Synthesis method of broadband excited phosphate red phosphor

A technology of red phosphor and broadband excitation, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of single excitation wavelength, easy drift of light color, short excitation range, etc., and achieve the effect of improving emission intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

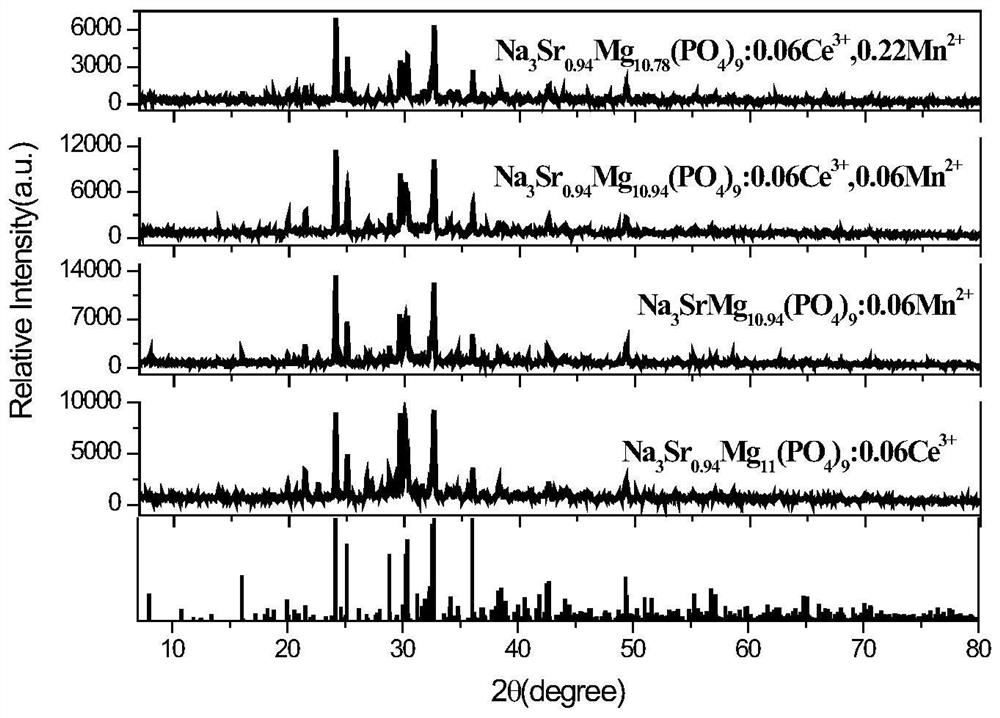

[0019] Weigh the medicines according to the raw material ratio in Table 1. Mix the medicines evenly in an agate mortar for 30 minutes; put the evenly ground sample into the corundum crucible, and insert the crucible with the sample into the one containing the activated carbon powder. In the large crucible, cover the lid, put the large crucible and the crucible lid in the oven, bake at 100~200℃ for 2 hours, then put the big crucible into the muffle furnace while it is hot, and bake at the temperature of 900~1000℃ for 7~ After 10 hours, naturally cooled to room temperature, take it out and grind uniformly to obtain a white powder. For the sake of comparison, the temperature in Examples 1 to 4 is unified at 920°C, and the reaction time is 10 hours.) After cooling to room temperature, take it out and grind uniformly to obtain a white powder.

[0020] Table 1 Raw material ratio

[0021]

