Determination method of protein powder freshness

A determination method and technology of protein powder, which can be used in measurement devices, instruments, scientific instruments, etc., can solve the problems of complex composition, large interference in determination, large precision, accuracy and detection limit error, etc., and achieve repeatability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

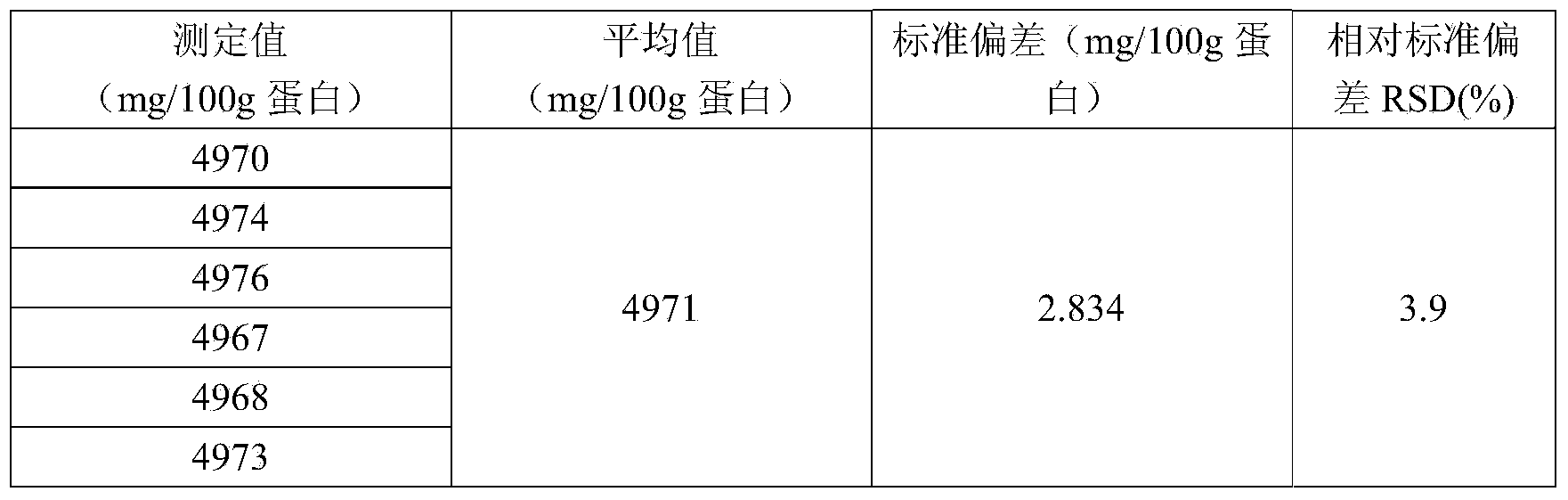

[0018] Precision experiment

[0019] Step 1, preparation of furosine standard solution: Weigh 2.5mg of furosine standard sample, dissolve it in a 25mL volumetric flask with 0.1mol / L hydrochloric acid, and its concentration is 100mg / L, as a standard stock solution, place in- Store in a refrigerator at 20°C. Pipette 2.0, 4.0, 6.0, 8.0ml fururine standard stock solution into a 10ml volumetric flask, dilute to the mark with 0.1mol / L hydrochloric acid and shake well.

[0020] Step 2, sample pretreatment: add 0.35g protein powder sample to 6mL hydrochloric acid solution and oxalic acid solution mixed solution, mix evenly, pass high-purity nitrogen gas into the solution, put it in an oven at 110°C for 24 hours, take it out and cool it down To room temperature, filter, get filtrate and make need testing solution, wherein the volume ratio of hydrochloric acid solution, oxalic acid solution is 8:1, the concentration of hydrochloric acid solution is 10.2mol / L, the concentration of oxali...

Embodiment 2

[0025] A method for measuring the freshness of protein powder, comprising the following steps:

[0026] Step 1, preparation of furosine standard solution: Weigh 2.5mg of furosine standard sample, dissolve it in a 25mL volumetric flask with 0.1mol / L hydrochloric acid, and its concentration is 100mg / L, as a standard stock solution, place in- Store in a refrigerator at 20°C. Pipette 2.0, 4.0, 6.0, 8.0ml fururine standard stock solution into a 10ml volumetric flask, dilute to the mark with 0.1mol / L hydrochloric acid and shake well.

