Mn < 4 + > activated antimonate narrow-band red fluorescent powder and preparation method thereof

A red phosphor, antimonate technology, applied in chemical instruments and methods, luminescent materials, electrical components, etc., to achieve the effects of simple preparation process, narrow emission peak, and low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] According to Li 4 al 1-0.5x Sb 1-0.5x o 6 :0.3%Mn 4+ The stoichiometric ratio, accurately weighed raw materials: 1.4778 grams of lithium carbonate, 0.5090 grams of alumina, 1.6152 grams of antimony pentoxide and 0.0034 grams of manganese carbonate. After fully grinding these raw materials and an appropriate amount of ethanol solution in an agate mortar, the obtained mixture was put into a muffle furnace and heated to 950° C. for 7 hours in an air atmosphere for calcination. After calcination, after cooling down to room temperature naturally, take it out and grind it evenly to get Li 4 AlSbO 6 :0.3%Mn 4+ red phosphor.

Embodiment 2

[0034] According to Li 4 al 1-0.5x Sb 1-0.5x o 6 :0.5%Mn 4+ According to the stoichiometric ratio, the raw materials were accurately weighed: 1.4778 grams of lithium carbonate, 0.5085 grams of alumina, 1.6136 grams of antimony pentoxide and 0.0057 grams of manganese carbonate. After fully grinding these raw materials and an appropriate amount of ethanol solution in an agate mortar, the obtained mixture was put into a muffle furnace and heated to 1000° C. for 6 hours in an air atmosphere for calcination. After calcination, after cooling down to room temperature naturally, take it out and grind it evenly to get Li 4 AlSbO 6 :0.5%Mn 4+ red phosphor.

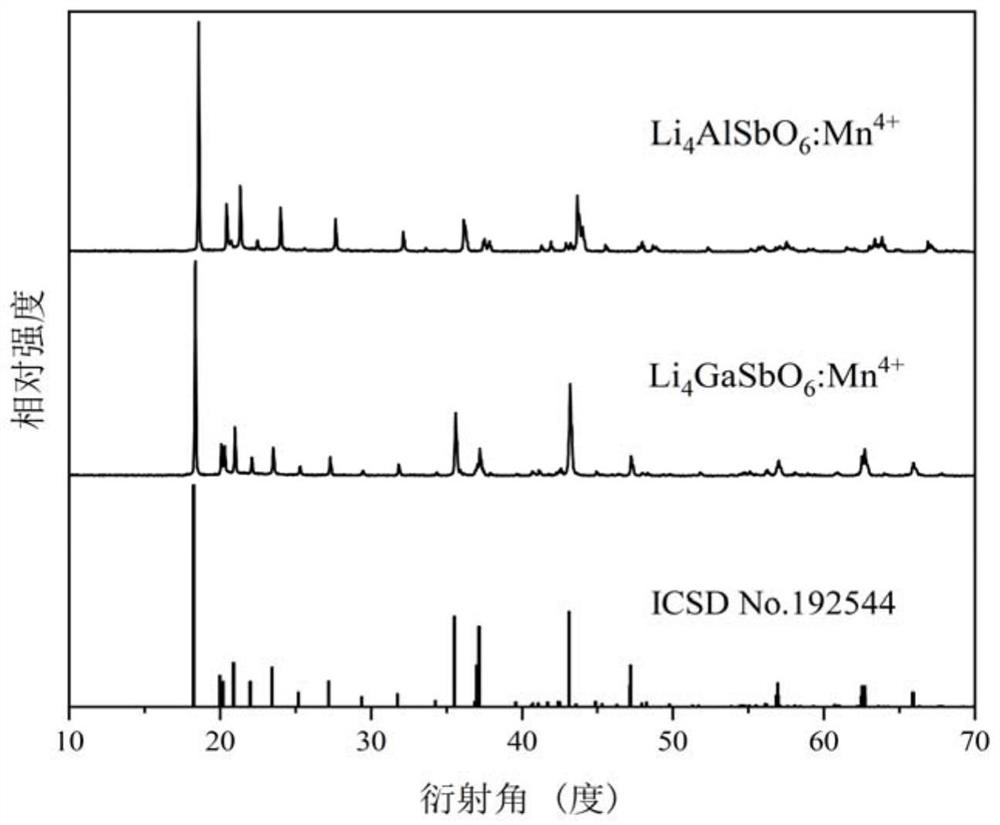

[0035] See attached figure 1 , which is the X-ray powder diffraction pattern of the sample prepared according to the technical scheme of this embodiment, and the test results show that the crystallinity of the prepared sample is relatively good, and it is a single-phase material.

