Printing apparatus and printing method

A printing device and printing head technology, applied in the directions of printing devices, printing, electrical components, etc., can solve the problems of heavy user burden, limited inspection accuracy, and difficulty in maintaining the quality of inspection results stably, and achieve the effect of high-precision judgment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

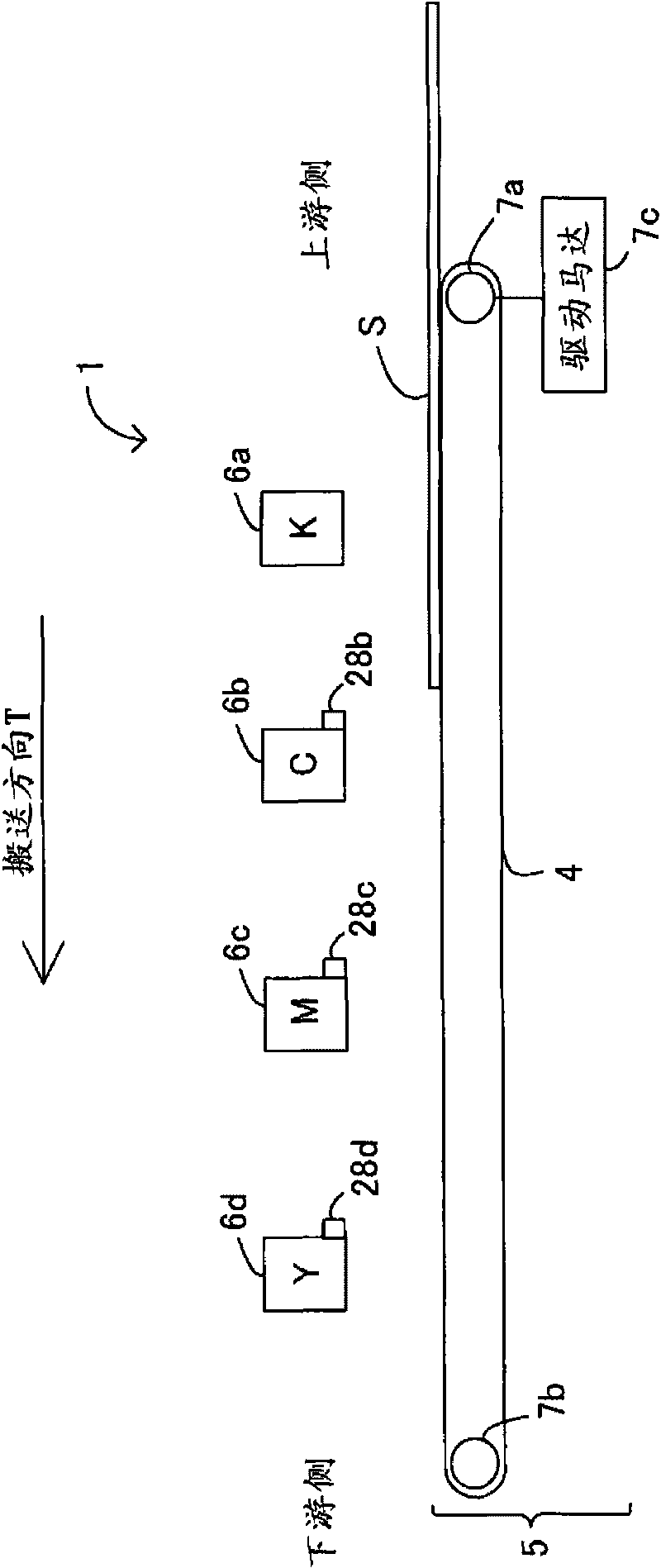

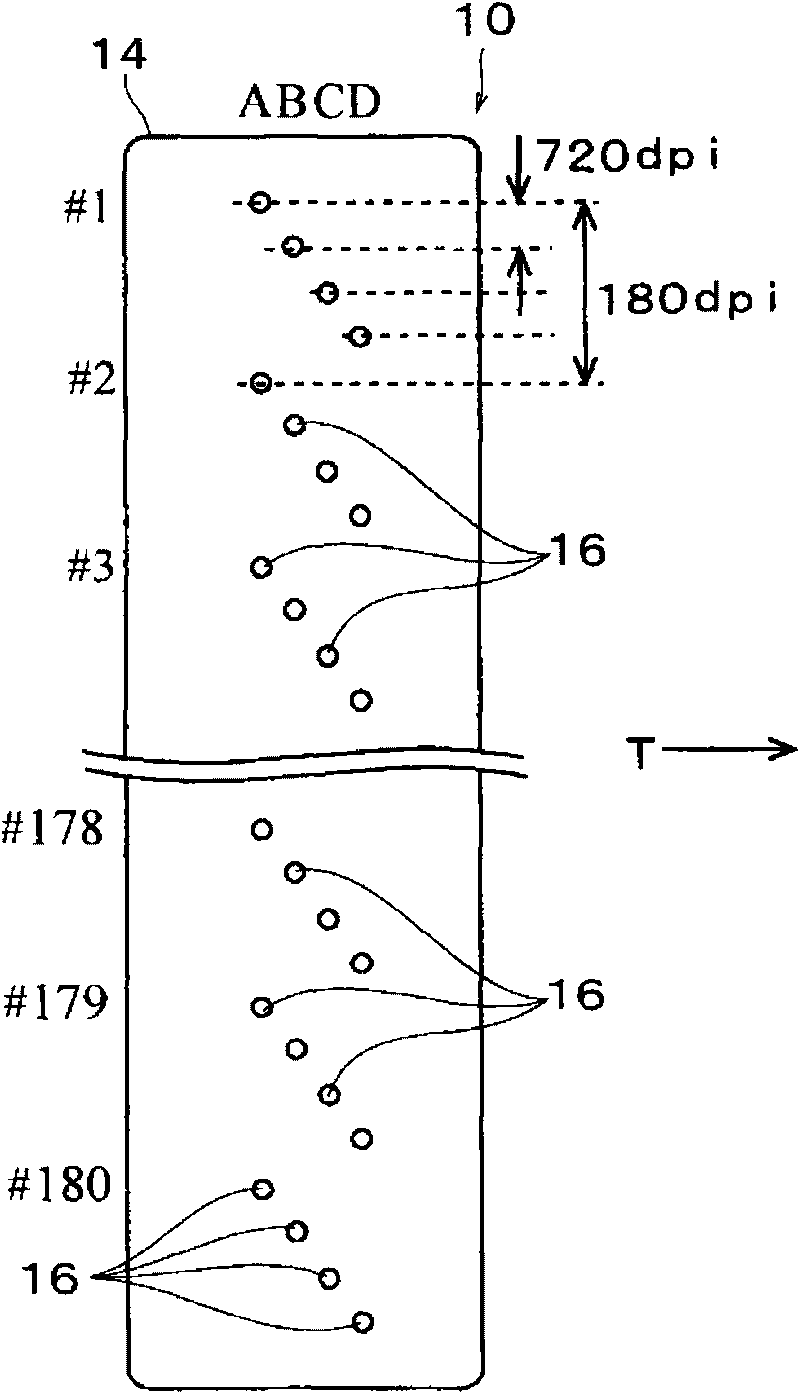

