Double-side molding process and die of wheel hub bearing outer ring

A double-sided forming, hub bearing technology, used in manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] specific implementation plan

[0021] The structure of the present invention will be further described below in conjunction with the accompanying drawings, but it cannot be construed as a limitation to the present invention, and the remaining unexplained parts of the present invention are consistent with the prior art.

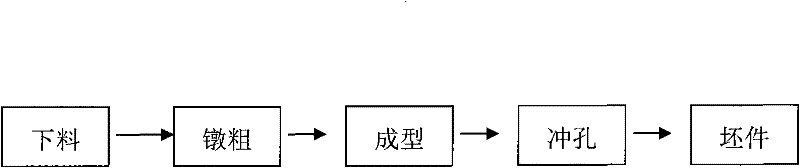

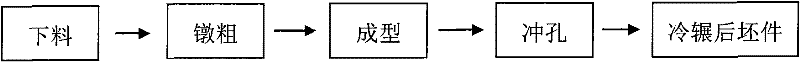

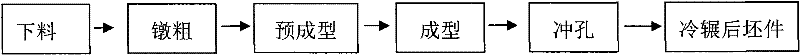

[0022] The double-sided forming process of the outer ring of the first-generation wheel hub bearing, such as image 3 As shown, the following process steps are included:

[0023] 1) Blanking: Design the forging drawing according to the size of the finished part. After designing the thickness of the material core, a fully formed forging volume can be obtained, and then calculate the diameter and length of the bar to ensure that the length-to-diameter ratio of the bar is 0.8-1.2.

[0024] 2) Upsetting: The upsetting diameter is only 0.5-1 mm smaller than the outer diameter of the forging molding.

[0025] 3) Preforming: The mold design of this station i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com