High, medium and low-poly theabrownin and preparation method thereof

A technology of theabrownin and high polymerization, applied in the food field, can solve the problems of not preparing theabrownin with different degrees of polymerization and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

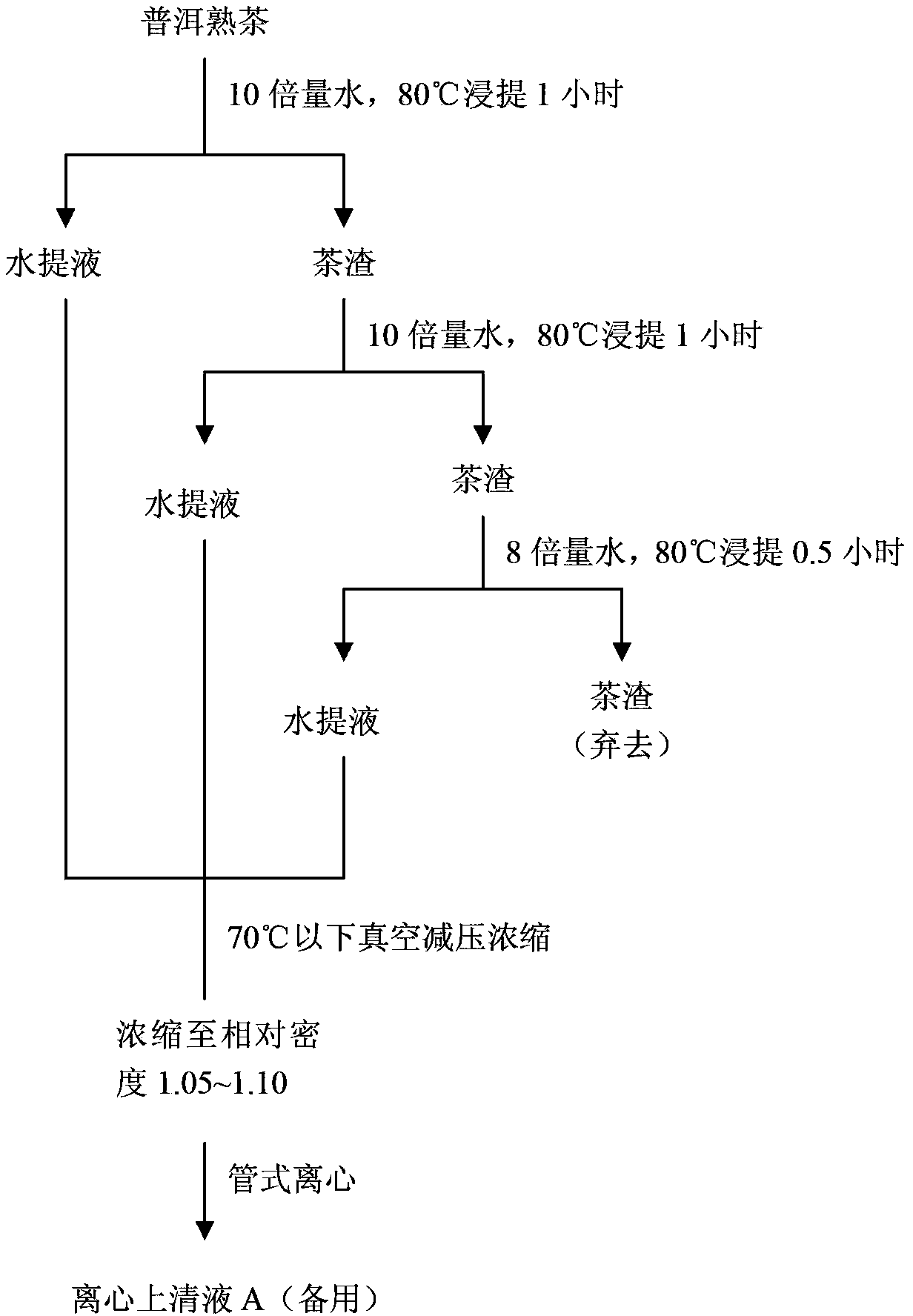

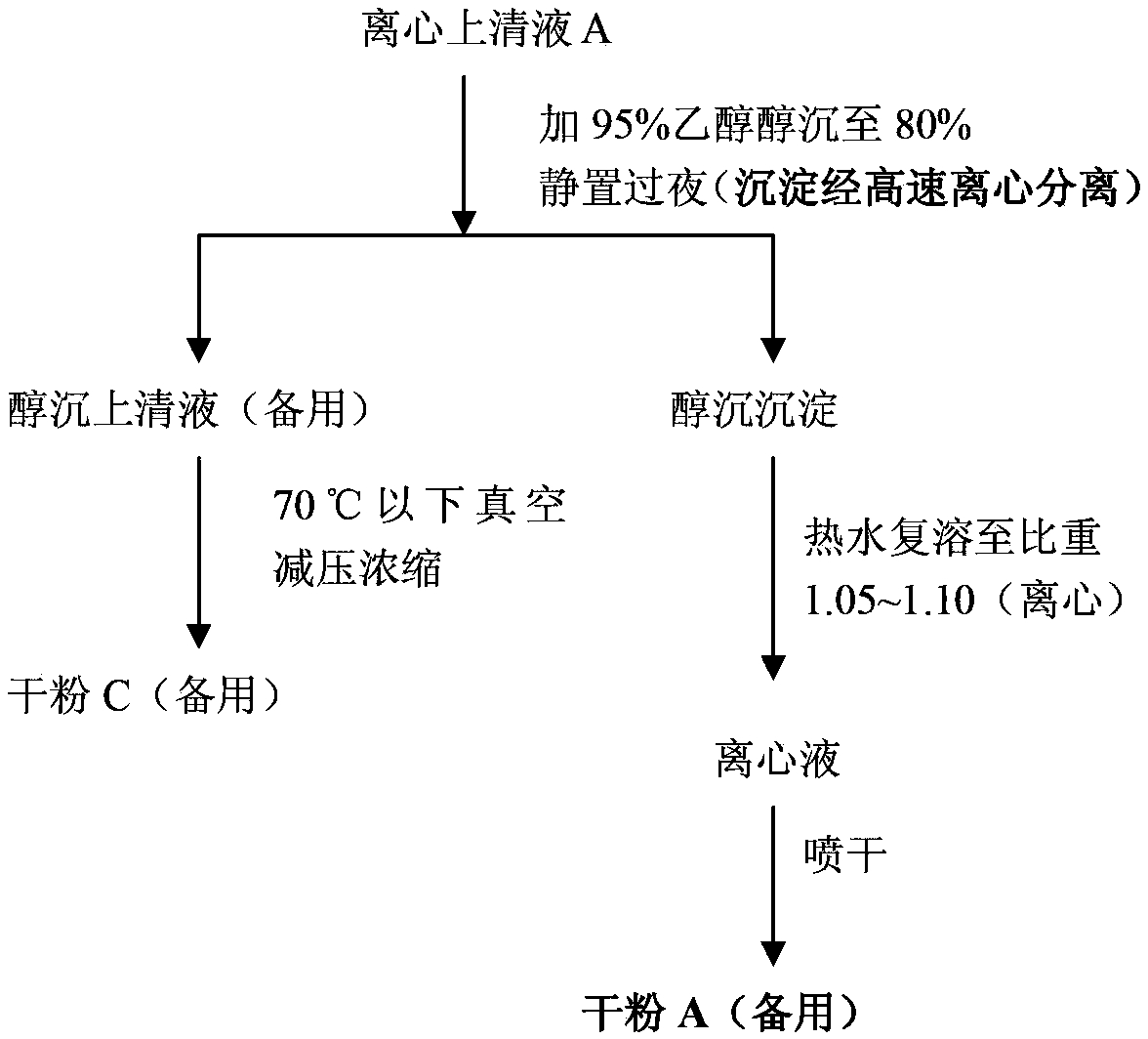

[0036] Take an appropriate amount of Pu’er ripe tea, add 10 times the amount of water and heat at 80°C to extract twice, 1 hour each time, filter, add 8 times the amount of water to the tea residue, heat at 80°C for 0.5 hour, filter, discard the tea residue, and combine the extracts , pass through a 300-mesh filter cloth, concentrate the filtrate under reduced pressure at 70°C to a relative density of 1.05-1.10, and centrifuge in a tube to obtain the centrifuged supernatant, add 95% ethanol to sink to an alcohol content of 80%, let it stand overnight at room temperature, and centrifuge , to obtain alcohol precipitation, heating water to redissolve to a specific gravity of 1.05-1.10, tube centrifugation to obtain a supernatant, and spray drying to obtain dry powder A. The dry powder A in the above flow chart is theabrownin dry powder.