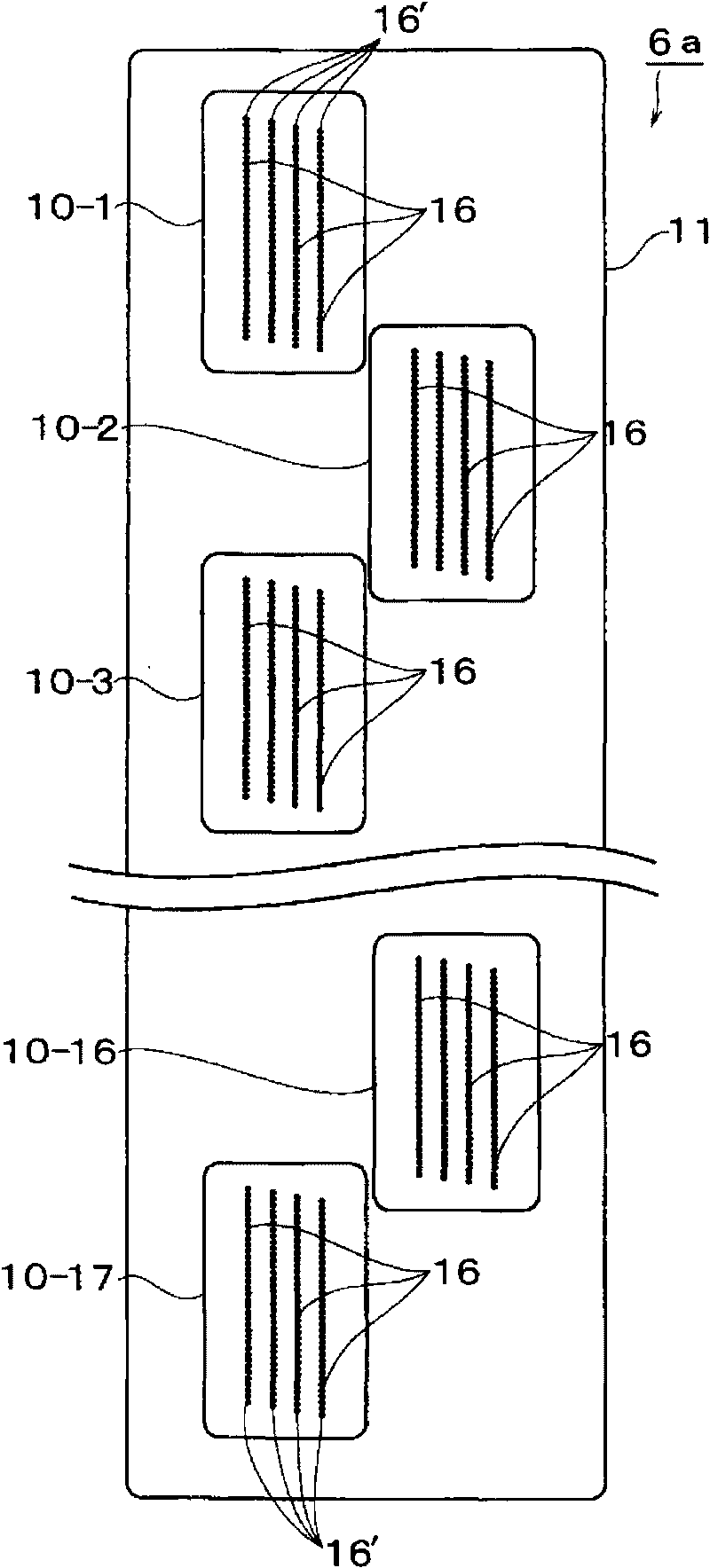

[0032] figure 1 A part of the configuration of an inkjet printer (hereinafter simply referred to as a printer) 1 according to the present embodiment is schematically shown. figure 1 The configuration of the printer 1 viewed from the side is shown. The printer 1 corresponds to an example of the printing device of the present invention. In the printer 1 , a plurality of print heads 6 a , 6 b , 6 c , and 6 d (print head groups) are arranged at predetermined intervals in a conveyance direction of paper S (print medium) (direction T indicated by arrows in the figure). In this embodiment, the print heads 6 a to 6 d are fixed inside the printer 1 .

[0033] The print heads 6a to 6d correspond to a plurality of ink colors used by the printer 1. For example, the print head 6a located on the most upstream side in the transport direction is used to eject black (K) ink, and is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com