Inbuilt damping device for hollow shaft

A technology of vibration damping device and hollow shaft, which is applied in the direction of spring/shock absorber, vibration suppression adjustment, rotation vibration suppression, etc., can solve the problem of occupying external space, and achieve space-saving, cost-saving, and obvious effects of vibration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

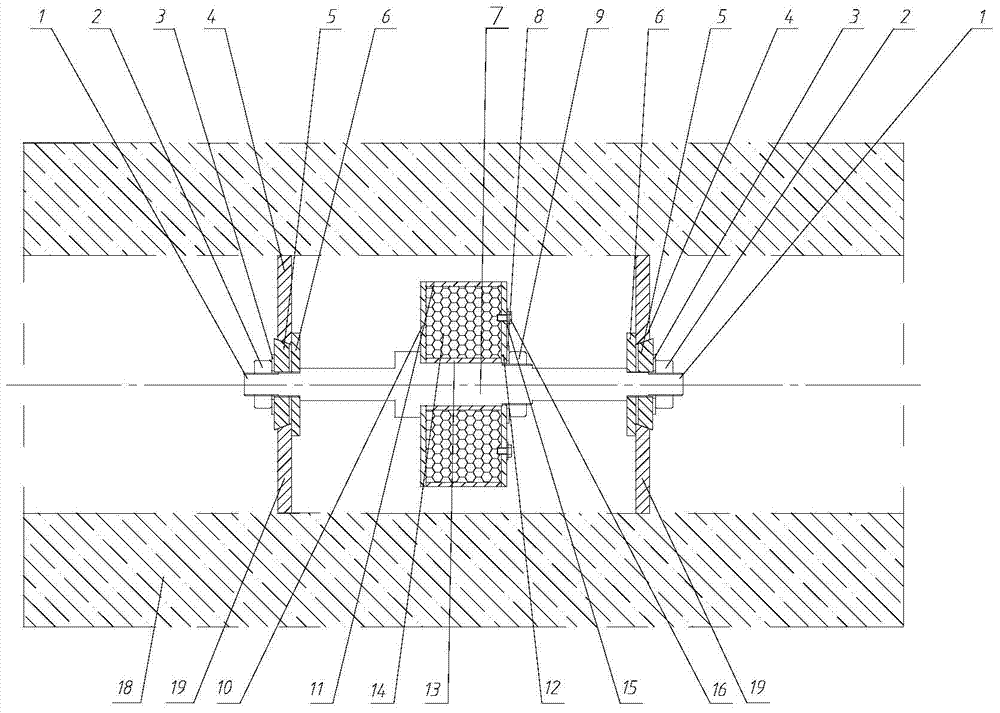

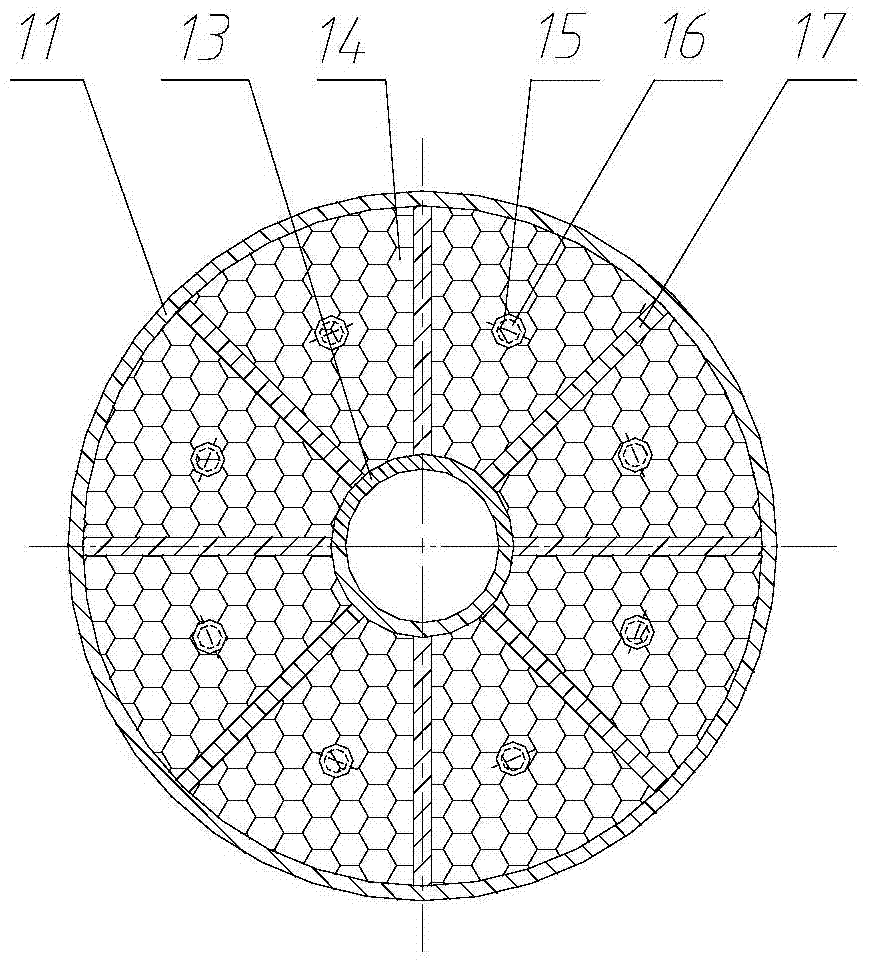

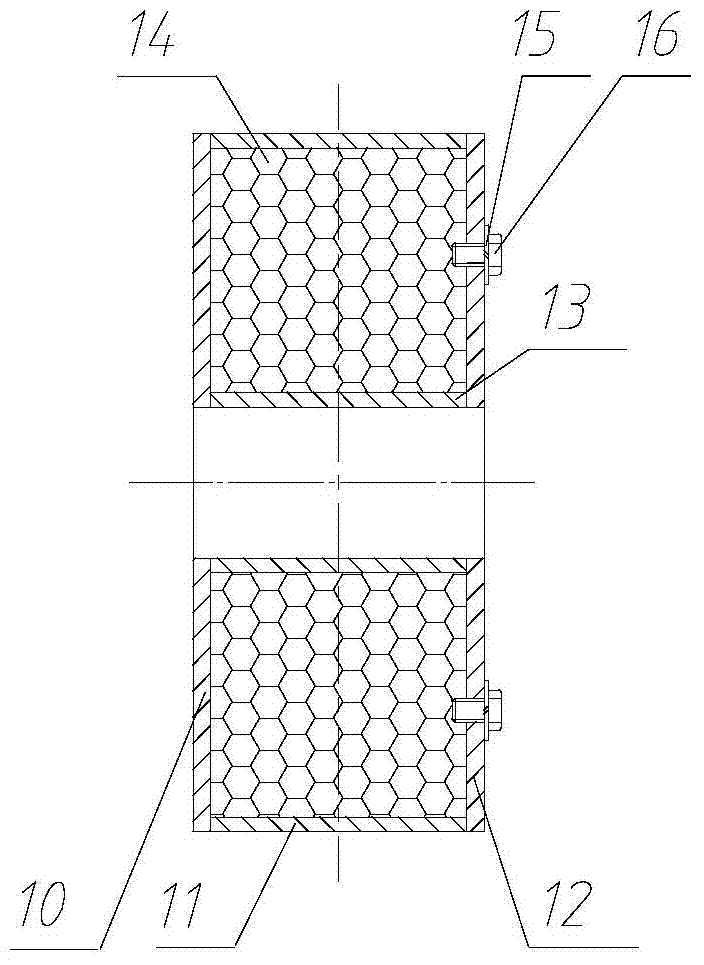

[0030] like figure 1 , 2 , 3, 4, 5, and 7, a hollow shaft built-in vibration damping device includes an elastic shaft 1 placed in the hollow shaft, and the elastic shaft 1 is a three-stage stepped shaft structure, wherein one end of the middle section is along the The axes are three diameters of large, medium and small in turn, and the two ends and one section are respectively from the end faces of the two ends of the middle section and are smaller than the small diameter of the middle section along the axis to the respective ends. The sections are all provided with threads; the middle diameter of the middle section is covered with a cylindrical inertial wheel 7 filled with damping particles 14 and a gasket 2 8, and the cylindrical inertial wheel 7 is fastened by connecting the nut 29 with the thread, The middle diameters of the two ends are respectively fitted with stoppers 6, pushers 5 and spacers 3, wherein the pushers 5 are truncated conical bodies with a central hole, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com