Patents

Literature

83 results about "Broadband excitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

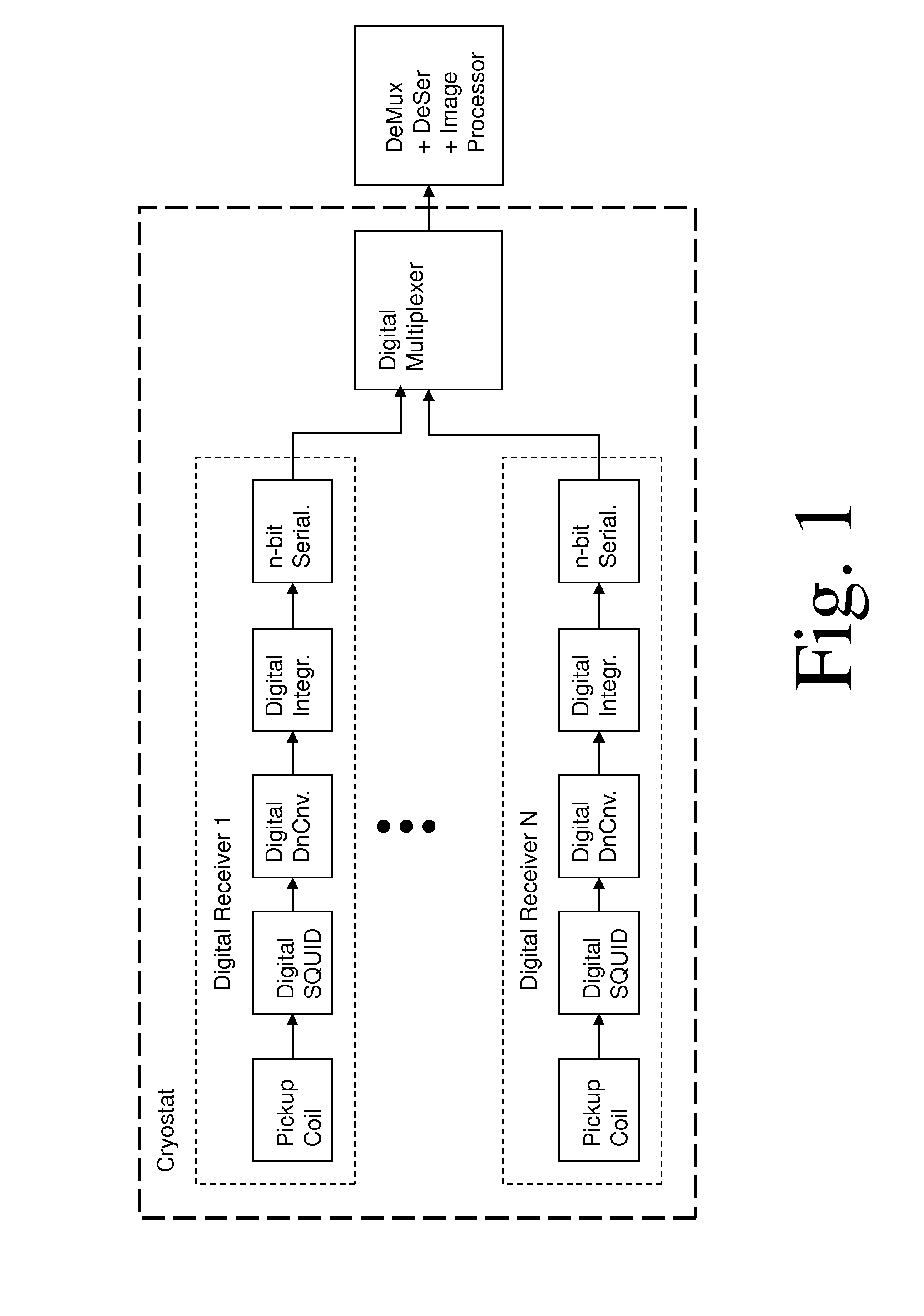

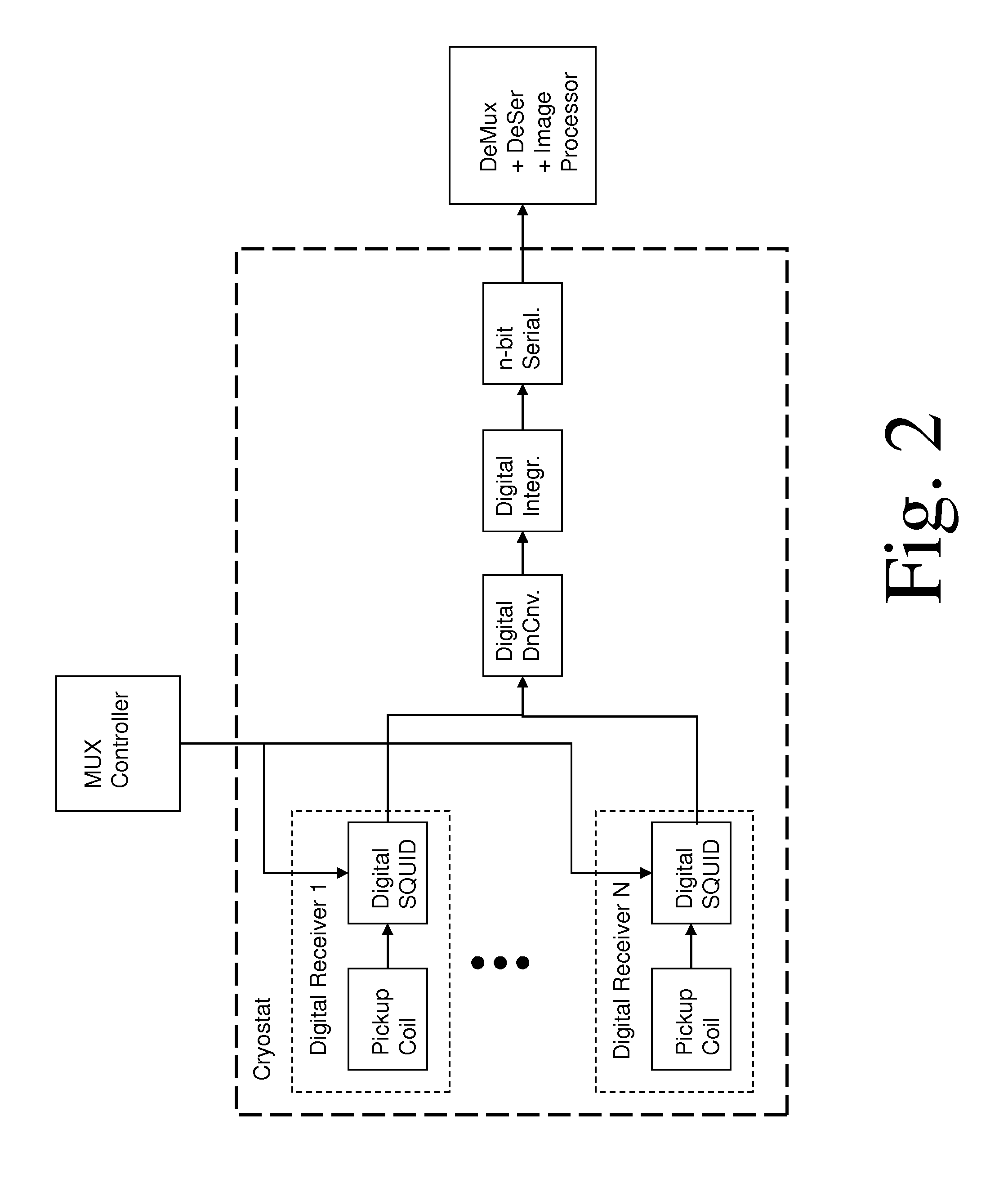

Magnetic resonance system and method employing a digital squid

ActiveUS8593141B1Fast imagingImprove spatial resolutionMagnetic property measurementsMeasurements using NMR imaging systemsVoxelData acquisition

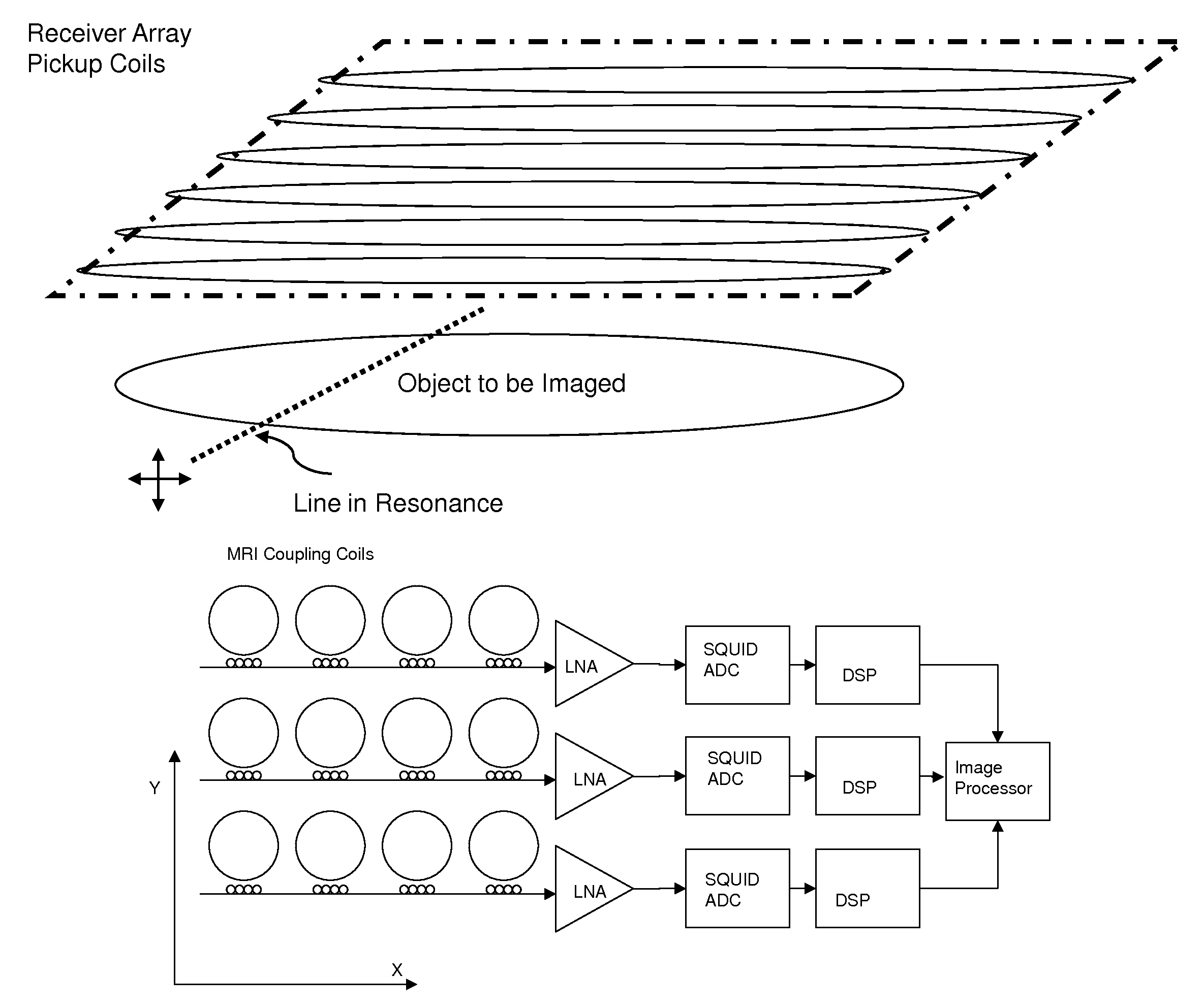

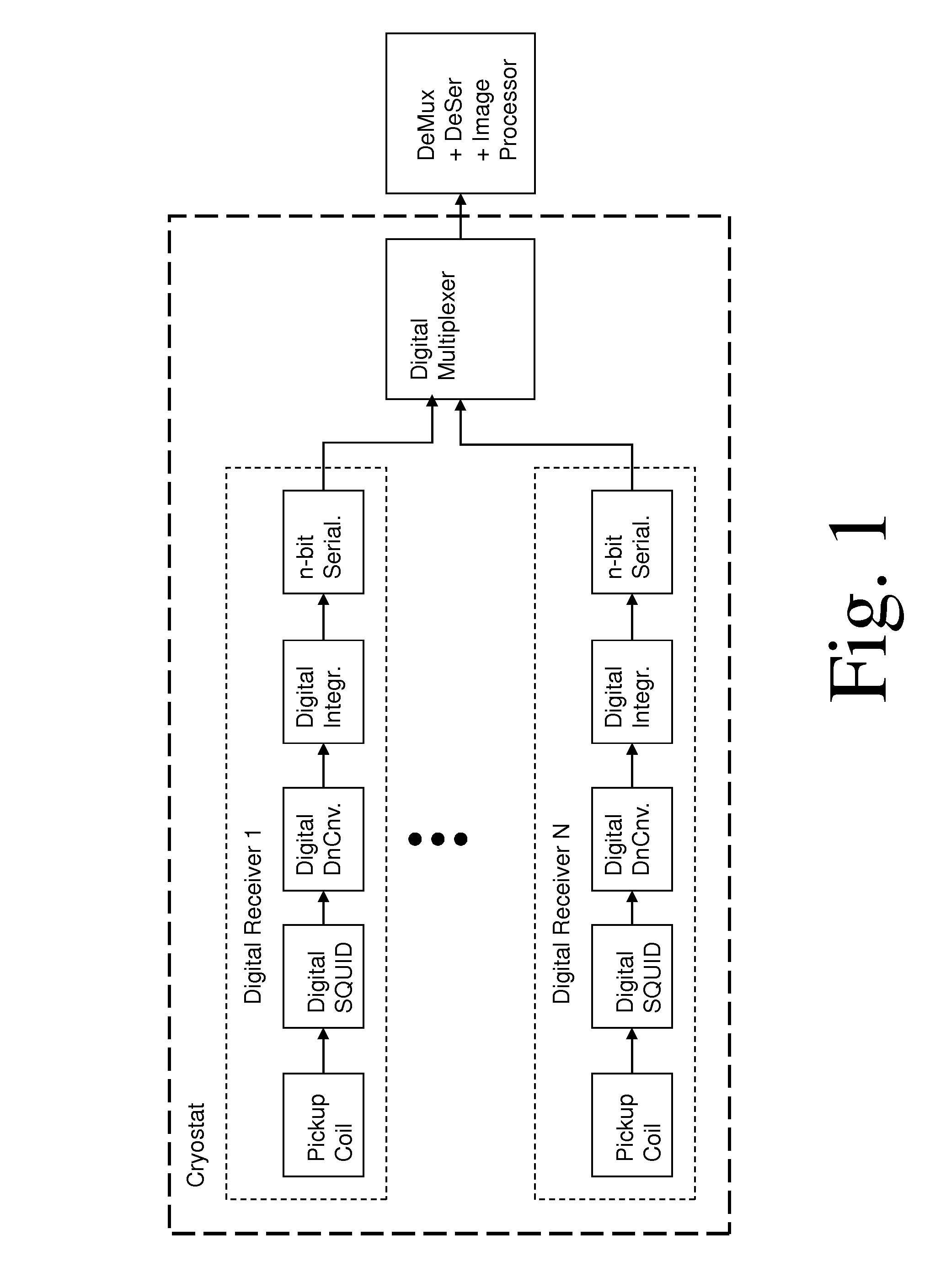

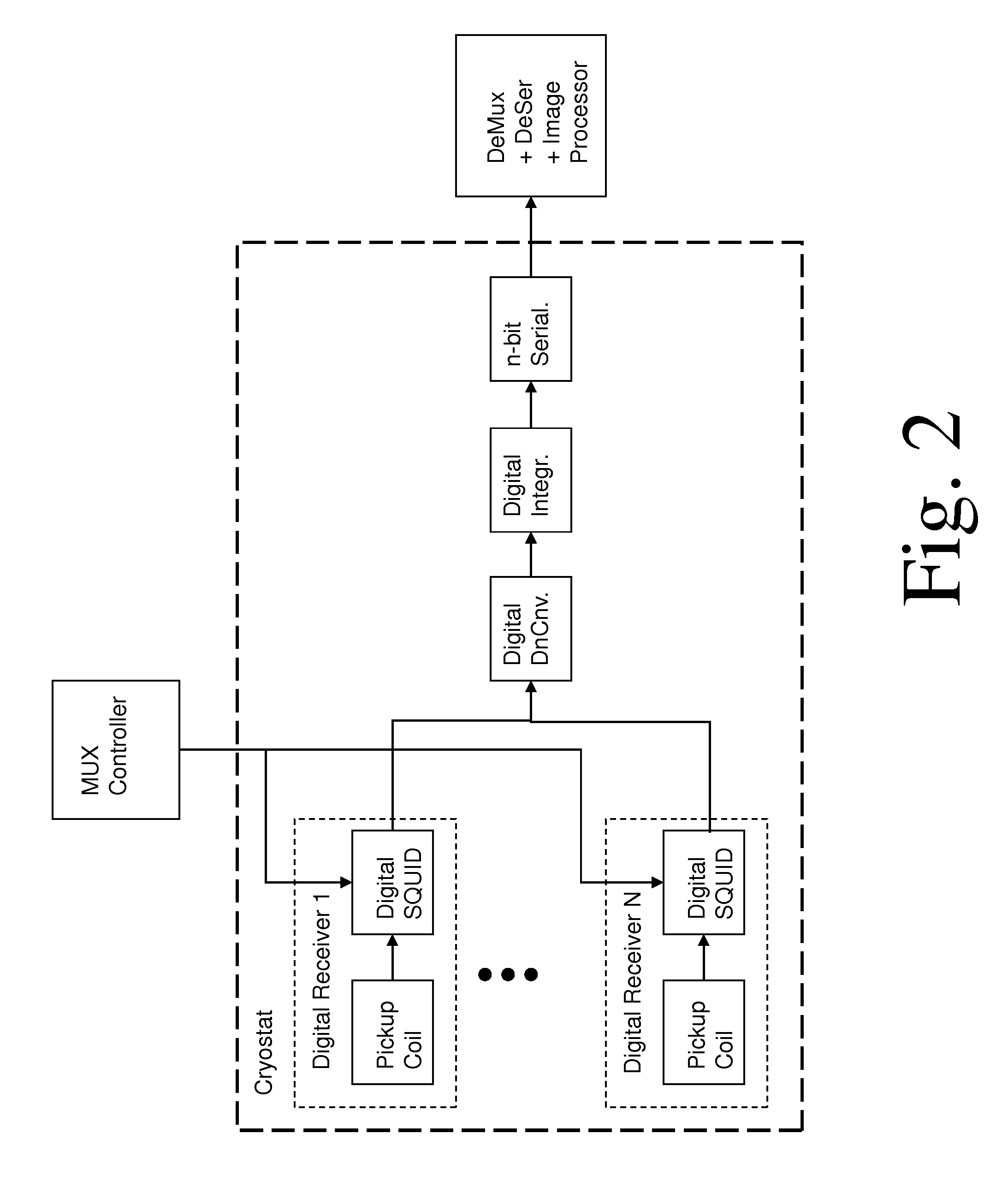

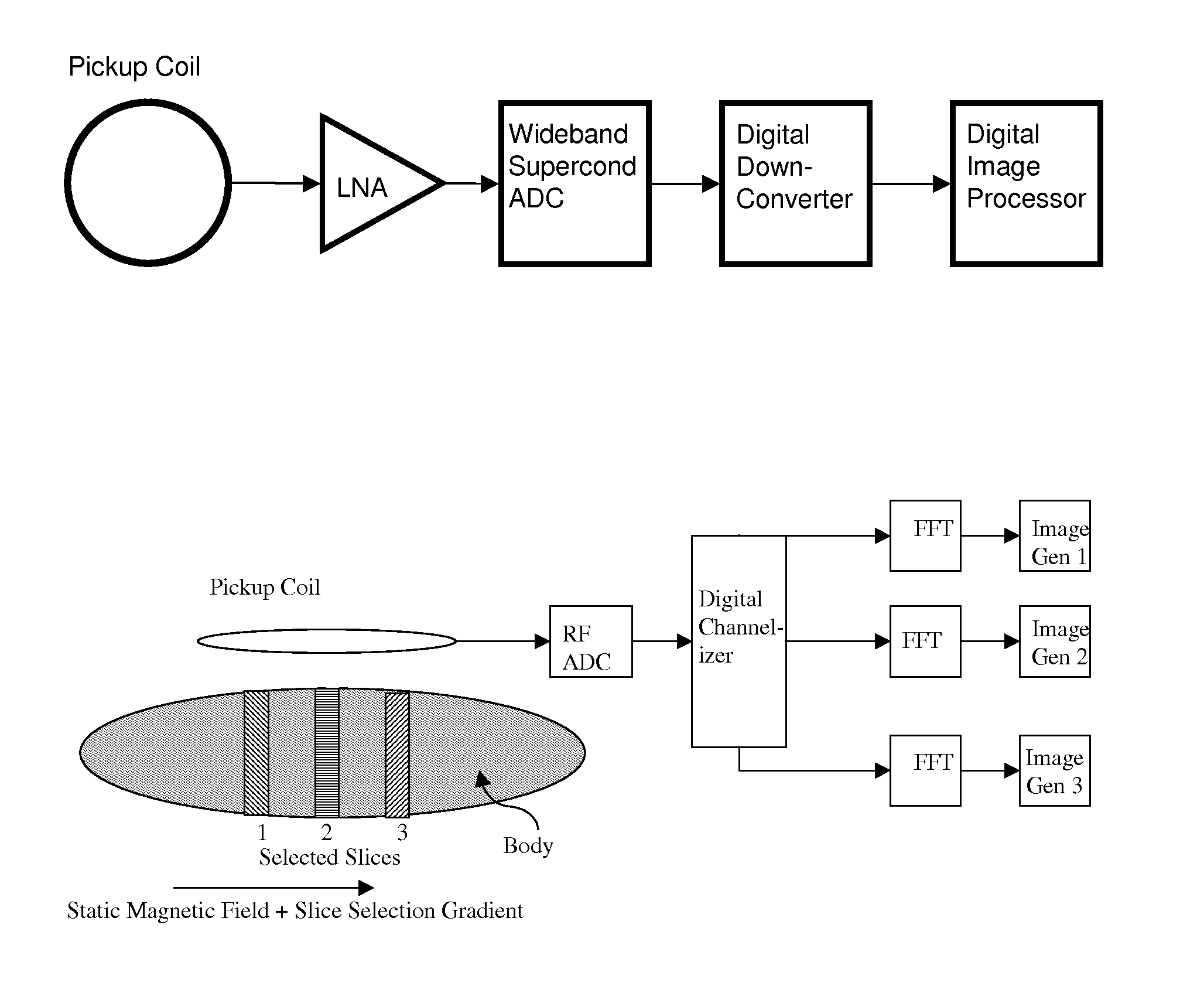

A magnetic resonance system, comprising at least one SQUID, configured to receive a radio frequency electromagnetic signal, in a circuit configured to produce a pulsatile output having a minimum pulse frequency of at least 1 GHz which is analyzed in a processor with respect to a timebase, to generate a digital signal representing magnetic resonance information. The processor may comprise at least one rapid single flux quantum circuit. The magnetic resonance information may be image information. A plurality of SQUIDs may be provided, fed by a plurality of antennas in a spatial array, to provide parallel data acquisition. A broadband excitation may be provided to address a range of voxels per excitation cycle. The processor may digitally compensate for magnetic field inhomogeneities.

Owner:THE JOHNSON REVOCABLE TRUST DATED 6 25 2003

Magnetic resonance system and method employing a digital SQUID

ActiveUS8618799B1Fast imagingImprove spatial resolutionMagnetic property measurementsMeasurements using NMR imaging systemsVoxelData acquisition

A magnetic resonance system, comprising at least one SQUID, configured to receive a radio frequency electromagnetic signal, in a circuit configured to produce a pulsatile output having a minimum pulse frequency of at least 1 GHz which is analyzed in a processor with respect to a timebase, to generate a digital signal representing magnetic resonance information. The processor may comprise at least one rapid single flux quantum circuit. The magnetic resonance information may be image information. A plurality of SQUIDs may be provided, fed by a plurality of antennas in a spatial array, to provide parallel data acquisition. A broadband excitation may be provided to address a range of voxels per excitation cycle. The processor may digitally compensate for magnetic field inhomogeneities.

Owner:THE JOHNSON REVOCABLE TRUST DATED 6 25 2003

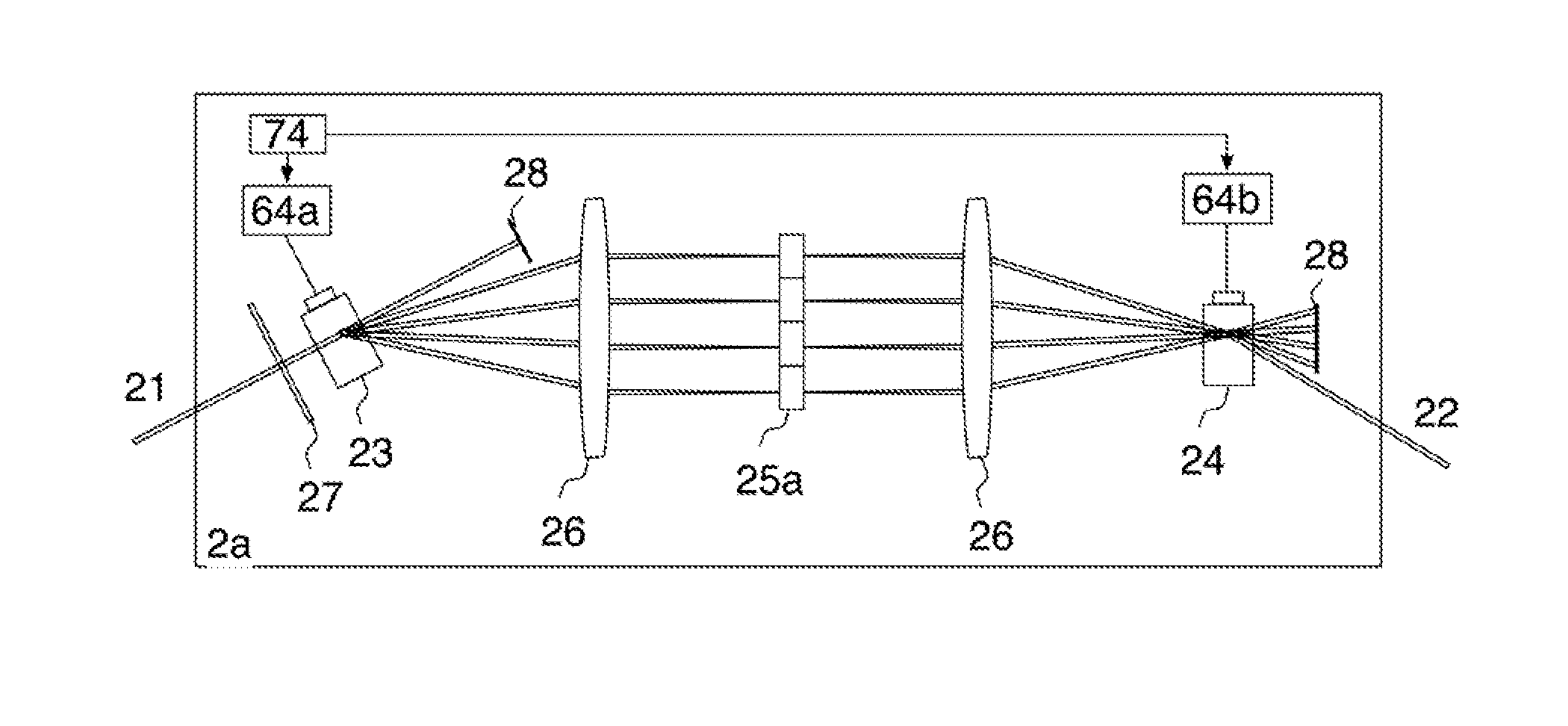

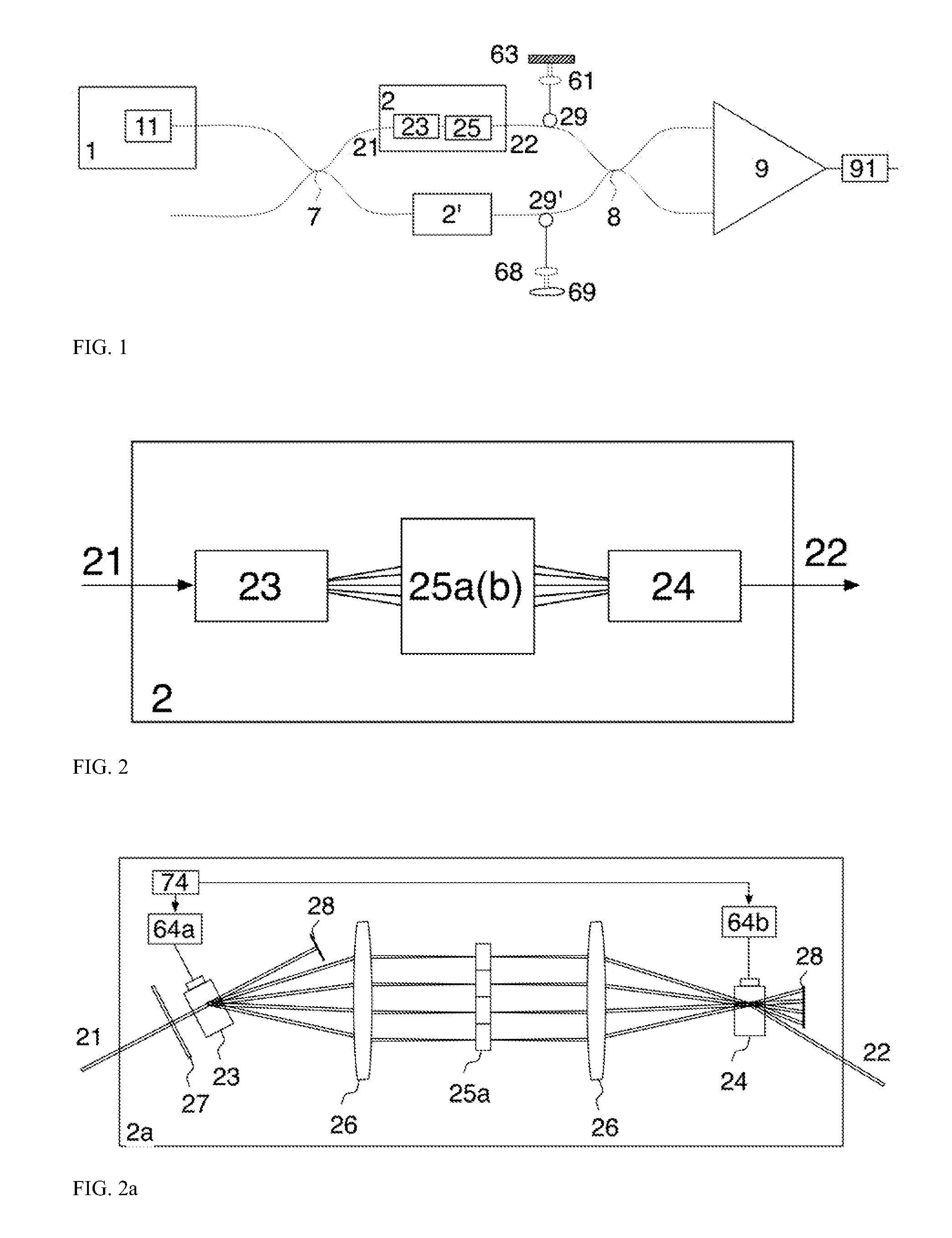

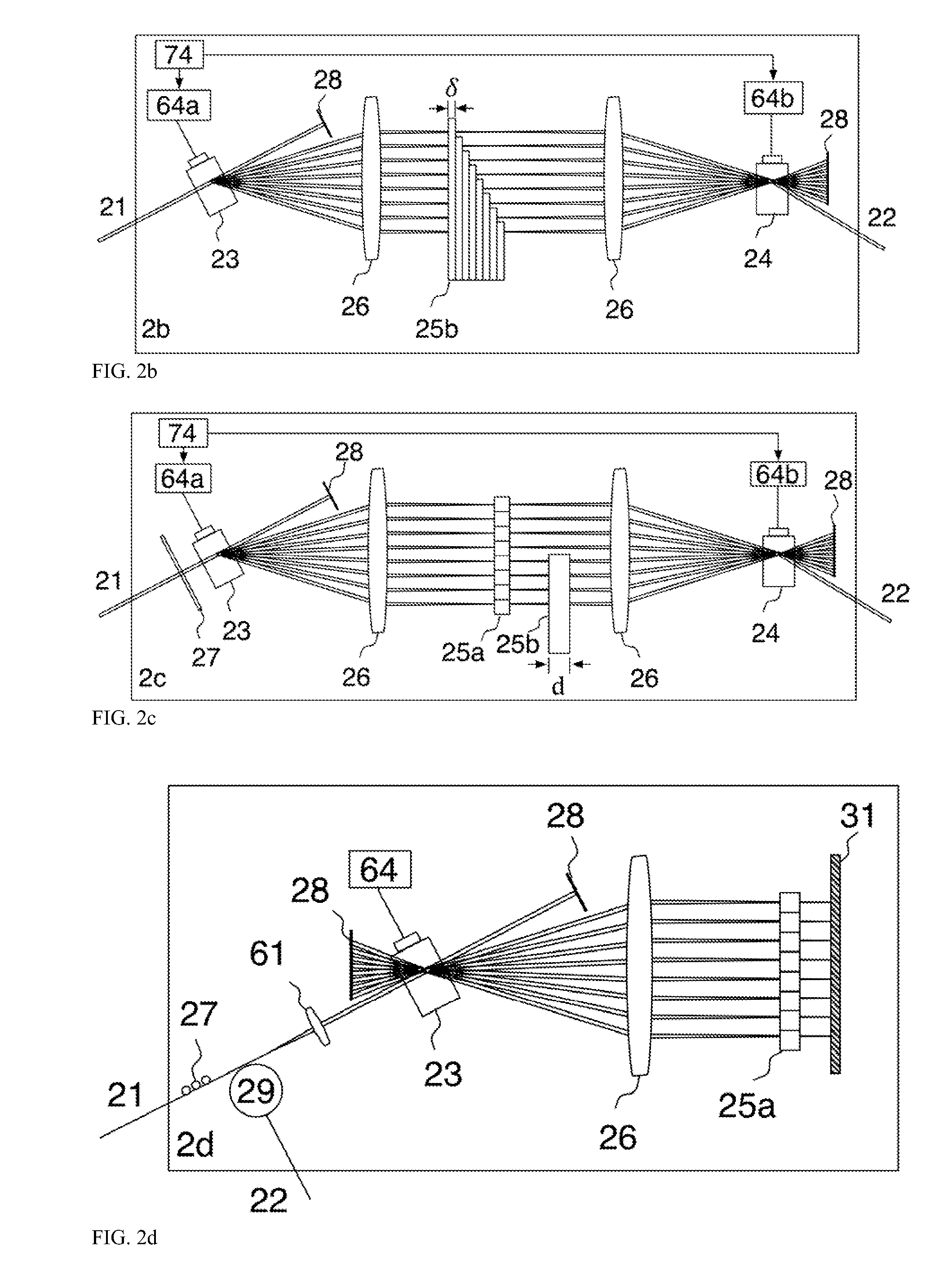

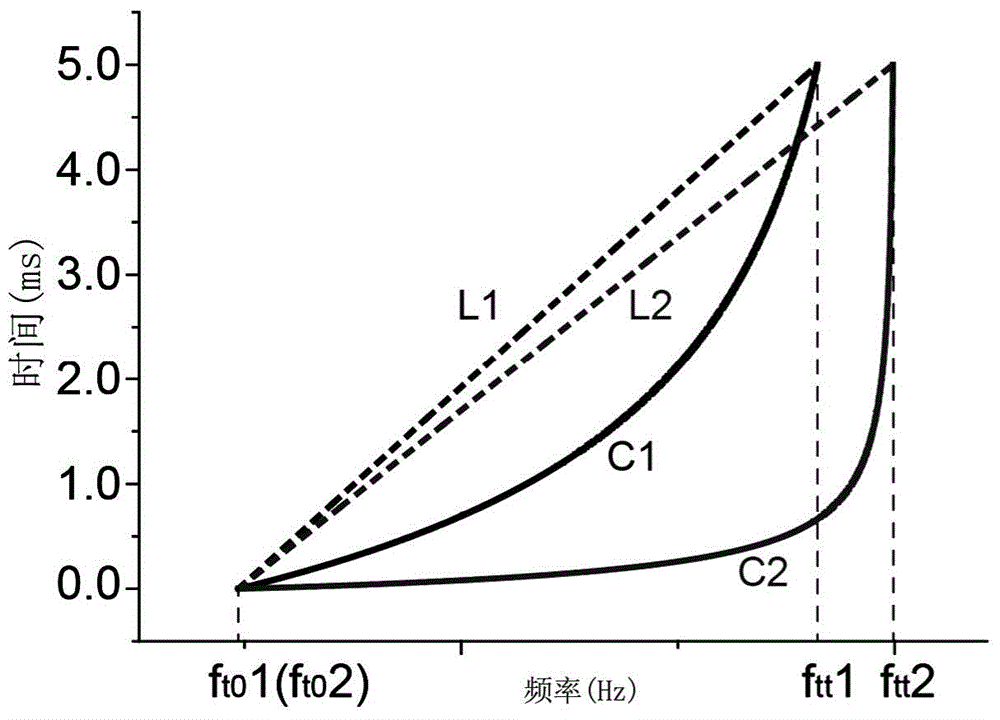

Multiple paths measuring and imaging apparatus and method

The invention discloses an optical interferometer which can be used to provide simultaneous measurements over multiple path lengths and methods to employ such an interferometer as to achieve a variety of functions covering simultaneous measurements at different depths separated by an increment of a multiple differential delay in the interferometer as well as simultaneous polarization measurements from a given depth and imaging. Configurations and methods are presented to encode the axial length in an object under investigation using frequency shifting as well as chirping the frequency of signals determining the frequency shifting. Methods are disclosed on the combination of multiple path configurations as to achieve versatile functionality in measurements, by using either broadband excitation or swept source excitation, combined with either discreet frequency shifting or chirped frequency shifting. Under swept source excitation, the invention discloses a long axial range apparatus, with constant sensitivity.