[0027] Step 2, sample pretreatment: add 0.35g protein powder sample to 6mL hydrochloric acid solution and oxalic acid solution mixed solution, mix evenly, pass high-purity nitrogen gas into the solution, put it in an oven at 110°C for 24 hours, take it out and cool it down To room temperature, filter, get filtrate and make need testing solution, wherein the volume ratio of hydrochloric acid solution, oxalic acid solution is 8:1, the concentration of ...

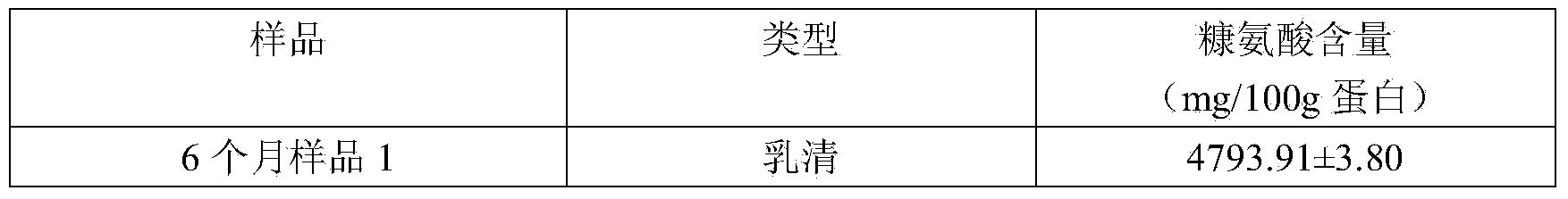

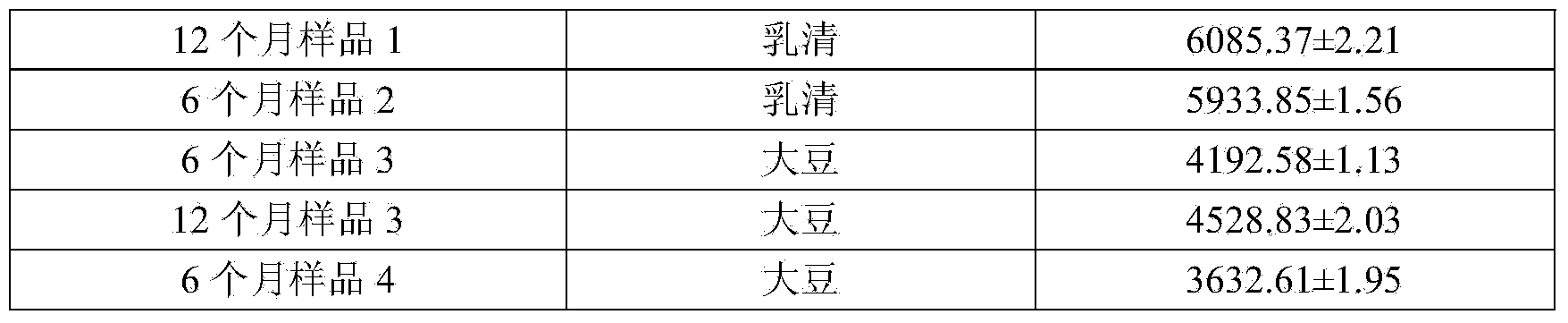

Embodiment 3

[0035] A method for measuring the freshness of protein powder, comprising the following steps:

[0036] Step 1, preparation of furosine standard solution: Weigh 2.5mg of furosine standard sample, dissolve it in a 25mL volumetric flask with 0.1mol / L hydrochloric acid, and its concentration is 100mg / L, as a standard stock solution, place in- Store in a refrigerator at 20°C. Pipette 2.0, 4.0, 6.0, 8.0ml fururine standard stock solution into a 10ml volumetric flask, dilute to the mark with 0.1mol / L hydrochloric acid and shake well.

[0037] Step 2, sample pretreatment: add 0.35g protein powder sample to 6mL hydrochloric acid solution and oxalic acid solution mixed solution, mix evenly, pass high-purity nitrogen gas into the solution, put it in an oven at 110°C for 24 hours, take it out and cool it down To room temperature, filter, get filtrate and make need testing solution, wherein the volume ratio of hydrochloric acid solution, oxalic acid solution is 8:1, the concentration of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com