Alkaline earth molybdate rare earth light conversion material and preparation method thereof

A technology of earth molybdate and salts, which is applied in the field of alkaline earth molybdate rare earth light conversion materials and its preparation, can solve the problems of weak absorption strength, etc., achieve the effects of easy operation, simple preparation method, and improved photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Sr 2 (Ca 1.01 Yb 3+ 0.02 Li + 0.02 ) MoO 6 Preparation of Rare Earth Light Conversion Materials

[0018] Strontium carbonate (SrCO 3 ) 0.5905g, calcium carbonate (CaCO 3 ) 0.2025g, molybdenum trioxide (MoO 3 ) 0.2879g, ytterbium trioxide (Yb 2 o 3 ) 0.0079g, charge compensator lithium carbonate (Li 2 CO 3 ) 0.0016g, after grinding and mixing the above-mentioned raw materials in an agate mortar, put them into a corundum crucible, first burn them in the air at 500°C for 14 hours, then take them out and grind them, then put them into a corundum crucible, and then put them in a corundum crucible Sinter in the air at 800°C for 14 hours, then take it out and grind it, put it into a corundum crucible, and finally sinter it in the air at 1000°C for 28 hours, cool to room temperature, take it out and grind it thoroughly to get the sample.

Embodiment 2

[0019] Example 2: Sr 2 (Ca 0.93 Yb 3+ 0.06 Li + 0.06 ) MoO 6 Preparation of Rare Earth Light Conversion Materials

[0020] Strontium carbonate (SrCO 3 ) 0.5909g, calcium carbonate (CaCO 3 ) 0.1862g, molybdenum trioxide (MoO 3 ) 0.2882g, ytterbium trioxide (Yb 2 o 3 ) 0.0238g, charge compensator lithium carbonate (Li 2 CO 3 ) 0.0045g, after grinding and mixing the above-mentioned raw materials in an agate mortar, put them into a corundum crucible, first burn them in the air at 600°C for 12 hours, then take them out and grind them, then put them into a corundum crucible, and then put them in a corundum crucible Sinter in the air at 900°C for 12 hours, then take it out and grind it, put it into a corundum crucible, and finally sinter it in the air at 1100°C for 24 hours, cool to room temperature, take it out and grind it thoroughly to get the sample.

Embodiment 3

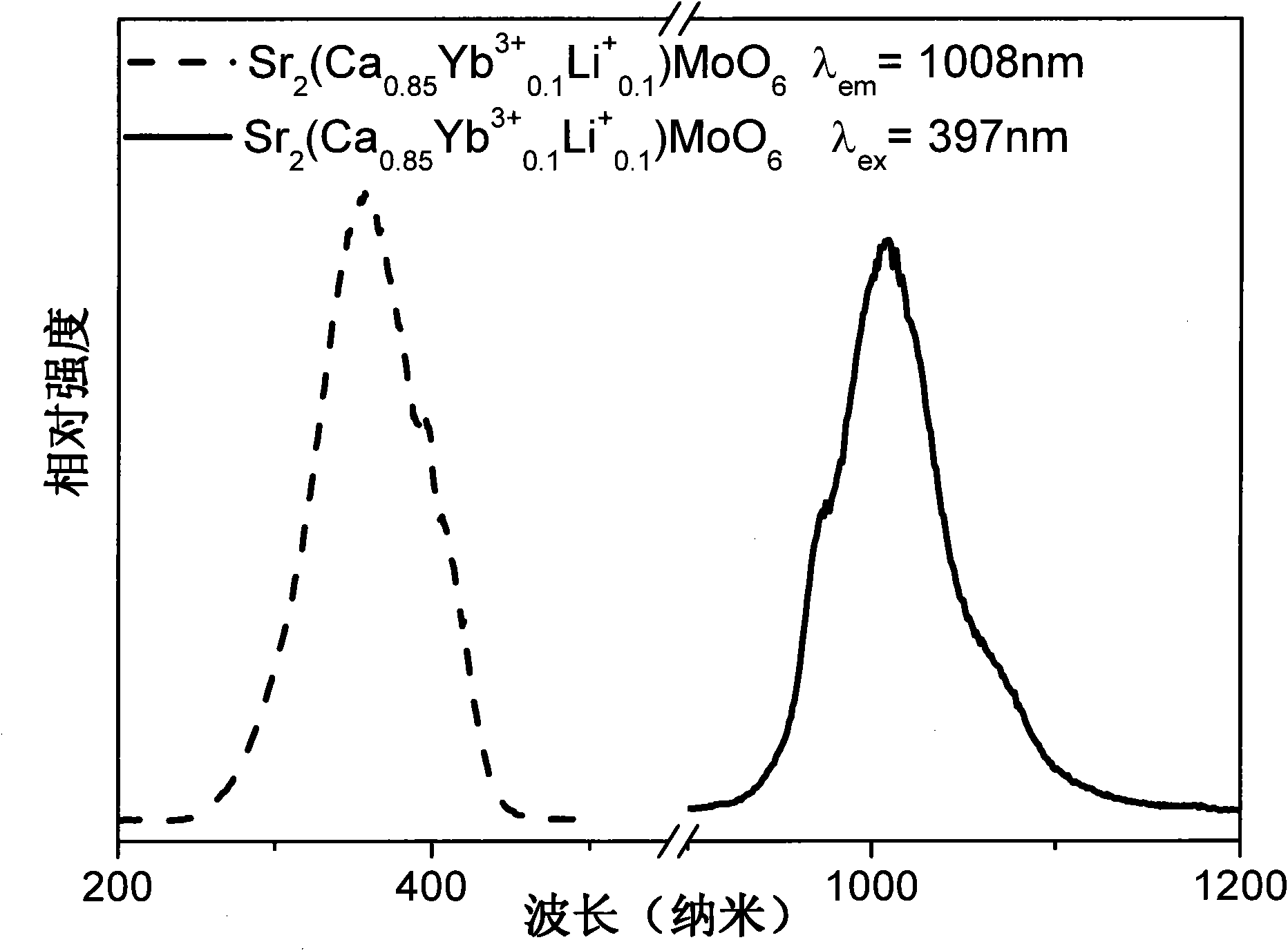

[0021] Example 3: Sr 2 (Ca 0.85 Yb 3+ 0.1 Li + 0.1 ) MoO 6 Preparation of Rare Earth Light Conversion Materials

[0022] Strontium carbonate (SrCO 3 ) 0.5907g, calcium carbonate (CaCO 3 ) 0.1705g, molybdenum trioxide (MoO 3 ) 0.2880g, ytterbium trioxide (Yb 2 o 3 ) 0.0394g, charge compensator lithium carbonate (Li 2 CO 3 ) 0.0076g, after grinding and mixing the above-mentioned raw materials in an agate mortar, put them into a corundum crucible, first burn them in the air at 700°C for 10 hours, then take them out and grind them, then put them into a corundum crucible, and then put them in a corundum crucible Sinter at 1000°C in the air for 10 hours, then take it out and grind it, put it into a corundum crucible, and finally sinter at 1200°C in the air for 20 hours, cool to room temperature, take it out and grind it thoroughly to get the sample. The room temperature excitation and emission spectra of this rare earth light conversion material are shown in figure 1 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com