Efficient red fluorescent material and preparation method thereof

A red fluorescence and high-efficiency technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of limited red phosphors, high color temperature, poor color rendering, etc., and achieve the effects of pure light color, simple preparation process and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

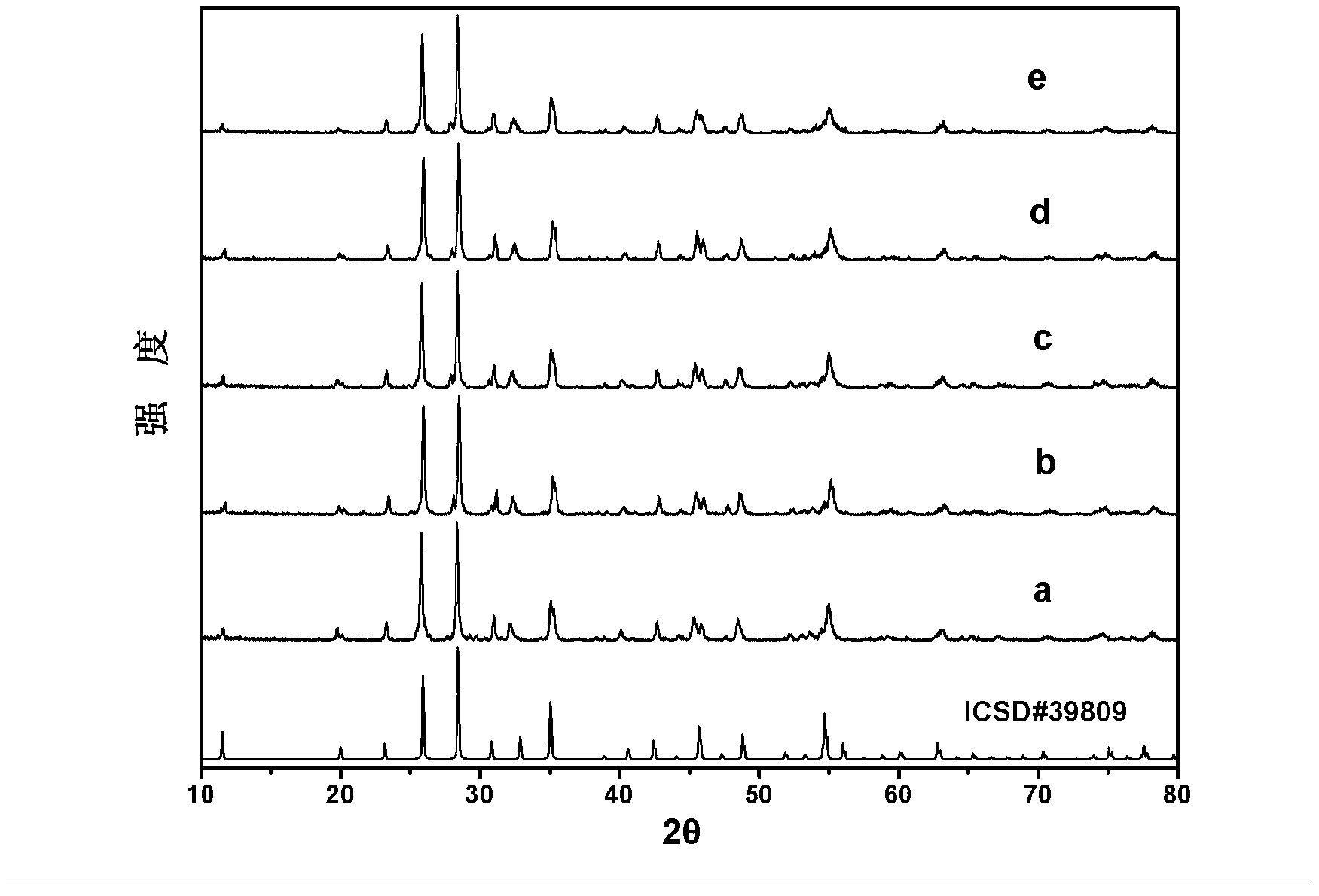

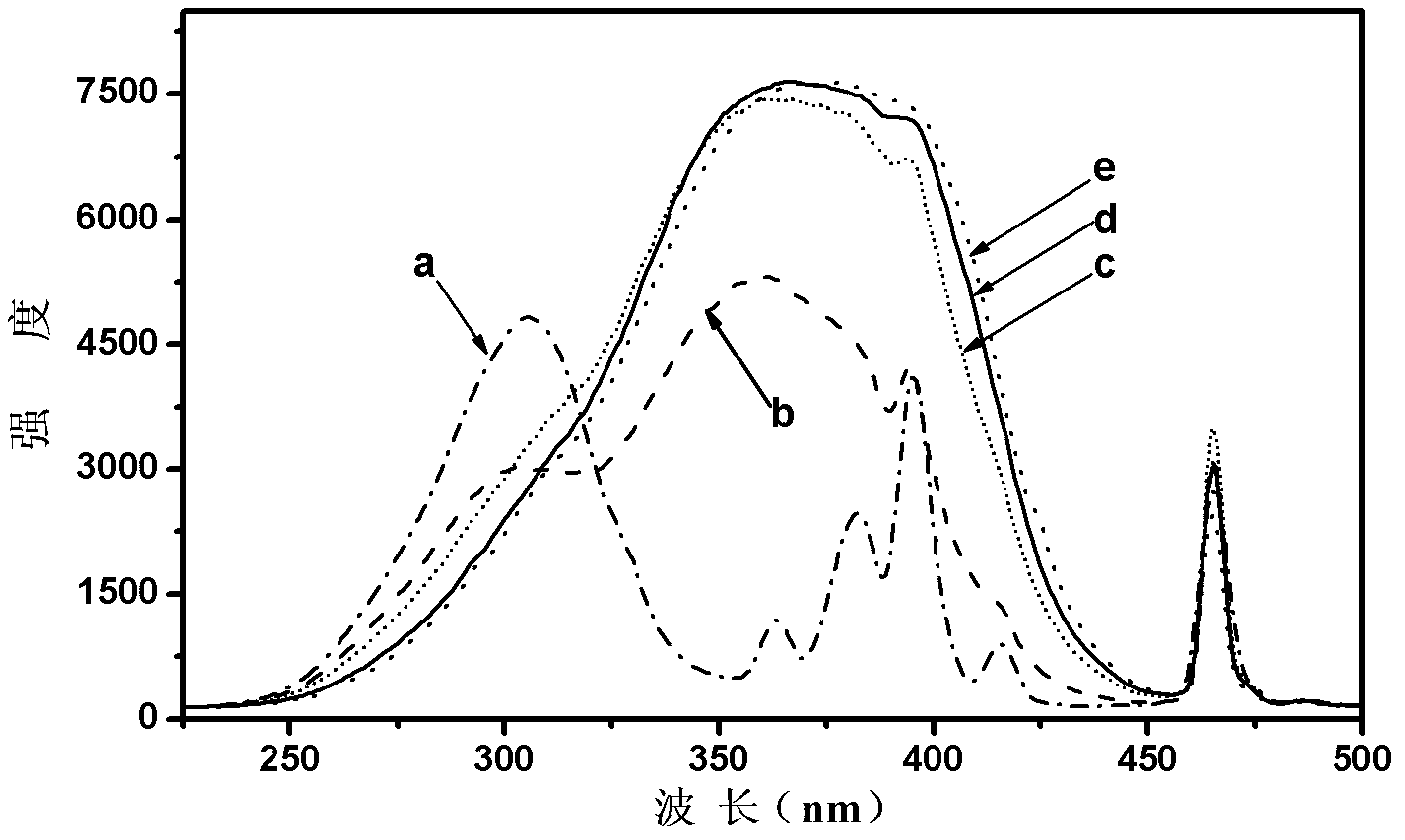

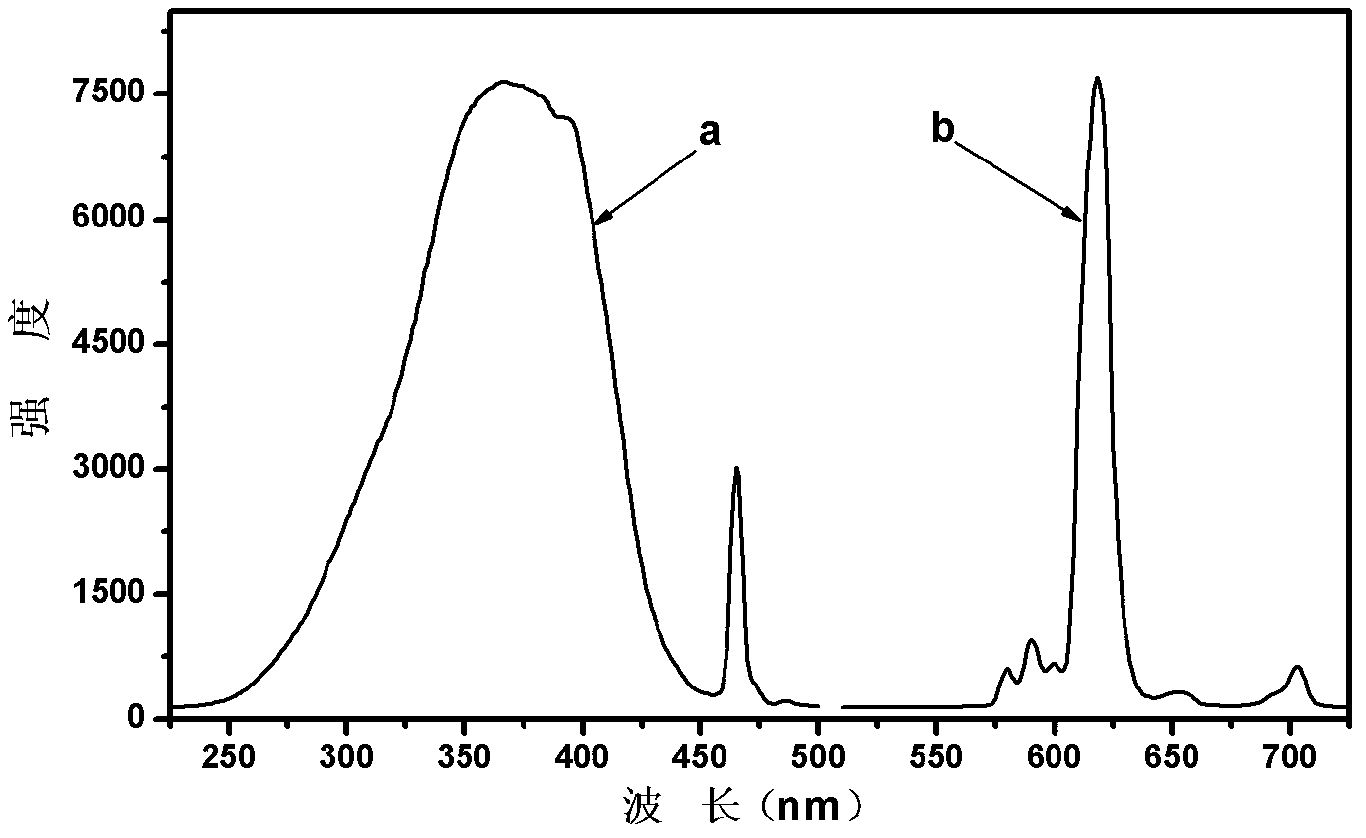

Embodiment 1

[0026] This embodiment provides a preparation method for a red fluorescent material, and the specific steps are as follows:

[0027] 1) Weigh 0.4399g (1.35mmol) La 2 o 3 , 0.0618g (1mmol) H 3 BO 3 , 0.2319g (1mmol) WO 3 , 0.0528g (0.15mmol) Eu 2 o 3 ;

[0028] 2) In the fume hood, mix the raw materials, add 50% ethanol liquid of the total mass of the sample, grind and mix;

[0029] 3) Dry in a blast drying oven at a temperature of 80°C;

[0030] 4) The above powders were roasted in a muffle furnace at 650°C for 6 hours, then ground after cooling down to room temperature naturally; then roasted at 950°C for 12 hours and ground to obtain the target product.

Embodiment 2

[0032] The preparation method of this example is the same as that described in Example 1, except that in step 1) 0.2319g (1mmol) WO 3 Converted to 0.2087g (0.9mmol) WO 3 and 0.0144g (0.1mmol) MoO 3 .

Embodiment 3

[0034] The preparation method of this example is the same as that described in Example 1, except that in step 1) 0.2319g (1mmol) WO 3 Converted to 0.1855g (0.8mmol) WO 3 and 0.0288g (0.2mmol) MoO 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com