Experimental modal analysis method of numerical control equipment

An experimental modal analysis and equipment technology, applied in measurement devices, vibration testing, machine/structural component testing, etc., can solve problems such as increased analysis difficulties, inability to accurately identify modal parameters, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

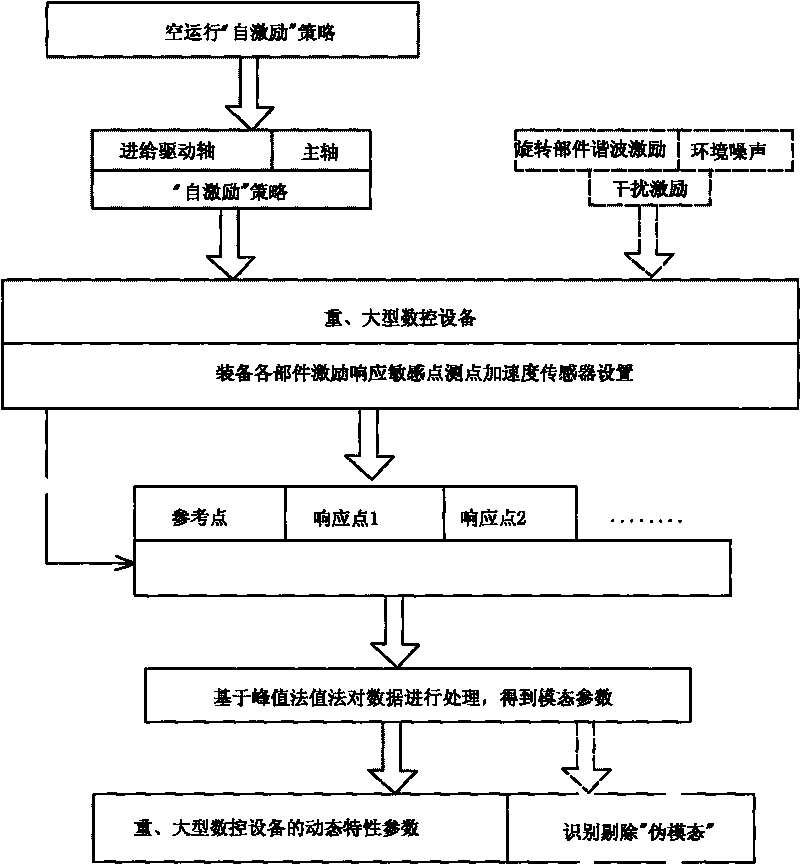

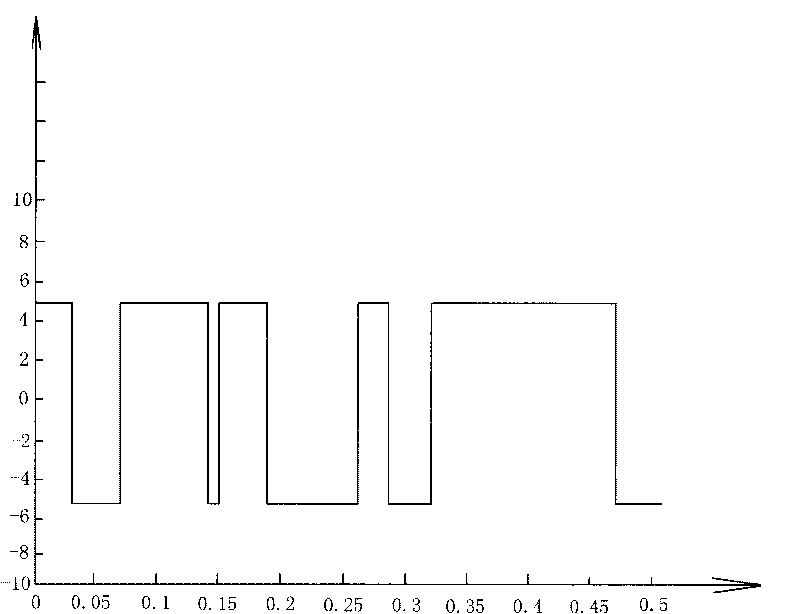

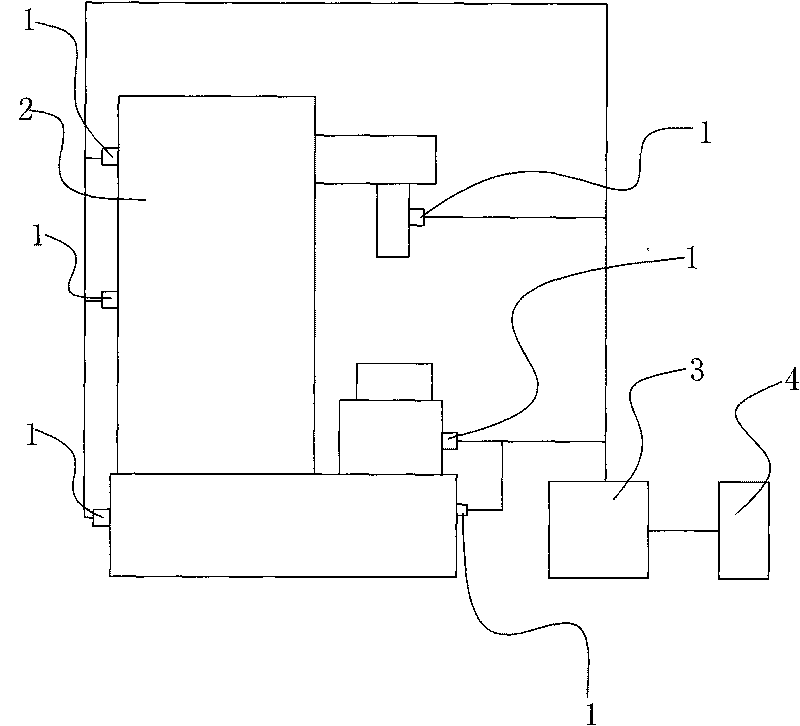

[0023] Such as figure 1 As shown, the process steps of a method for numerically controlled equipment experiment modal analysis in the present invention are as follows: 1) "self-excitation" input, using the law of movement of numerically controlled equipment to input self-excited signals to the numerically controlled equipment, and generating Input excitation; 2) On the basis of analyzing the sensitive points of the excitation response of each component of the CNC equipment, obtain the point with a large response range of the CNC equipment as the reference point and the response point, and optimize the arrangement of the reference point and the response point; 3) The self-excitation signal is in the The reference point and the response point generate a self-excitation response, collecting the response signal generated by the reference point and the response point after the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com