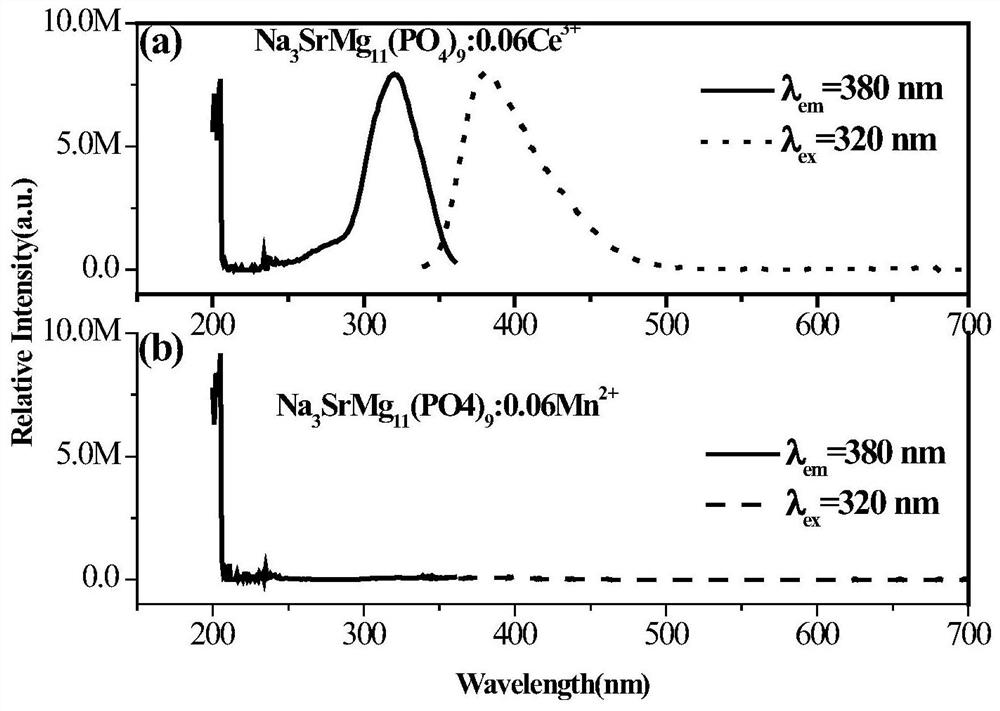

[0022] Place the samples of Examples 1 and 2 in the solid sample tank of the FLS920 transient / stea...

Embodiment 5~12

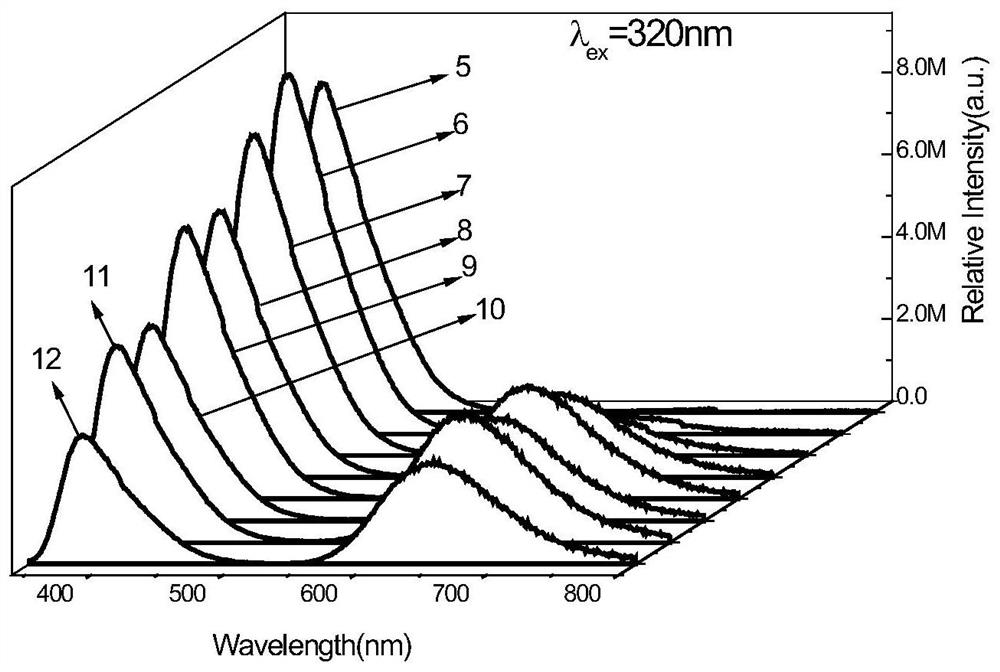

[0026] Weigh the medicines according to the raw material ratio in Table 2. Mix the medicines evenly in an agate mortar for 30 minutes; put the evenly ground sample into the corundum crucible, and insert the crucible with the sample into the one containing the activated carbon powder. In the large crucible, cover the lid, put the large crucible and the lid of the crucible in the oven, bake at 100~200℃ for 2 hours, then put the big crucible in the muffle furnace while it is hot, and bake at the temperature of 900~1000℃ for 7~ After 10 hours, naturally cooled to room temperature, take it out and grind uniformly to obtain white powder. For the convenience of comparison, the temperature in Examples 5-12 is uniformly 920°C, and the reaction time is 10 hours) After cooling to room temperature, take it out and grind uniformly to obtain broadband excited phosphate red phosphor.

[0027] Table 2 Raw material ratio

[0028]

[0029] The prepared Ce 3+ ,Mn 2+ Co-doped phosphors, the emission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com