Safety lifting hook and manufacturing method thereof

A safety hook and manufacturing method technology, applied in the field of hooks, can solve the problems of being broken by hanging objects, people being burned, and the hanging container overturning and unhooking (such as a ladle containing molten metal, etc.), so as to ensure personal safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

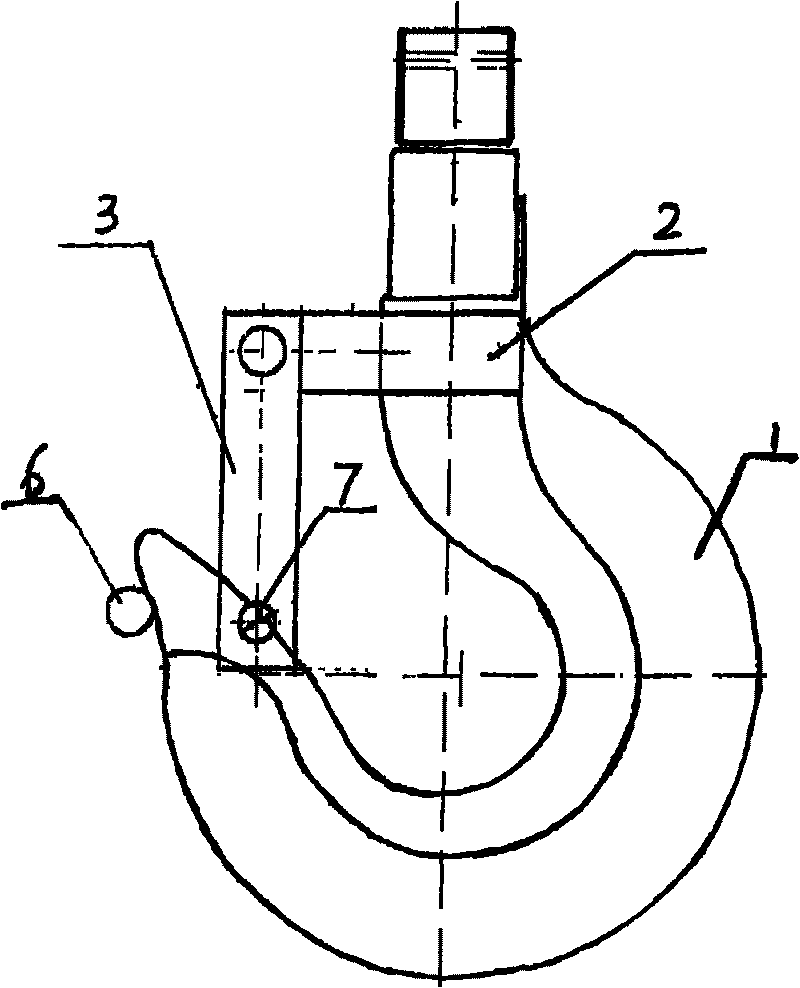

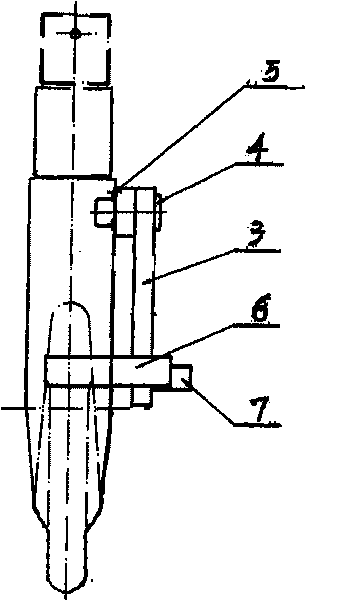

[0016] Modified hooks such as figure 1 , 2 as shown,

[0017] A safety hook, which includes a safety hook 1, a support plate 2 is welded on one side of the hook 1, the support plate is 10mm thick, 30mm wide, and 100mm long, and a column pin 4 and a cotter pin pass through the left end of the support plate 2 5 Connect the baffle 3, the baffle 3 is 10mm thick, 30mm wide, and 100mm long, the baffle pin 6 is welded on the front and bottom of the hook tip, its diameter is 12mm, and the dial pin 7 is welded on the lower end of the baffle 3, the specification is Φ8×20mm.

[0018] A method for manufacturing a safety hook, the steps are as follows:

[0019] a. Set a support plate 2 on one side of the hook 1;

[0020] b. Connect the baffle plate 3 on the support plate 2 through the column pin 4 and the cotter pin 5;

[0021] c. The stop pin 6 is set at the front and bottom of the hook 1;

[0022] d. The dial pin 7 is welded on the lower end of the baffle plate 3 .

Embodiment 2

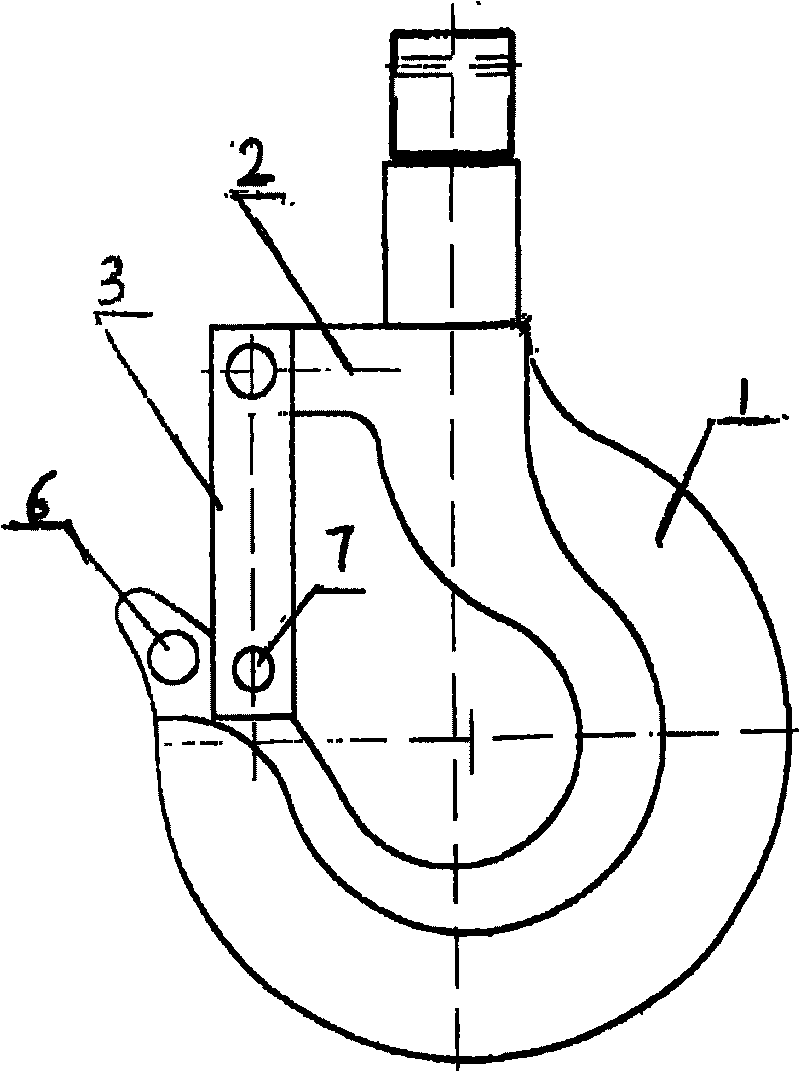

[0024] Newly made hooks such as image 3 , 4 shown.

[0025] A safety hook, which includes a hook 1, a support plate 2 and the hook body are integrally forged, and its outer surface is flat with the side of the hook. The baffle is 10mm thick, 30mm wide, and 100mm long. The stop pin 6 is integrally forged with the hook and is located on the hook tip side. Its diameter is 12mm. The dial pin 7 is welded to the lower end of the baffle 3, and its specification is Φ8×20mm.

[0026] A method for manufacturing a safety hook, the steps are as follows:

[0027] a. The support plate 2 and the hook body of the hook 1 are integrally forged;

[0028] b. Connect the baffle plate 3 on the support plate 2 through the column pin 4 and the cotter pin 5;

[0029] c. The retaining pin 6 is integrally forged with the hanging body;

[0030] d. The dial pin 7 is welded on the lower end of the baffle plate 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com