Owner:UNIVERSITY OF KENT

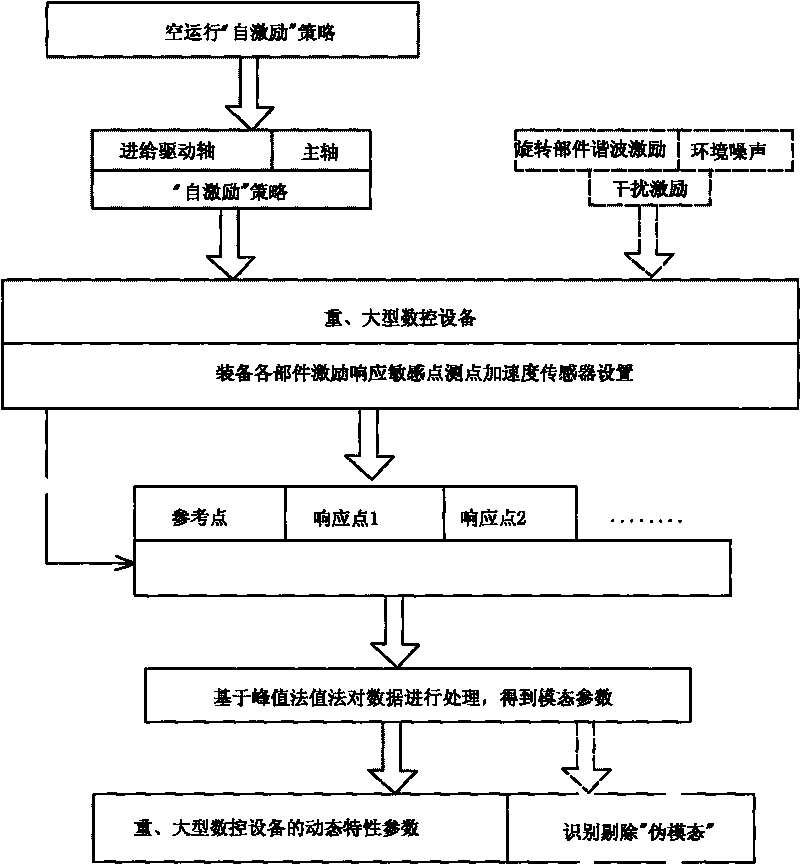

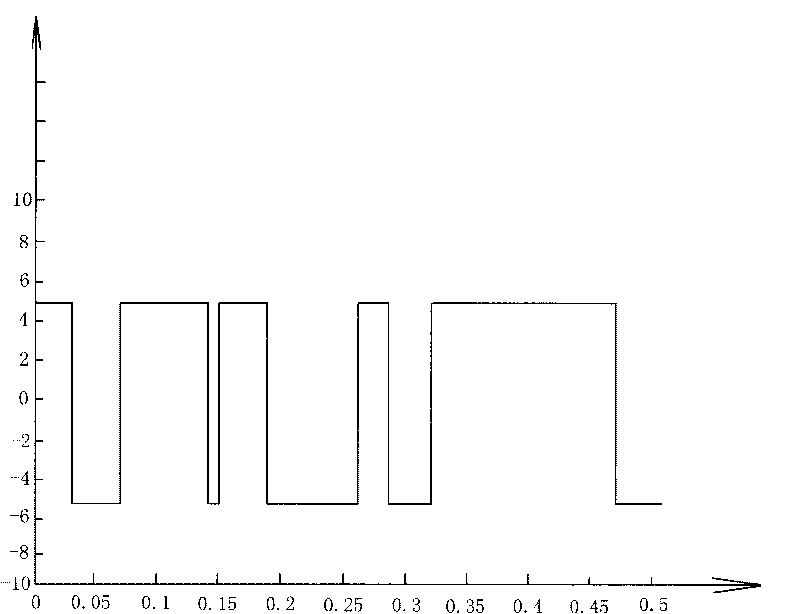

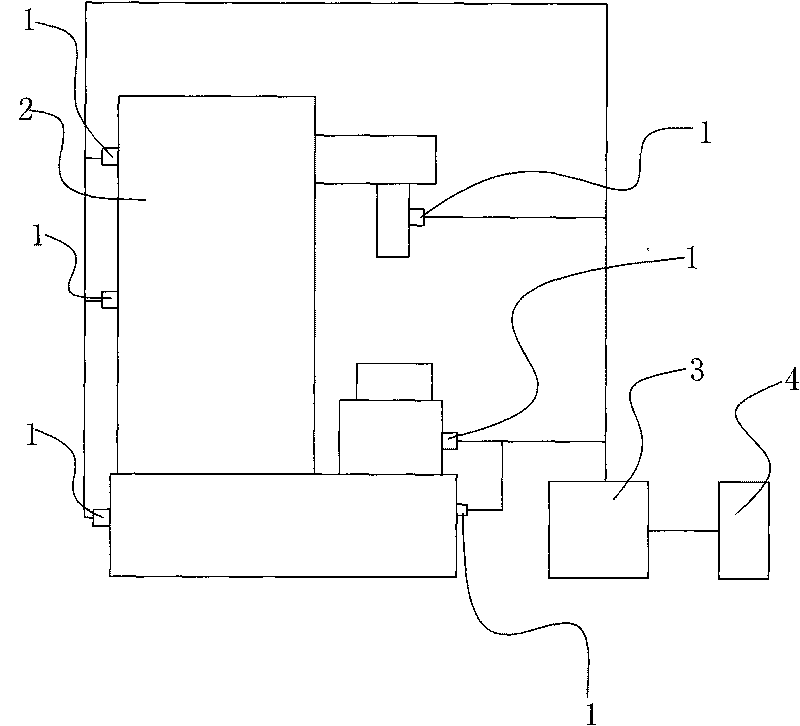

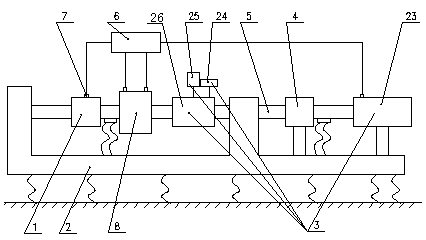

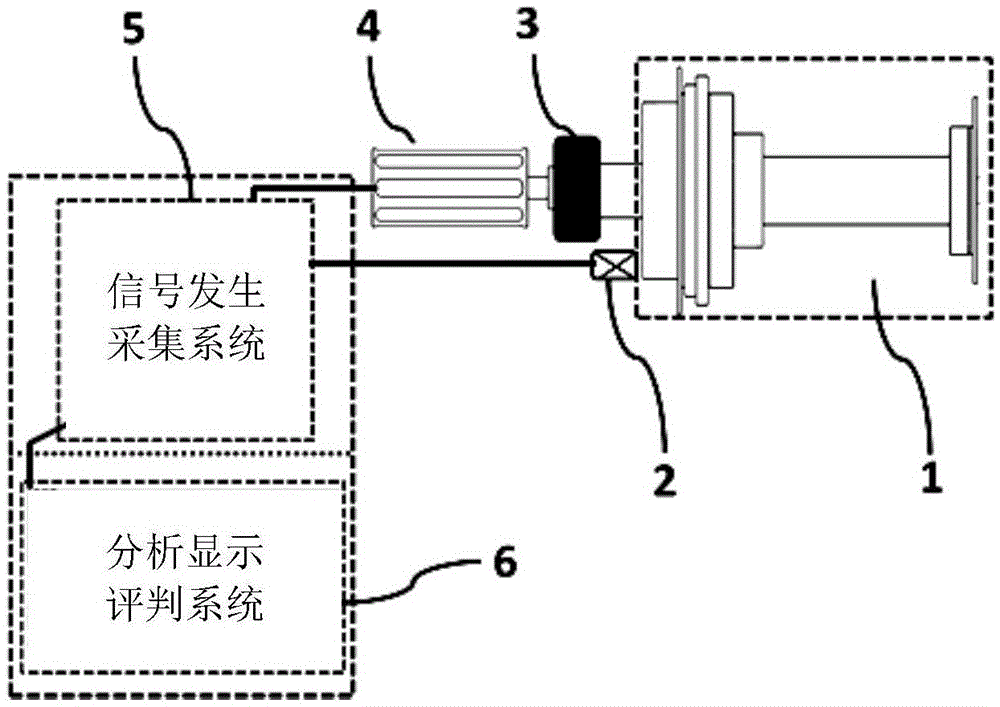

Experimental modal analysis method of numerical control equipment

ActiveCN101718613AConvenient and fast dynamic characteristic analysisReduce testing costsVibration measurement in solidsVibration testingNumerical controlPeak value

The invention discloses an experimental modal analysis method of numerical control equipment, which belongs to the technical field of the performance parameter analysis of the numerical control equipment; the method comprises the following steps of: carrying out self-excitation input and generating broadband excitation to the structure of the numerical control equipment by self excitation; based on the analysis of the sensitive point of the excitation response of each component of the numerical control equipment, optimizing the arrangement of test points; picking up the excitation response signal data of each arrangement test point; collecting the excitation response signal data; analyzing and reprocessing the collected data; and based on a peak value method, processing the excitation response signal data of a reference point and each response point to obtain the dynamic property parameters of the structure of the numerical control equipment. The invention breaks through the defect that the traditional experimental modal analysis technology needs to additionally add excitation input and carry out various forced assumptions on the excitation input, and the experimental cost can be greatly lowered because external excitation is not needed.

Owner:DG HUST MFG ENG RES INST +1

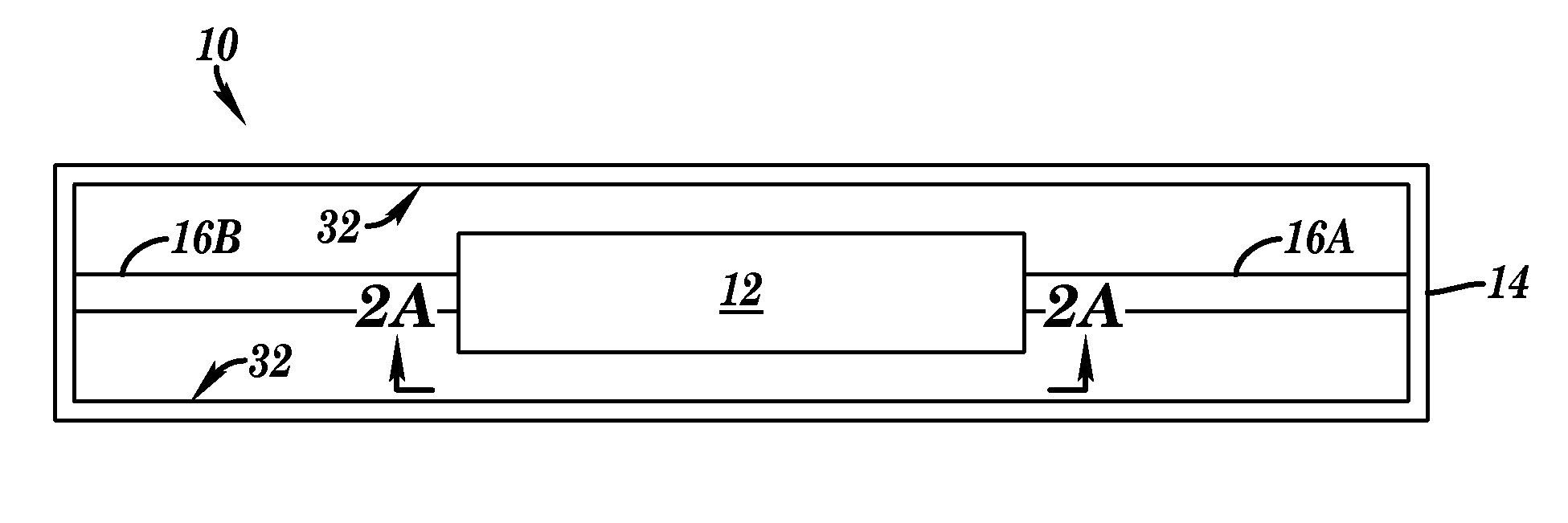

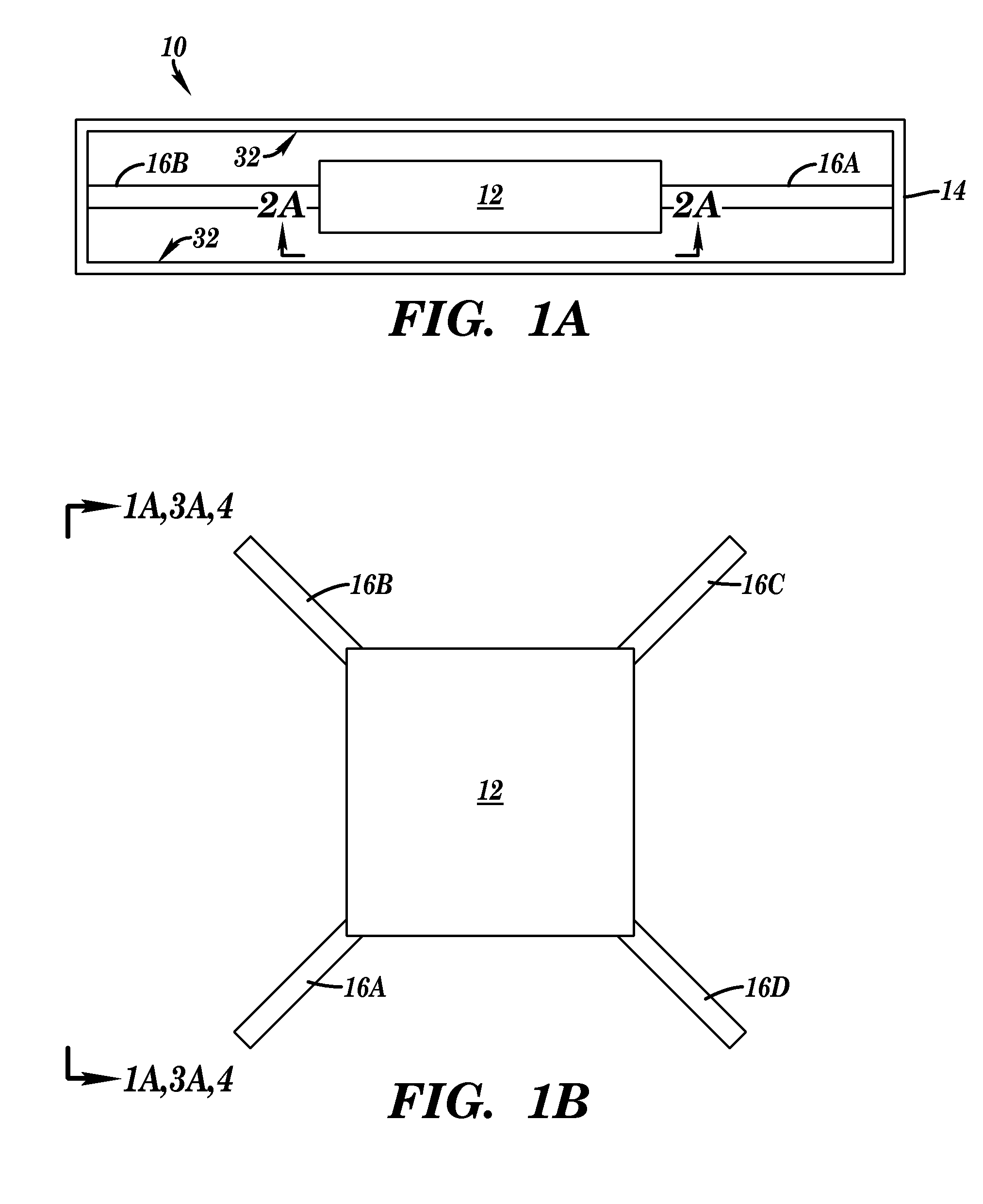

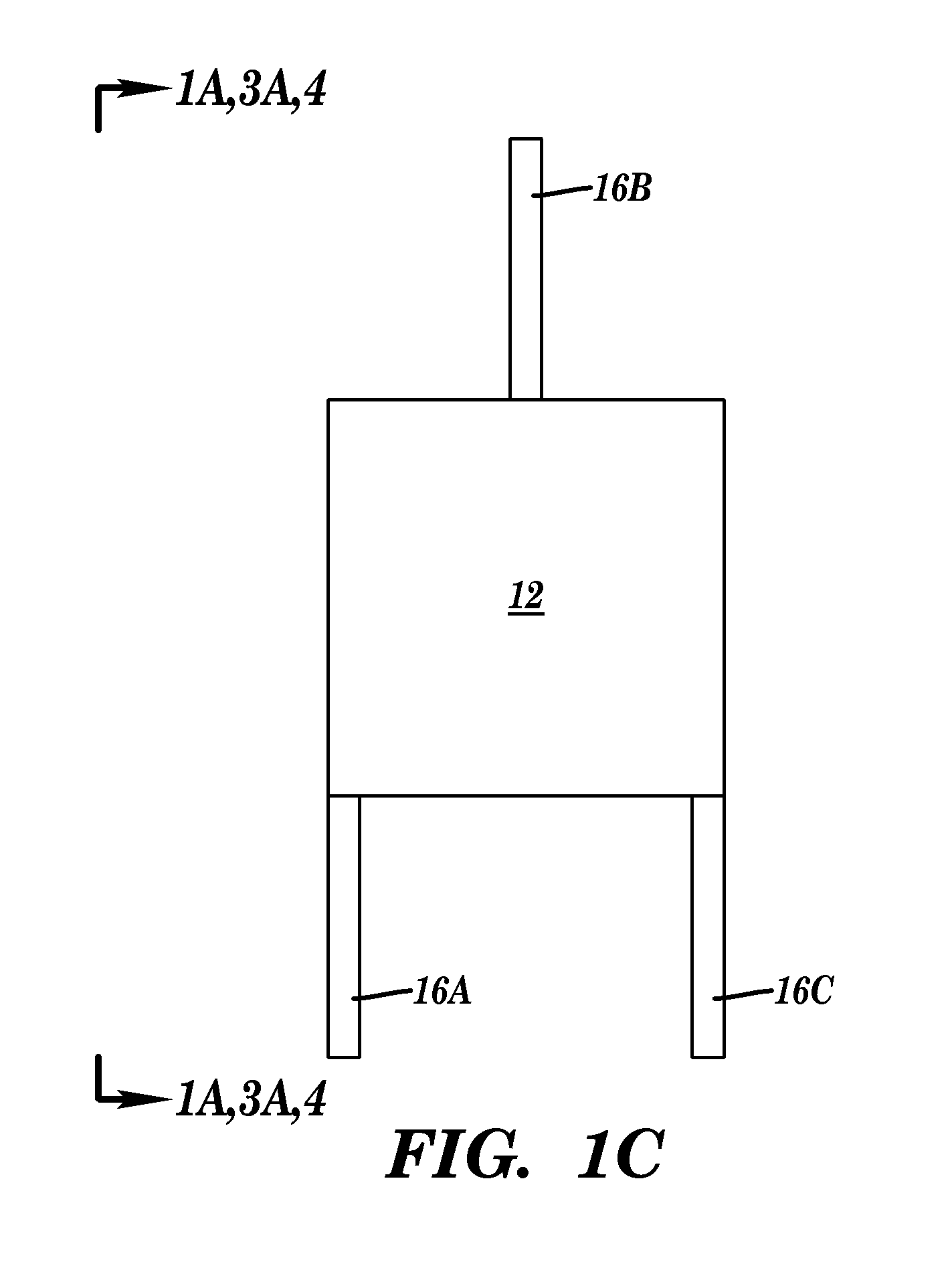

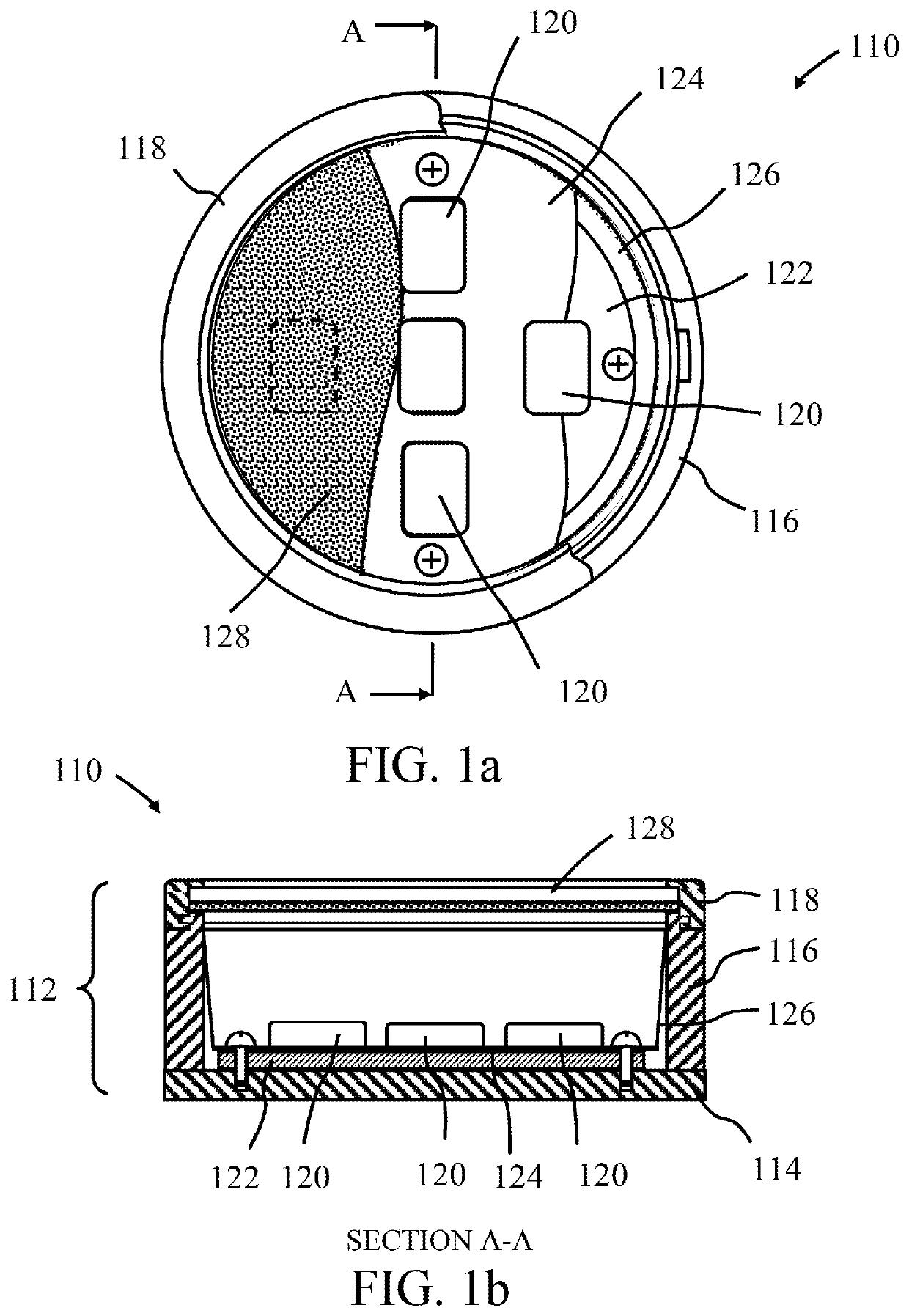

Internal vibration impulsed broadband excitation energy harvester systems and methods

InactiveUS20150349667A1Maximize power generationEasy to integratePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesElectricityEnergy harvester

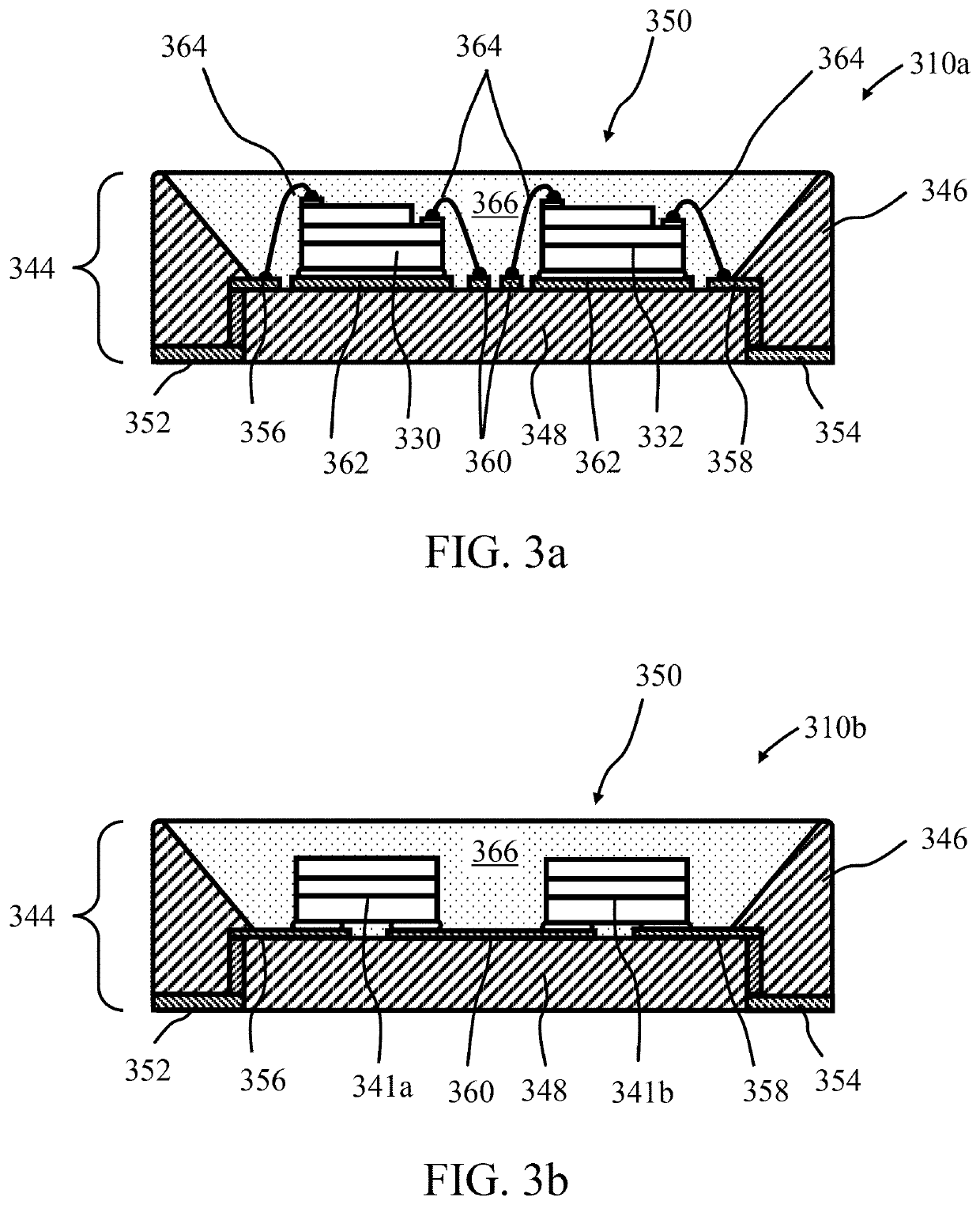

The present invention relates to an energy harvester system. The energy harvester system includes an energy harvester device, a housing comprising internal walls surrounding at least a portion of the energy harvester device, and a flexible supporting structure supporting the energy harvester device within the housing. Movement of the housing causes the internal walls of the housing, or structures connected to the internal walls, to contact the energy harvester device, whereby the flexible supporting structure and the energy harvester device move such that the energy harvester device contacts the internal walls or structures connected to the internal walls at least one additional time (or multiple times), thereby producing energy. Also disclosed is a system comprising an electrically powered apparatus and the energy harvester system of the present invention electrically coupled to the apparatus. The present invention further relates to a method of powering an electrically powered apparatus with the energy harvester system of the present invention.

