Method for producing seamless steel tube by combination of drawing and expanding and device thereof

A technology for seamless steel pipes and steel pipes, applied in the field of steel pipe production, can solve the problems of time-consuming, material-consuming, labor-consuming, increasing steel pipe production costs, and inability to use them, and achieves the effects of saving production costs, having far-reaching production significance, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

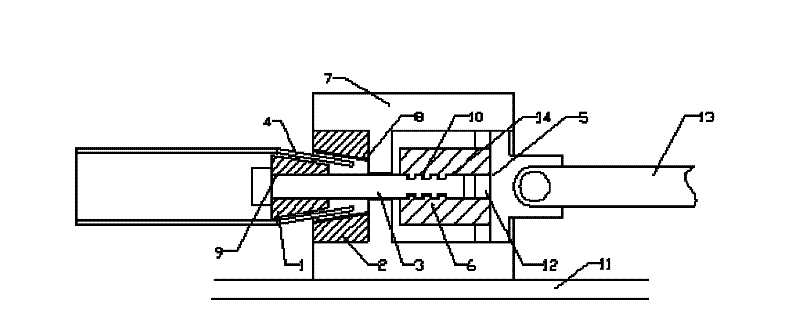

[0017] The method for producing a seamless steel pipe by combining drawing and diameter expansion provided in this embodiment includes the use of a drawing power source, which is characterized in that an open-type locking member is fixedly connected to the nozzle of the steel pipe to be drawn, and the open-type There is a detachable locking device on the locking part. When pulling, the detachable locking device locks the open locking part and is connected with the pulling power source, and the detachable locking device is pulled under the action of the pulling power source. device, and pull the steel pipe to be drawn; after the drawing is completed, the detachable locking device releases the open-type locking piece, and then enters the steel pipe fixedly connected with the open-type locking piece into the diameter-expanding process; The mouth is fixedly connected with an open-type locking piece, so when expanding the diameter, it is not necessary to remove the open-type locking...

Embodiment 2

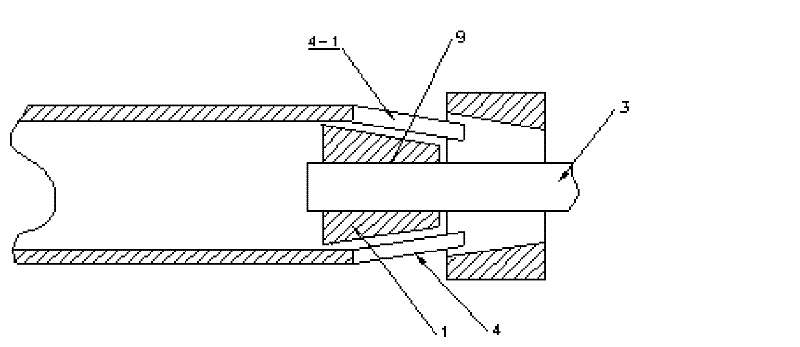

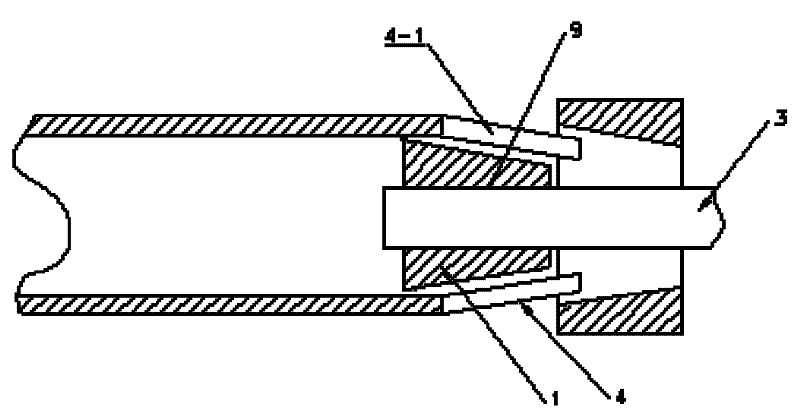

[0020] Such as figure 2 As shown, the open-type locking member 4 fixedly connected to the nozzle of the steel pipe described in this embodiment is welded with two wing plates 4-1 on the nozzle of the steel pipe. The connection of the tapered pulling body 1 is that one end of the locking rod 3 is provided with a thread, and a screw hole is provided in the through hole 9 of the outer tapered pulling body 1, and one end of the locking rod 3 is connected with the outer cone through the thread. The screw holes on the shaped drawing body 1 are connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com