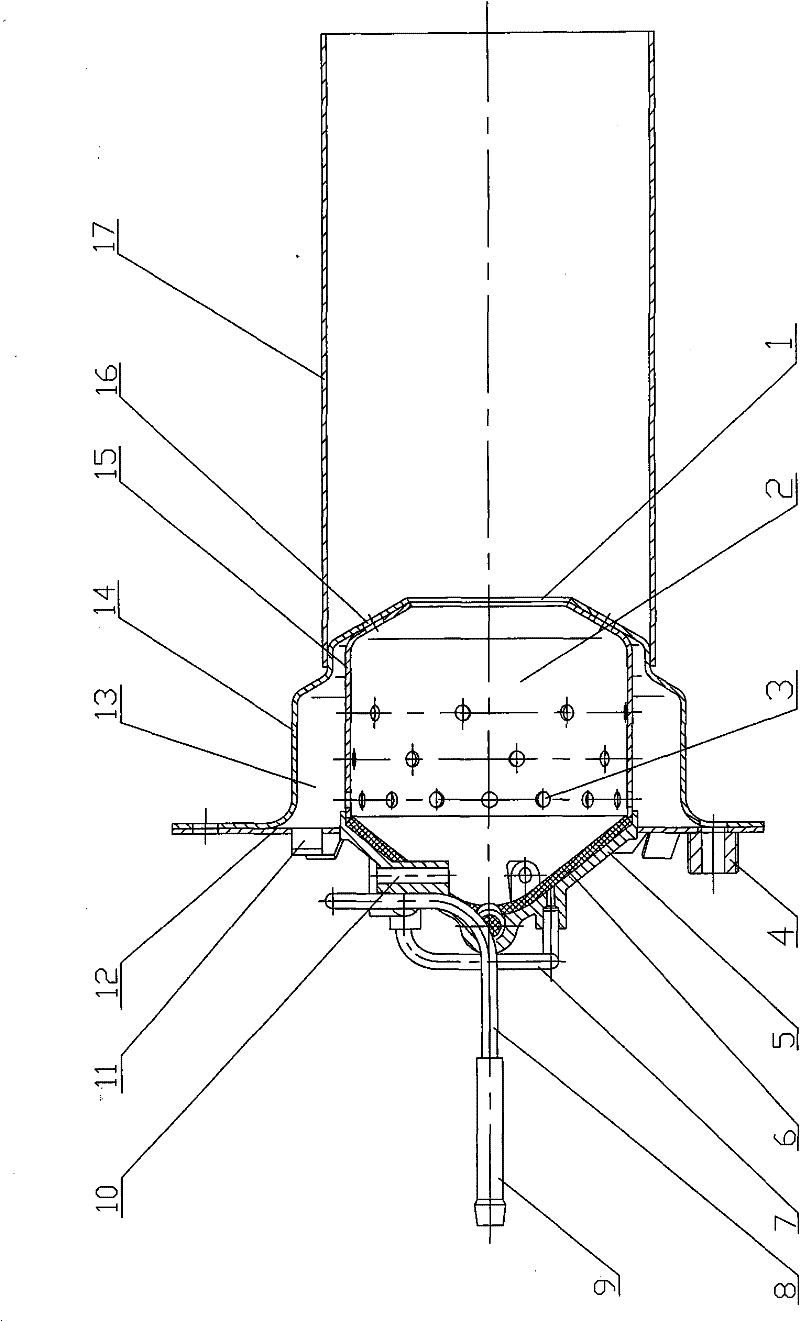

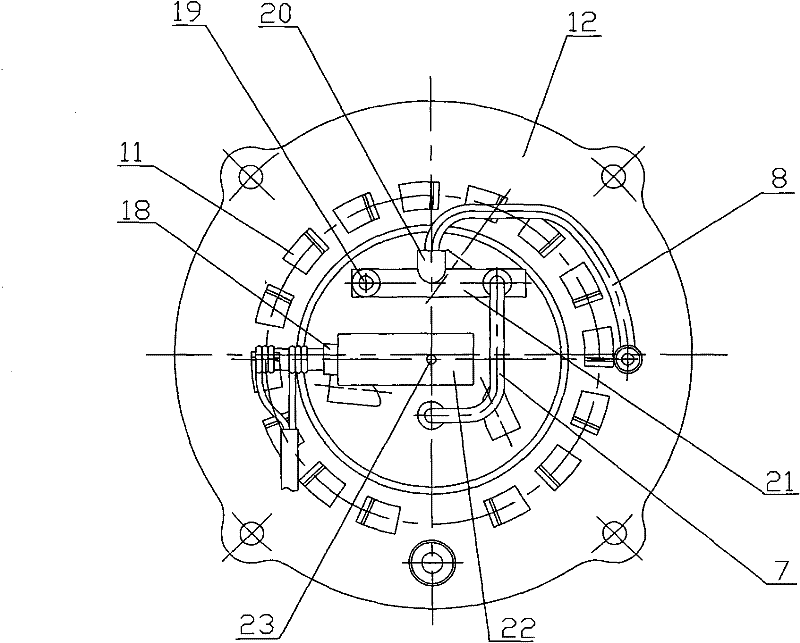

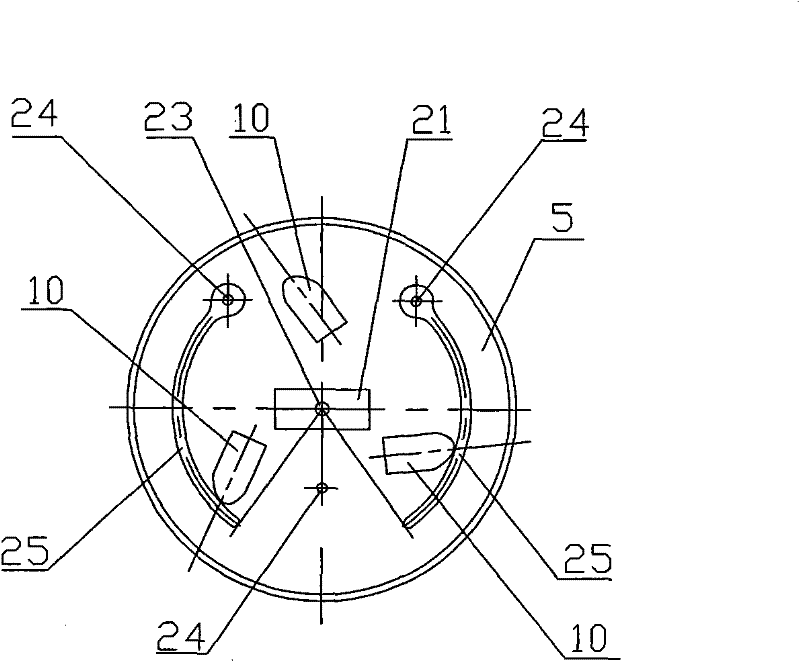

[0014] The fuel oil heater burner of multi-point fuel supply of the present invention, its structure is as figure 1 shown. Including conical combustion chamber cover 5, oil suction liner 6, primary combustion cylinder 15, secondary combustion cylinder 17, air intake guide cylinder 14, air intake swirl plate 12, oil supply straight pipe 9, oil supply elbow pipe 8, Cloth oil branch pipe 7, glow plug 18. The conical oil-absorbing liner 6 is close to the inner surface of the conical combustion chamber cover, and the two are fixed as one by spot welding. The front end of the primary combustion tube 15 is inserted into the end positioning notch of the combustion chamber cover 5, which has the effect of pushing and pressing the oil-absorbing liner 6, and is connected with the combustion chamber cover 5 as a whole by welding. The cylinder wall of the primary combustion cylinder 15 is distributed with 2 to 5 circles of several air inlet holes 3 in the upper direction. The tail end o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap