Self-balancing suction penetration bucket foundation of offshore wind power generating set and construction method thereof

A barrel-shaped foundation and offshore wind power technology, which is applied to wind turbine components, wind power generation, wind engines, etc., can solve construction problems, excessive wear of generator sets, high cost, etc., and achieve simple construction process, enhanced rigidity, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

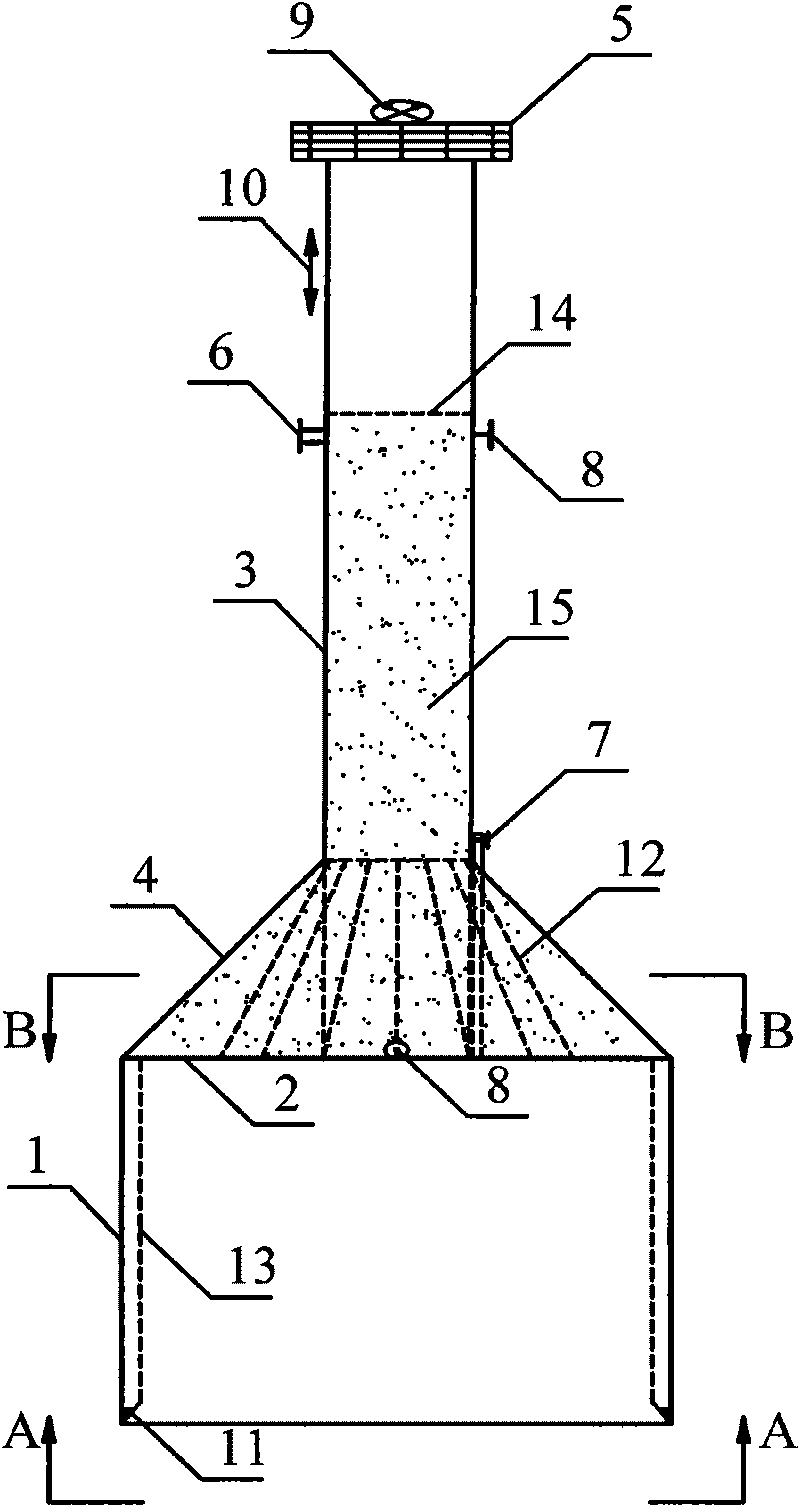

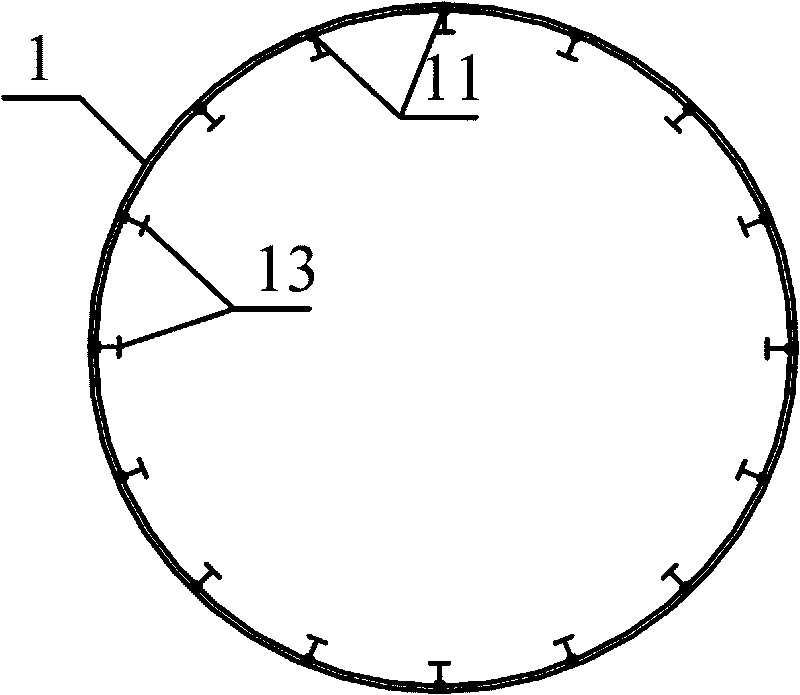

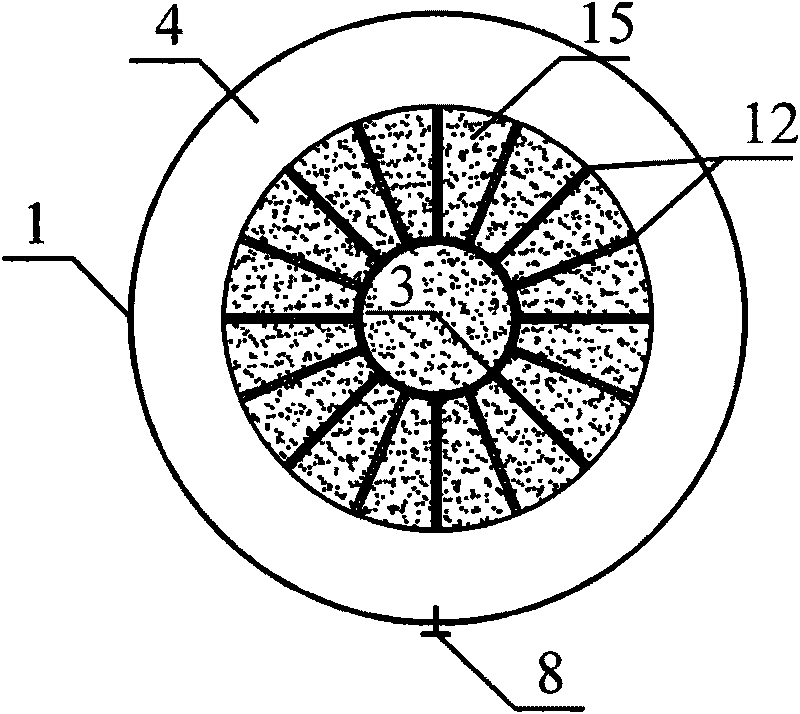

[0029] Such as figure 1 As shown, the barrel foundation of the present invention includes a barrel skirt 1, a barrel cover 2 and a connecting cylinder 3 fixedly connected together from bottom to top in sequence, and a spraying device is installed on the bottom of the barrel skirt 2, and the nozzle 11 of the spraying device is fixedly installed on the The bottom end face of the barrel skirt 2. A horizontal displacement sensor 9 is installed on the guardrail 5 at the top of the connecting cylinder 3 to monitor the inclination of the barrel foundation during sinking, and a vertical displacement sensor 10 on the side wall of the connecting cylinder 3 is used to monitor the inclination of the barrel foundation. The vertical sinking displacement during the sinking process. In the cavity of the connecting cylinder 3, a connecting cylinder top plate 14 is fixedly installed, and the connecting cylinder top plate 14 can be installed on the top of the connecting cylinder 3 or at an appr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com