Rat-proof and termite-proof cable and preparation method thereof

A rodent-proof cable and termite-proof technology, applied in cable/conductor manufacturing, insulated cables, power cables with shielding layer/conductive layer, etc., can solve cable faults, affect rodent-proof performance, and cable sheath bite through And other problems, to achieve the effect of high bending strength and impact strength, good scratch resistance, rodent and ant resistance, and good environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

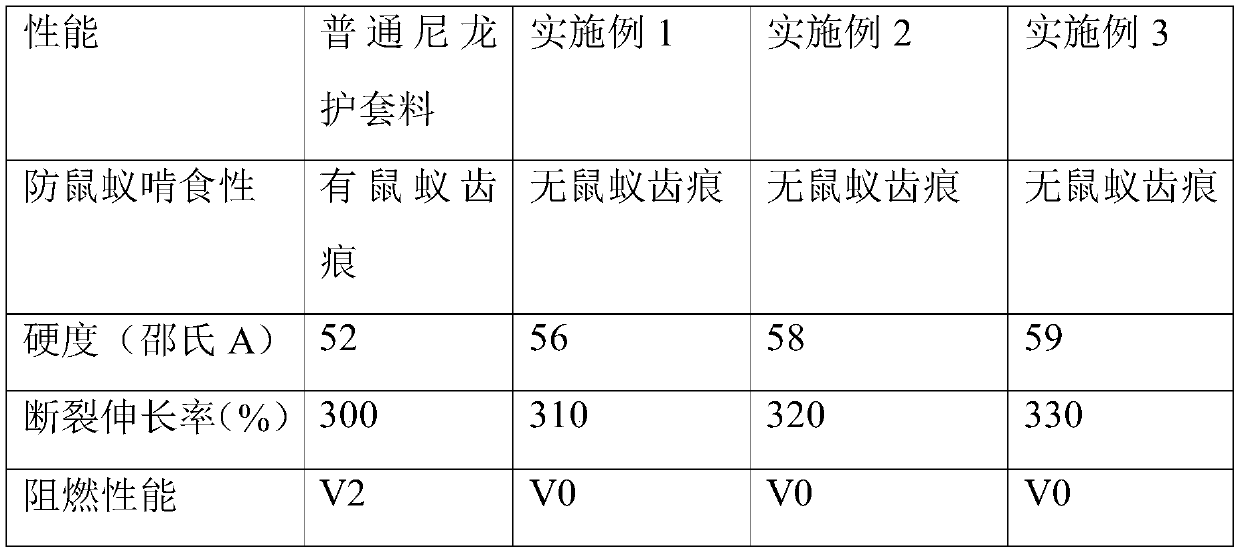

Embodiment 1

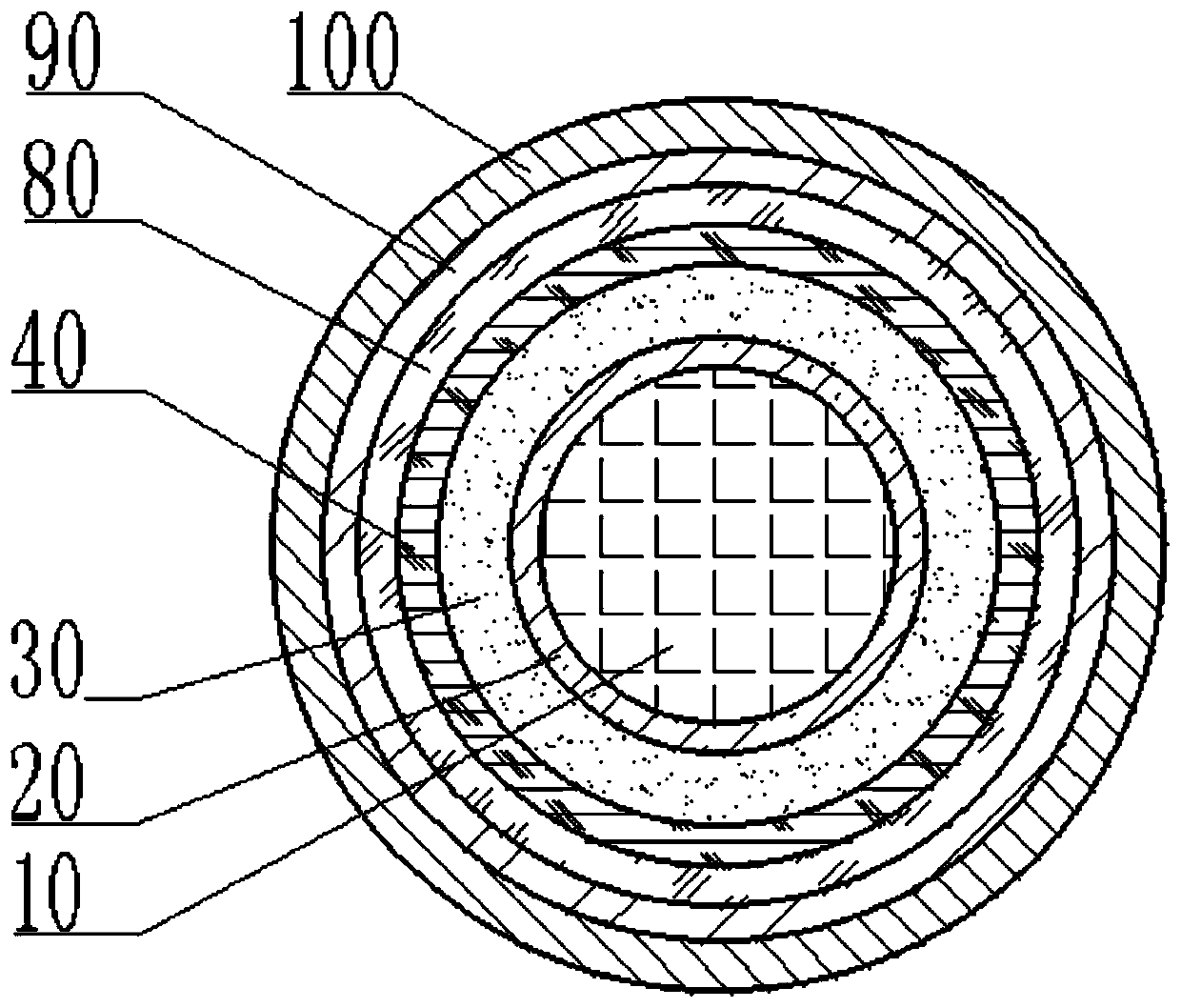

[0056] refer to figure 1 As shown, this embodiment provides a new type of rodent-proof cable, including a cable core and a protective layer. The cable core is twisted by at least one insulated core. The insulated core includes a conductor 10 and is wrapped around the conductor 10 in turn. The outer conductor shielding layer 20, the insulating layer 30, and the insulating shielding layer 40. The protection layer includes an inner sheath 80 , a nylon sheath 90 and an outer sheath 100 in sequence along the axial direction away from the cable core.

[0057] The preparation method of the rodent-proof cable of this embodiment is:

[0058] 1. Preparation of nylon sheath material: take 30kg of nylon resin with weight average molecular weight ≥ 15,000 and viscosity ≥ 15g / min, modifier 5kg, lubricant 0.3kg, antioxidant 1kg, aluminum hydroxide 70kg, zinc borate 20kg, 2kg of anti-termite masterbatch, 5kg of silicone masterbatch and 10kg of brown corundum micropowder are mixed evenly at ...

