Absorption type heat pump

An absorption heat pump and absorption liquid technology, applied in the field of absorption heat pumps, can solve problems such as heat loss and inability to absorb heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

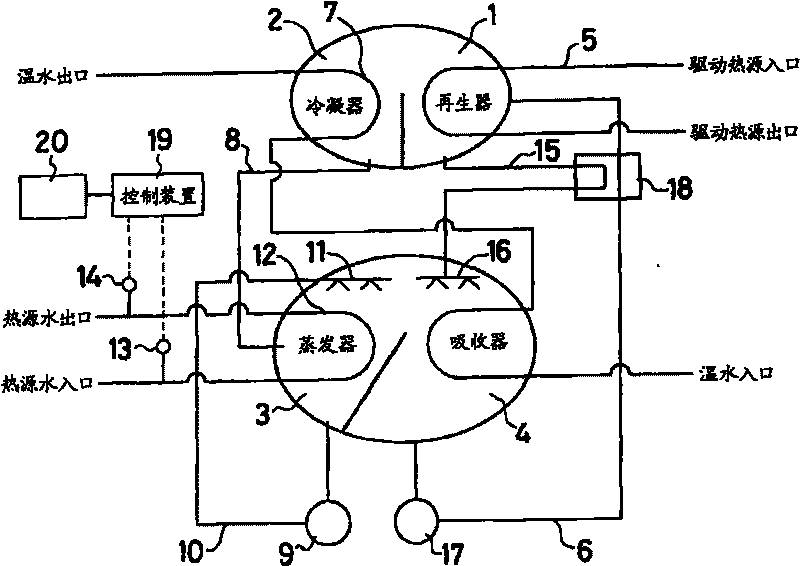

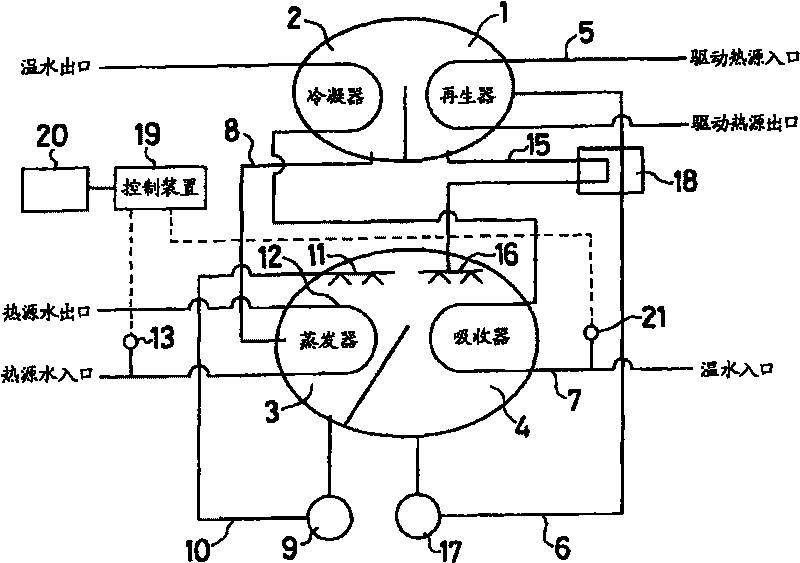

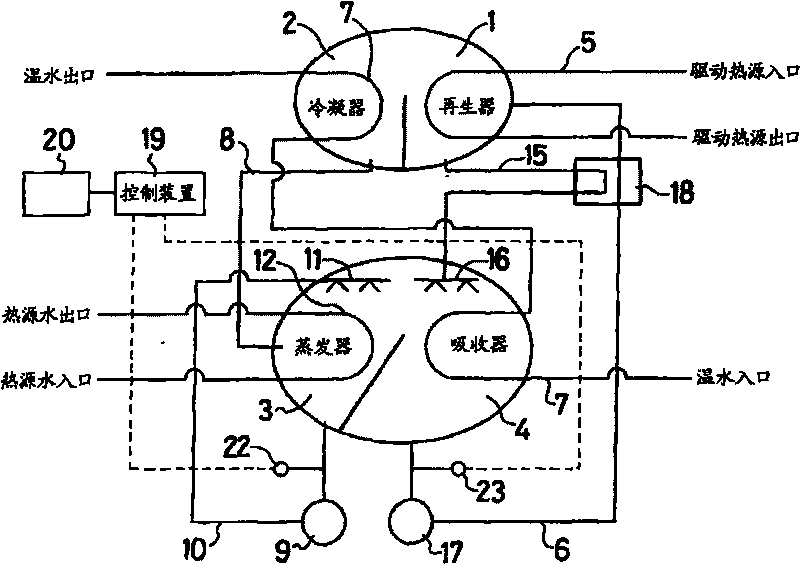

[0036] Hereinafter, embodiments of the present invention will be described based on the drawings. figure 1 It is a configuration diagram showing the first embodiment of the absorption heat pump of the present invention. exist figure 1 In , reference numeral 1 denotes a regenerator, 2 denotes a condenser provided adjacent to the regenerator 1 , 3 denotes an evaporator, and 4 denotes an absorber provided adjacent to the evaporator 3 . At this time, a lithium bromide aqueous solution was used as the absorbing liquid, and water was used as the refrigerant.

[0037] In the regenerator 1, for example, steam at about 170°C discharged from the boiler passes through the driving heat source pipe 5, and returns to the regenerator 1 through the dilute absorption liquid pipe 6 connected to the absorber 4. The dilute absorption liquid is heated, so that the refrigerant vapor is evaporated and separated.

[0038]The refrigerant vapor that has been evaporated and separated in the regenerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com