Owner:WIRELESS SENSOR SOLUTIONS LLC

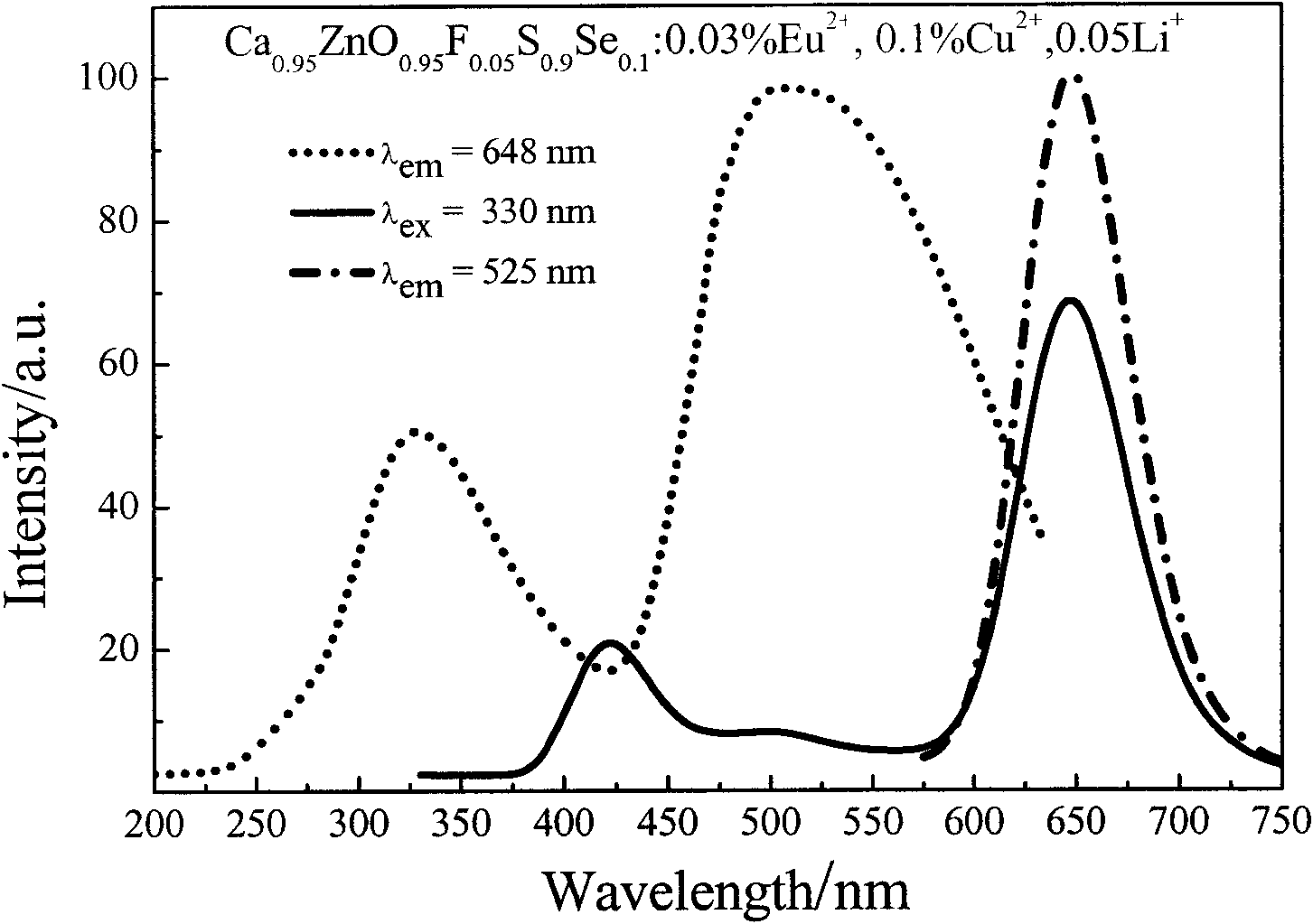

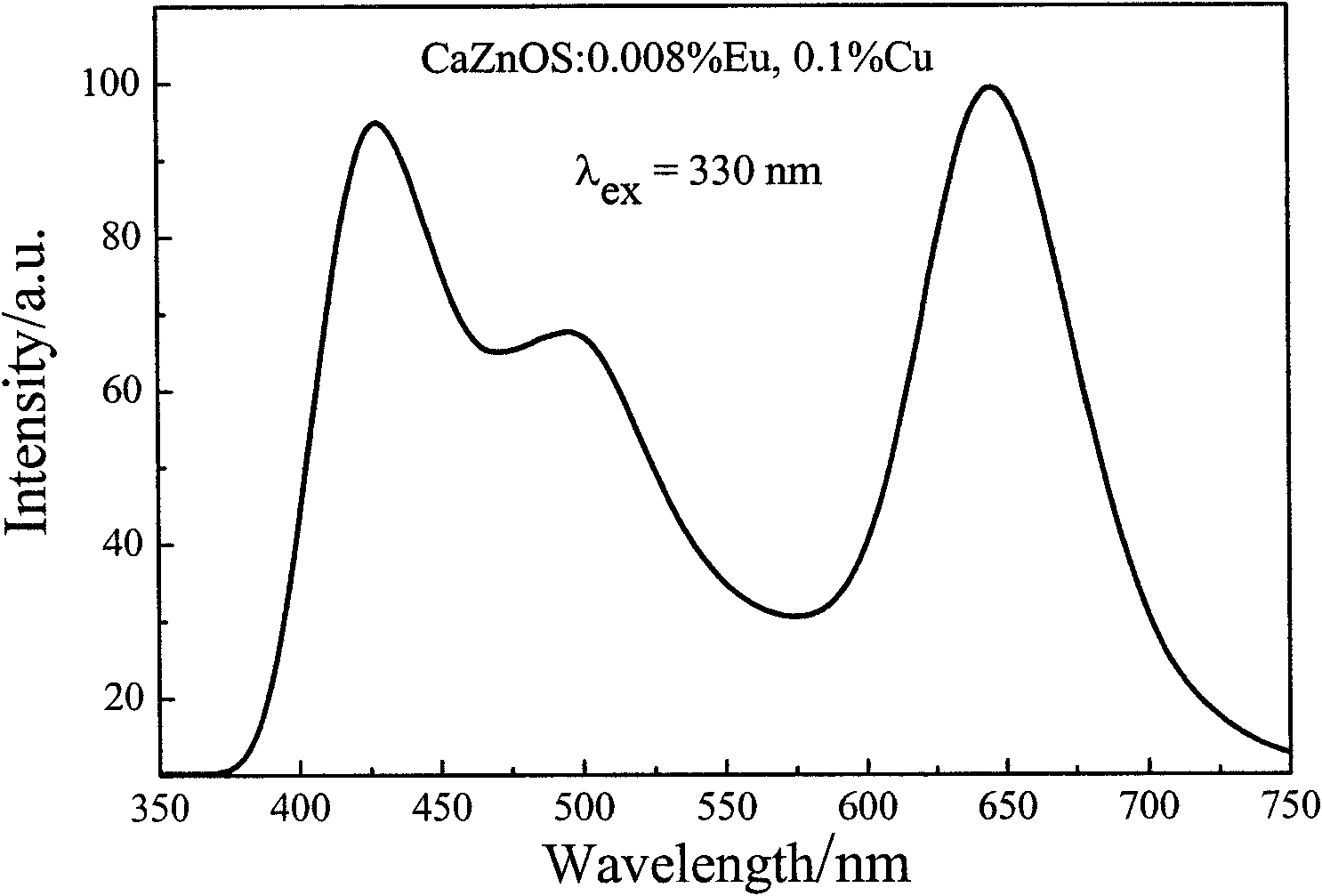

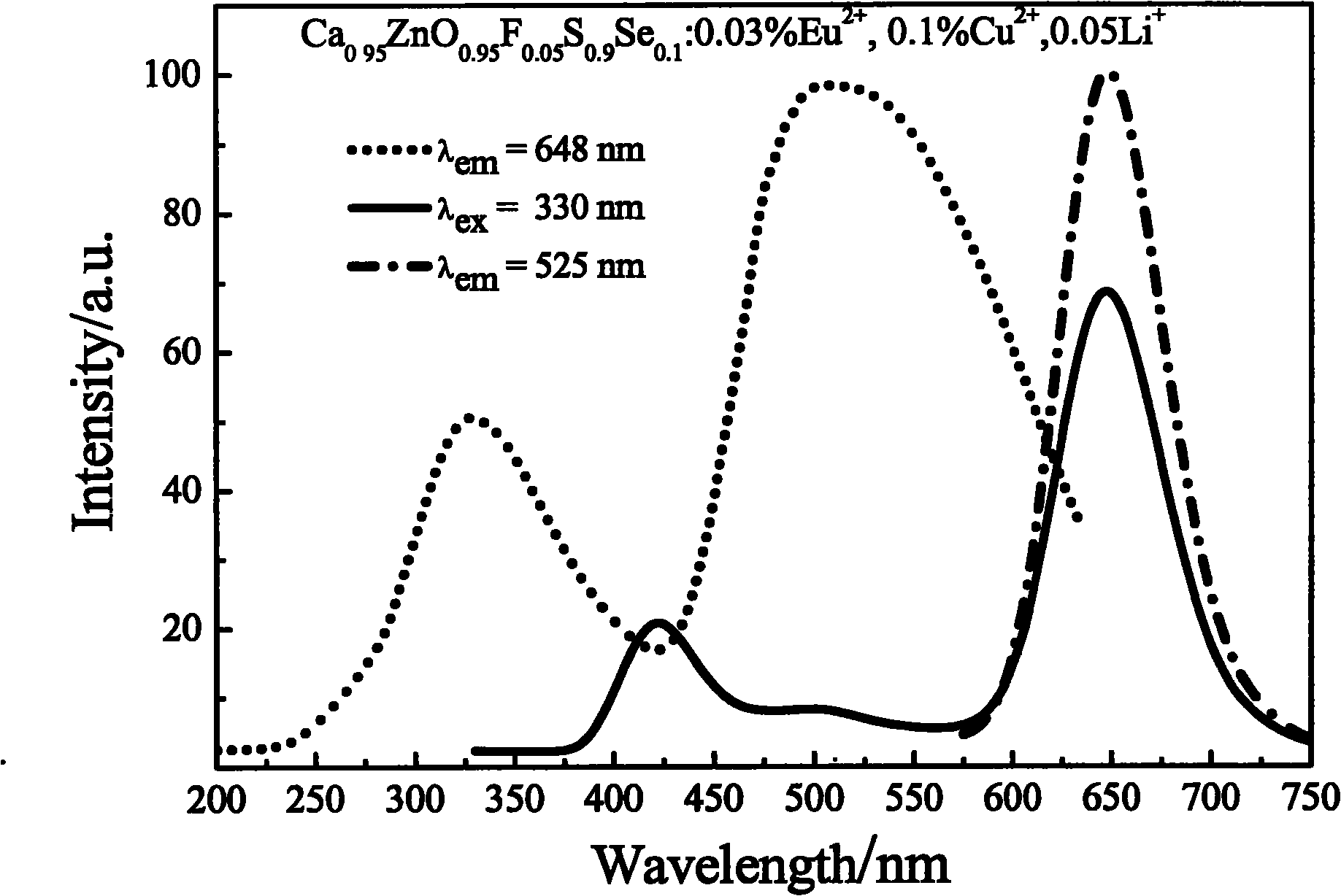

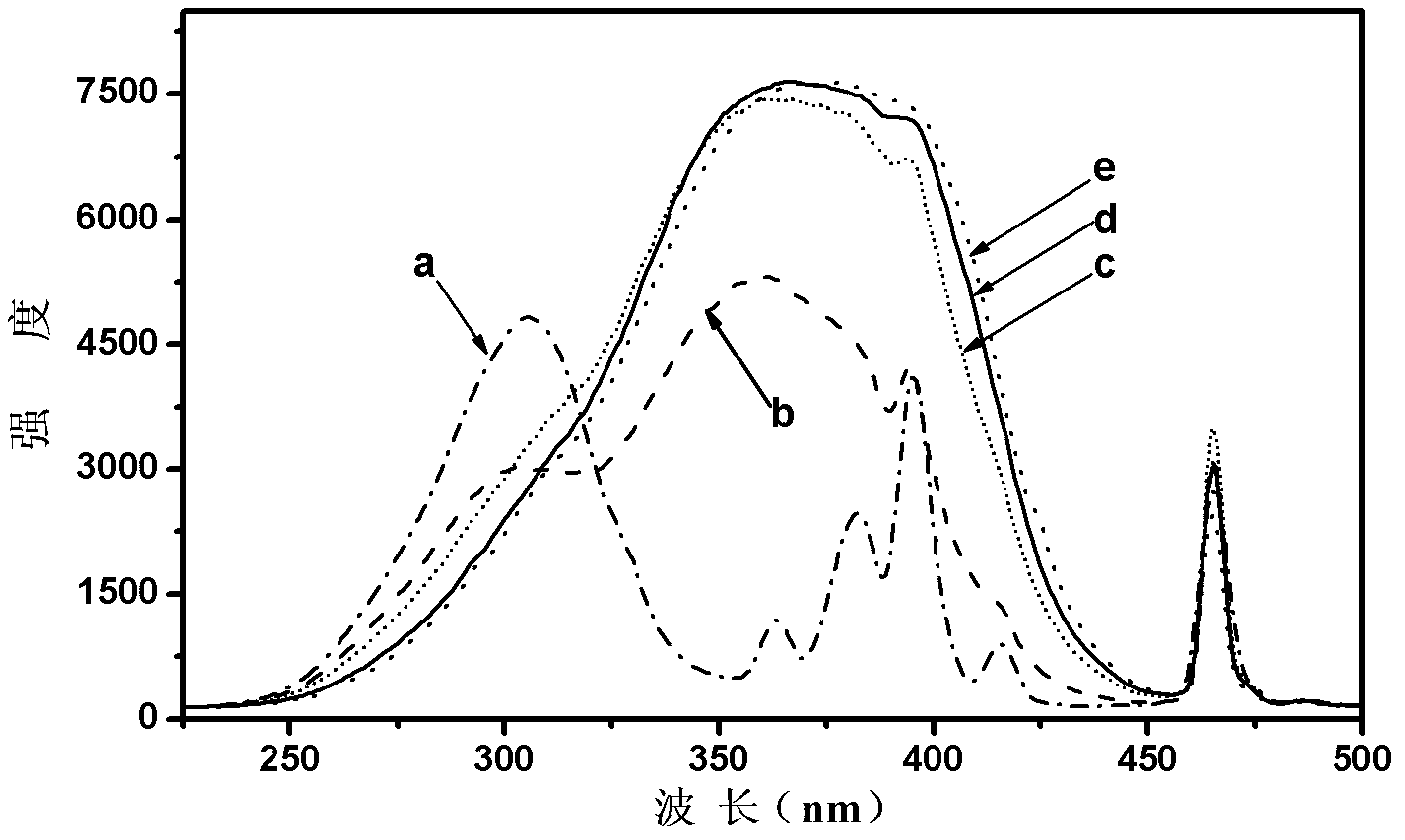

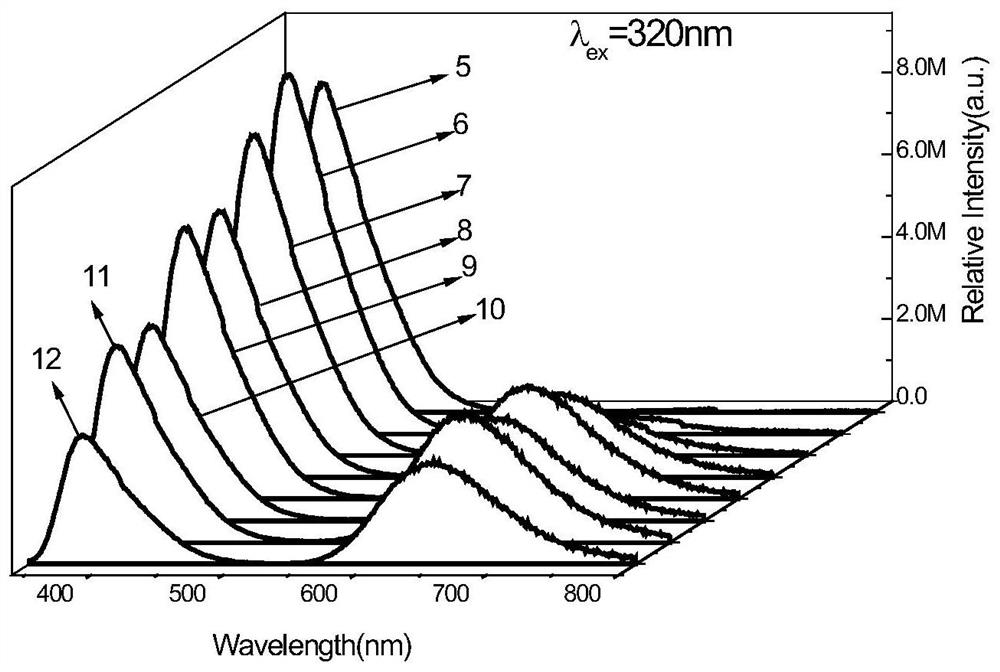

A kind of double excitation double emission phosphor and preparation method and application method thereof

A kind of fluorescent powder is based on metal sulfoxide, Eu2+ and Cu2+ are co-activators, and other ions are sensitizers. aA, bB, cC, dD, eE. Among them: A is one or two of Y3+, La3+, Ce3+, Pr3+, Nd3+, Sm3+, Gd3+, Tb3+, Dy3+, Ho3+, Er3+, Tm3+, Yb3+, Lu3+; B is Bi3+, Sb3+, Mn2+, Pb2+ One or two; C is one or two of F-, Cl-, Br-, I-; D is one or two of Se2-, Te2-. E is one or more of Li+, Na+, K+, Rb+, Cs+, Ag+ and H3BO3. The phosphor has a broadband dual excitation spectrum and a broadband dual emission spectrum, the dual excitation band spectrum is located in the 200-425nm and 425-610nm area, and the dual emission band spectrum is located in the 400-550nm and 600-750nm area. Phosphors can be used in agricultural films, solar photovoltaic cells and LED devices.

Owner:HUNAN NORMAL UNIVERSITY

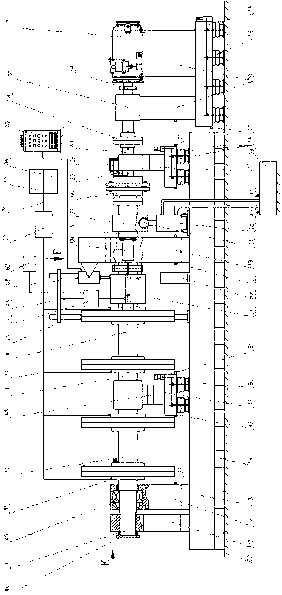

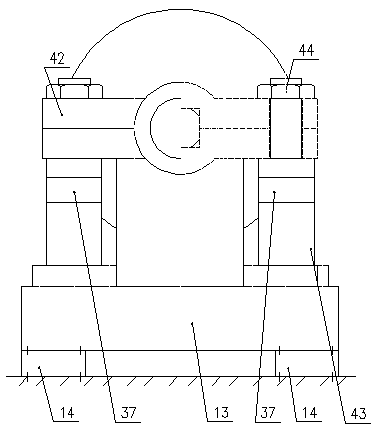

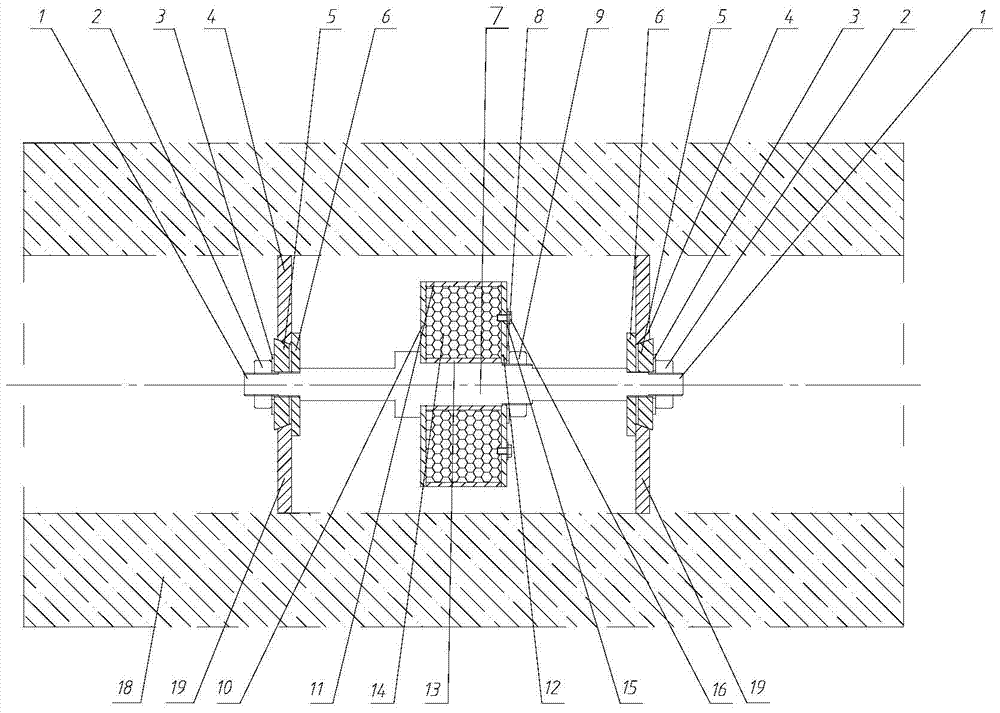

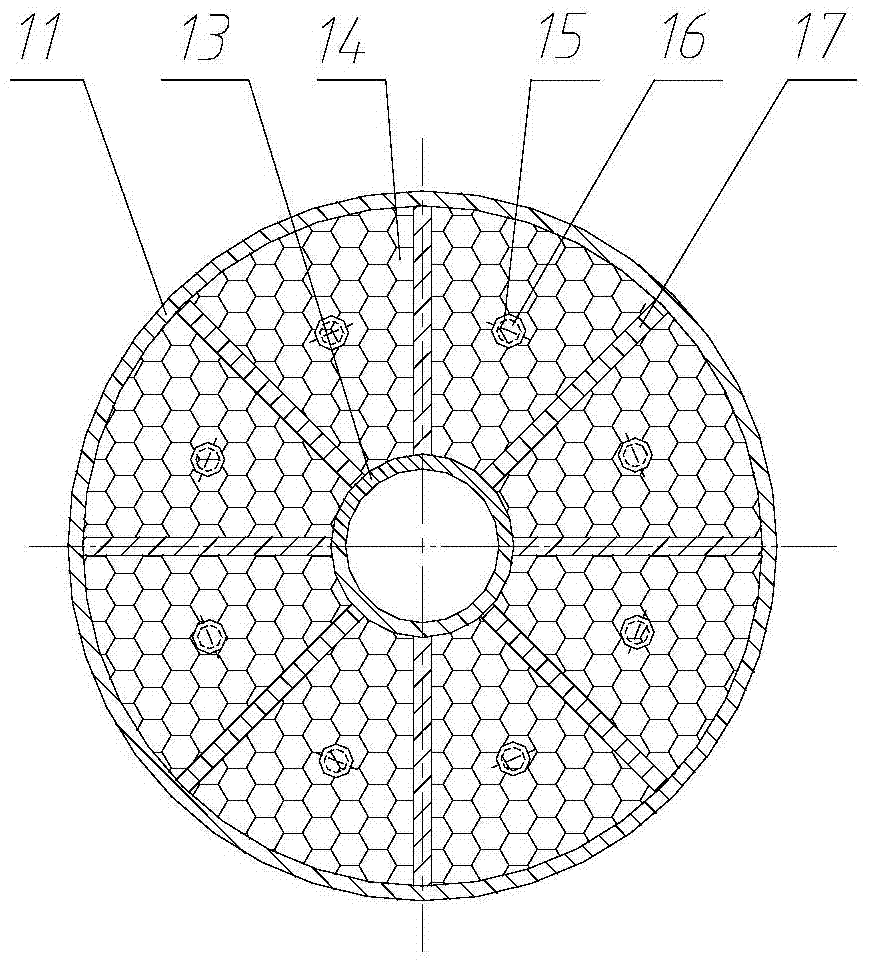

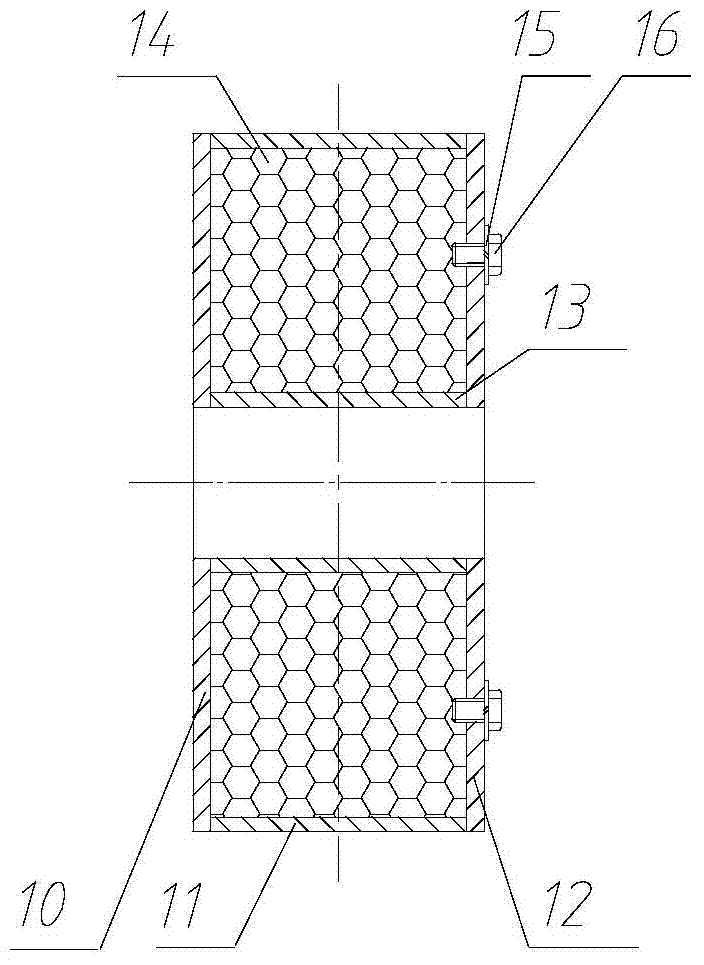

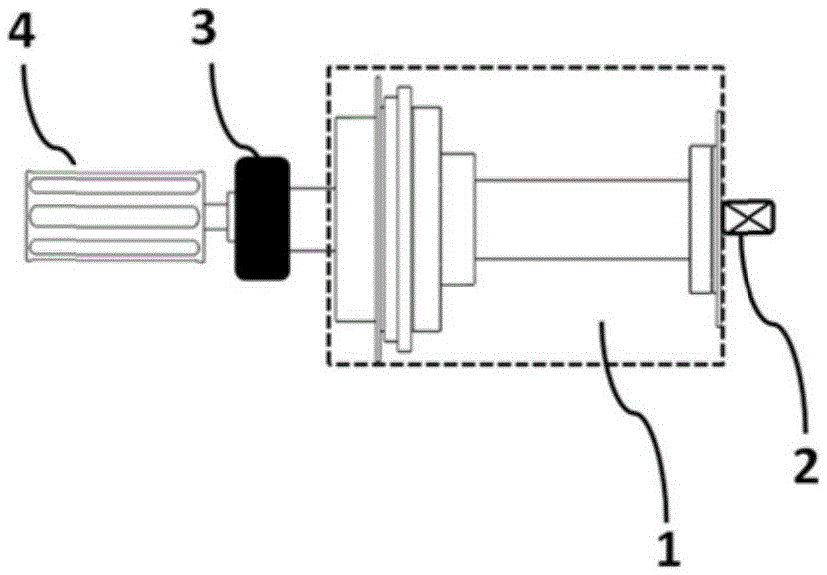

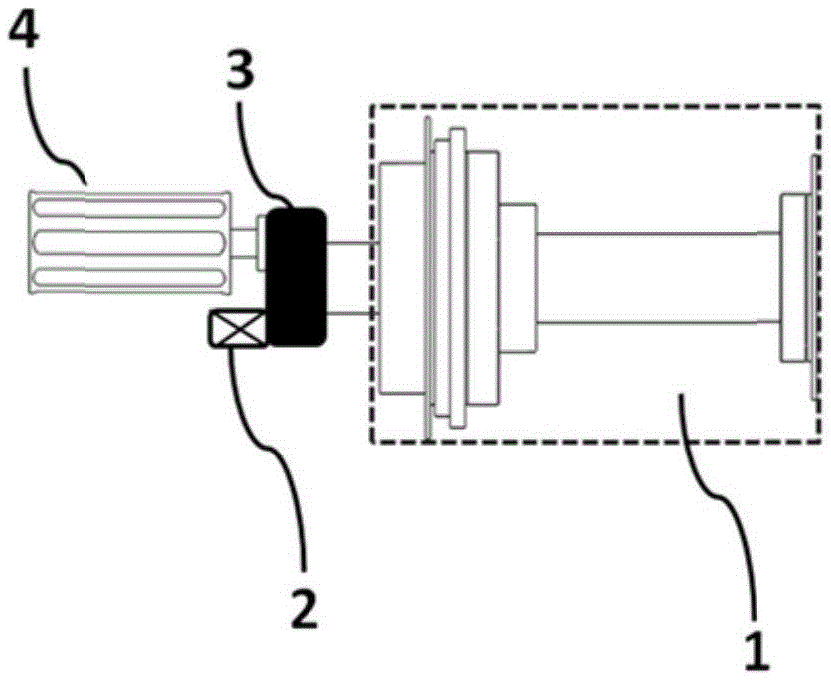

Testing apparatus for clutches or couplings

ActiveCN103308308AMeet testing needsRealize vibration level drop testMachine gearing/transmission testingCouplingEngineering

The invention relates to a testing apparatus for clutches or couplings. The testing apparatus comprises a rack system, a excitation system and a testing system, wherein the excitation system is composed of a vibrating excitation device, a torque loading and fatigue excitation device and an exciting force transmission shafting; an elastic shaft device, the vibrating excitation device and the torque loading and fatigue excitation device are installed on a mounting platform device; a device to be tested is connected between the elastic shaft device and the vibrating excitation device; the output end of a broadband excitation device of the vibrating excitation device is connected with the torque loading and fatigue excitation device and outputs broadband vibrating force to the device to be tested through an exciting force transmission device; the output end of a low-frequency excitation device is connected with the exciting force transmission device; a medium-high-frequency excitation device is installed on the exciting force transmission device; one end of the exciting force transmission device is connected with the device to be tested, the other end of the exciting force transmission device is connected with the exciting force transmission shafting; and sensors are installed at two ends of the device to be tested, the elastic shaft device and the vibrating excitation device respectively, and the sensors are connected with a signal acquisition and data analysis device.

Owner:上海中船重工船舶推进设备有限公司

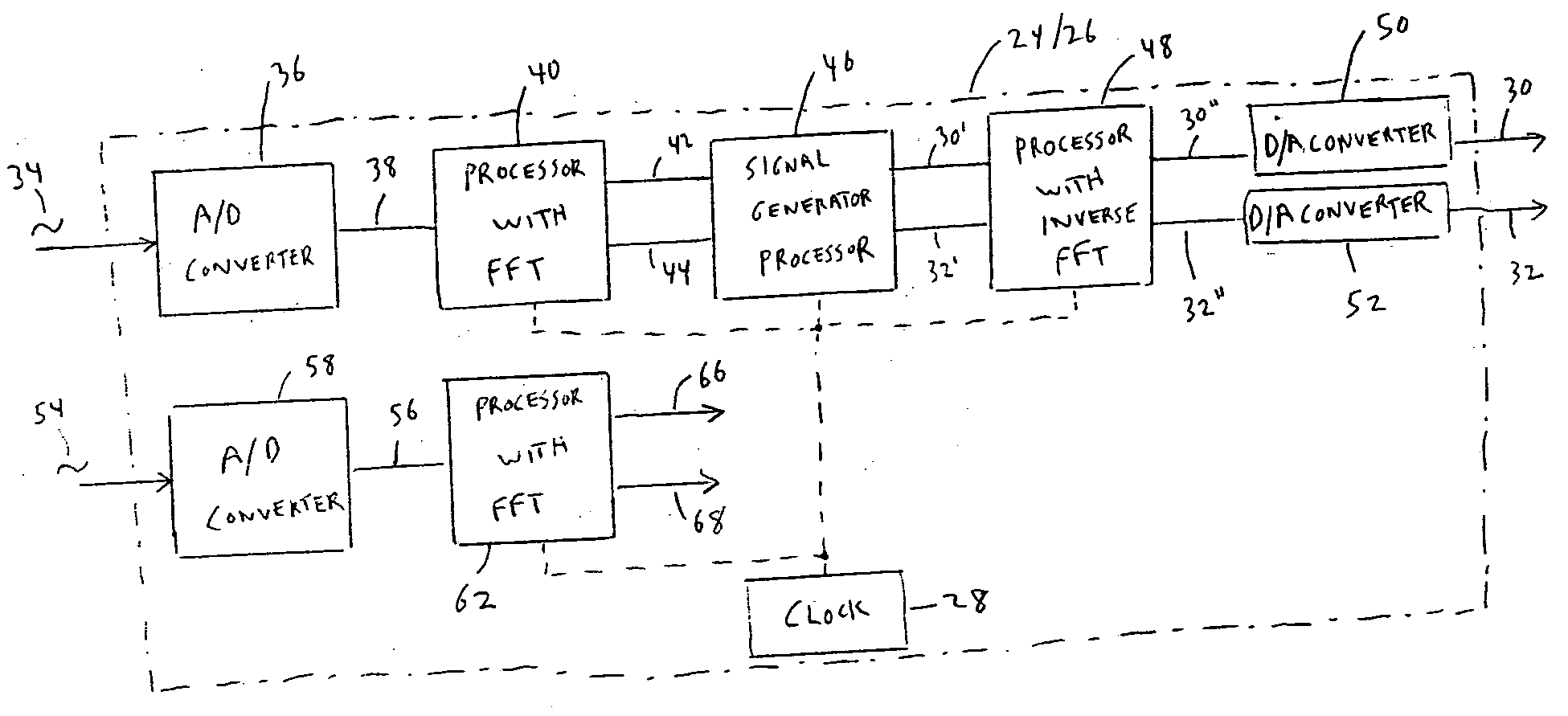

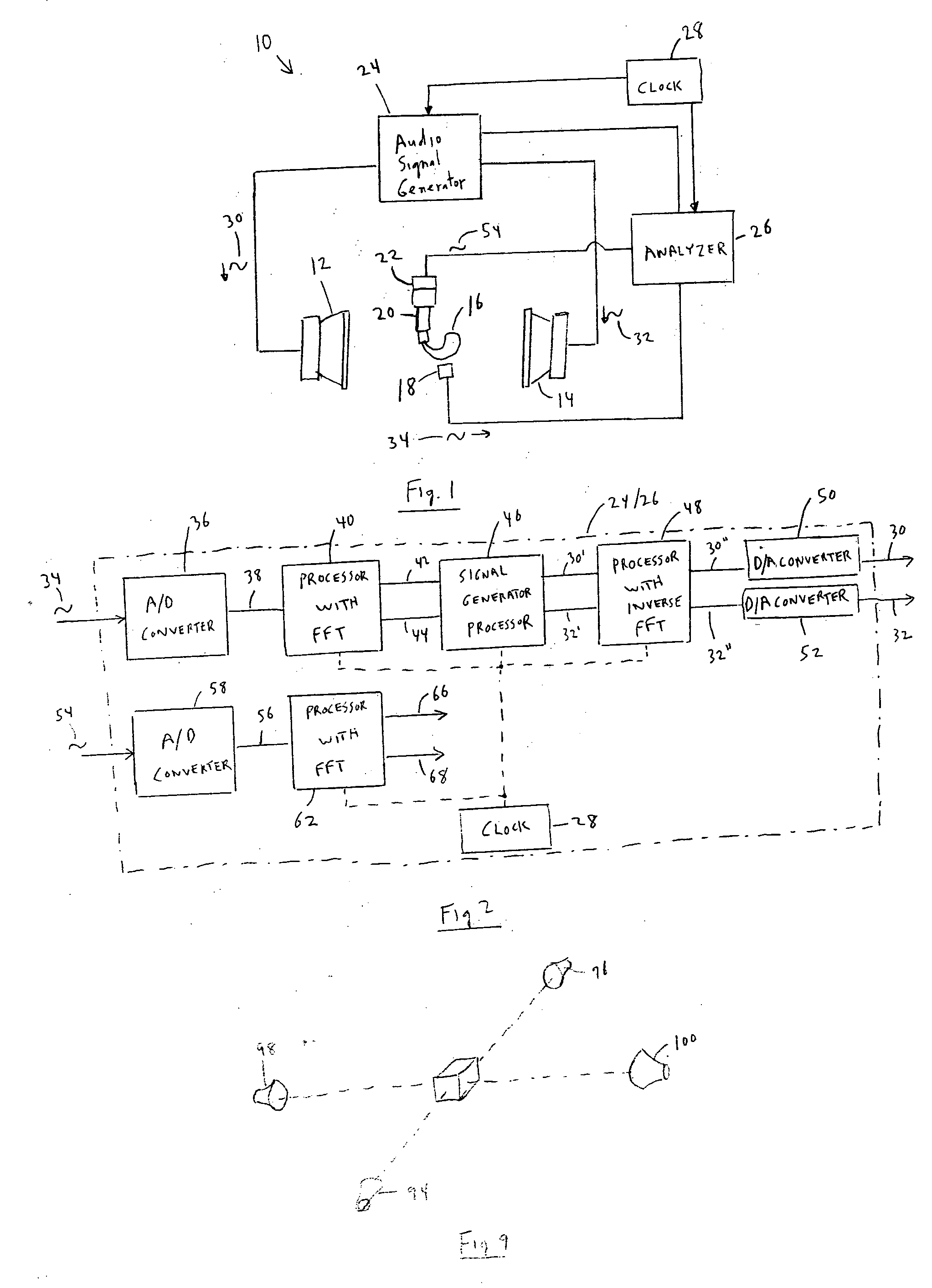

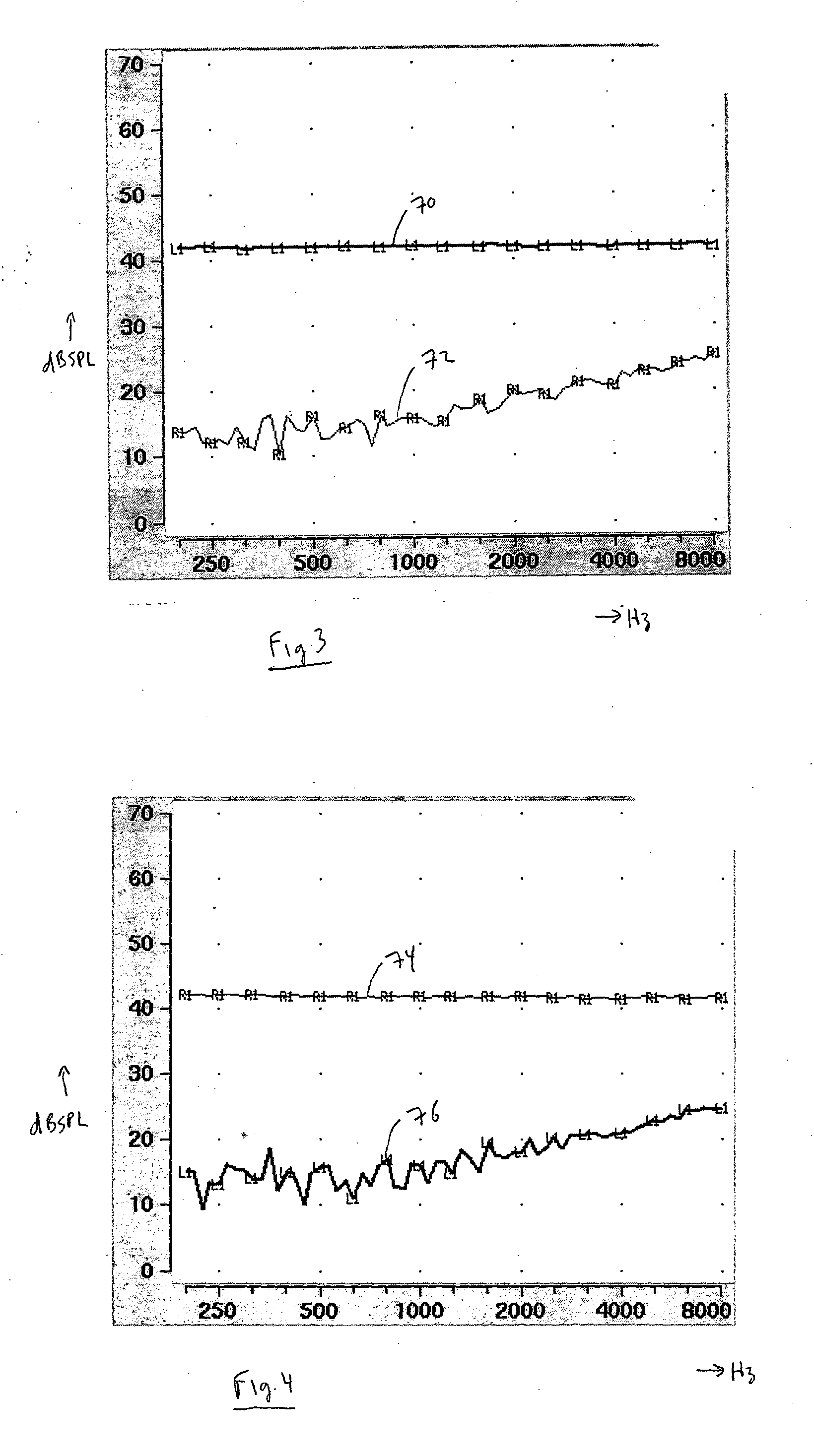

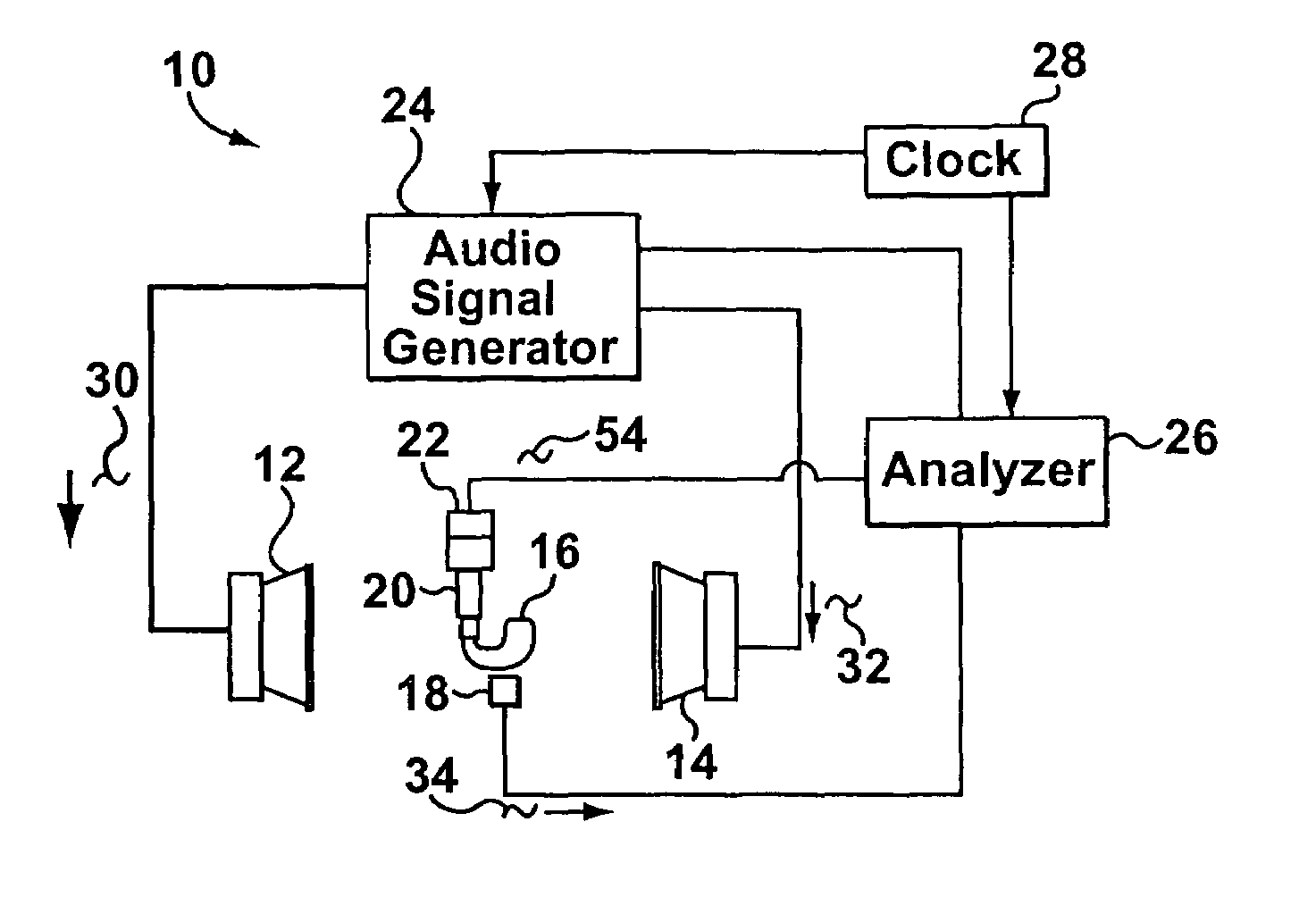

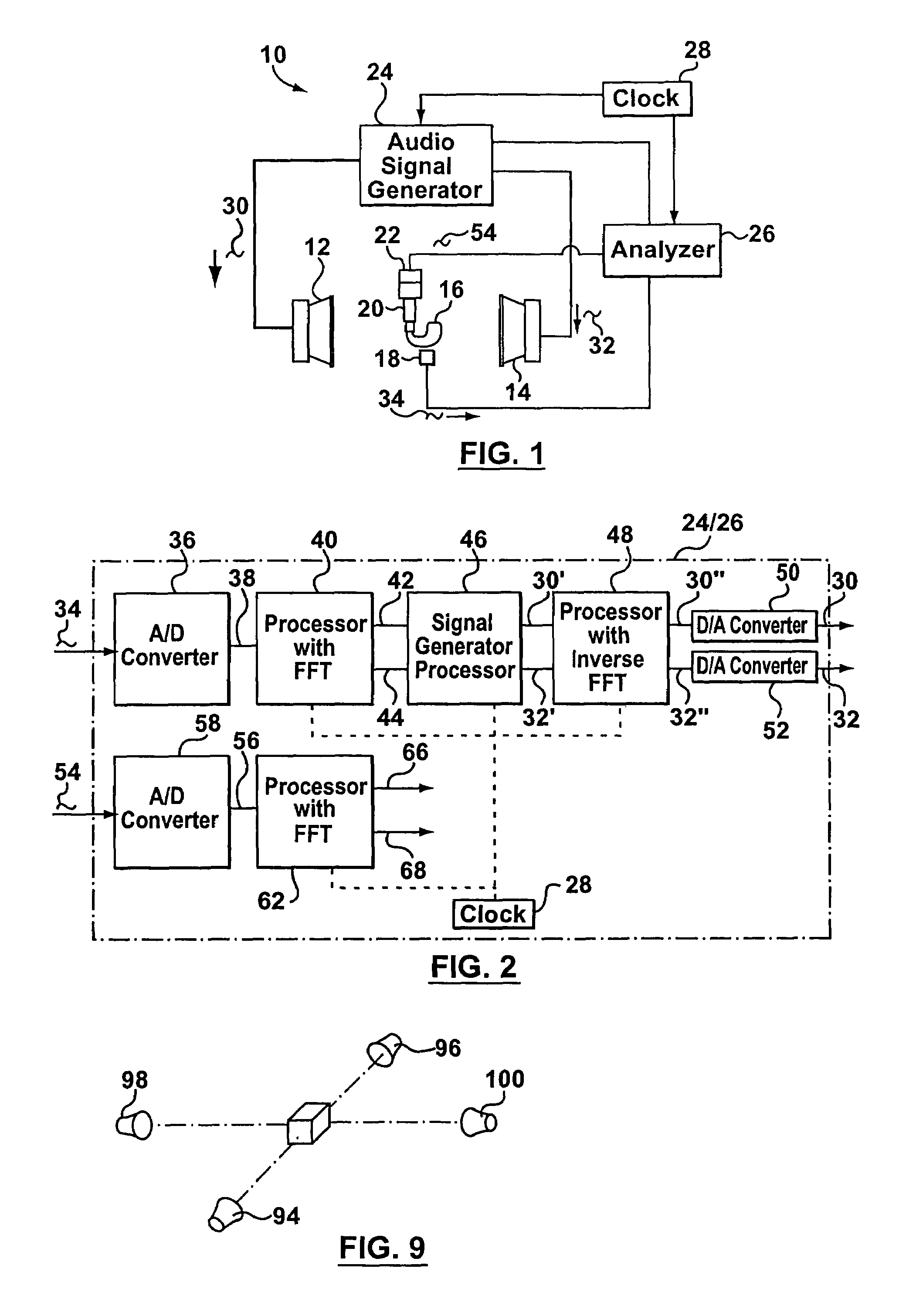

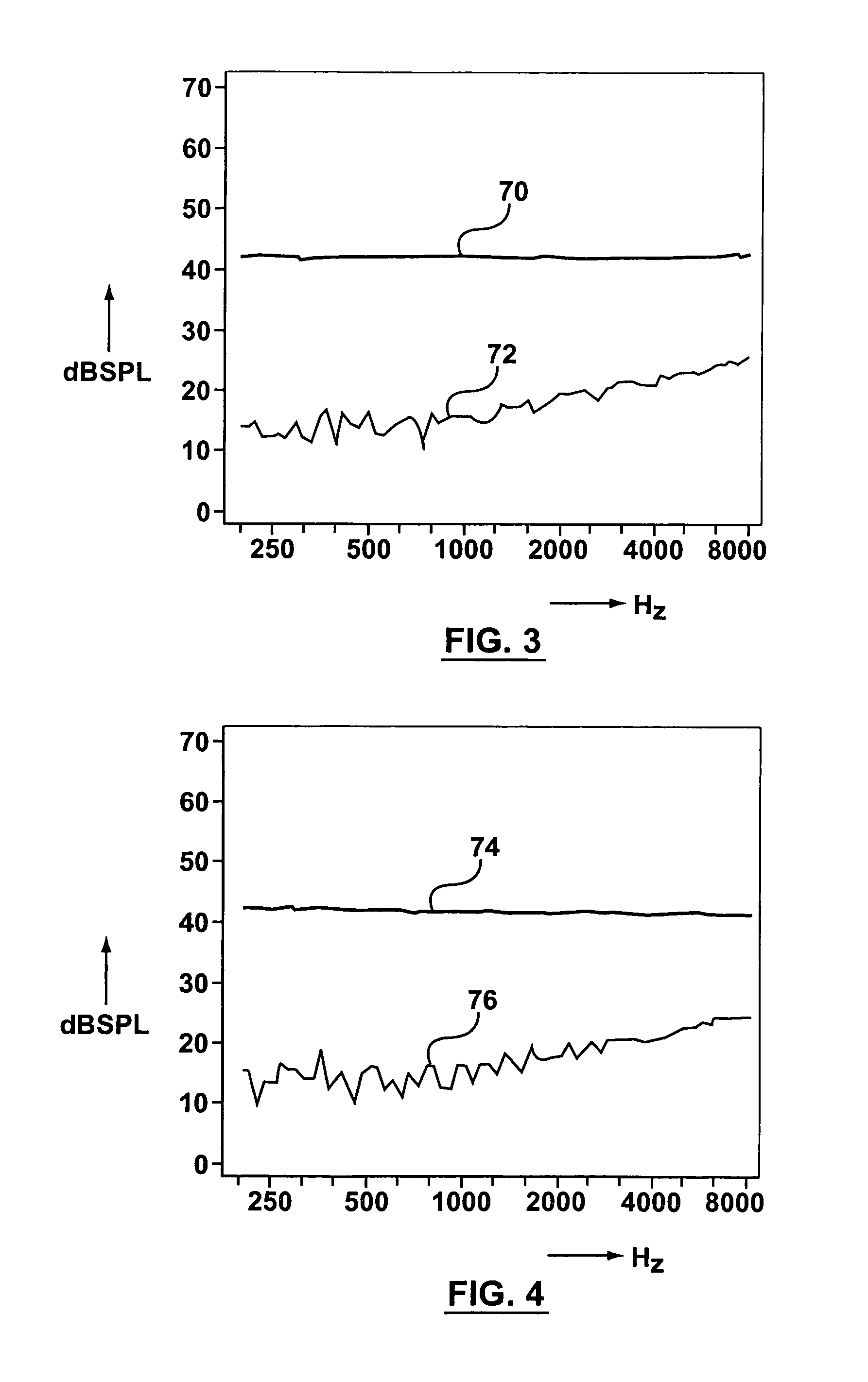

Directional hearing aid tester

ActiveUS20050053250A1Test accurateAnalysing solids using sonic/ultrasonic/infrasonic wavesSets with desired directivityHearing aidLoudspeaker

Method and apparatus for testing a directional acoustic device such as a directional hearing aid having level-dependent non-linear circuitry, in which two or more speakers are placed at desired positions relative to the hearing aid, e.g. in front and behind the hearing aid. The speakers are excited simultaneously with broadband excitation signals formed from components which are orthogonal to each other, e.g. sinusoids, where the bin frequencies of the Direct Fourier Transform (“DFT”) of one excitation signal are different from the bin frequencies of the other excitation signal. Thus, the response to each excitation signal can easily be extracted without filtering, allowing the directional characteristics of the hearing aid to be evaluated.

Owner:RHINOMETRICS

Inbuilt damping device for hollow shaft

ActiveCN103671699ALow costSave spaceRotating vibration suppressionInertia force compensationCircular coneLongitudinal vibration

An inbuilt damping device for a hollow shaft comprises an elastic shaft arranged in the hollow shaft. The elastic shaft is of a three-segmental stepped shaft structure. One end of the middle segment is sequentially divided into a large diameter, a medium diameter and a small diameter along the axial line; the segments at the two ends are respectively divided into large diameters, medium diameters and small diameters in sequence along the axial line in the direction from the two end faces of the middle segment to the respective ends in the mode of being smaller than the small diameter of the middle segment; the segments of the small diameters of the three segments of stepped shafts are all provided with threads; a cylindrical inertia wheel and a second spacer are installed on the medium diameter of the middle segment in a sleeved mode, and the cylindrical inertia wheel is filled with damping particles and is fastened by connecting a second nut and the threads; the medium diameters of the segments at the two ends are respectively sleeved with a stop block, a taper and a first spacer, wherein the tapers are circular-frustum-shaped bodies provided with center holes; upper membranes and lower membranes are installed on the outer conical surfaces of the tapers in a sleeved mode and provided with taper holes; the tapers are fastened by connecting first nuts and the threads. According to the inbuilt damping device for the hollow shaft, torsional vibration, transverse vibration, longitudinal vibration and coupling vibration on a shafting can be simultaneously controlled; furthermore, the inbuilt damping device has the damping effect of more than 10dB on broadband excitation force within a wide rotating speed range of the shafting.

Owner:JIANGSU UNIV OF SCI & TECH

Directional hearing aid tester

ActiveUS7062056B2Test accurateAnalysing solids using sonic/ultrasonic/infrasonic wavesSets with desired directivityFourier transform on finite groupsHearing aid

Method and apparatus for testing a directional acoustic device such as a directional hearing aid having level-dependent non-linear circuitry, in which two or more speakers are placed at desired positions relative to the hearing aid, e.g. in front and behind the hearing aid. The speakers are excited simultaneously with broadband excitation signals formed from components which are orthogonal to each other, e.g. sinusoids, where the bin frequencies of the Direct Fourier Transform (“DFT”) of one excitation signal are different from the bin frequencies of the other excitation signal. Thus, the response to each excitation signal can easily be extracted without filtering, allowing the directional characteristics of the hearing aid to be evaluated.

Owner:RHINOMETRICS

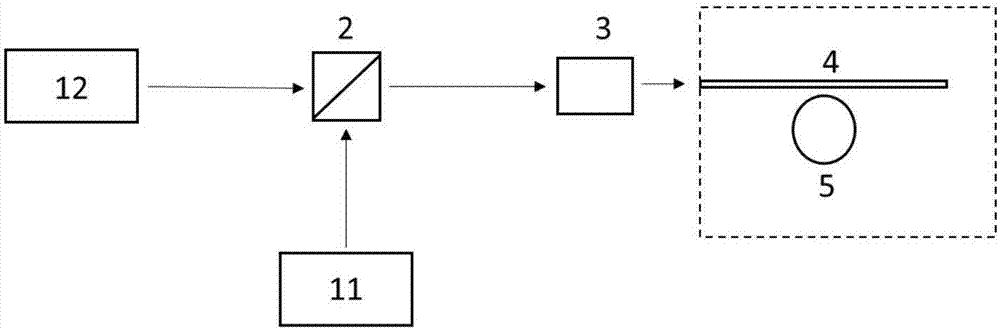

On-chip broadband coupling optical microcavity system and coupling method thereof

ActiveCN107508140AEffectively stimulate the whispering gallery modeHigh intrinsic quality factorLaser detailsSemiconductor laser optical deviceRadiation lossExcited state

The present invention discloses an on-chip broadband coupling optical microcavity system and a coupling method thereof. In the invention, a non-circular optical microcavity and an optical waveguide prepared on a chip are adopted, and the slight deformation of the non-circular optical microcavity causes the eigenstate echo wall mode originally distributed only in the edge of the circular optical microcavity to extend into the non-circular optical microcavity, forming a "tail"; laser and the "tail" of the non-circular optical microcavity are in phase matching, so as to stimulate the excited state echo wall mode of the non-circular optical microcavity; the echo wall mode of the non-circular optical microcavity can be refracted into the optical waveguide through its "tail"; the optical waveguide enables effective broadband excitation and collection of the echo wall mode in the non-circular optical microcavity, i.e., the completion of the effective broadband coupling of the optical waveguide and the non-circular optical microcavity; and the deformation of the non-circular optical microcavity is so little that the non-circular optical microcavity can maintain high intrinsic quality factors (> 10<4>) without introducing large radiation losses.

Owner:PEKING UNIV

Method and system for on-line detection of pretightening force of fastening device

ActiveCN105424258AReal-time judgment of preload conditionBreach of integrityMeasurement of torque/twisting force while tighteningTime responseFrequency spectrum

The invention provides a method and system for the on-line detection of a pretightening force of a fastening device, and the method comprises the steps: carrying out the shock excitation of a detected workpiece system, wherein the detected workpiece system mainly consists of a fastening piece and a mechanism which is fastened by the fastening piece; carrying out the vibration pick-up of a real-time response signal of the detected workpiece system for the shock excitation; obtaining the real-time frequency spectrum response information of the detected workpiece system according to the real-time response signal; and recognizing an axial pretightening force of the fastening piece according to the real-time frequency spectrum response information. The method and system gives consideration to the rigidness change of the detected workpiece system before and after the fastening piece carries out pretightening, and the rigidness change enables the detected workpiece system to generate the change of frequency spectrum response under broadband excitation. Therefore, the method and system recognizes the axial pretightening force through the analysis of the frequency spectrum response and the change of multi-order mode modal response, thereby achieving the on-line detection.

Owner:杨斌堂

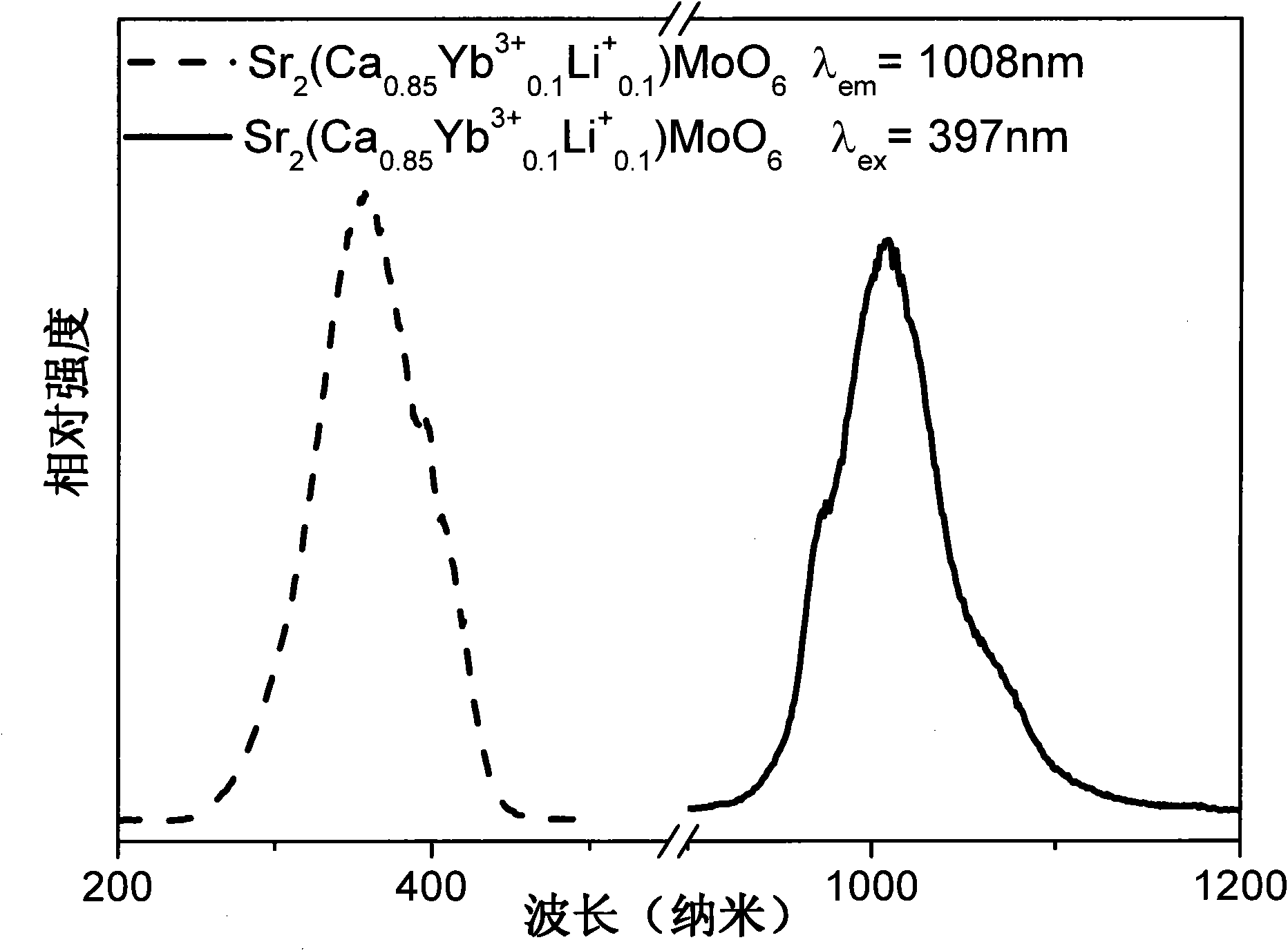

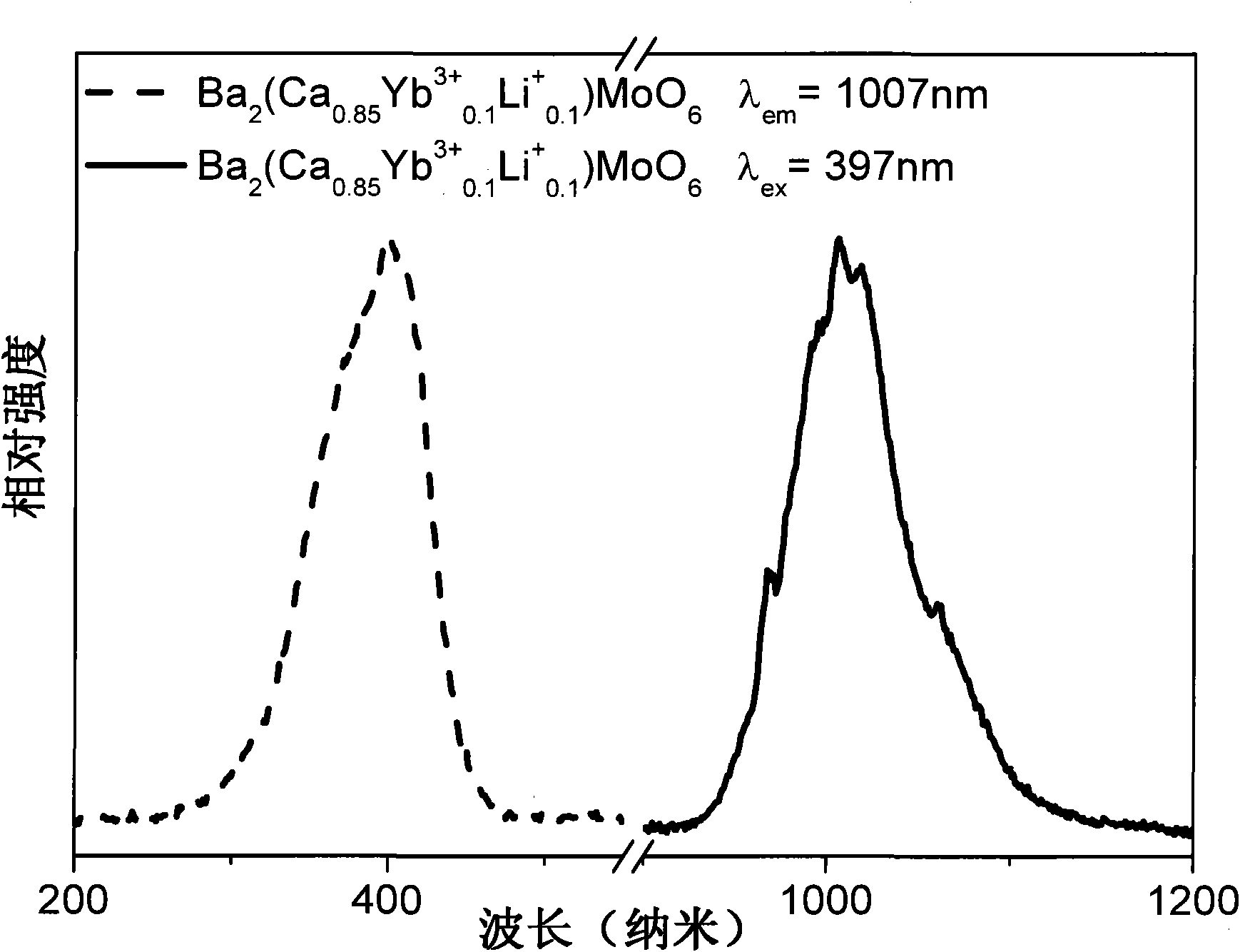

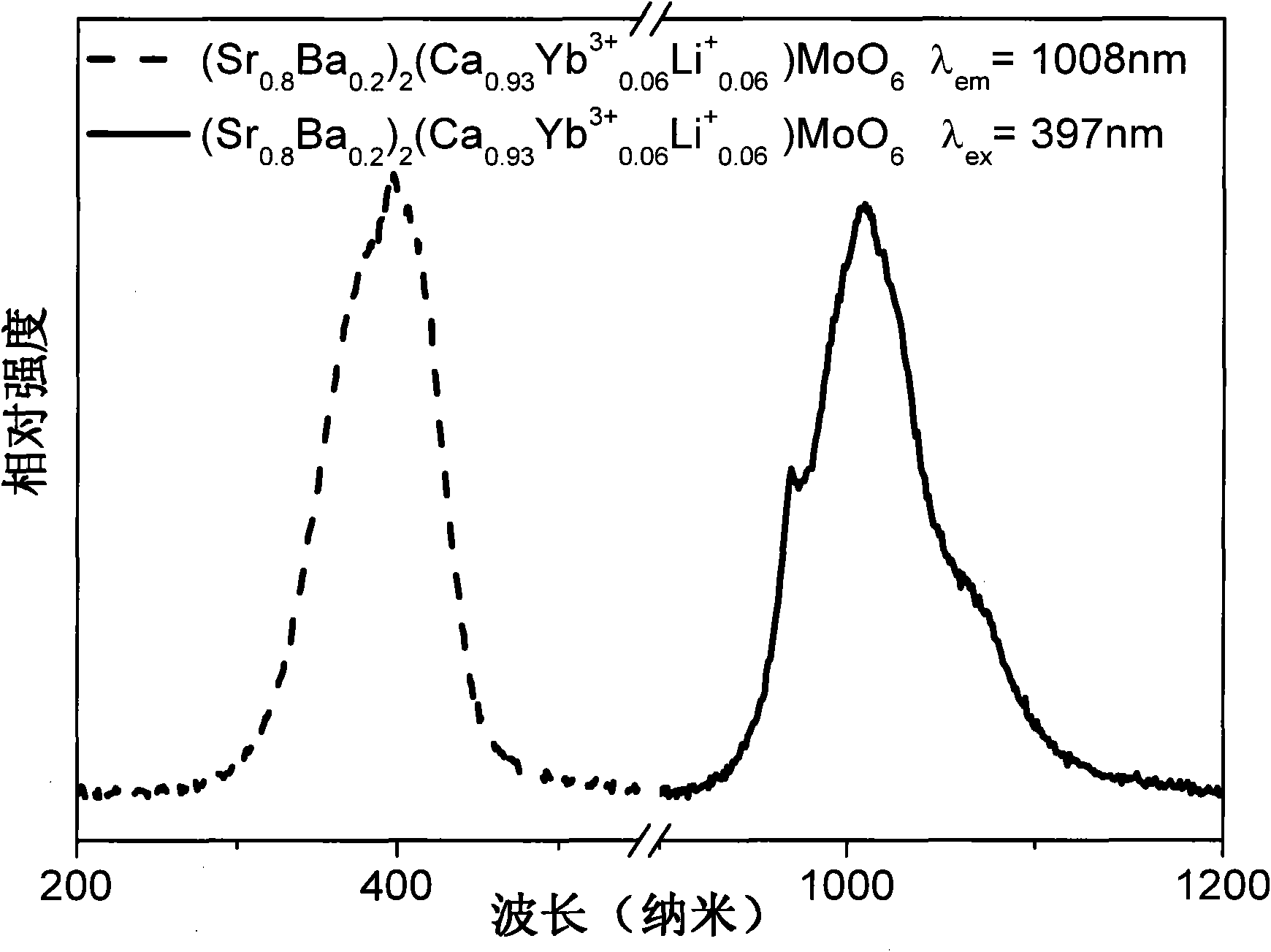

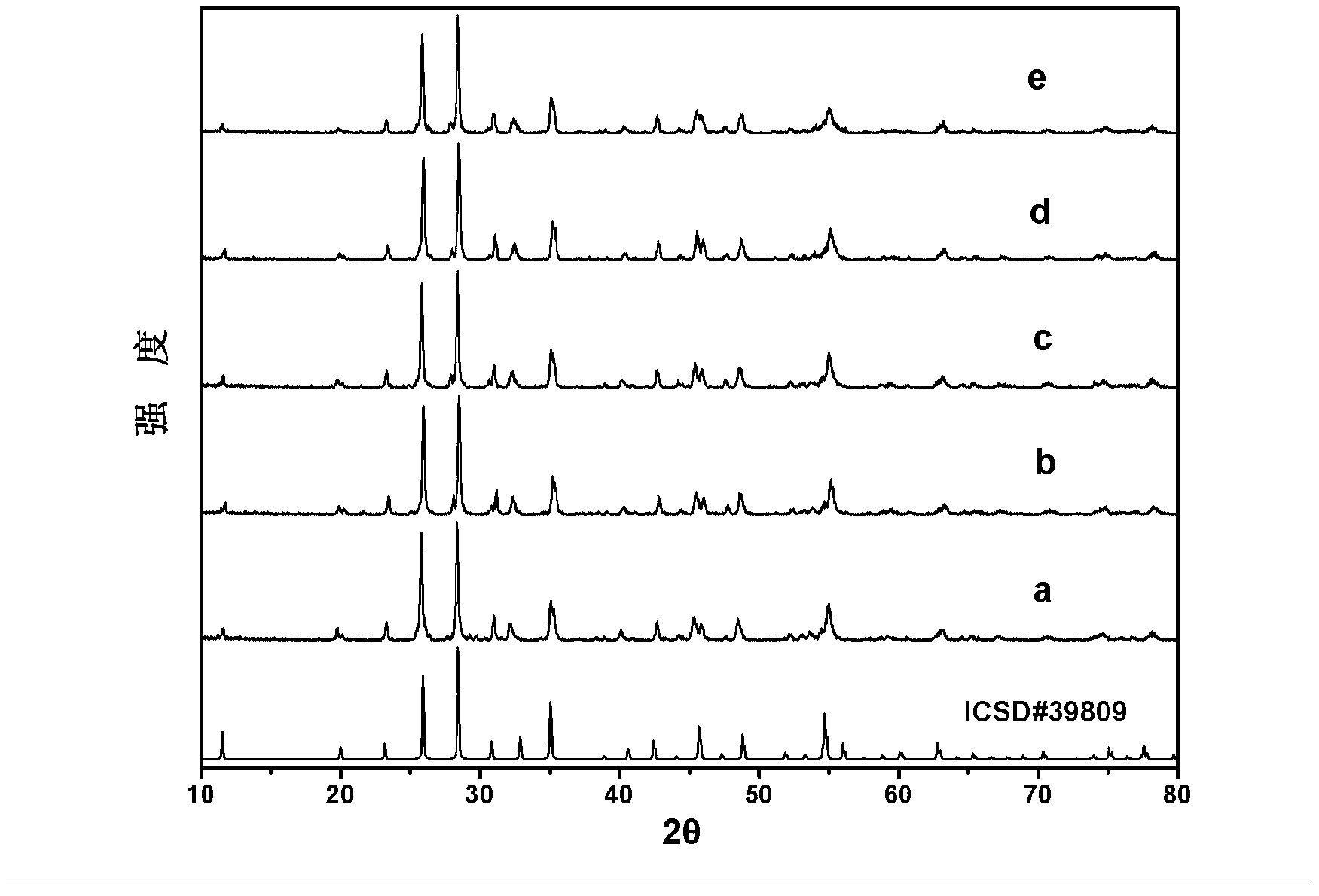

Alkaline earth molybdate rare earth light conversion material and preparation method thereof

InactiveCN101962545AWide excitation spectrumStrong absorption capacityLuminescent compositionsAir atmosphereMolybdate

The invention discloses an alkaline earth molybdate rare earth light conversion material and a preparation method thereof. The light conversion material has a composition general formula of (Sr1-xBax)2(Ca1.05-2yYbyLiy)MoO6, wherein x is greater than or equal to 0 and less than or equal to 1; and y is greater than or equal to 0.02 and less than or equal to 0.12. The preparation method of the fluorescent powder comprises the following steps of: accurately weighing raw materials according to the proportion of the general formula; fully grinding and uniformly mixing oxides or corresponding salts of elements in the composition general formula; sintering the mixture in air atmosphere at the temperature of between 500 and 700 DEG C for 10 to 14 hours, cooling and crushing the mixture; then sintering the mixture in the air atmosphere at the temperature of between 800 and 1,000 DEG C for 10 to 14 hours, cooling and uniformly grinding the mixture in an agate mortar; and finally sintering the mixture in the air atmosphere at the temperature of between 1,000 and 1,200 DEG C for 20 to 28 hours, cooling and uniformly grinding the mixture in the agate mortar so as to obtain the alkaline earth molybdate fluorescent powder. The rare earth light conversion material disclosed by the invention has the advantages of broadband excitation, strong near infrared emission and the like from an ultraviolet region to a visible region and can be used as the rare earth light conversion material for silicon-based solar cells.

