Ultraviolet excited or near ultraviolet excited borate fluorescent powder and preparation method thereof

A fluorescent powder and borate technology, applied in the field of fluorescent powder materials, can solve the problems of lack of red components in white light, reabsorption, increased cost, etc., and achieve the effect of simple and feasible production method, stable performance, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

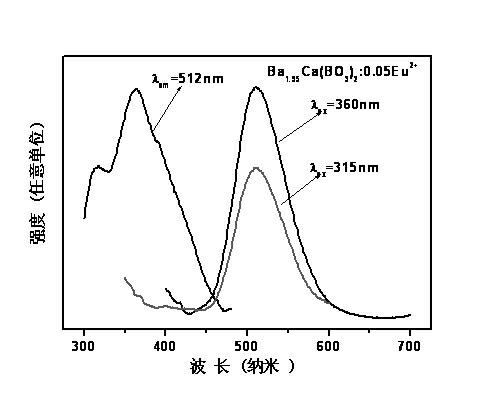

[0025] Ba 1.95 Ca(BO 3 ) 2 :0.05Eu 2+ Phosphor powder

[0026] The ratio of raw materials is shown in Table 1.

[0027] Table 1: Ba 1.95 Ca(BO 3 ) 2 :0.05Eu 2+ Phosphor powder ratio

[0028] raw material

BaCO 3

CaCO 3

h 3 BO 3

Eu 2 o 3

weight

2.886 grams

0.751 grams

0.951 grams

0.066 grams

[0029] Accurately weigh the above raw materials, use absolute ethanol as a dispersant, carefully grind them in an agate mortar, and put them into a small alumina crucible. Using hydrogen as a reducing agent, put it into a tube-type atmosphere furnace, keep it warm at 950°C for 2 hours, cool it down to room temperature naturally, take it out, and crush and grind the resultant to obtain the example material.

[0030] With XRD test, it is found that it has the same 2 Ca(BO 3 ) 2 The same diffraction pattern, indicating that it is the same as Ba 2 Ca(BO 3 ) 2 have the same crystal structure. The sample can be e...

Embodiment 2

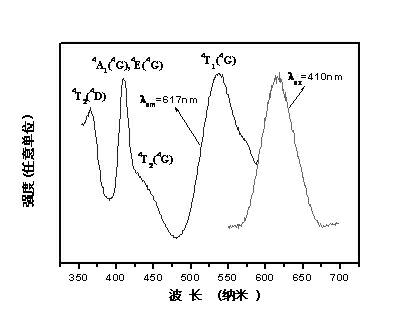

[0032] Ba 2 Ca 0.85 (BO 3 ) 2 : 0.15Mn 2+ Phosphor Powder Phosphor Powder

[0033] The ratio of raw materials is shown in Table 2.

[0034] Table 2: Ba 2 Ca 0.85 (BO 3 ) 2 : 0.15Mn 2+ Phosphor powder

[0035] raw material

BaCO 3

CaCO 3

h 3 BO 3

MnCO 3

weight

2.960 grams

0.751 grams

0.951 grams

0.129 grams

[0036] Accurately weigh the above raw materials, use absolute ethanol as a dispersant, carefully grind them in an agate mortar, and put them into a small alumina crucible. Using activated carbon as a reducing agent, put it into a tube-type atmosphere furnace, keep it warm at 960°C for 6 hours, cool it down to room temperature naturally, take it out, crush and grind the resultant, and obtain the example material.

[0037] With XRD test, it is found that it has the same 2 Ca(BO 3 ) 2 The same diffraction pattern, indicating that it is the same as Ba 2 Ca(BO 3 ) 2 have the same crystal structure. ...

Embodiment 3

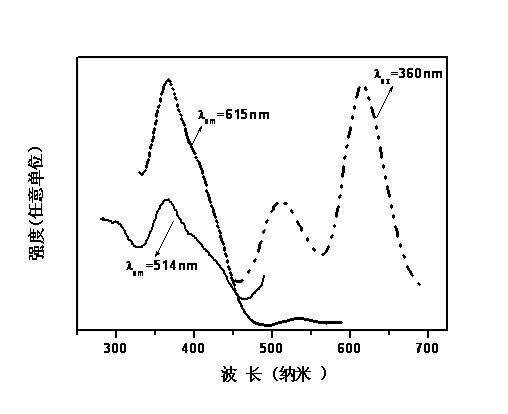

[0039] Ba 1.95 Ca 0.975 (BO 3 ) 2 :0.05Eu 2+ , 0.025Mn 2+ Phosphor powder

[0040] The ratio of raw materials is shown in Table 3.

[0041] Table 3: Ba 1.95 Ca 0.975 (BO 3 ) 2 :0.05Eu 2+ , 0.025Mn 2+ Phosphor powder

[0042] raw material

BaCO 3

CaCO 3

h 3 BO 3

Eu 2 o 3

MnCO 3

weight

2.886 grams

0.732 grams

0.951 grams

0.066 grams

0.022 grams

[0043] Accurately weigh the above raw materials, use absolute ethanol as a dispersant, carefully grind them in an agate mortar, and put them into a small alumina crucible. Using hydrogen as a reducing agent, put it into a tube-type atmosphere furnace, keep it warm at 960°C for 6 hours, cool it down to room temperature naturally, take it out, and crush and grind the resultant to obtain the example material.

[0044] With XRD test, it is found that it has the same 2 Ca(BO 3 ) 2 The same diffraction pattern, indicating that it is the same as Ba 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com