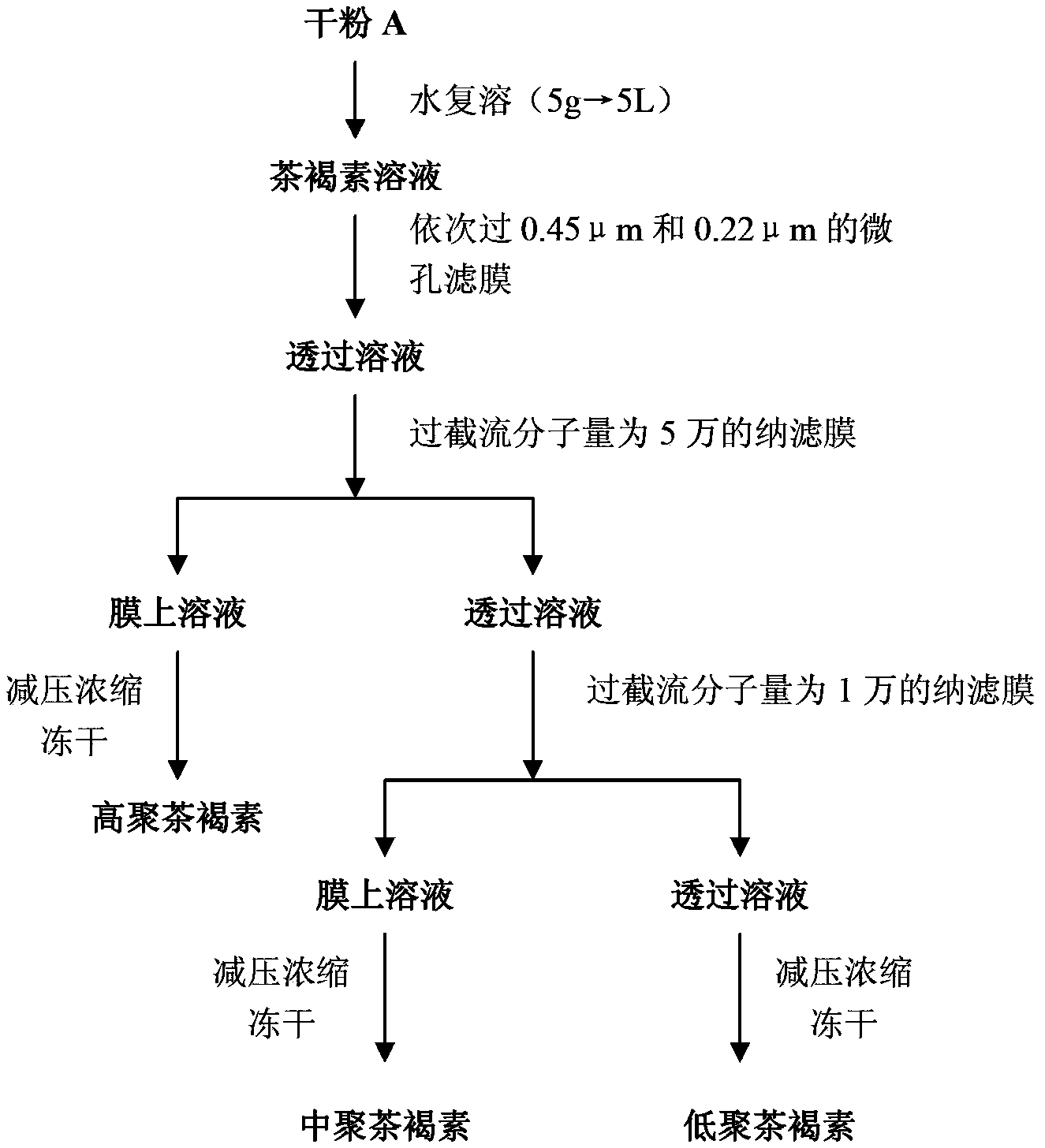

[0037] Preparation process of theabrownin with different degrees of polymerization

[0038] Take theabrownin dry powder and redissolve in water...

Embodiment 2

[0040] Take an appropriate amount of Pu’er ripe tea, add 5 times the amount of water and heat at 90°C to extract once for 2 hours, the extract is passed through a 300-mesh filter cloth, the filtrate is concentrated under reduced pressure at 70°C to a relative density of 1.05-1.10, and centrifuged in a tube to obtain the centrifuge. Add 90% ethanol to ethanol to settle to 70% alcohol content, cool and stand for 12 hours, centrifuge to obtain alcohol precipitate, heat water to redissolve to specific gravity 1.05-1.10, tube centrifuge to obtain supernatant, spray dry , to obtain dry powder A, dry powder A in the above flow chart is theabrownin dry powder.

[0041] Preparation process of theabrownin with different degrees of polymerization

[0042] Take theabrownin dry powder and redissolve in water (2.5g → 5L), pass through 0.45μm and 0.22μm microporous membranes successively, and filter the filtrate with a nanofiltration membrane with a cut-off molecular weight of 50,000, and de...

Embodiment 3

[0044]Take an appropriate amount of Pu’er cooked tea, add 20 times the amount of water, heat at 100°C and extract 3 times, each time for 0.5 hours, filter, combine the extracts, pass through a 300-mesh filter cloth, and concentrate the filtrate under reduced pressure at 70°C to a relative density of 1.05-1.10. centrifuge to obtain the centrifuged supernatant, add 100% ethanol to ethanol to precipitate to alcohol content of 75%, let it stand at room temperature for 24 hours, centrifuge to obtain ethanol precipitation, heat water to redissolve to a specific gravity of 1.05-1.10, and tube centrifuge to obtain The supernatant was spray-dried to obtain dry powder A, and the dry powder A in the above flow chart was theabrownin dry powder.

[0045] Preparation process of theabrownin with different degrees of polymerization

[0046] Take the theabrownin dry powder and redissolve it in water (10g → 5L), pass through 0.45μm and 0.22μm microporous membranes in sequence, and filter the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com