Two-position three-way electric explosion valve used for primary reversing system

A two-position three-way, reversing system technology, applied in the field of electric explosion valve, can solve the problems of high energy consumption, slow response speed of electric explosion valve, etc., and achieve the effect of simple control, high working pressure and guaranteed reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

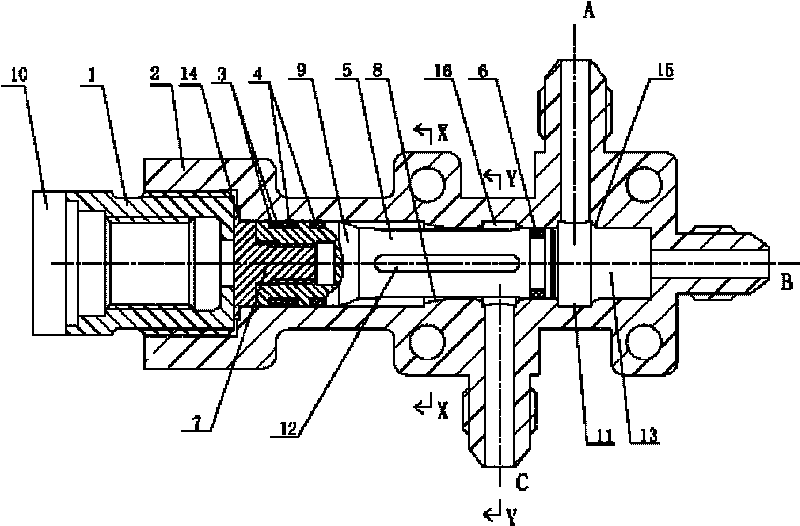

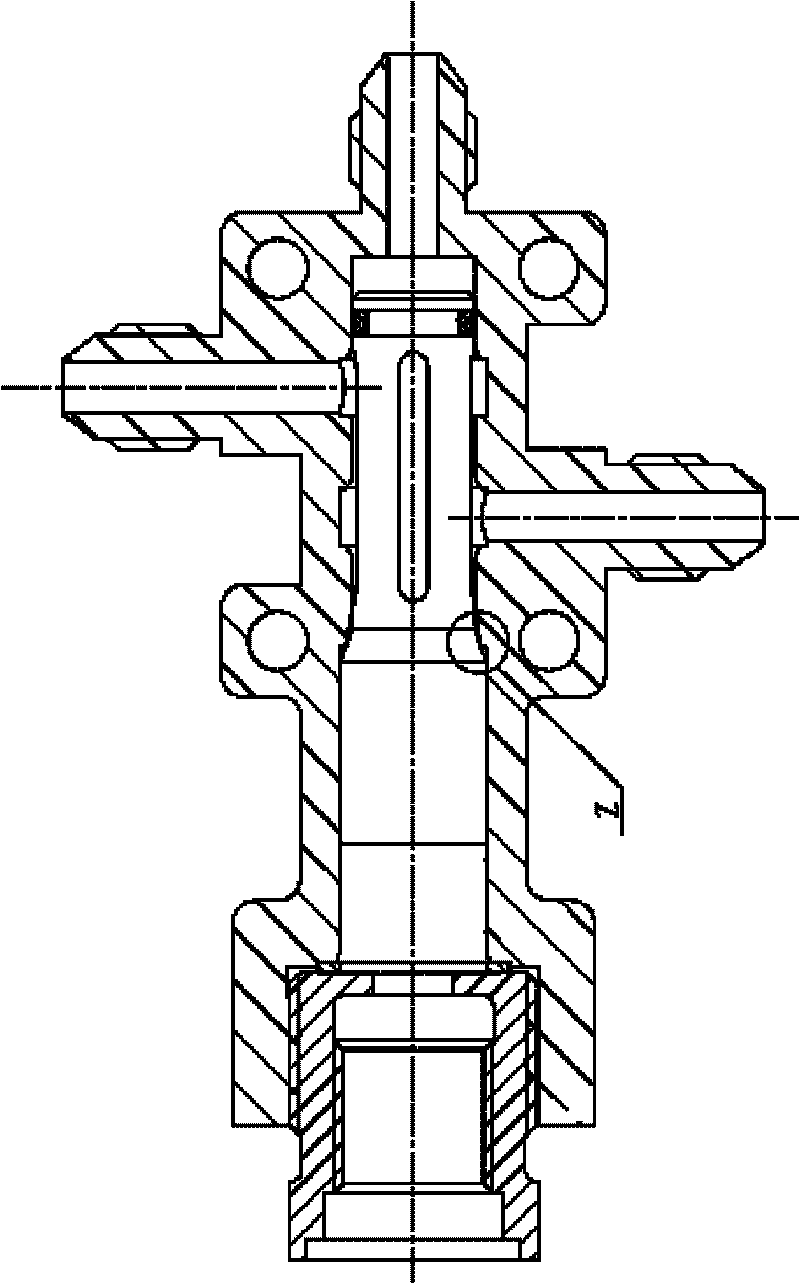

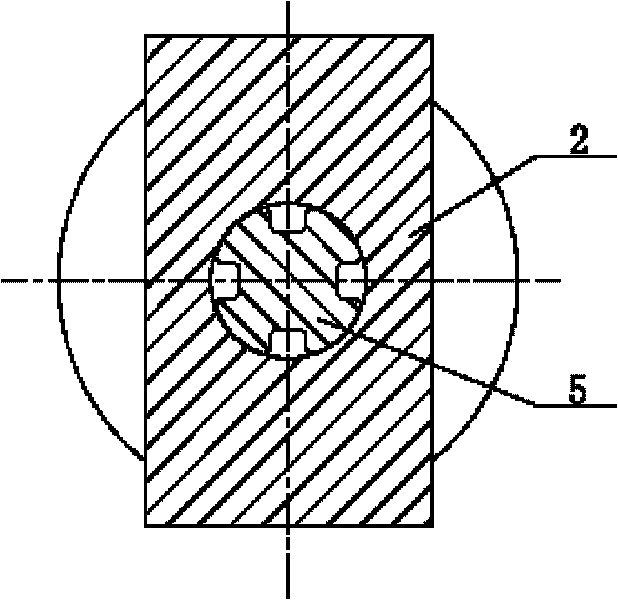

[0028] The two-position three-way electric explosion valve of the present invention includes a housing 2, a valve core 7 and a plunger assembly arranged in the housing 2 and coaxially fixed, an adapter cap 1 screwed to the housing 2, and an adapter cap 1 connected electric squib 10; the housing 2 is provided with a medium inlet A, a first medium outlet B, and a second medium outlet C, and an inner chamber 13 is arranged axially inside the housing 2, and the first medium outlet B is set in the shell The right end face of the body 2, the medium inlet A is set on the side of the housing 2, the second medium outlet C is set on the left side of the medium inlet, the medium inlet A, the first medium outlet B, and the second medium outlet C are all connected to the inner cavity 13 Interconnected; the intersecting hole 11 is provided at the intercommunication between the medium inlet A and the inner cavity 13, and the intersecting hole 16 is provided at the intercommunication between t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap