White LED packaging structure capable of reducing color temperature drifting and manufacturing method of white LED packaging structure

A technology of LED packaging and LED chips, applied in the field of optoelectronics, can solve the problems of poor consistency of white light LED luminous color coordinates and color temperature, uneven distribution of phosphor powder, uneven surface shape, etc., to improve color temperature consistency, luminous The effect of uniform color and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

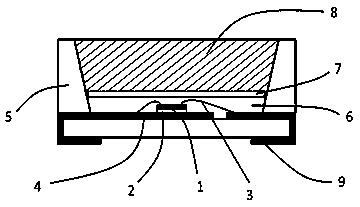

[0029] In this embodiment, transparent silicone resin is used to make transparent sheet 7, phosphor powder and silicone resin are used to make fluorescent glue 8, silver glue is used as die-bonding glue 2, and silicone resin is used as encapsulation glue 6, which is used to package white LEDs that can reduce color temperature drift. .

[0030] refer to figure 1 , a white LED packaging structure that improves the color temperature consistency. The LED chip 1 is fixed on the bottom of the cup-shaped bracket 4 with silver glue 2. The electrodes are correspondingly connected, that is, the positive pole of the LED chip 1 is connected to the positive pole of the cup-shaped bracket 4, the negative pole of the LED chip 1 is connected to the negative pole of the cup-shaped bracket 4, and the silicone resin 6 is coated on the top of the LED chip 1 and a transparent silicone resin sheet 7 is set. , the fluorescent glue 8 is arranged on the top of the transparent silicone resin sheet 7 ...

Embodiment 2

[0040] In this embodiment, transparent silicon rubber is used to make transparent sheet 7, phosphor powder and silicone resin are used to make fluorescent glue 8, silver glue is used as crystal-bonding glue 2, and silicone resin is used as packaging glue 6, which is used to package white light that can reduce color temperature drift. LED.

[0041] refer to figure 1 , a white LED packaging structure that improves the color temperature consistency. The LED chip 1 is fixed on the bottom of the cup-shaped bracket 4 with silver glue 2. The electrodes are correspondingly connected, that is, the positive pole of the LED chip 1 is connected to the positive pole of the cup-shaped bracket 4, the negative pole of the LED chip 1 is connected to the negative pole of the cup-shaped bracket 4, and the silicone resin 6 is coated on the top of the LED chip 1 and a transparent silicone rubber sheet 7 is set. , the fluorescent glue 8 is arranged on the top of the transparent silicon rubber she...

Embodiment 3

[0051] In this embodiment, transparent epoxy resin is used to make transparent sheet 7, fluorescent powder and silicone resin are used to make fluorescent glue 8, silver glue is used as crystal-bonding glue 2, and silicone resin is used as encapsulation glue 6, which can reduce color temperature drift. White LEDs.

[0052] refer to figure 1 , a white LED packaging structure that improves the color temperature consistency. The LED chip 1 is fixed on the bottom of the cup-shaped bracket 4 with silver glue 2. The electrodes are correspondingly connected, that is, the positive pole of the LED chip 1 is connected to the positive pole of the cup-shaped bracket 4, the negative pole of the LED chip 1 is connected to the negative pole of the cup-shaped bracket 4, and the silicone resin 6 is coated on the top of the LED chip 1 and a transparent epoxy resin sheet is set 7. A fluorescent glue 8 is arranged on the top of the transparent epoxy resin sheet 7 .

[0053] The packaging metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com