Trolley

A trolley and hand lever technology, applied in the field of trolleys, can solve the problems of unadjustable use angle, influence on handling, and trolley movement, etc., and achieve the effects of easy classification management, easy stacking, and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

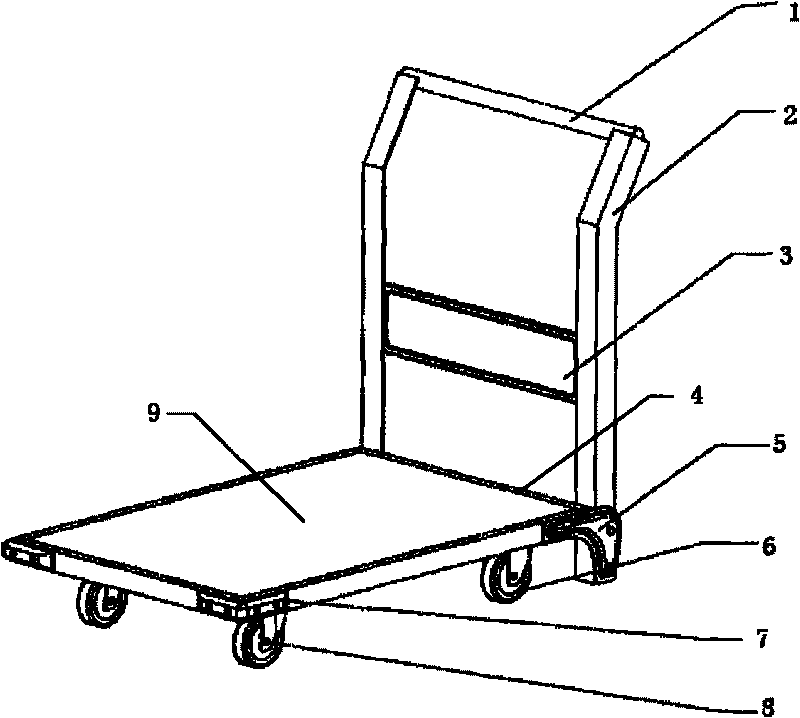

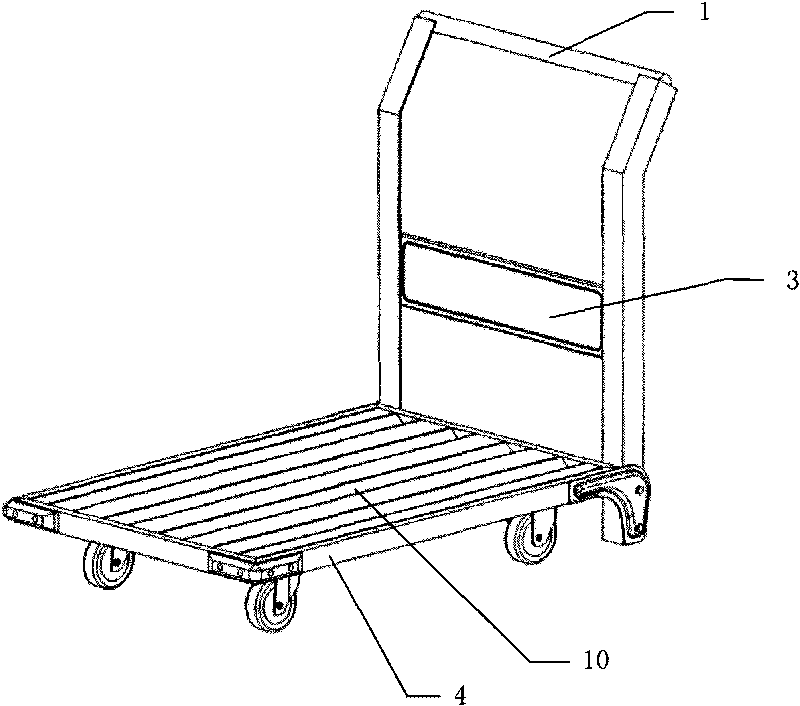

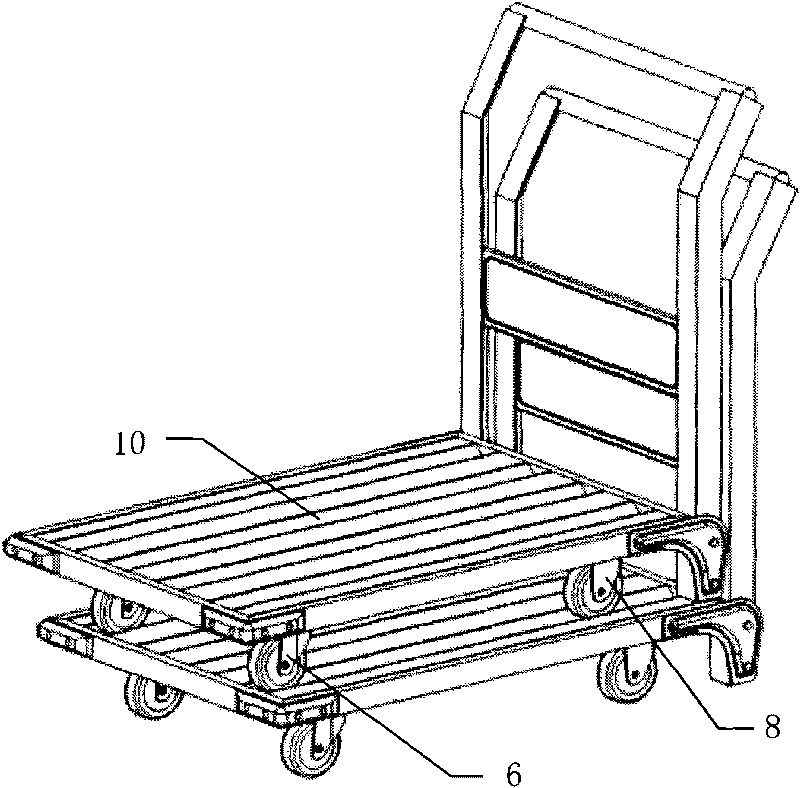

[0026] Such as Figure 1~5 Shown trolley, comprises handle 1, handle bar 2, bottom frame 4, caster, and the top of hand bar 2 is provided with handle 1, and the low end of bottom frame 4 is distributed with caster, and its special feature is: described The end of the handle bar 2 presents a movable connection with the handle bar connecting part 5 through the rotating shaft, and the handle bar connecting part 5 is fixed on the bottom frame 4 at the same time. Therefore, the angle between the handle bar 2 and the bottom frame 4 can be adjusted through the handle bar connecting piece 5, which is convenient for the staff to use. recombine Figure 4 It can be seen that the handle bar 2 can also be turned backwards through the rotating shaft, so that the trolley can be folded. Looking further, since the end of the handle bar 2 is lower than the bottom plane of the casters after being rotated by the rotating shaft, the inner width of the handle 2 is greater than the outer width of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com