Embodiment 2

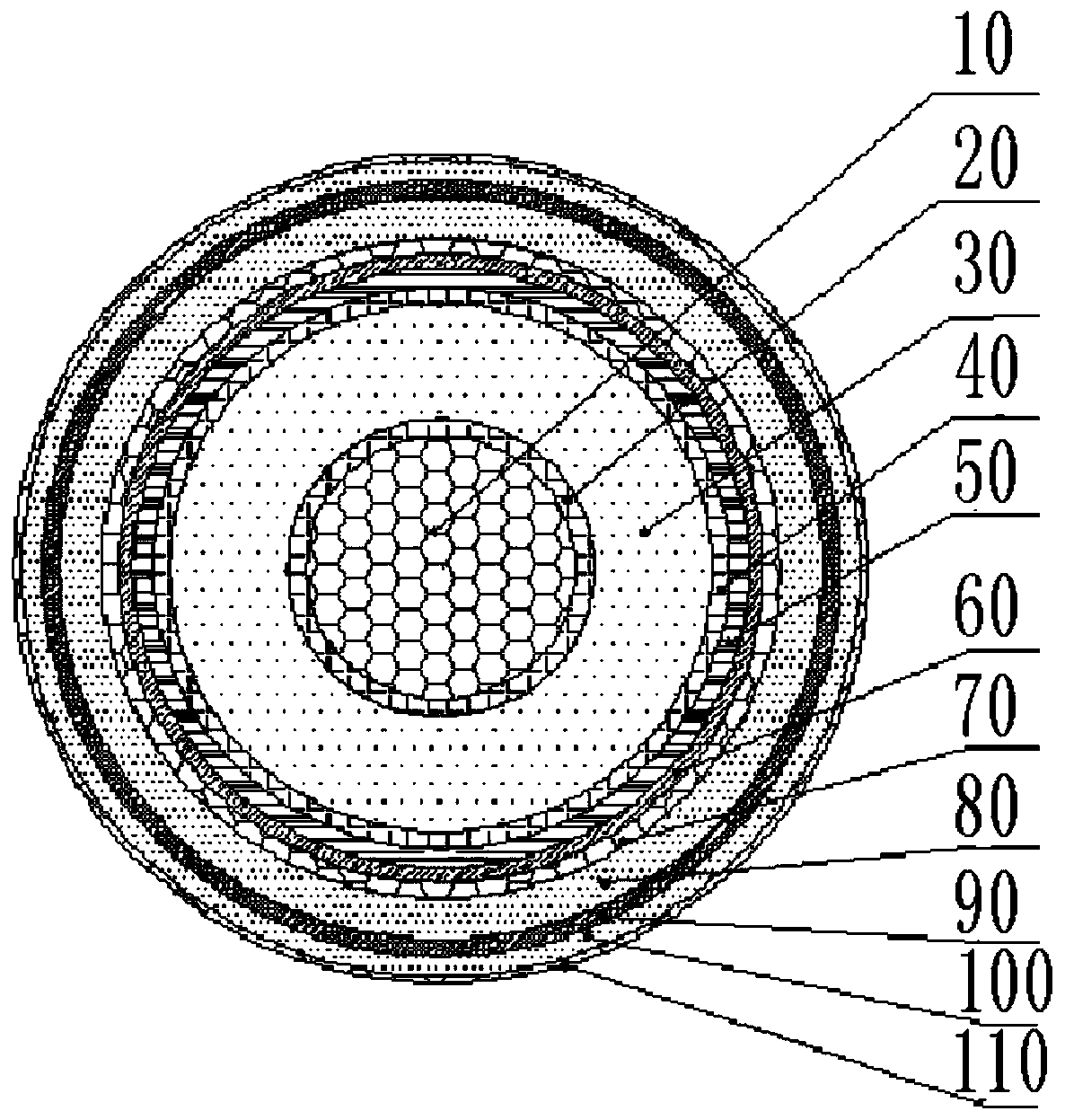

[0064] refer to figure 2 Shown, as the novel anti-rodent and ant cable of embodiment 2 of the present invention, comprise: buffering water blocking belt 50, metal sheath layer 60, anticorrosion layer 70, inner sheath 80, nylon sheath 90, outer sheath 100 and semiconducting layer 110 .

[0065] The preparation method is as follows:

[0066] 1. Preparation of nylon sheath material: take 40kg of nylon resin with weight average molecular weight ≥ 15,000 and viscosity ≥ 15g / min, modifier 7kg, lubricant 0.4kg, antioxidant 1.5kg, aluminum hydroxide 95kg, zinc borate 35kg , 3kg of anti-termite masterbatch, 6.5kg of silicone masterbatch and 12.5kg of brown corundum micropowder are mixed uniformly at 25-75°C, kneaded, mixed, extruded at 195-215°C, cooled by hot water, cut Granules to make nylon sheath material;

[0067] 2. The preparation steps of the finished cable are as follows:

[0068] The first step is to wrap the buffer water-blocking tape 50 on the cable core; the second st...

Embodiment 3

[0074] Other operating steps and cable structure in this embodiment are the same as those in Embodiment 2, except for the ingredients of the nylon sheath material.

[0075] The ingredients of the nylon sheath material in this example are: 50 kg of nylon resin with weight average molecular weight ≥ 15,000 and viscosity ≥ 15 g / min, 10 kg of modifier, 0.5 kg of lubricant, 2 kg of antioxidant, 120 kg of aluminum hydroxide, 50kg of zinc borate, 4kg of anti-termite masterbatch, 8kg of silicone masterbatch and 15kg of brown corundum micropowder.

[0076] The modifier used in this example is a combination of thermoplastic elastomer and polyolefin elastomer polypropylene.

[0077] The lubricant used in this example is calcium stearate.

[0078] The antioxidant used in this example is dihydroquinoline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com