Owner:SUN YAT SEN UNIV

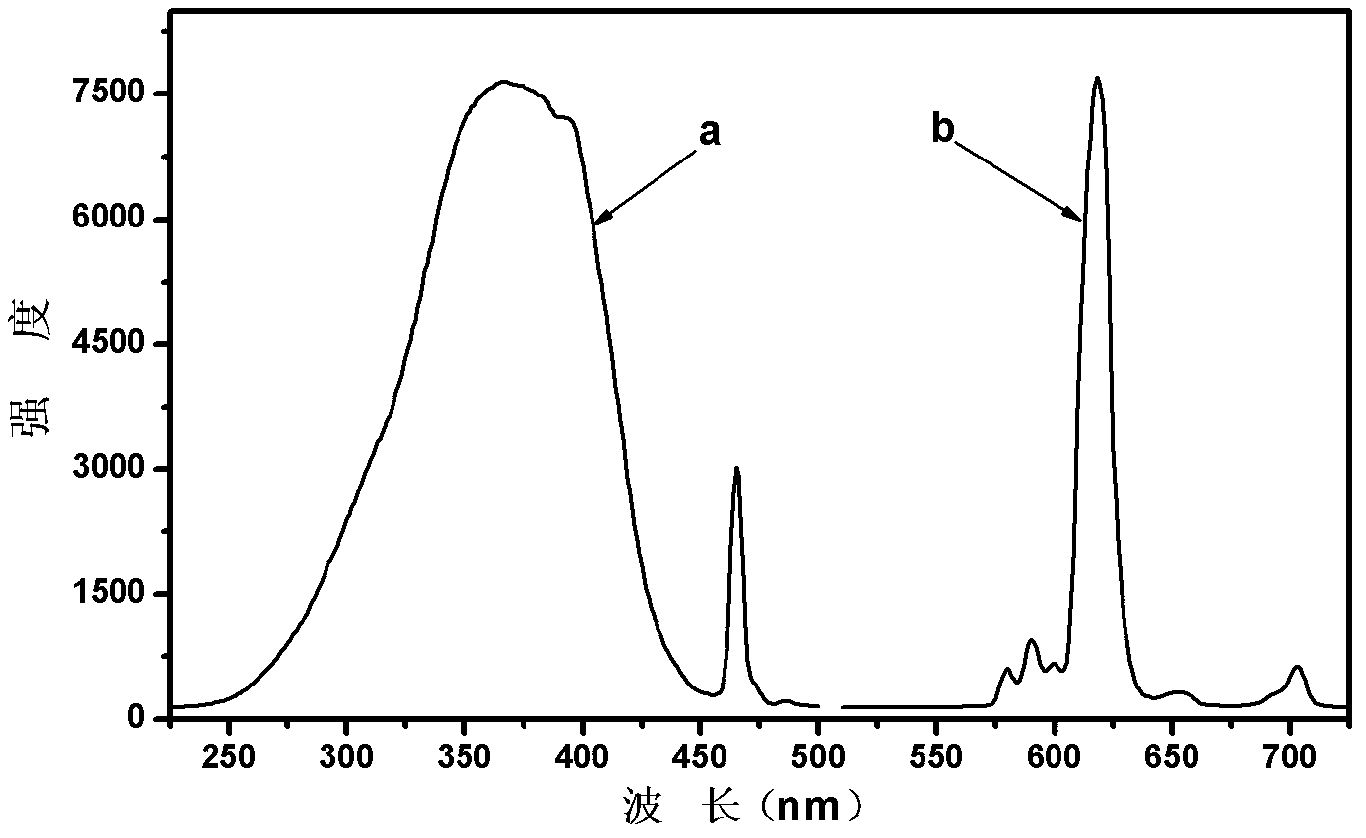

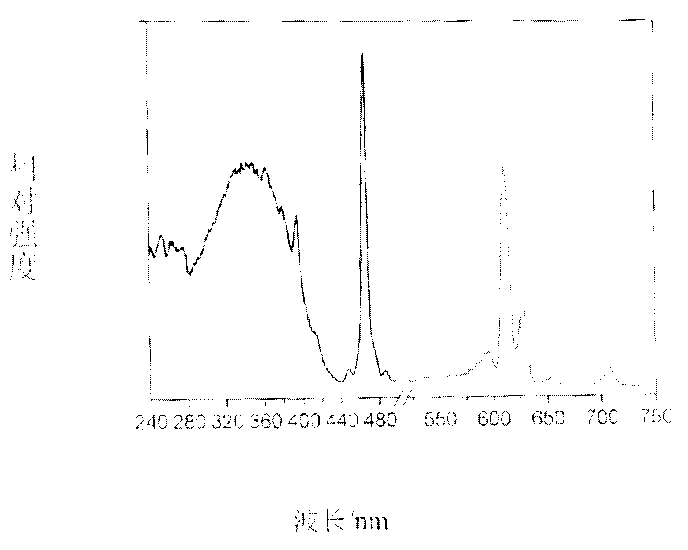

Efficient red fluorescent material and preparation method thereof

InactiveCN103289695AUniform light colorSimple preparation processLuminescent compositionsPhosphorUltraviolet

The invention discloses an efficient red fluorescent material which is excited by an LED (light-emitting diode) chip from near ultraviolet to purple light. The composition of the efficient red fluorescent material is as follows: La[3-y]BW[1-x]MoxO9:Eu<3+>y, wherein x is smaller than or equal to 0.5 and greater than or equal to 0, and y is smaller than or equal to 1.5 and greater than or equal to 0. The invention also discloses a preparation method and a performance research result of the fluorescent material. The fluorescent material has strong broadband excitation in an area from ultraviolet to purple lights, has a sharp line excitation peak at the blue light position of 466nm, and is matched with the chip from the near ultraviolet to ultraviolet purple light and the blue light chip in the market respectively; a sharp line red light of which the main peak is 618nm is emitted; the color purity is high. Compared with the red phosphor in the market, the efficient red fluorescent material has the advantages of simple and mild preparation condition, good stability, low preparation cost and the like, so that the material has a wide application prospect.

Owner:SHANGHAI NORMAL UNIVERSITY

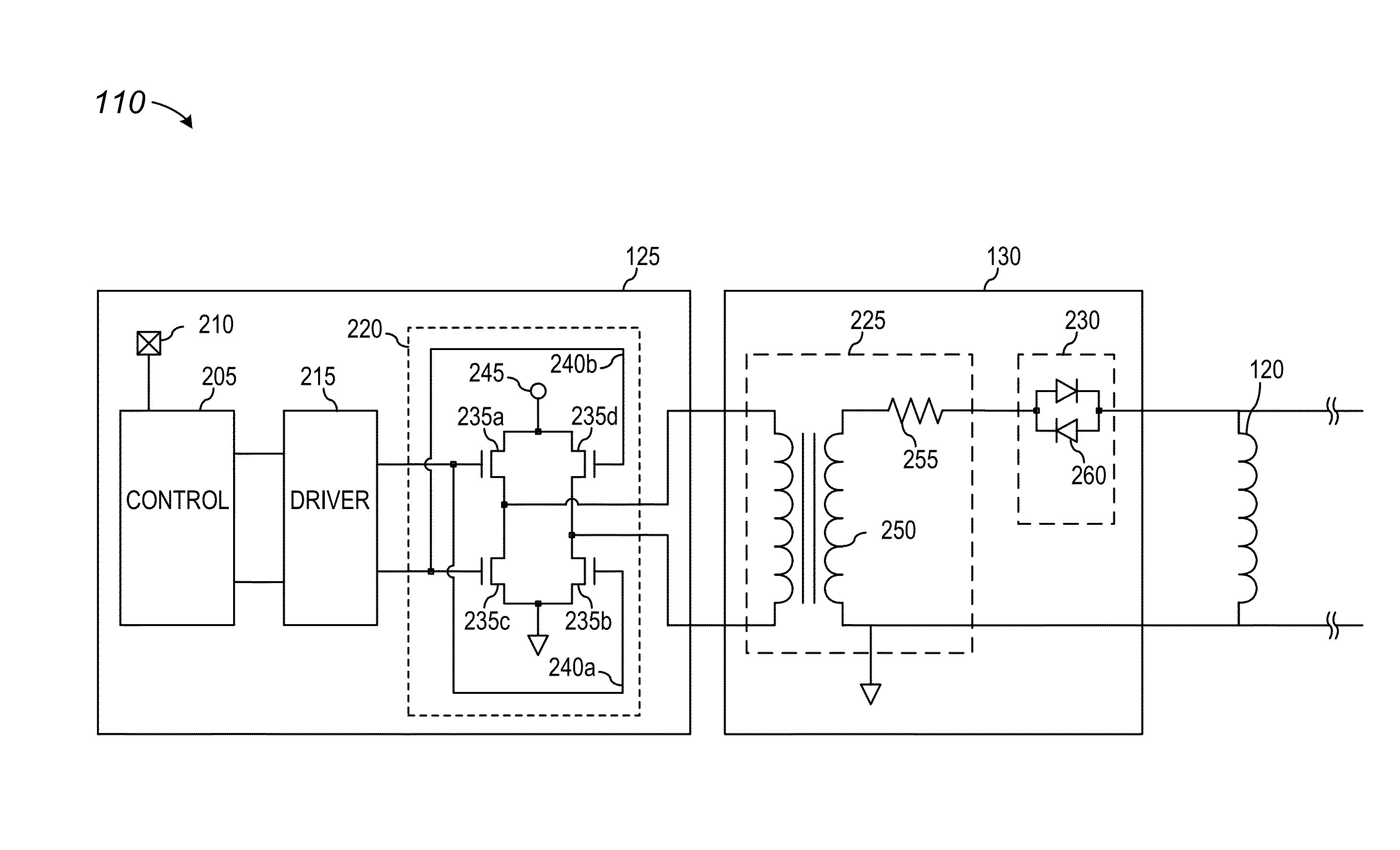

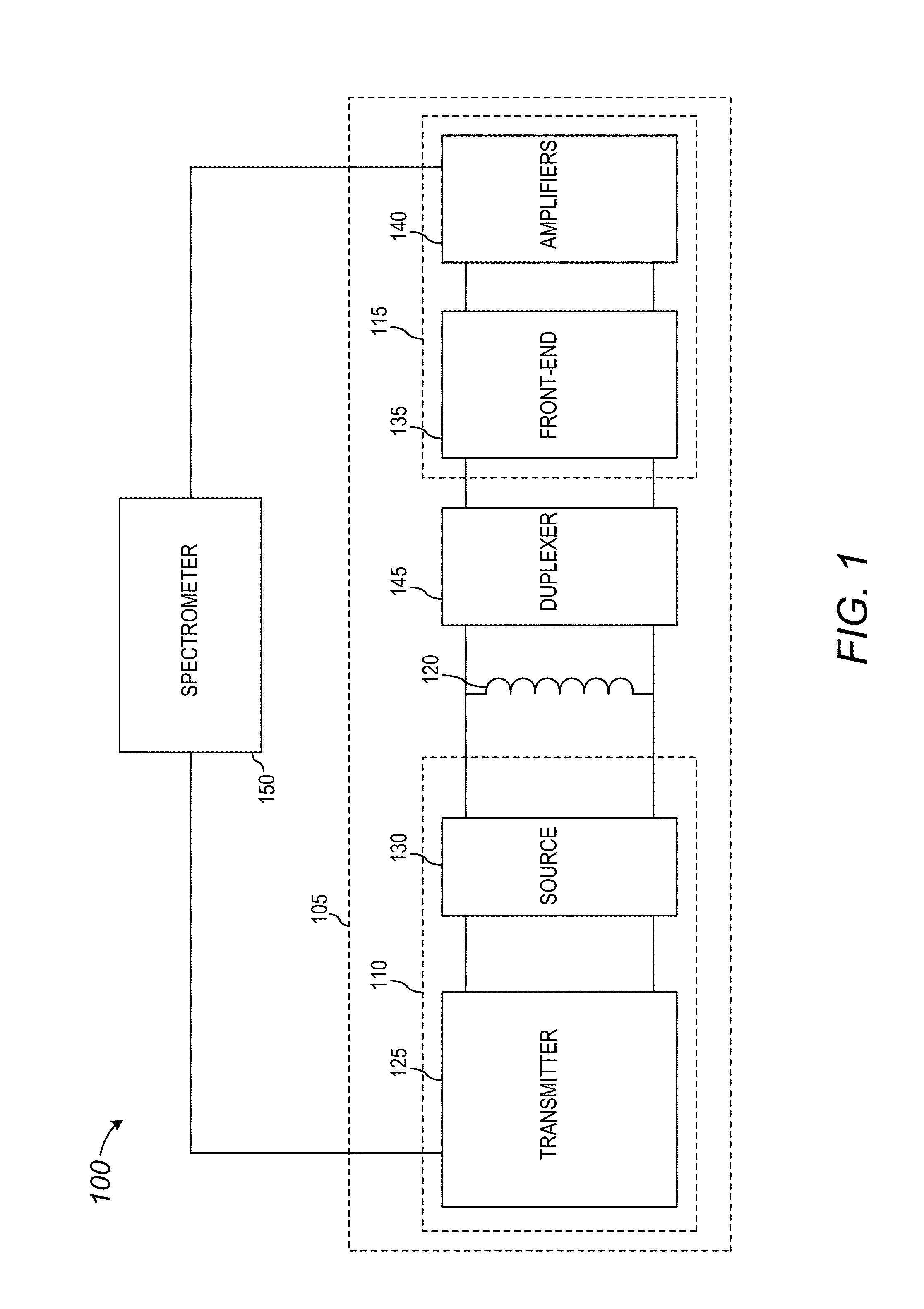

Broadband circuit for nuclear magnetic resonance

ActiveUS20150253396A1Wide rangeAnalysis using nuclear magnetic resonanceElectric/magnetic detectionNMR - Nuclear magnetic resonanceResonance

A device and system for generating a broadband excitation signal and corresponding excitation field to a substance under test in an NMR system is presented. The excitation signal is generated, according to a broadband transmitter, to a coil in the NMR system. A corresponding broadband receiver is also presented that acquires a response signal resulting from a response field emanating from the substance under test. Neither the transmitter nor the receiver require that the frequency of operation be determined according to a particular configuration of electrical devices to determine a resonance characteristic that tunes to a particular operational frequency. Rather, the operational frequency is determined according to control and driver devices triggered according to command and control signals in the case of the transmitter, and according to reactive elements, that are not configured as a tuned circuit, in the case of the receiver.

Owner:TURBOSPEC LLC

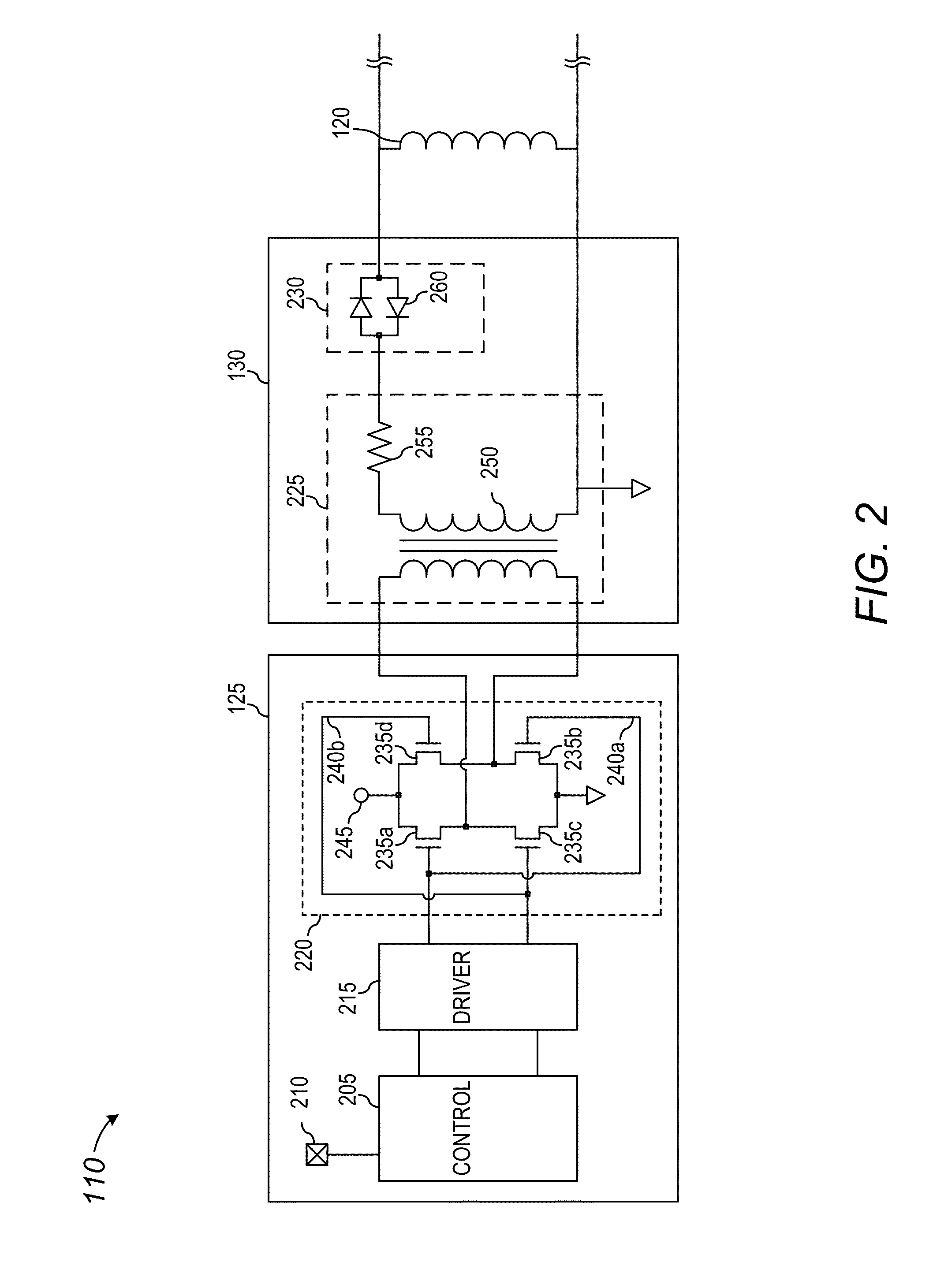

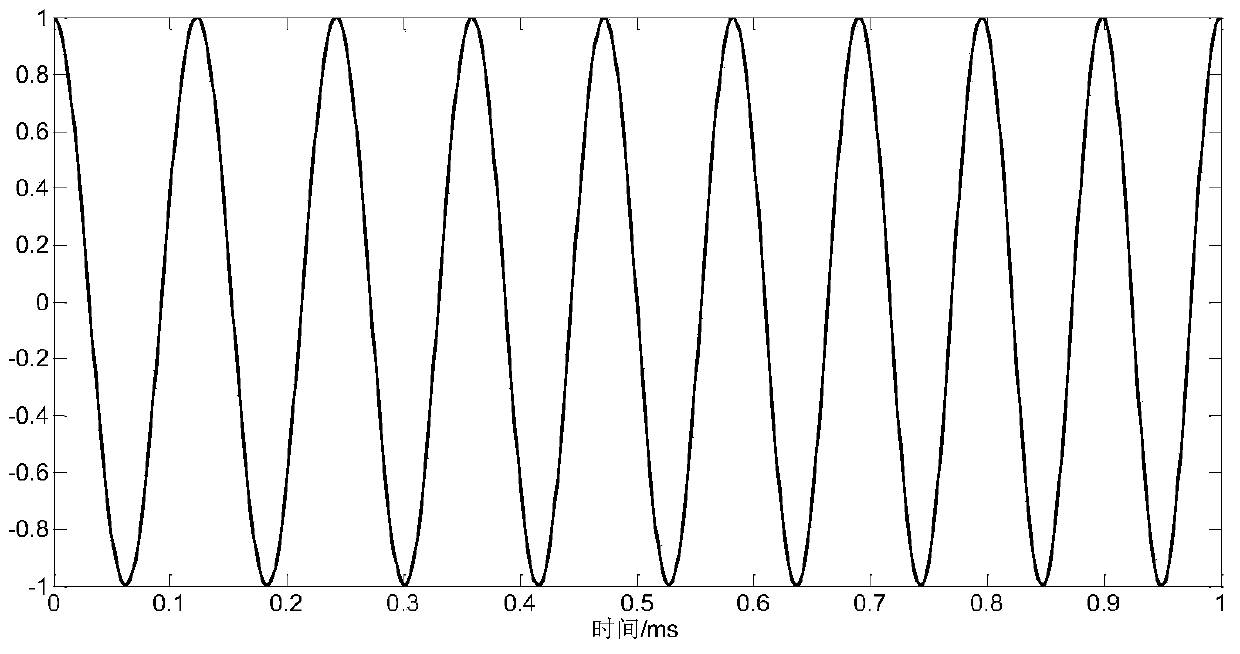

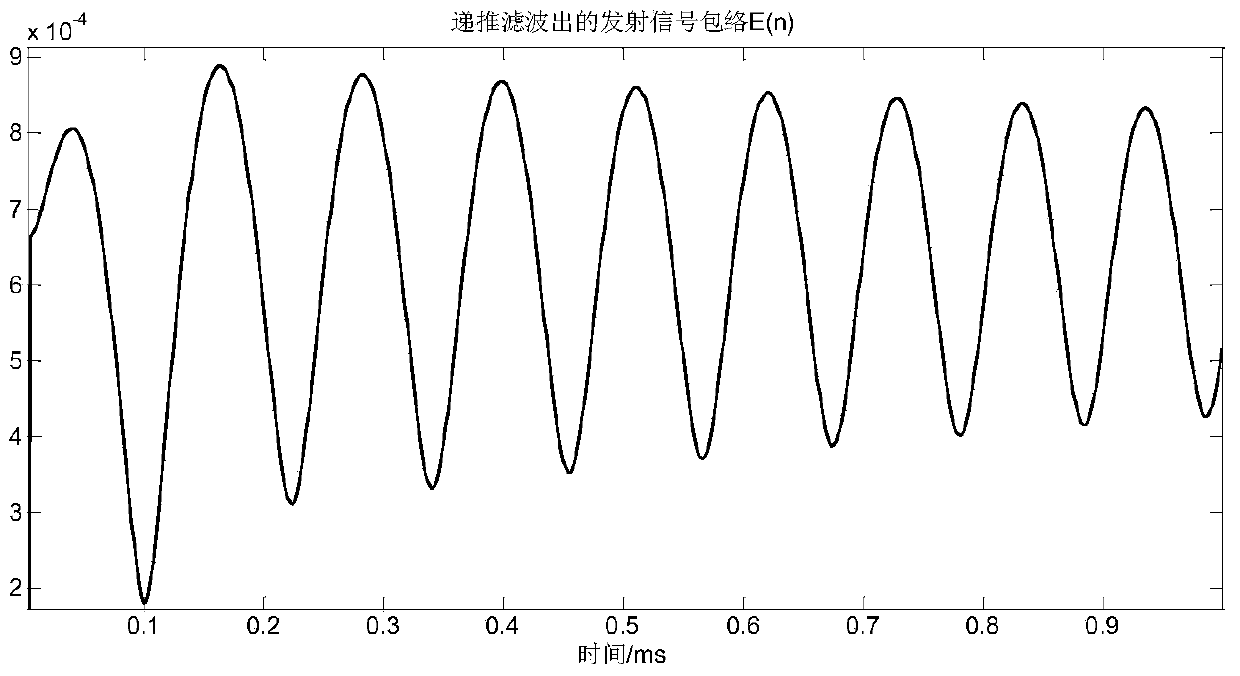

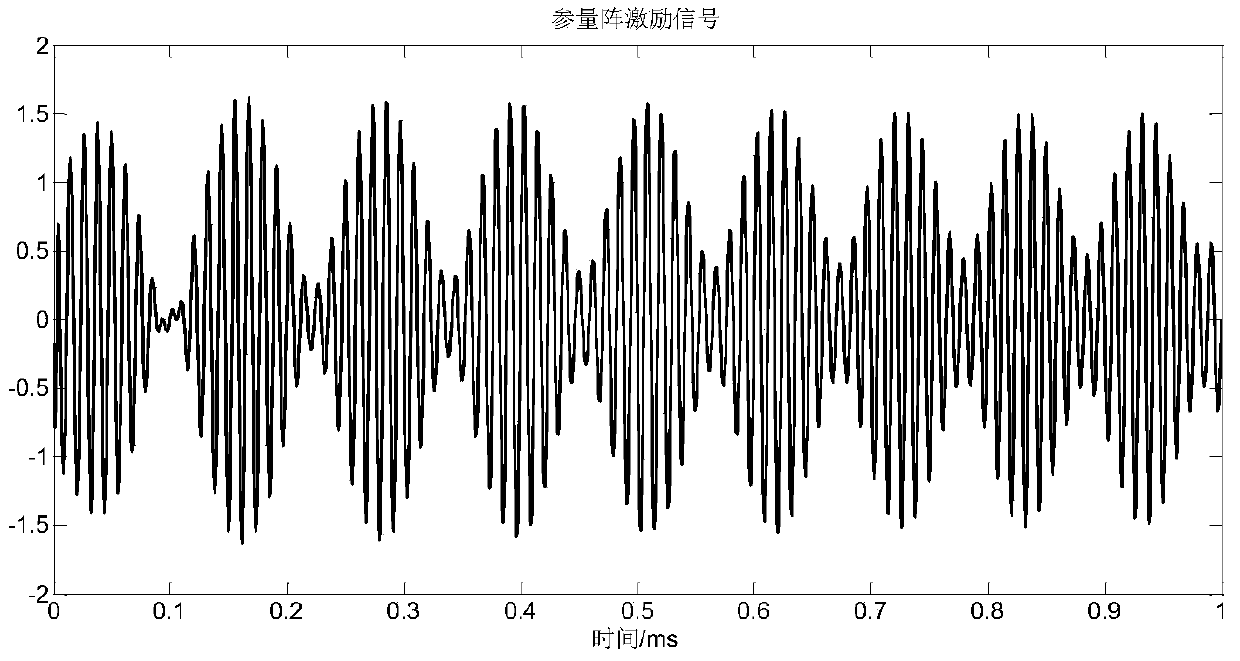

Recursive filtering modulating method of transient broadband excitation signal of parametric array sonar

ActiveCN104199037ALow costSmall amount of calculationAcoustic wave reradiationCarrier signalParametric array

The invention relates to a recursive filtering modulating method of a transient broadband excitation signal of parametric array sonar. The method comprises the following steps: performing recursive filtering for a signal to be processed through a recursive filtering device to obtain X(n+1); obtaining an envelope E(n+1); performing up-sampling for the envelope E(n+1) through an interpolation filter; performing double-sideband amplitude modulation together with a digital carrier signal; performing D / A conversion to obtain an analog signal, and thus obtaining the excitation signal of a parametric emitting system. The method applies to both parametric array sonar and an air acoustical parametric array system; the application scope of acoustical parametric array is widely expanded, and a predictable huge potential market value is brought.

Owner:HARBIN ENG UNIV

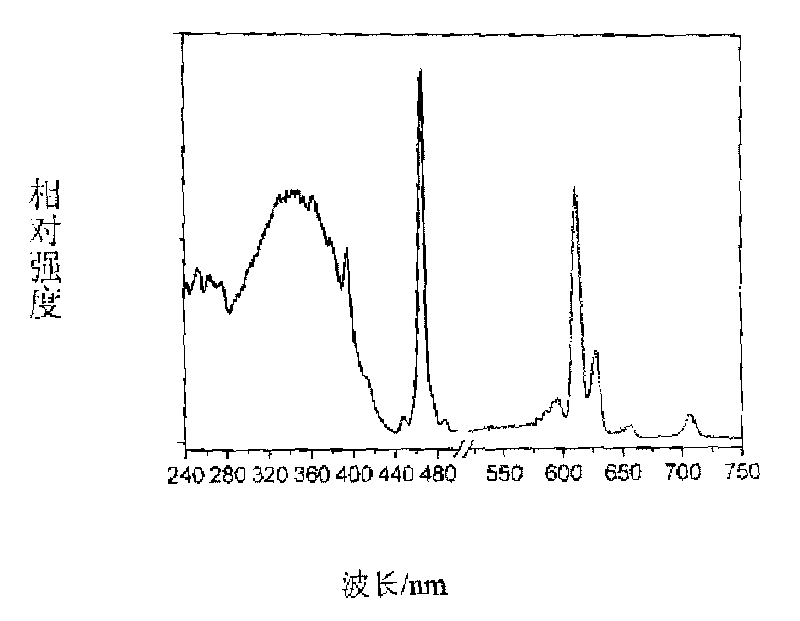

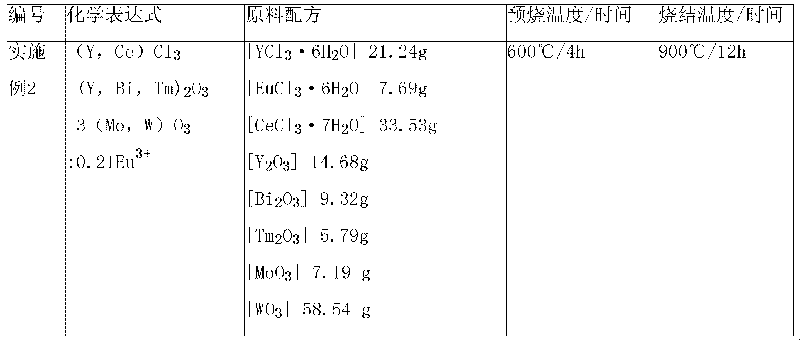

Red fluorescent powder excitated by near-ultraviolet broadband and preparation method thereof

ActiveCN101709216AHigh color purityStable physical and chemical propertiesLuminescent compositionsLuminous intensityUltraviolet lights

The invention discloses red fluorescent powder excitated by near-ultraviolet broadband and a preparation method thereof. The chemical expression of the red fluorescent powder is R1R23-R32O3-3R4O3:xEu3+, wherein R1 is one, two or more of Y3+, La3+, Gd3+, Pr3+, Sm3+ and Bi3+, and R2 is one, two or three of Cl-, Br- and I-; R3 is one, two or more of La3+, Gd3+, Y3+, Pr3+, Sm3+, Bi3+, Tm3+ and Dy3+; R4 is W6+ or / and Mo6+; and x is equal to 0.005-2.0. The preparation process comprises the steps of preparing a raw material of powder, preparing a mixture material, prefiring, sintering and postprocessing. The red fluorescent powder presents broadband excitation and sharp peak transmission to near-ultraviolet light, and red has high luminescence intensity and good color purity.

Owner:山东格新精工有限公司

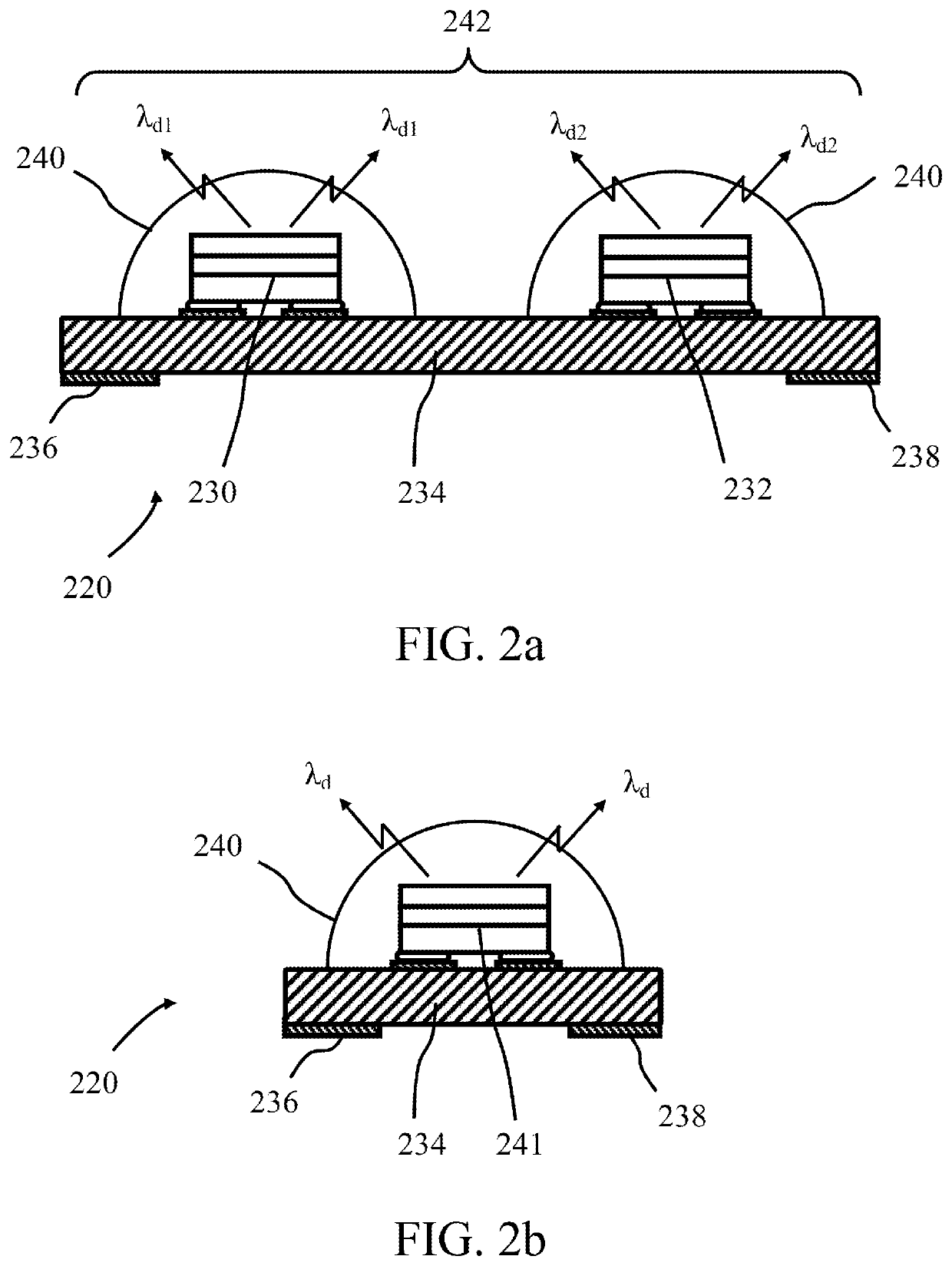

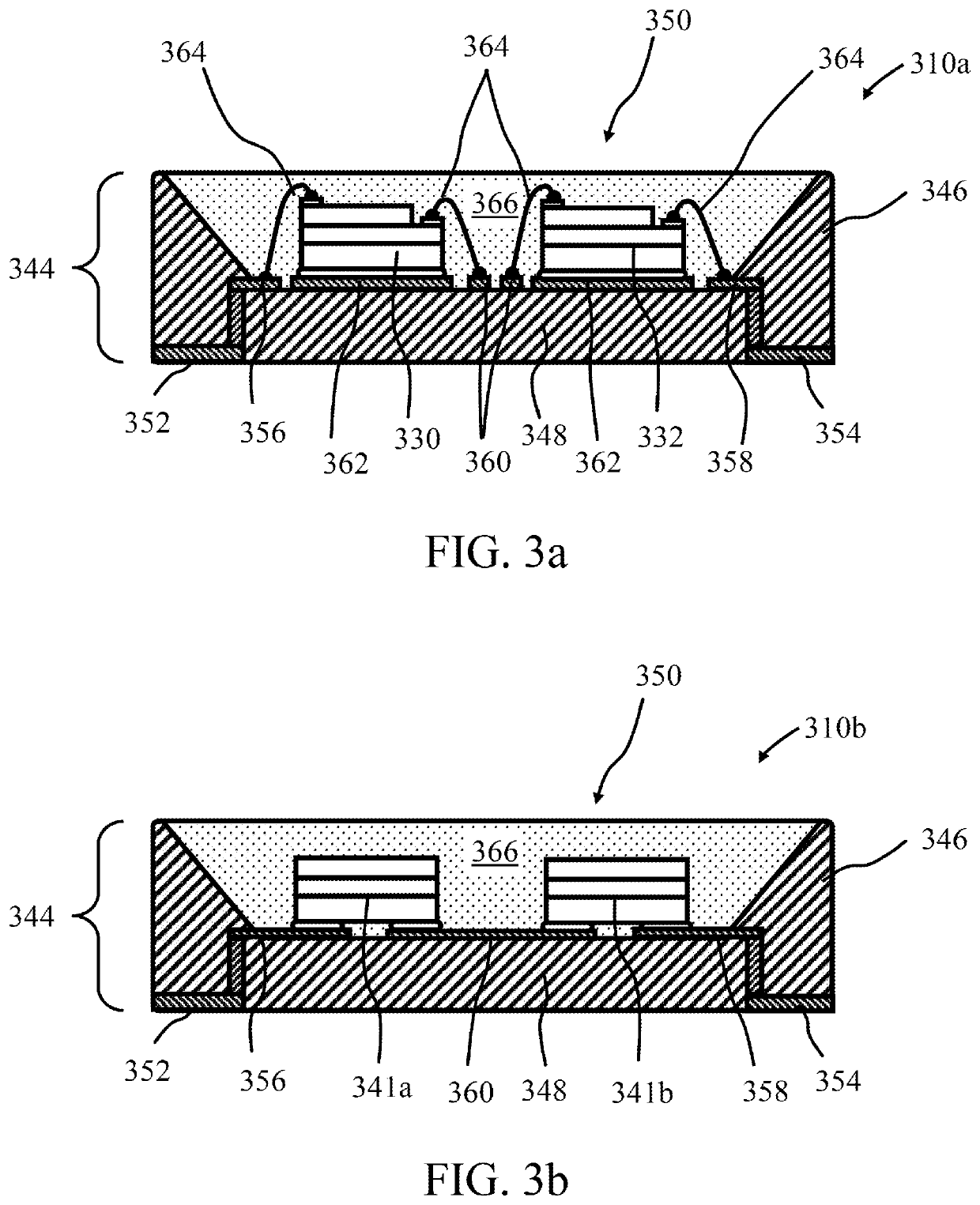

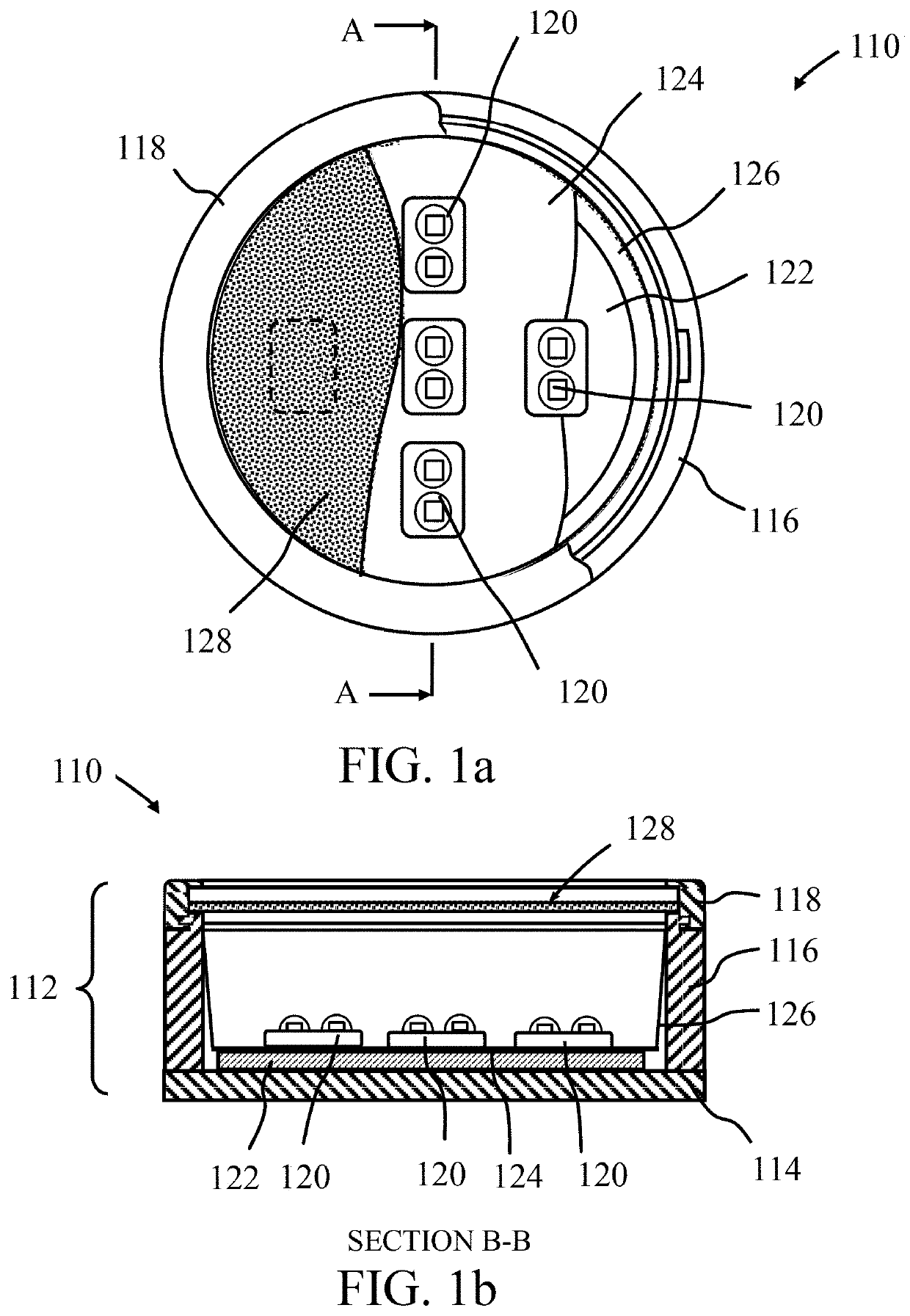

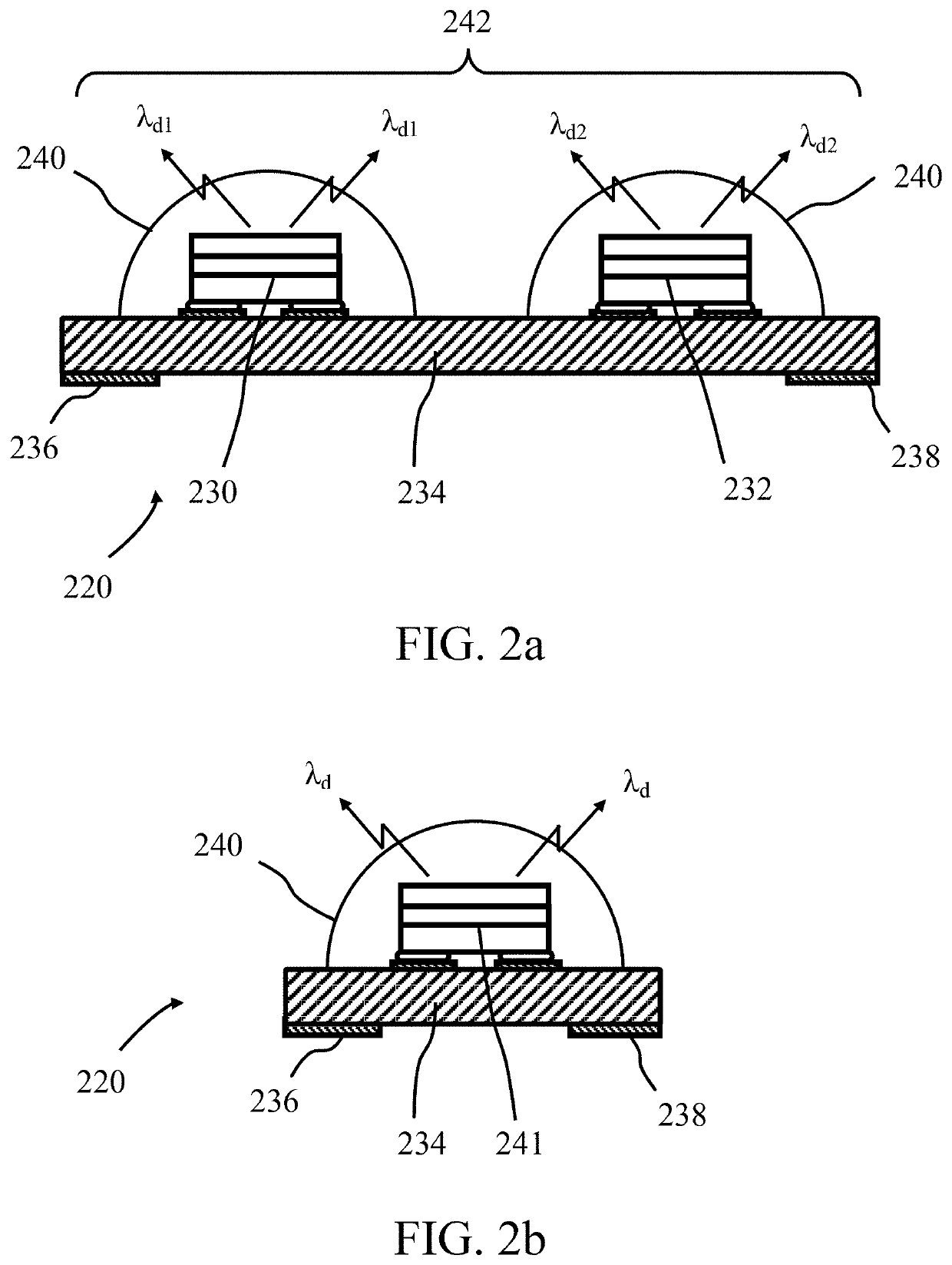

Full spectrum white light emitting devices

ActiveUS10685941B1Good curative effectSolid-state devicesRadiation therapyPhotoluminescenceBroadband excitation

A full spectrum white light emitting device comprises: photoluminescence materials which generate light with a peak emission wavelength in a range from about 490 nm to about 680 nm; and a broadband solid-state excitation source operable to generate broadband excitation light with a dominant wavelength in a range from about 420 nm to about 480 nm. The device is operable to generate white light with a Correlated Color Temperature in a range from about 1800K to about 6800K, a CRI R9 less than 90, a spectrum whose intensity decreases from its maximum value in the orange to red region of the spectrum to about 50% of said maximum value at a wavelength in a range from about 645 nm to about 695 nm, and over a wavelength range from about 430 nm to about 520 nm, a maximum percentage intensity deviation of light emitted by the device is less than 60% from the intensity of light of at least one of a black-body curve and CIE Standard Illuminant D of the same Correlated Color Temperature.

Owner:BRIDGELUX INC

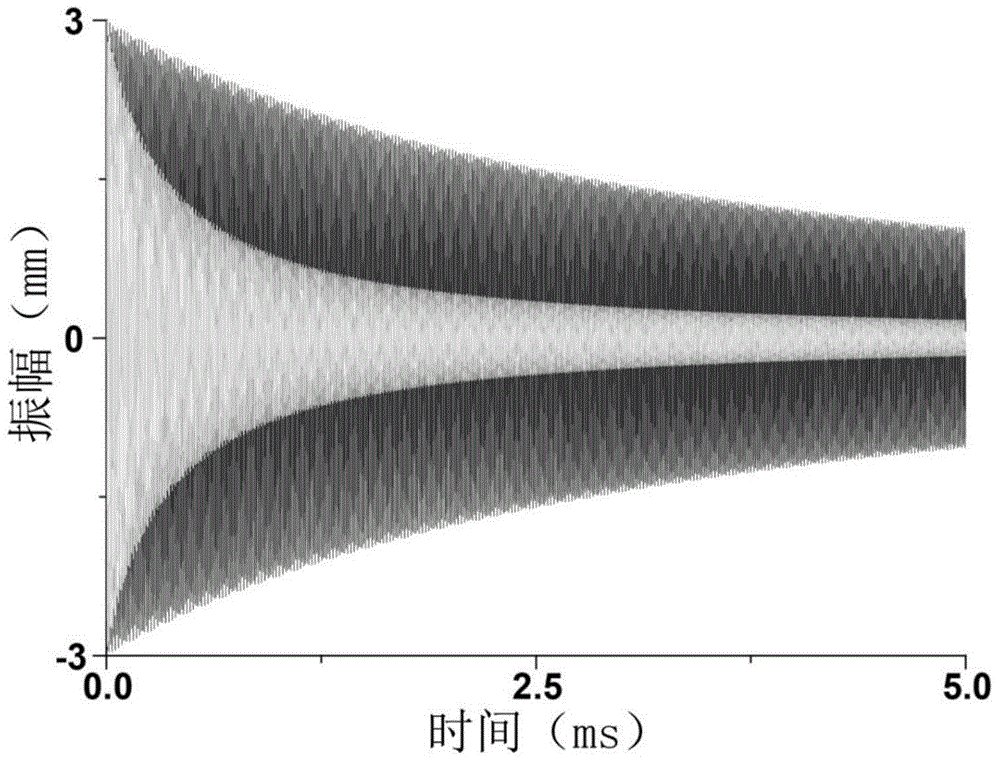

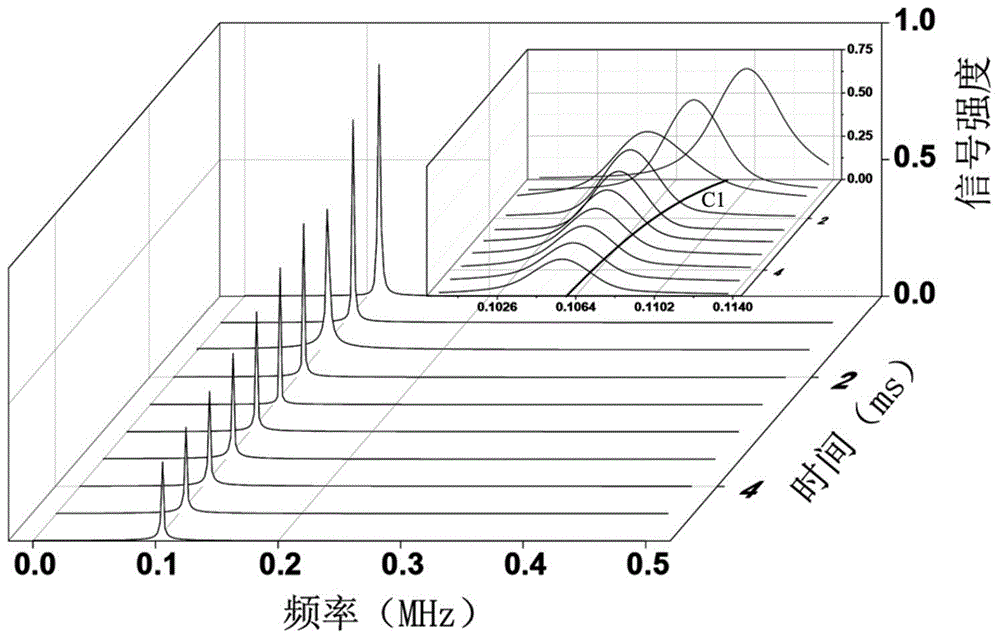

Ion structure analysis method

InactiveCN105424789AEasy to detectRealize non-destructive testingMaterial analysis by electric/magnetic meansSpecial data processing applicationsStructure analysisTime–frequency analysis

The present invention relates to an ion structure analysis method, which comprises: imprisoning and exciting ions, wherein a radio frequency electric field with a high-order component is applied onto an ion mass analyzer, and an auxiliary alternating current electric field or a broadband excitation electric field is applied onto the ion mass analyzer to make the sample ions be excited to achieve a certain motion amplitude, wherein the motion amplitude does not exceed the imprisoning capacity of the ion mass analyzer, and is recorded as the initial motion amplitude, and the moment is recorded as the first moment; carrier gas is continuously introduced into the ion mass analyzer, and a certain vacuum degree in the ion mass analyzer is maintained, wherein the sample ions collide with the carrier gas, the motion amplitude gradually reduced until a second moment is achieved, and the time domain signal of the image current produced by the sample ions during the process from the first moment to the second moment is collected; and signal processing is performed, wherein the time domain signal is analyzed by using a time frequency analysis method to obtain the time change characteristic curve containing the corresponding relation between the corresponding size ion motion frequency and the ion and carrier gas collision cross section area so as to distinguish the ions having different sizes.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

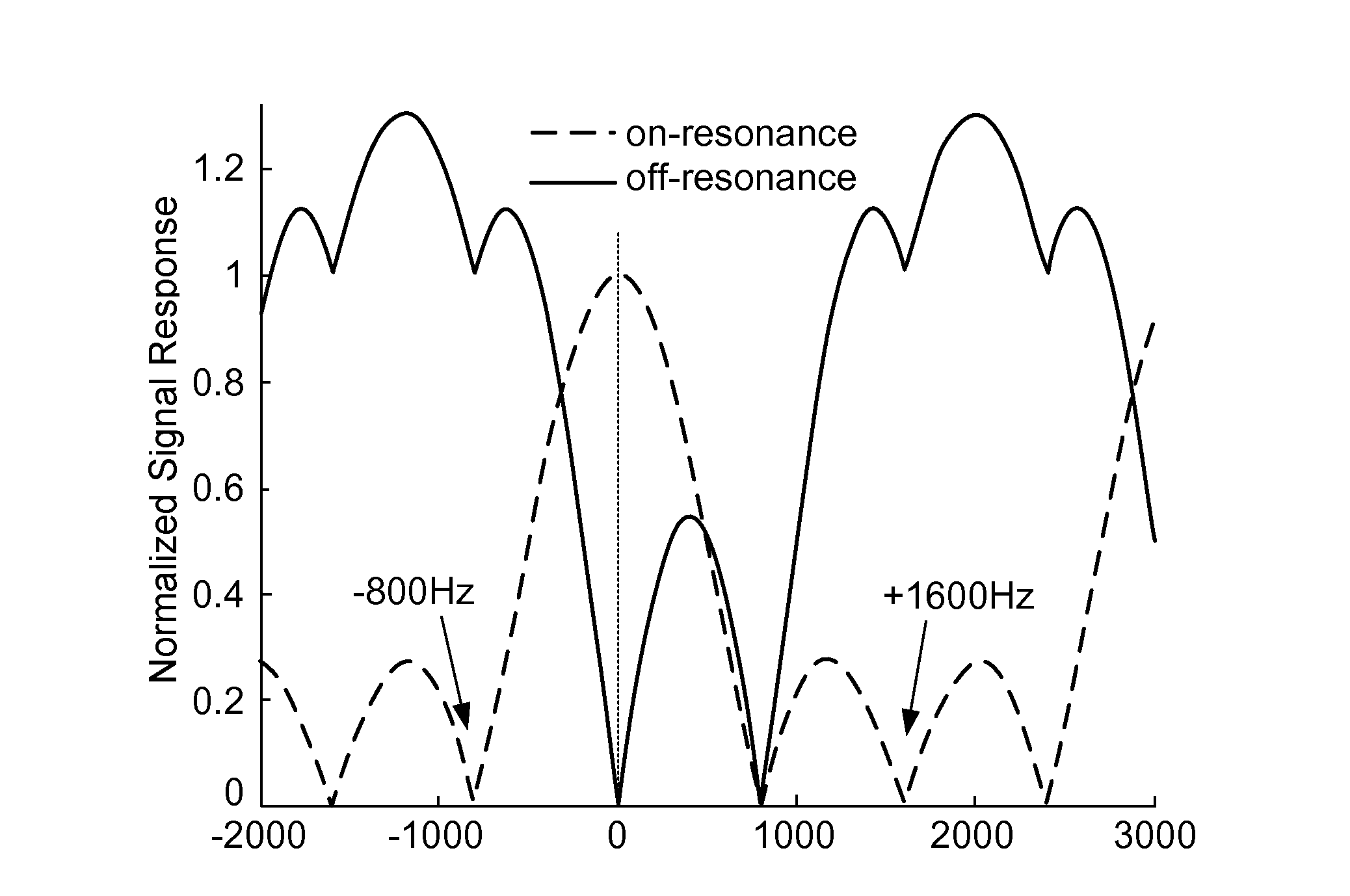

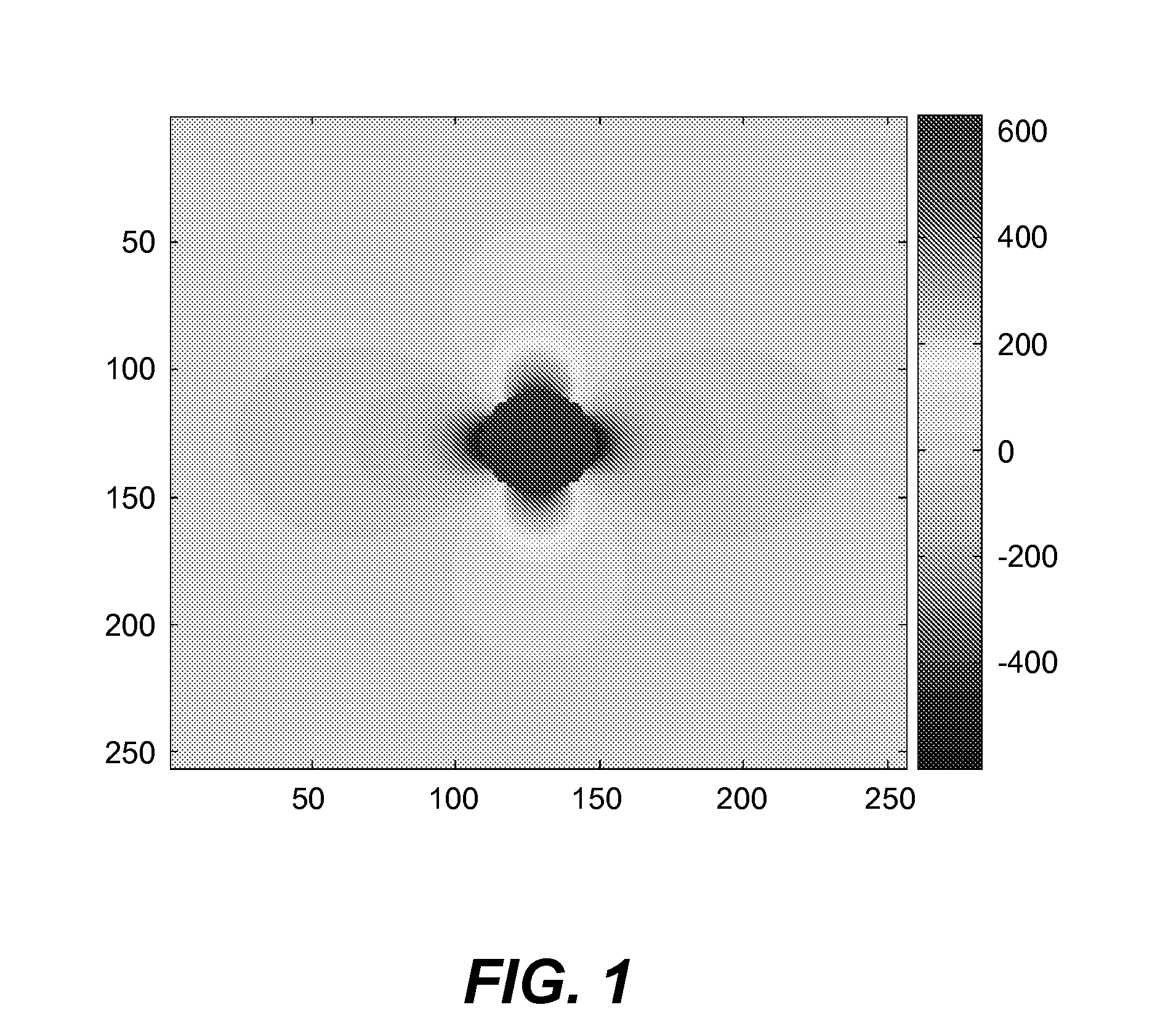

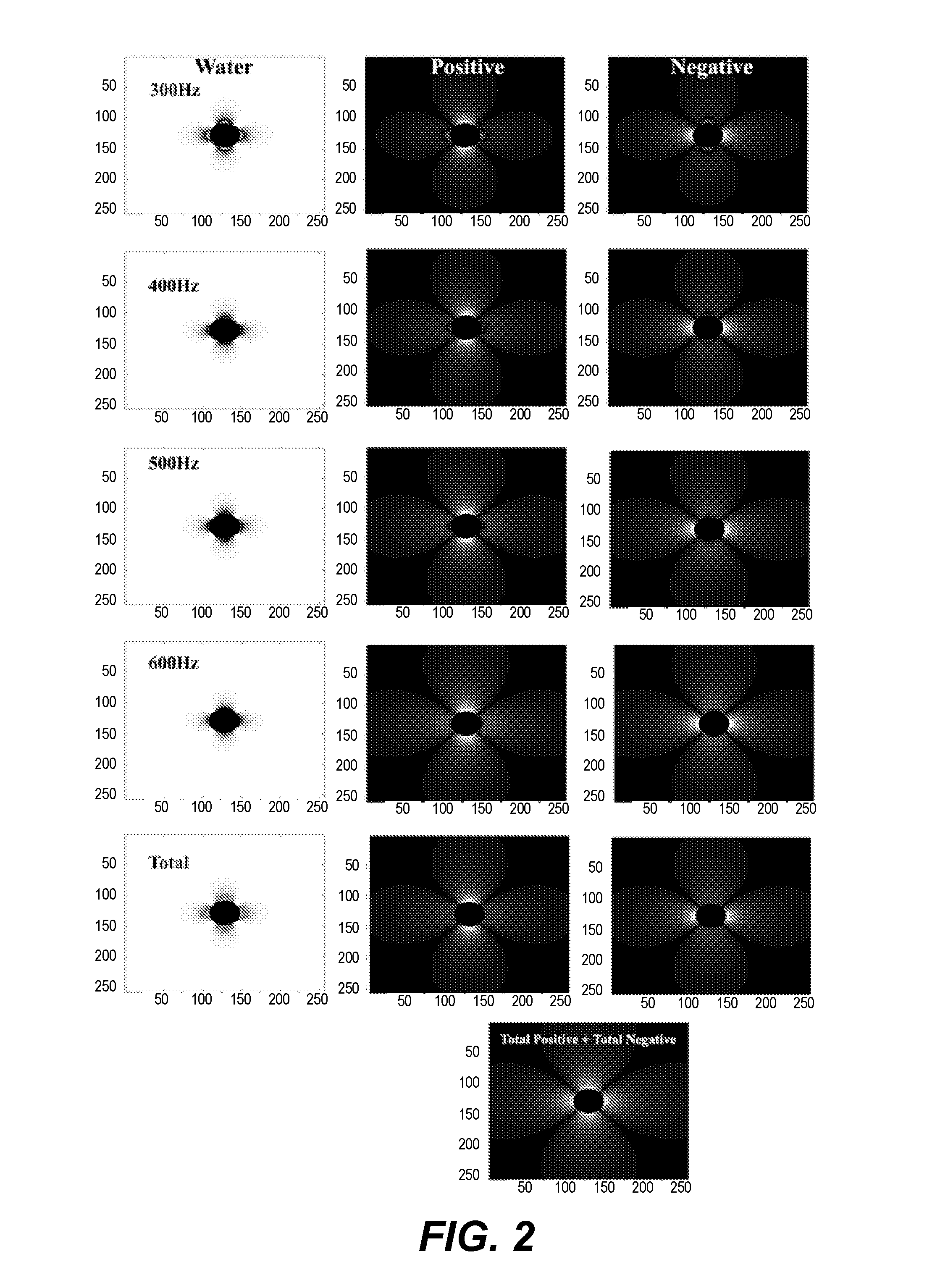

Positive contrast MRI using positive and negative field inhomogeneity

ActiveUS7480525B2Precise positioningMagnetic measurementsDiagnostic recording/measuringBroadband excitationFrequency offset

The acquisition of multiple images at slightly different time shifts from the spin echo (or from TE=0 for gradient echo sequences), allows the separation of on-resonance spins from off-resonance spins by encoding this information in the received signal. The excitation pulse can be a standard broadband excitation that will excite all spins. The separation of on- and off-resonance spins is then performed on the received signal. The polar and equatorial lobes of a magnetic particle such as SPIO produce signals from excited water molecules near the particle which are frequency offset above and below the frequency of signals from water molecules unaffected by the particle.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

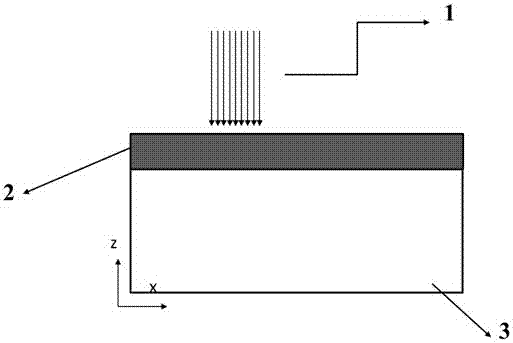

Bowknot-shaped antenna achieving waveguide mode of UWB (ultra wide band) excitation of surface plasma

InactiveCN106873075AWith broadband characteristicsImprove excitation efficiencyOptical light guidesPlasmonic waveguideGaussian beam

The invention relates to a bowknot-shaped antenna achieving a waveguide mode of UWB (ultra wide band) excitation of surface plasma, and the antenna structure comprises a silicon dioxide bottom layer and a silver layer, which are arranged at the top and bottom. The silver layer is deposited on the surface of the low-refractive-index silicon dioxide through a magnetron sputtering machine, and is shaped like a racket, wherein the surface of the racket is rectangular, and the handle of the racket is in the shape with the equal width, thereby forming a strip-shaped waveguide. Two isosceles triangles with the opposite top points are etched through a focused ion beam, thereby forming the bowknot-shaped antenna structure. A focused Gaussian light beam irradiates the bowknot-shaped antenna structure vertically, thereby exciting the surface plasma. The method solves a problem that the surface plasma is low in excitation efficiency in the prior art, and the excitation light covers most of the visual light till the near infrared range. The antenna is unique in broadband characteristics, and will be widely used in the next generation plasma integrated chip and a function device.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

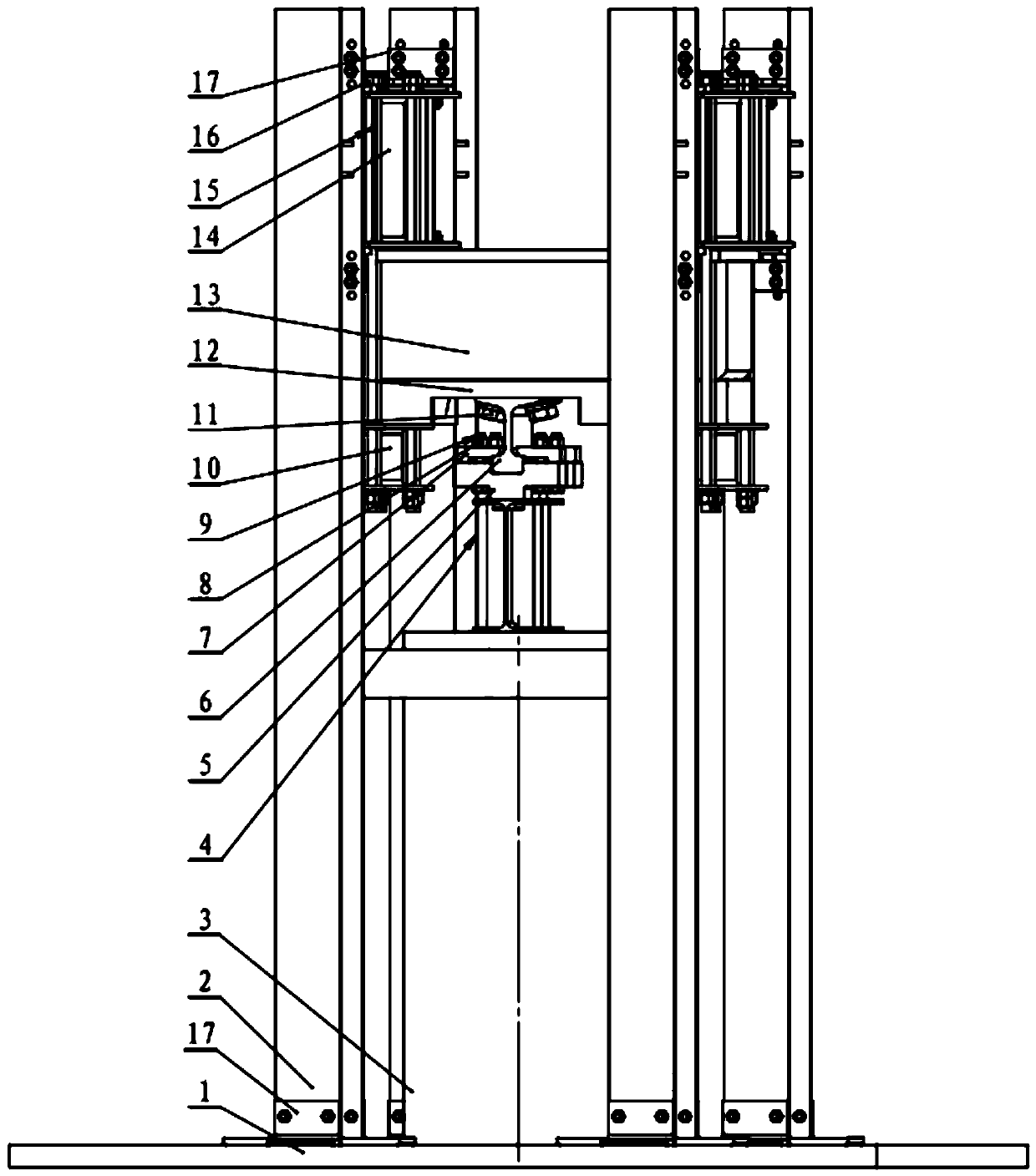

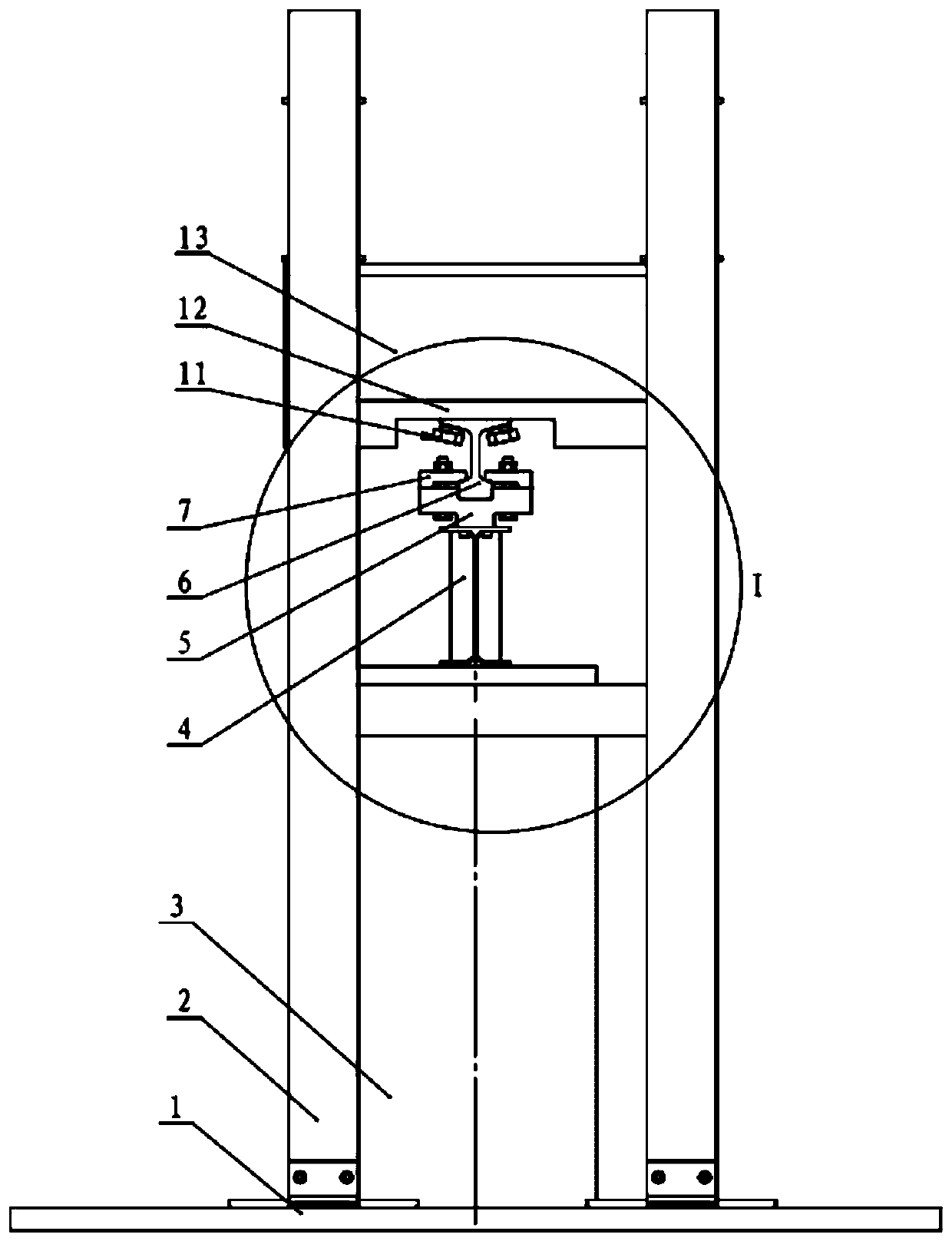

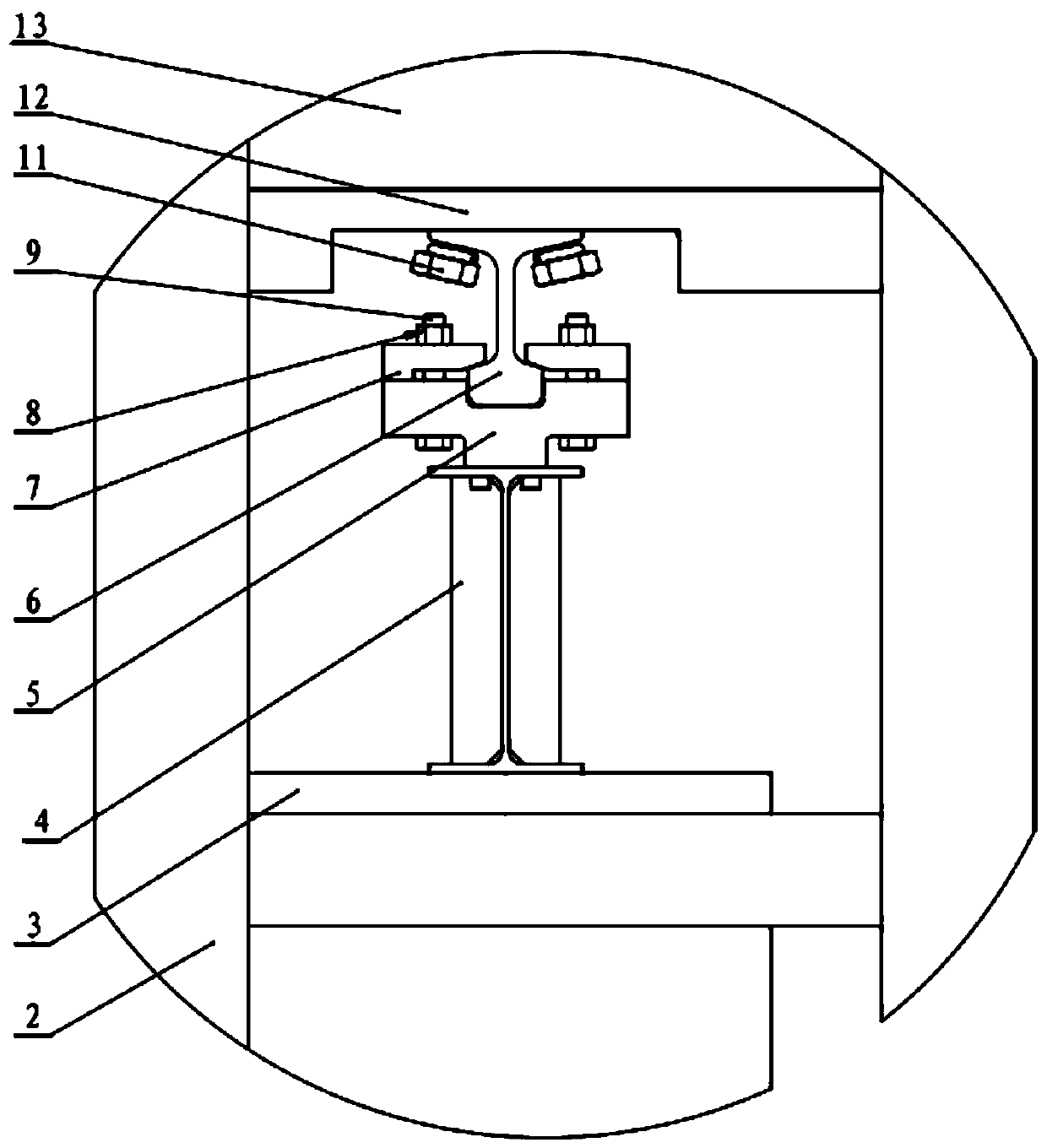

Dynamic and fatigue performance detection device and method for steel rail assembling fastener system

The invention relates to a dynamic and fatigue performance detection device and method for a steel rail assembling fastener system, and is used for carrying out dynamic mechanics behavior detection and fatigue performance detection on the steel rail assembling fastener system. The detection device comprises a bottom plate, vertical stand columns, a vibration exciter, an actuation head, a transition sliding block, a tongue plate, auxiliary beams, a box body and upper cross beams, wherein the vertical stand columns are fixedly connected with the bottom plate; the auxiliary beams and the upper cross beams are independently connected with the vertical stand columns; the box body is positioned between the auxiliary beams and the upper cross beams and is used for fixing a sleeper; the vibrationexciter is fixed on the bottom plate; the actuation head of the vibration exciter is connected with the transition sliding block; the transition sliding block is used for supporting the rail head of the steel rail; and the tongue plate is used for realizing connection between the rail head of the steel rail and the transition sliding block. By use of the detection device, in the dynamic and fatigue experiment of the assembling fastener system, the influence of reality factors, including vehicle speed, axle load, rail structure, circuit line font, rail surface state and the like, can be fully considered, broadband excitation and multi-working-condition detection are realized, and in addition, the detection device is convenient in operation and low in cost.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

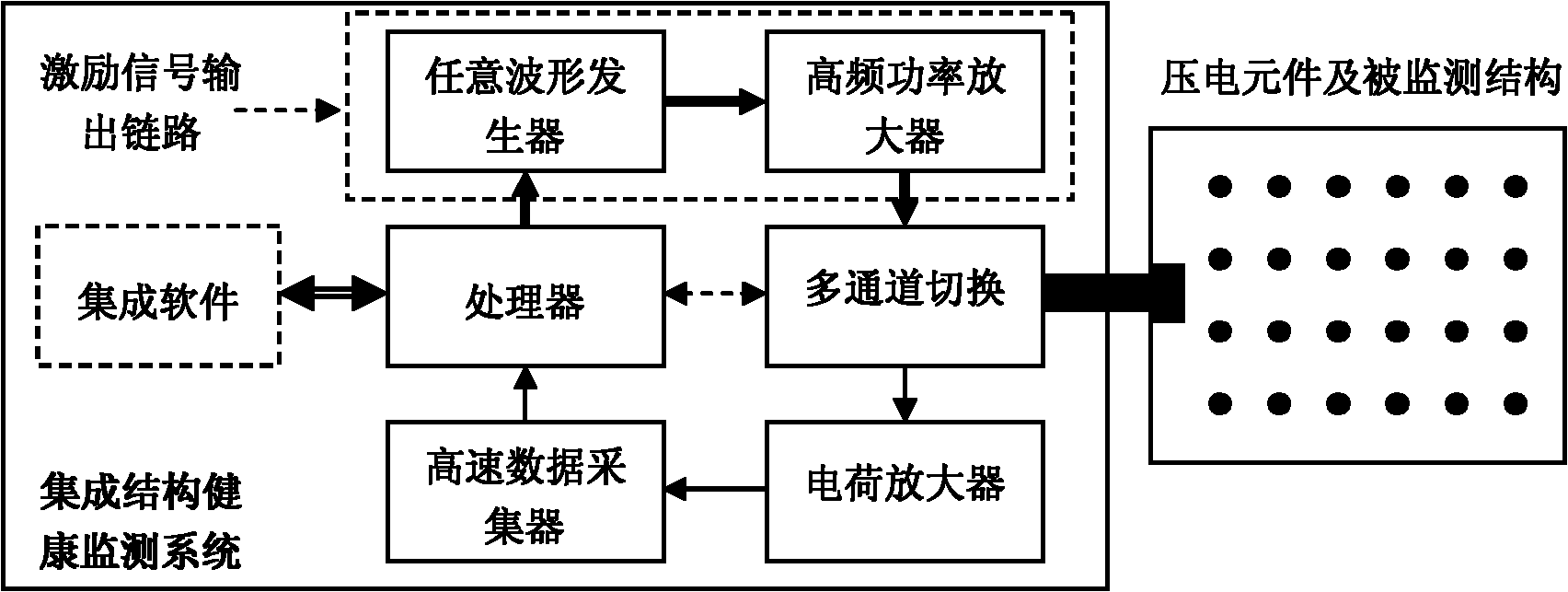

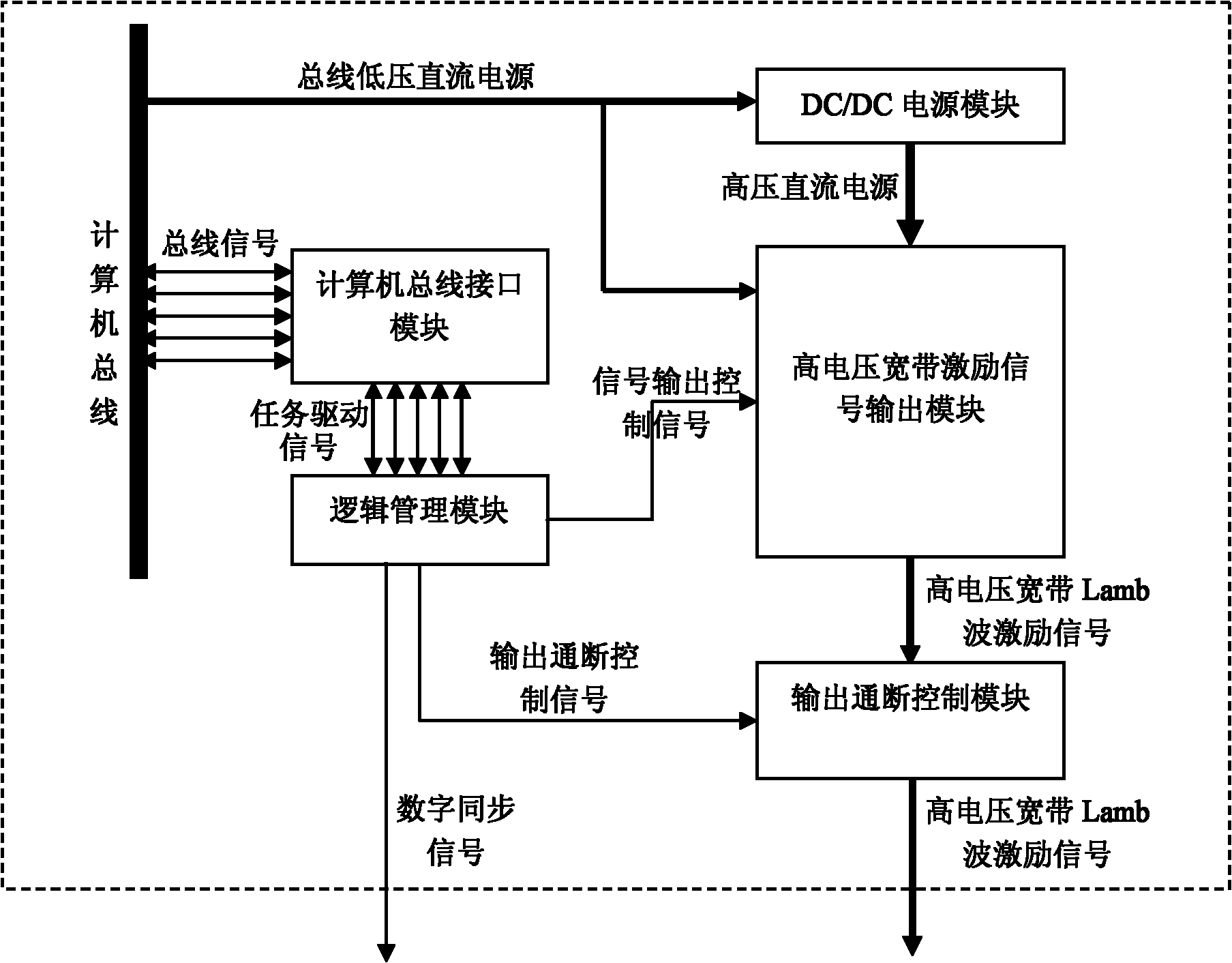

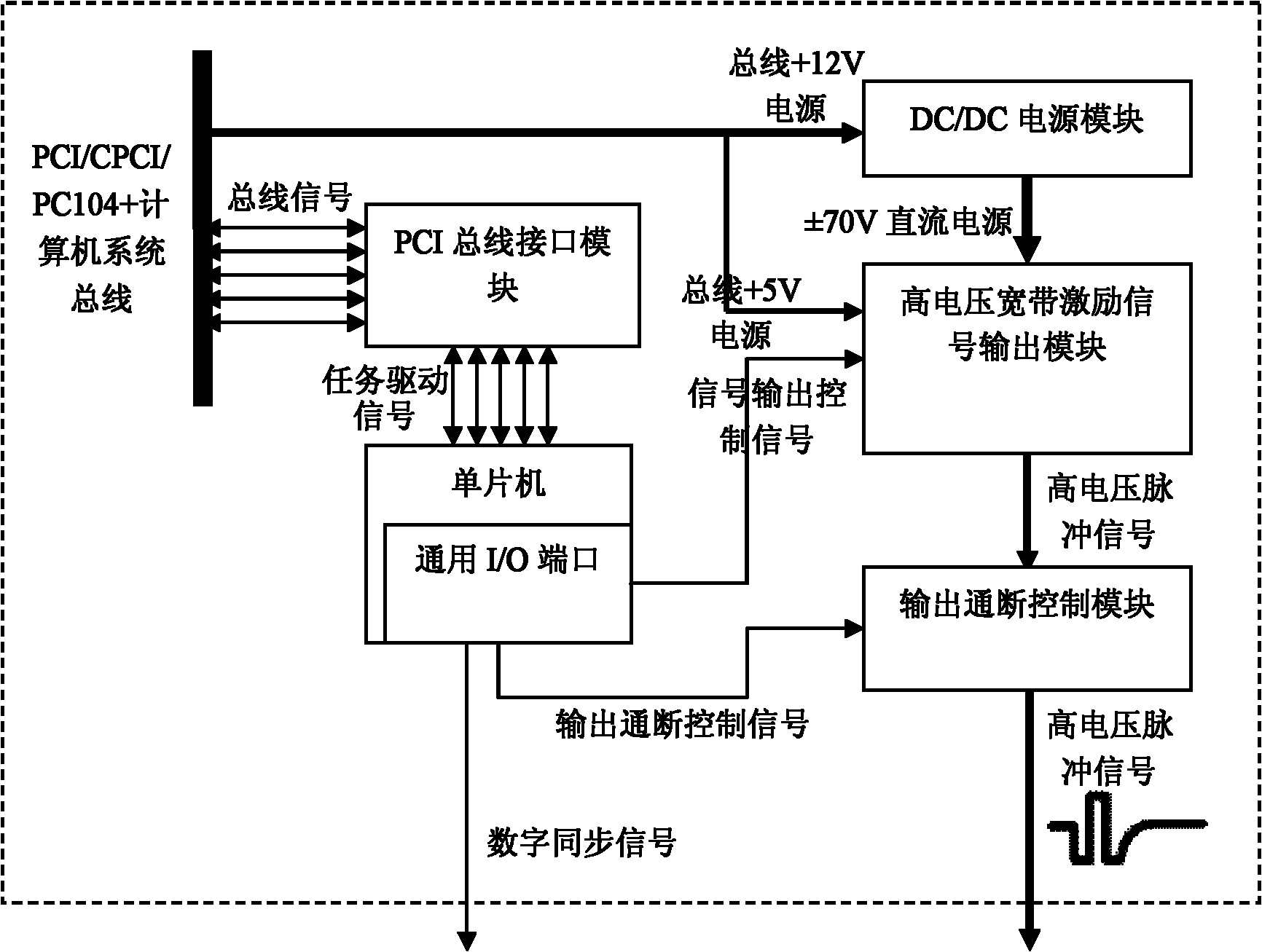

Broadband Lamb wave excitation signal generator applied to structural health monitoring

ActiveCN102156171AGuaranteed completenessEasy to implementUltrasonic/sonic/infrasonic wave generationCommunication interfaceStructure health monitoring

The invention discloses a broadband Lamb wave excitation signal generator applied to structural health monitoring, comprising a computer bus interface module, a logic management module, a high-voltage broadband excitation signal output module, a DC / DC (Direct Current / Direct Current) power supply module and an output on-off control module, wherein a computer bus communication interface module is connected with a computer bus; the logic management module is connected with the computer bus interface module; the DC / DC power supply module is subjected to voltage conversion after receiving a bus low-voltage direct current power supply; the bus low-voltage direct current power supply directly provides low-voltage power supply to the high-voltage broadband excitation signal output module; and thehigh-voltage broadband excitation signal output module generates a high-voltage broadband excitation signal to drive a piezoelectric element to work. By using the invention, cost and power consumption of an integrated structural health monitoring integrated system based on the piezoelectric element and an active Lamb wave can be reduced, reliability and integration of software and hardware of theintegrated system can be improved, and the development of a portable structural health monitoring system and the realization of an aircraft carried structure health monitoring system can be promoted.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Nitride phosphor and preparation method thereof

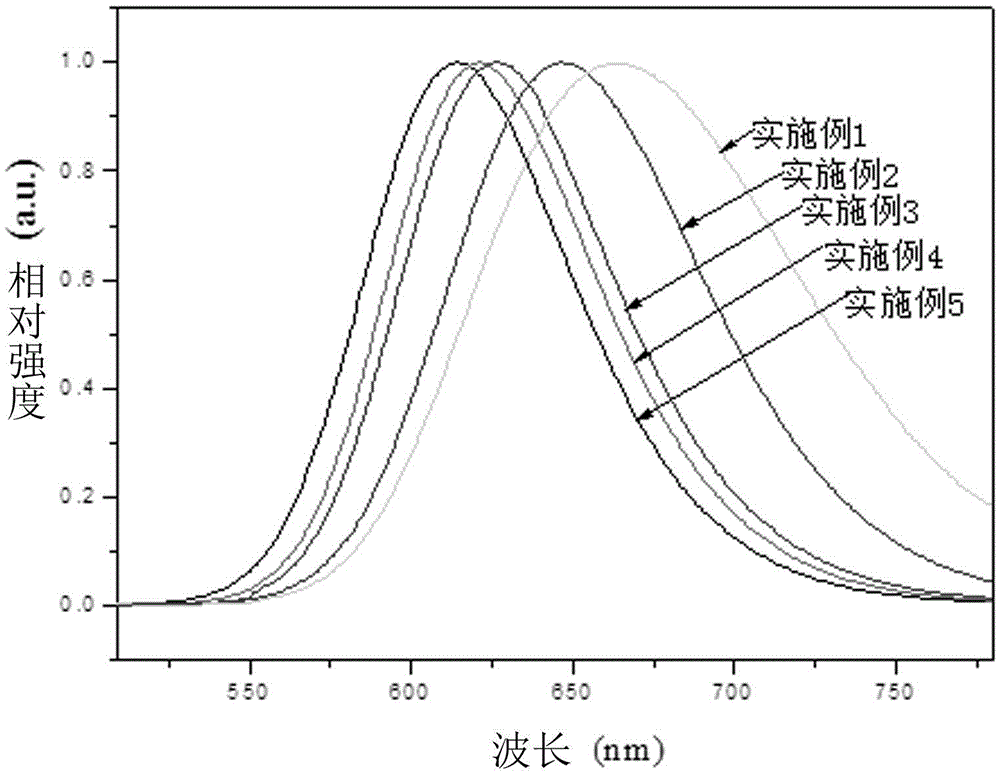

ActiveCN105255485AImprove luminous efficiencyStable chemical propertiesLuminescent compositionsBroadband excitationLuminescence

The invention discloses a nitride phosphor and a preparation method thereof. The nitride phosphor comprises the chemical composition of A1-xMpQqN3: xR, and the invention further discloses the preparation method of the nitride phosphor. The excitation spectrum of the phosphor adopts broadband excitation, the range covers almost ultraviolet and blue light, the phosphor is matched with LED chip emission spectrum and emits red light, the luminous efficiency is high, the half peak width is wide, and the chemical property is stable. The phosphor spectrum is adjustable, and the emission peak wavelength can be moved to 665 nm from 610 nm by changing the proportion of metallic elements in the A1-xMpQqN3: xR. High-purity ultrafine silicon powder can be further added to the phosphor so as to remove adsorbed oxygen contained in silicon nitride, the oxygen content of the phosphor is reduced, and the luminescence property of the phosphor is improved.

Owner:JIANGMEN KANHOO IND

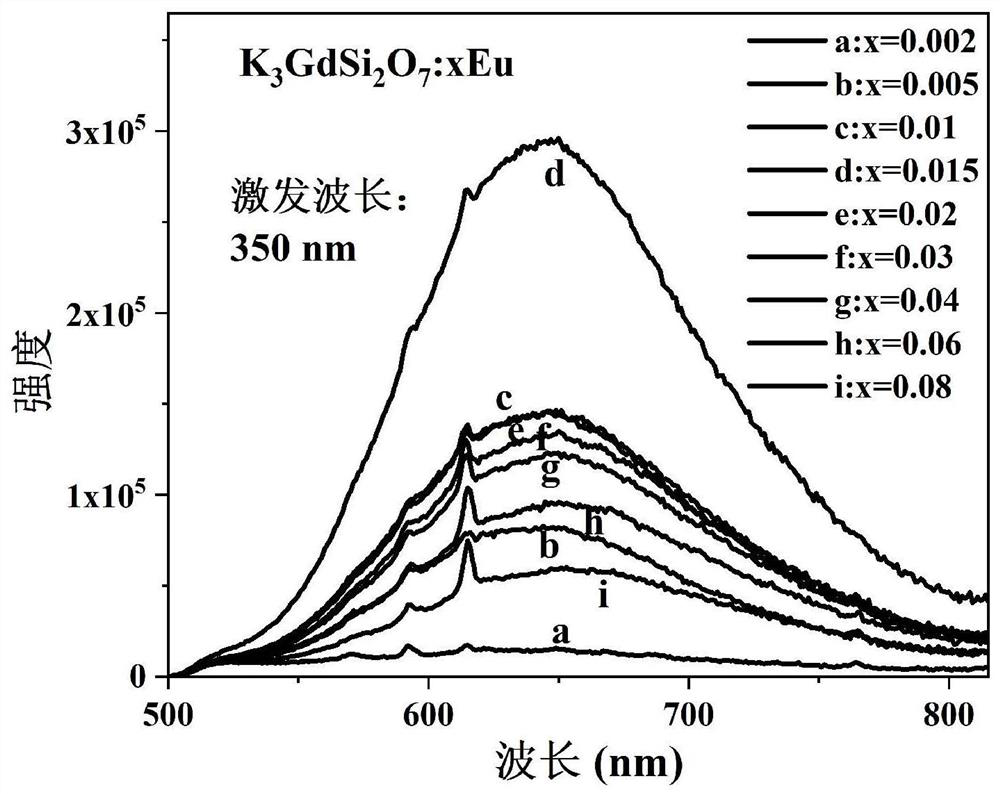

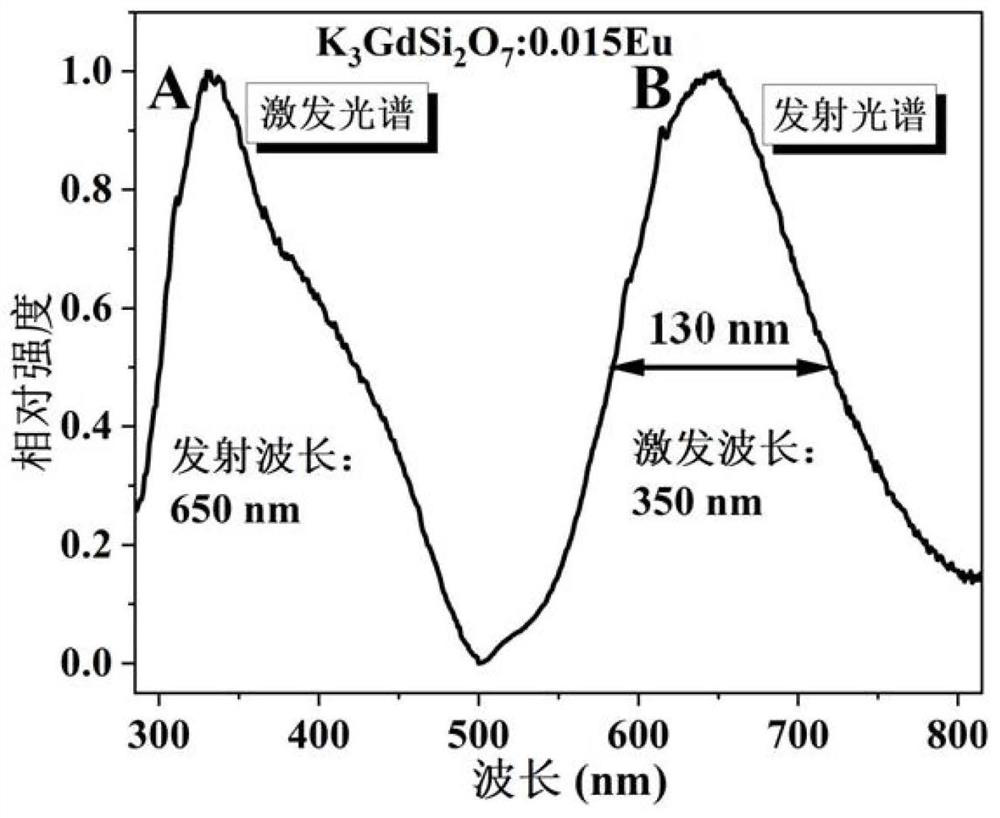

Europium-doped ultra-wideband red fluorescent material as well as preparation method and application thereof

ActiveCN113185977ABreakthrough can only emit blue lightBreakthrough green lightEnergy efficient lightingLuminescent compositionsUltra-widebandGreen-light

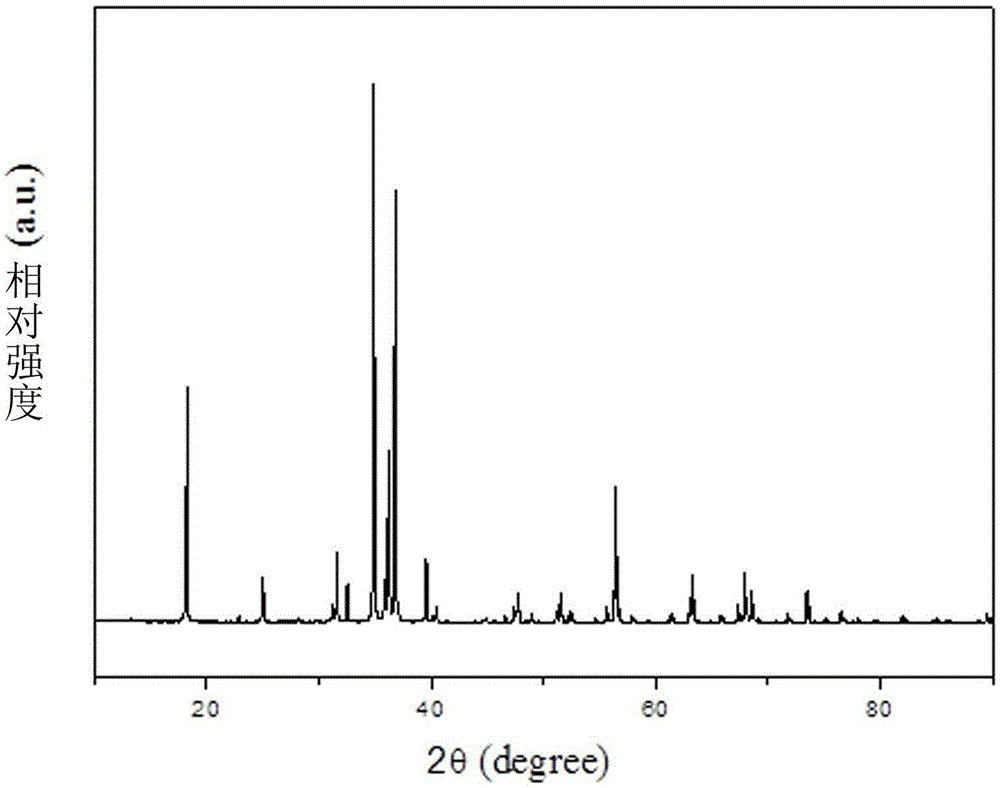

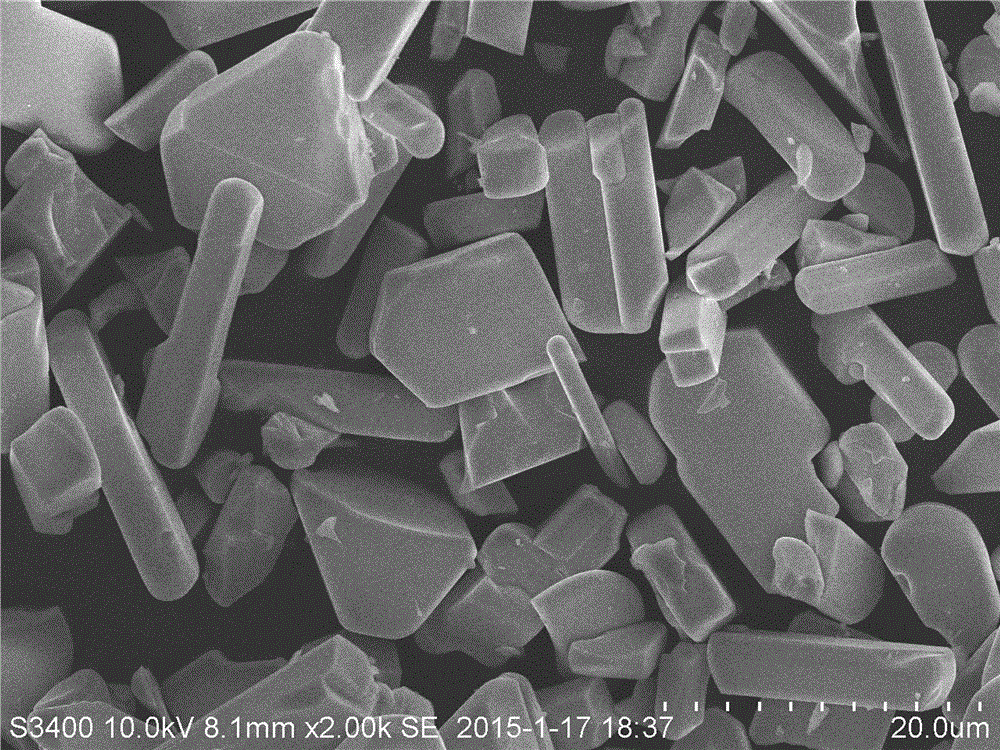

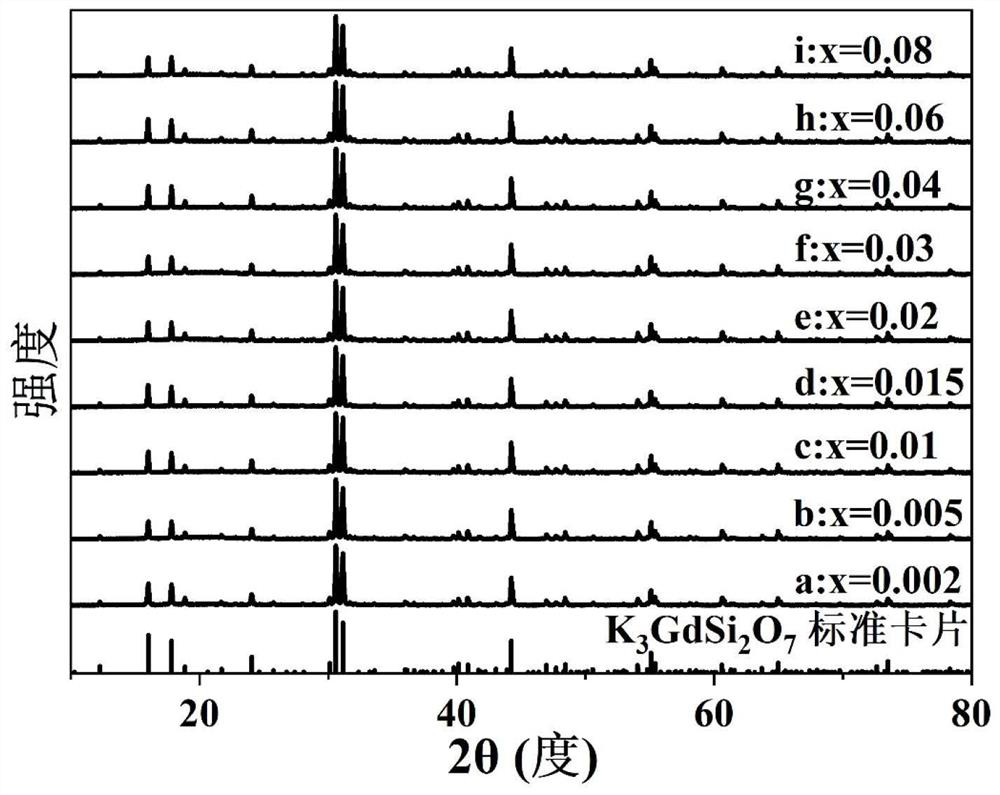

The invention discloses a europium-doped ultra-wideband red fluorescent material as well as a preparation method and application thereof. The chemical general formula of the material is K3GdSi2O7: xEu, wherein x is more than or equal to 0.002 and less than or equal to 0.2, and Eu refers to two ions coexisting in different chemical valence states of Eu < 2 + > and Eu < 3 + >. By changing the doping concentration and excitation wavelength of Eu, the chromaticity of the fluorescent powder can be controllably adjusted in a red light range. The fluorescent powder provided by the invention has a broadband excitation spectrum in ultraviolet and blue light regions (285nm to 500nm), and can be packaged on a high-brightness near ultraviolet LED chip to prepare a warm white light LED lighting device; the Eu < 2 + > fluorescent powder has ultra-wideband emission within the wavelength range of 500-815 nm, the full width at half maximum reaches up to 120 nm or above, ultra-wideband red light emission of Eu < 2 + > ions can be achieved, and the limitation that Eu < 2 + > ions in most silicate oxide fluorescent powder can only emit blue light, green light or yellow light is broken through.

Owner:HANGZHOU DIANZI UNIV

Full Spectrum White Light Emitting Devices

ActiveUS20200347999A1Good curative effectReduce light intensityPlanar light sourcesLight source combinationsBroadband excitationStandard illuminant

A full spectrum white light emitting device may include a broadband solid-state excitation source for generating broadband excitation light with a dominant wavelength from about 420 nm to about 480 nm and a full width at half maximum intensity greater than about 25 nm; and a narrowband red photoluminescence material with an emission peak wavelength from about 620 nm to about 640 nm and a full width at half maximum emission intensity of less than about 30 nm; where the device has an efficacy of at least 130 lm / W and generates white light with a CRI Ra≥90, and where over a wavelength range from about 430 nm to about 520 nm, a maximum percentage intensity deviation of the white light from the intensity of light of a black-body curve or CIE Standard Illuminant D of the same Correlated Color Temperature is less than about 50%.

Owner:BRIDGELUX INC

Mn < 4 + > activated antimonate narrow-band red fluorescent powder and preparation method thereof

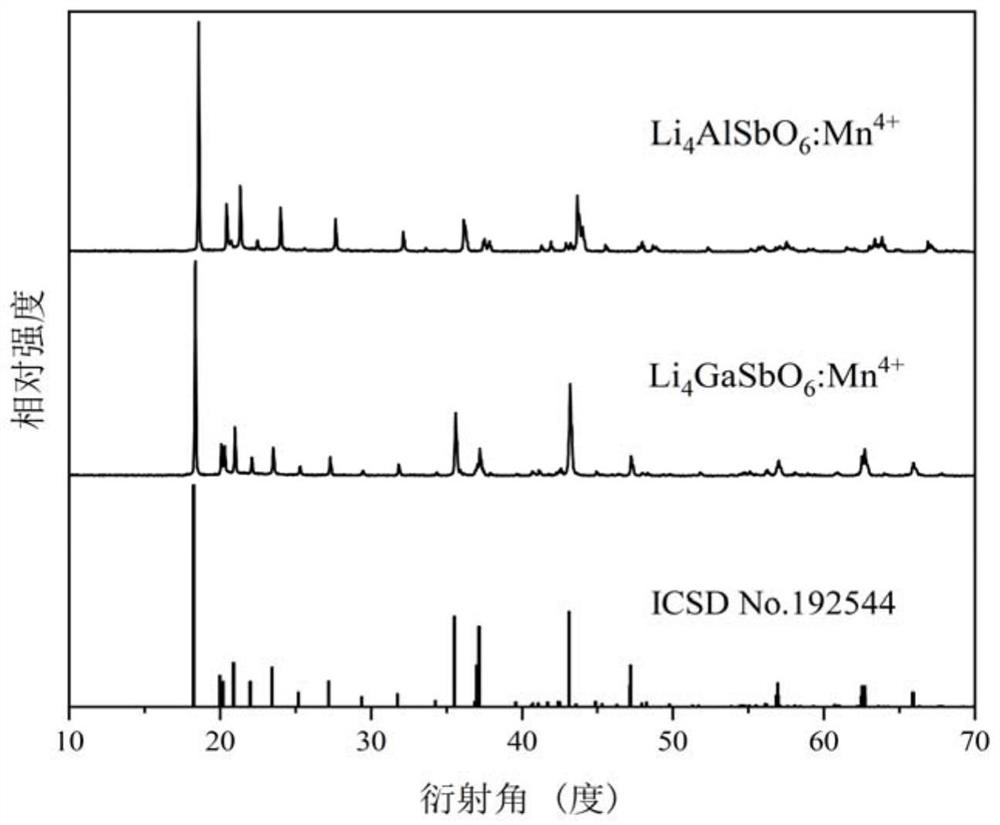

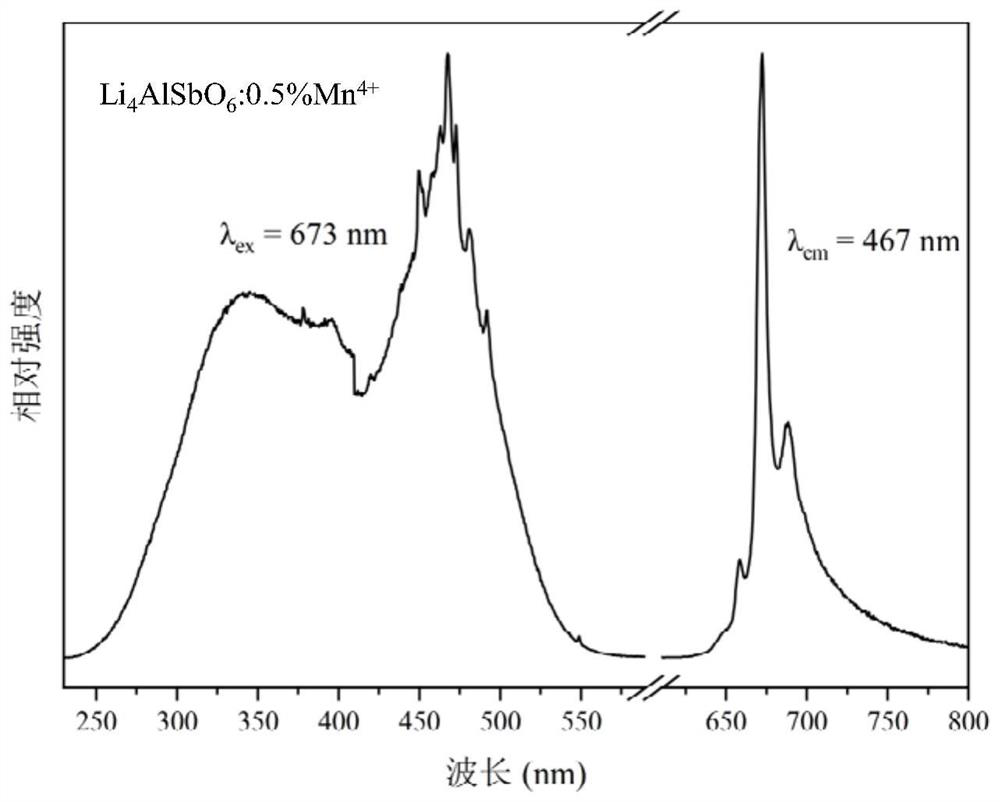

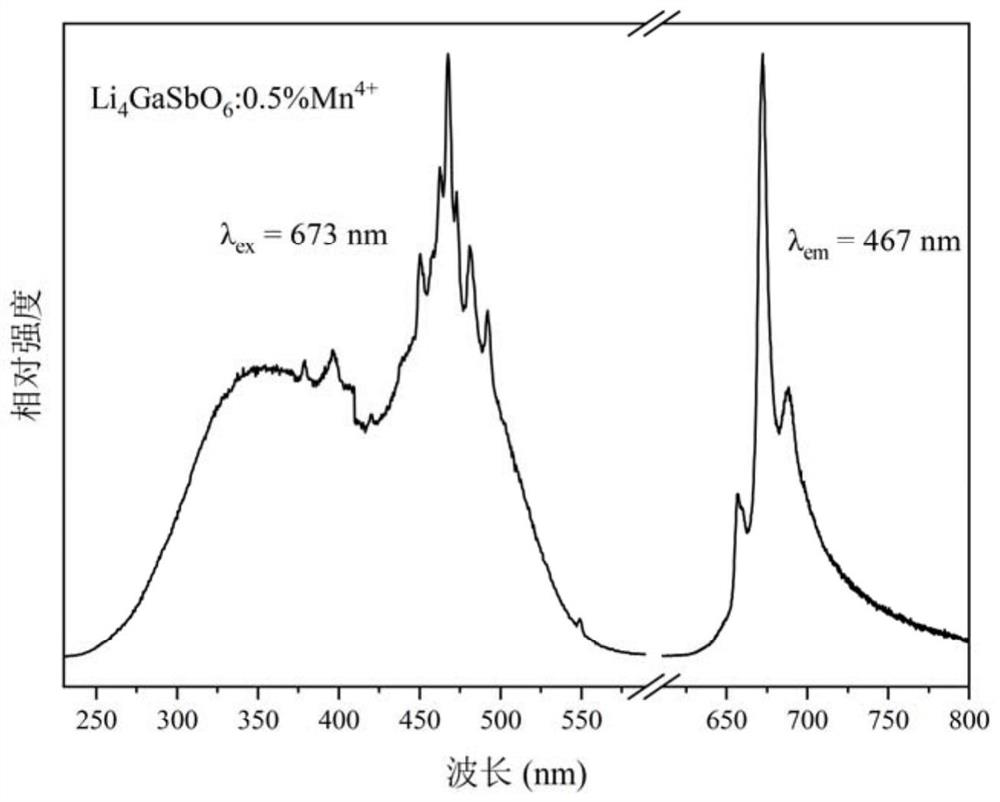

PendingCN113403074AImprove matchNarrow emission peakEnergy efficient lightingLuminescent compositionsBroadband excitationPhotochemistry

The invention discloses Mn < 4 + > activated antimonate narrow-band red fluorescent powder and a preparation method thereof. The general chemical formula of the fluorescent powder is Li<4>M<1-0. 5x>Sb<1-0. 5x>O<6>: xMn < 4 + >, M is at least one of Al and Ga, x is the molar ratio of Mn < 4 + > doping, and x is more than 0 and less than or equal to 0.03. The fluorescent powder has the characteristics of broadband excitation and narrowband emission, can be well matched with commercial near ultraviolet or blue light LED chips, and is narrow in emission peak and high in color purity. In addition, the fluorescent powder is prepared by adopting a high-temperature solid-phase synthesis method, the synthesis process is simple, the synthesis temperature is low, the chemical performance is stable, and no pollution is caused. The fluorescent powder can be widely applied to illumination of warm white light LED devices excited by near ultraviolet or blue light LED chips.

Owner:NANCHANG UNIV

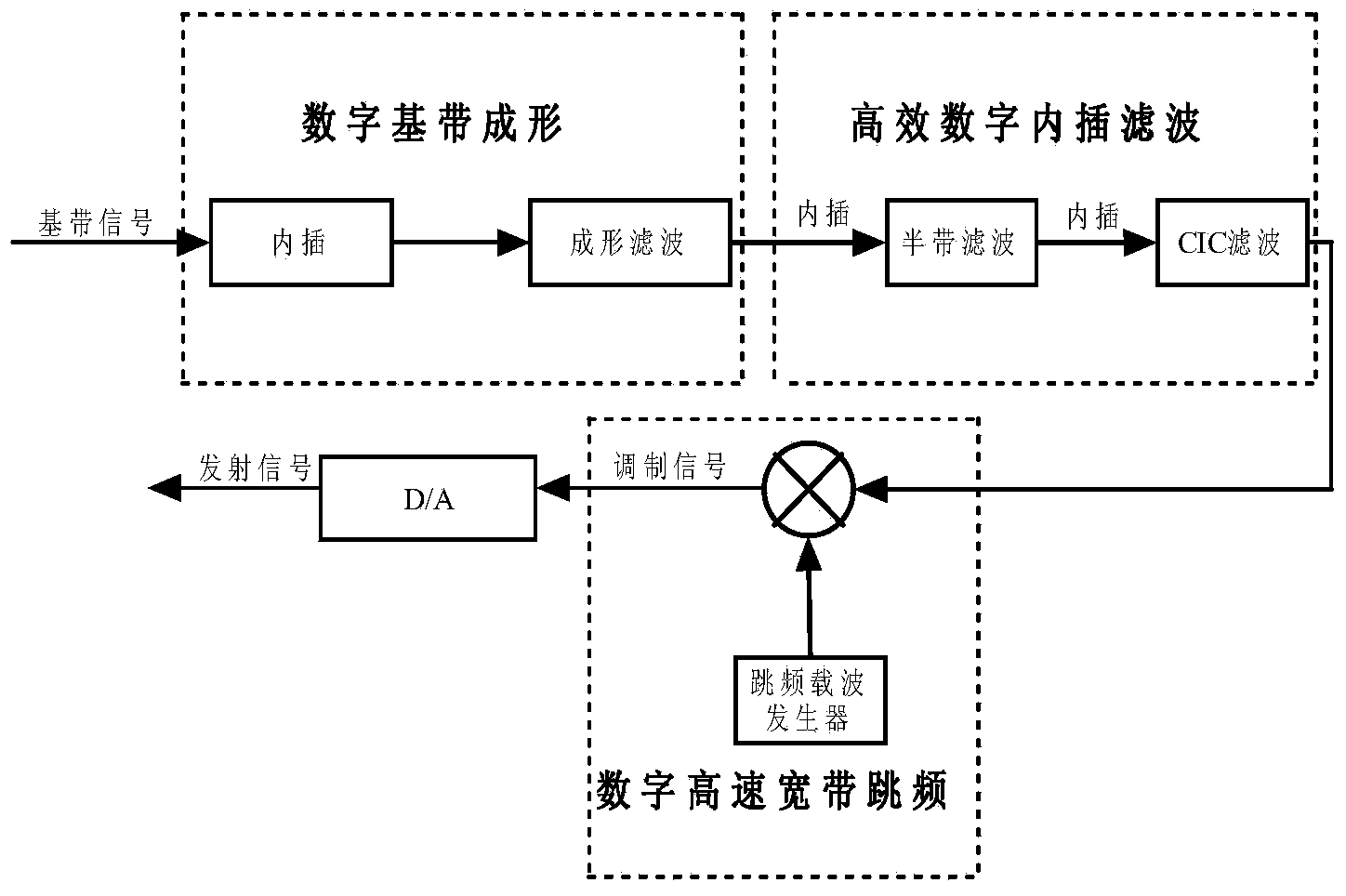

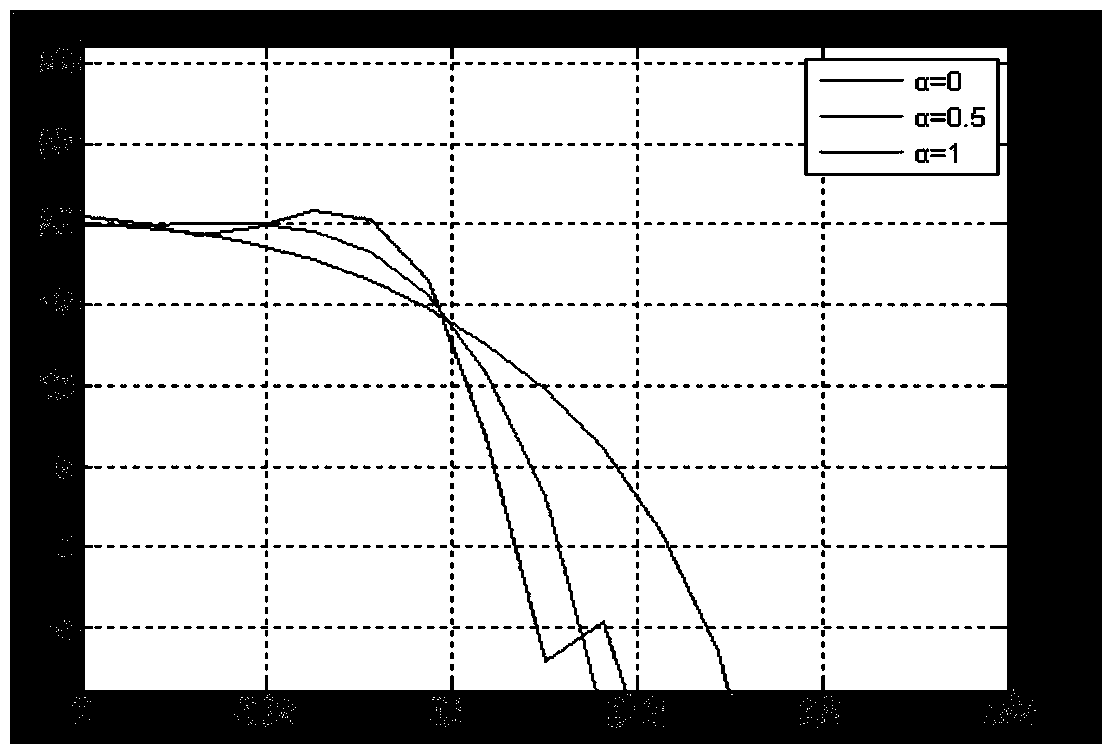

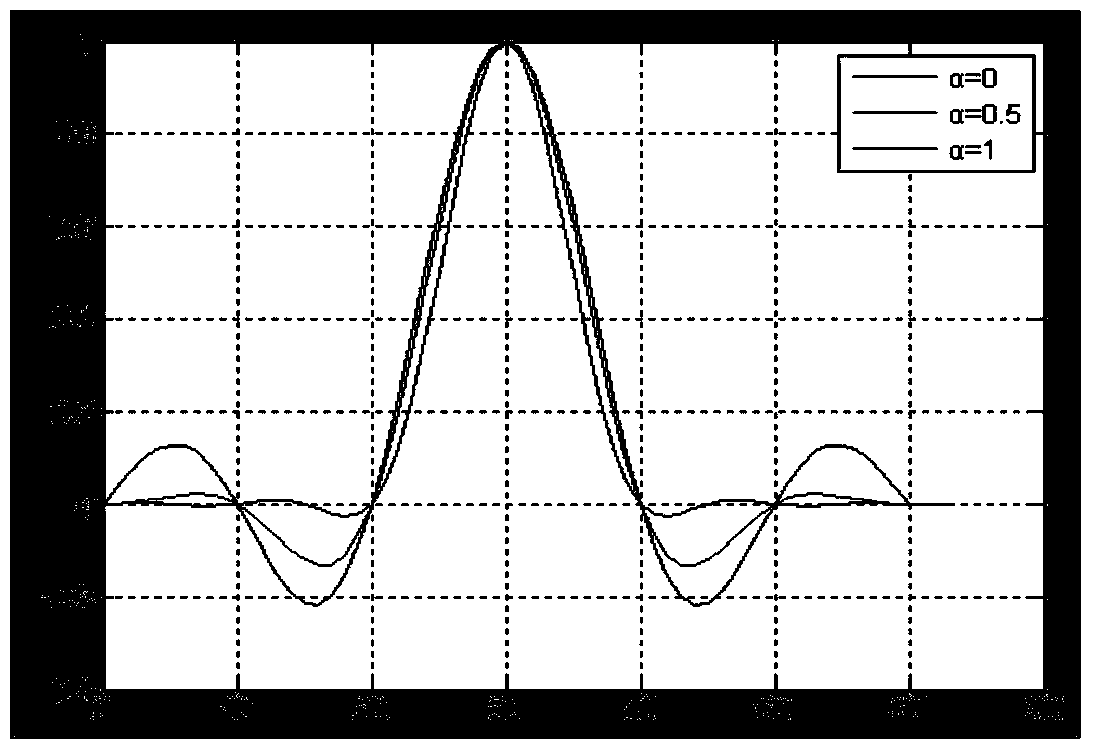

Device and method for implementing digital broadband excitation source

ActiveCN103716018ASimplified Design ArchitectureReduce design difficultyTransmitter/receiver shaping networksSingle pulse train generatorIntegratorFrequency mixer

The invention relates to the technical field of wireless communication, and discloses a device and a method for implementing a digital broadband excitation source. The device comprises a baseband forming unit, an interpolation filtering unit, a broadband frequency hopping unit and a digital-to-analog conversion unit which are sequentially connected in series, wherein the baseband forming unit, the interpolation filtering unit and the broadband frequency hopping unit are full-digital units; the baseband forming unit comprises a baseband interpolation pulse forming filter; the interpolation filtering unit comprises a half-band filter and a CIC (cascade integrator comb) filter which are connected in series; the broadband frequency hopping unit comprises a frequency mixer and a frequency hopping carrier generator which is coupled to the input end of the frequency mixer. According to the device and the method, the design architecture of the whole transmission channel is greatly simplified, the design difficulty and the design cost are reduced, and the reliability, flexibility and stability of a system are improved. A powerful technical support is provided for engineering implementation; meanwhile, a design scheme and an implementation way, which are more efficient and more practical, are provided for equipment and the system with requirements.

Owner:SICHUAN JIUZHOU ELECTRIC GROUP

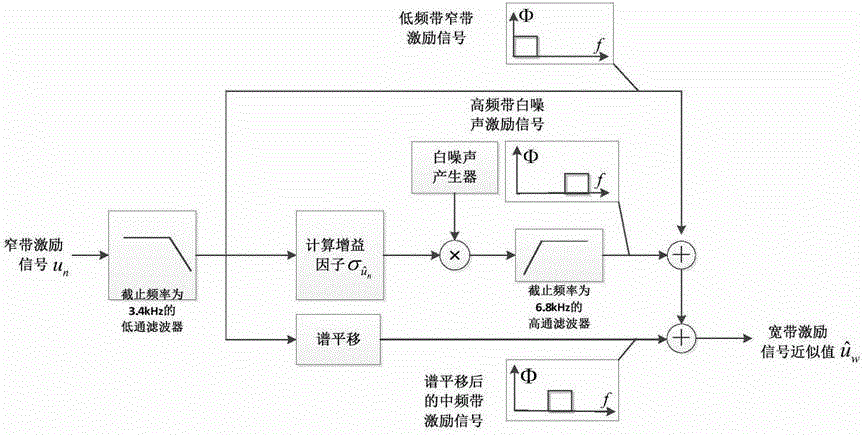

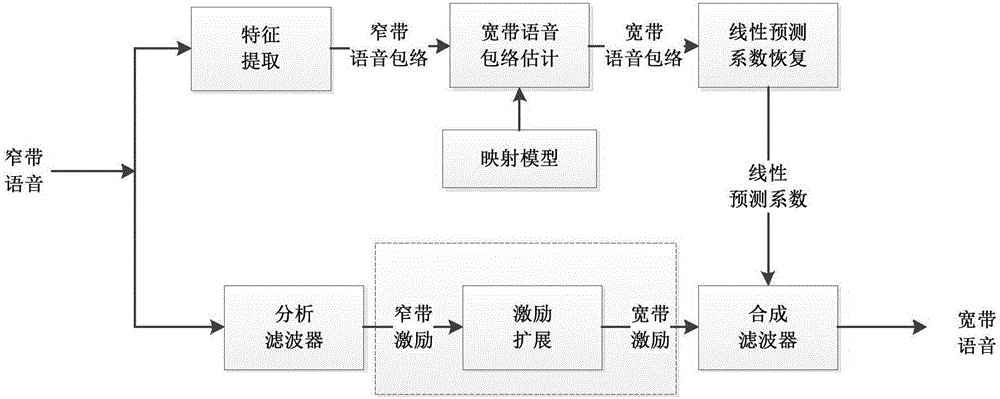

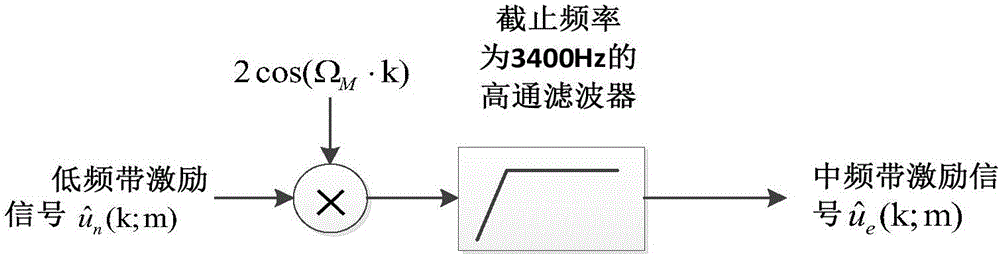

Broadband excitation signal synthesis method based on segmented expansion

InactiveCN105047201AHarmonic structure preservedReduce operational complexitySpeech analysisLow-pass filterBroadband excitation

The invention provides a broadband excitation signal synthesis method based on segmented expansion. According to the method, two methods of narrow-band excitation spectrum translation and white noise excitation are combined, narrow-band excitation signals pass through a low-pass filter, first frequency-band excitation signals are outputted, after the translation of the first frequency-band excitation signal spectrum and high-pass filtering of the first frequency-band excitation signals are performed, second frequency-band excitation signals are obtained, white noise via energy adjustment is multiplexed by gain factors to obtain third frequency-band excitation signals, and finally, the first frequency-band excitation signals, the second frequency-band excitation signals, and the third frequency-band excitation signals are synthesized to form complete broadband excitation signals. According to the method, the harmonic structure of the excitation signals can be well reserved, too many artificial harmonic waves are not introduced, the operation complexity of the algorism is not high, the realization is easy, the performance of the conventional bandwidth expansion technology is improved, and the communication quality of narrow-band voice is improved.

Owner:SYSU CMU SHUNDE INT JOINT RES INST +1

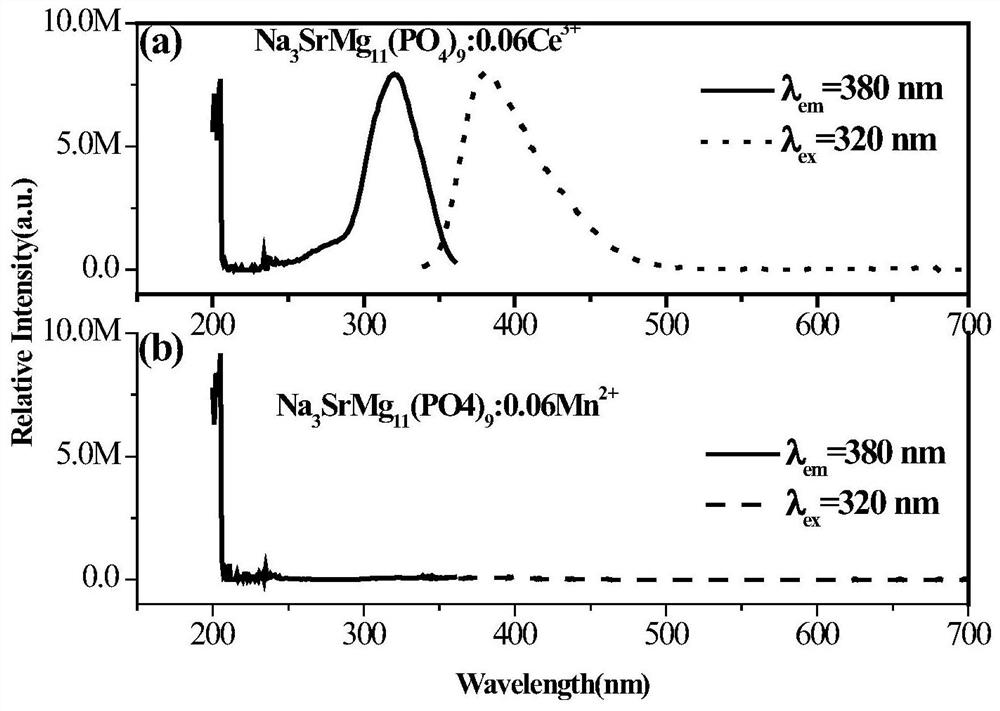

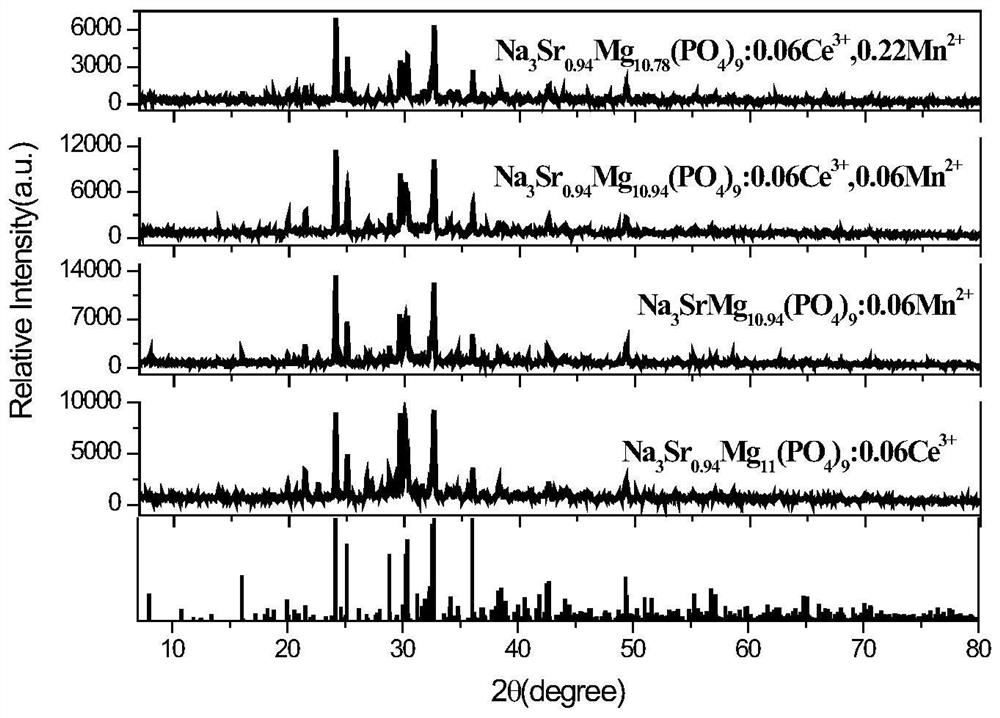

Synthesis method of broadband excited phosphate red phosphor

PendingCN111978960AOvercoming poor color renderingOvercoming the defect of narrow excitation wavelengthLuminescent compositionsActivated charcoal powderPhosphate

The invention provides a synthesis method of a broadband excited phosphate red phosphor. The method comprises the steps of firstly weighing corresponding oxide, carbonate and phosphate, mixing the weighed materials, grinding the materials in an agate mortar evenly and then putting the powder into a corundum crucible; putting the corundum crucible containing samples into a large crucible containingactivated carbon powder, covering the large crucible with a lid, putting the large crucible and the lid into a drying oven, and carrying out baking at 100-200 DEG C for 2 hours; and putting the largecrucible into a muffle furnace while the large crucible is hot, carrying out roasting at 900-1,000 DEG C for 7-10 hours, carrying out natural cooling to room temperature, then taking out a product and grinding the product evenly to obtain white powder. The broadband excited phosphate red phosphor prepared by the method overcomes the defects that a traditional phosphor is poor in color rendering property and small in excitation wavelength; and by using a method of codoping Ce<3+> / Mn<2+>, a phosphate matrix red phosphor with good color rendering is prepared within a wide ultraviolet excitationrange through energy transfer between ions.

Owner:HEZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com