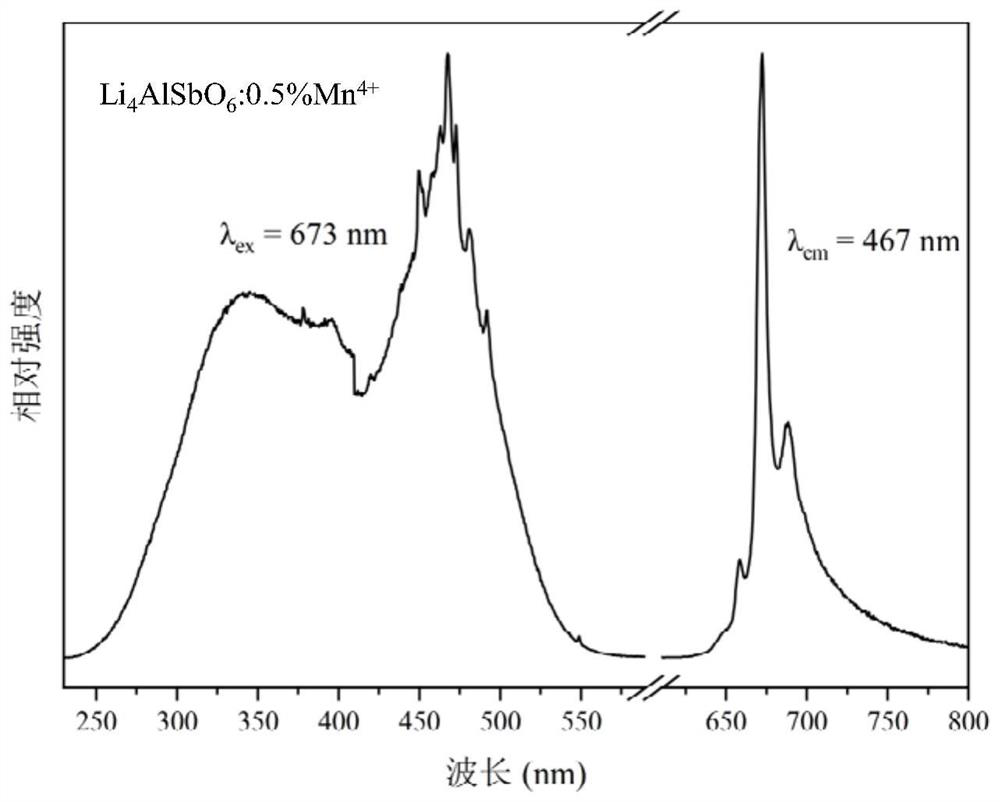

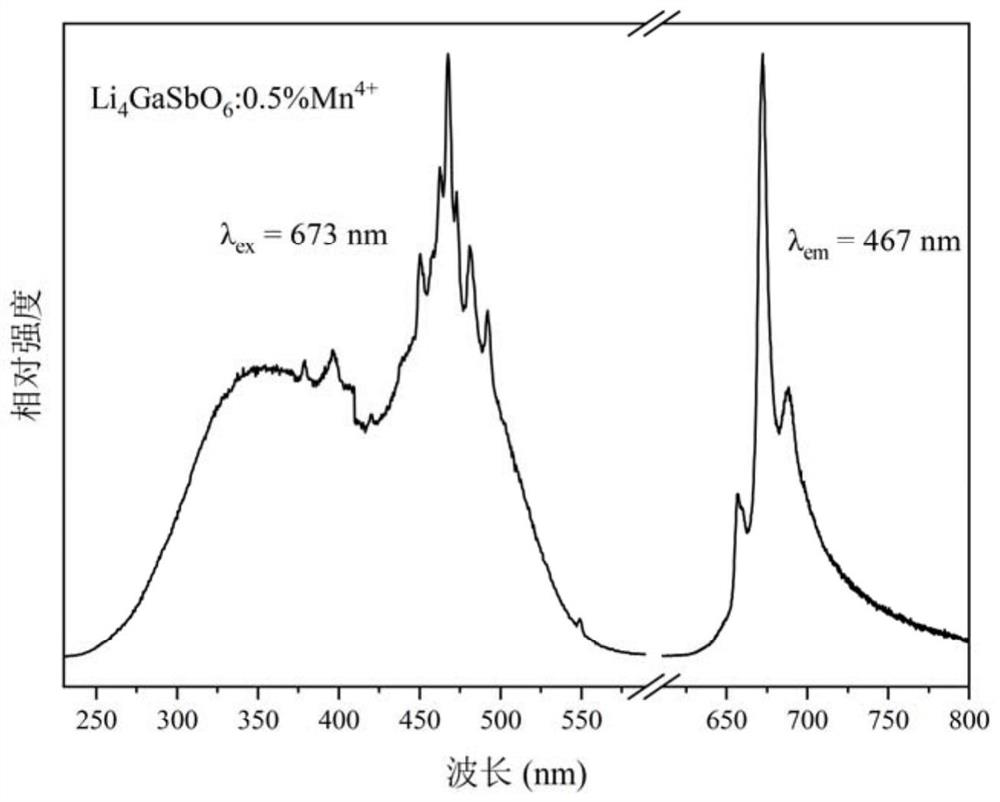

[0036] See attached figure 2, which is t...

Embodiment 3

[0039] According to Li 4 Al 1-0.5x Sb 1-0.5x o 6 :0.7%Mn 4+ The stoichiometric ratio, accurately weighed raw materials: 1.4778 grams of lithium carbonate, 0.5080 grams of alumina, 1.6119 grams of antimony pentoxide and 0.0080 grams of manganese carbonate. After fully grinding these raw materials and an appropriate amount of ethanol solution in an agate mortar, the obtained mixture was put into a muffle furnace and heated to 1050° C. for 5 hours in an air atmosphere for calcination. After calcination, after cooling down to room temperature naturally, take it out and grind it evenly to get Li 4 AlSbO 6 :0.7%Mn 4+ red phosphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com