Novel process for LED fluorescent coating

A fluorescent powder and new process technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of inconsistent distance between LED chips, uneven light color, and light color shift of LED components, so as to improve LED light intensity, The effect of uniform light spot or light color and thin mixed thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The LED fluorescent powder coating process method of the present invention is carried out according to the following steps:

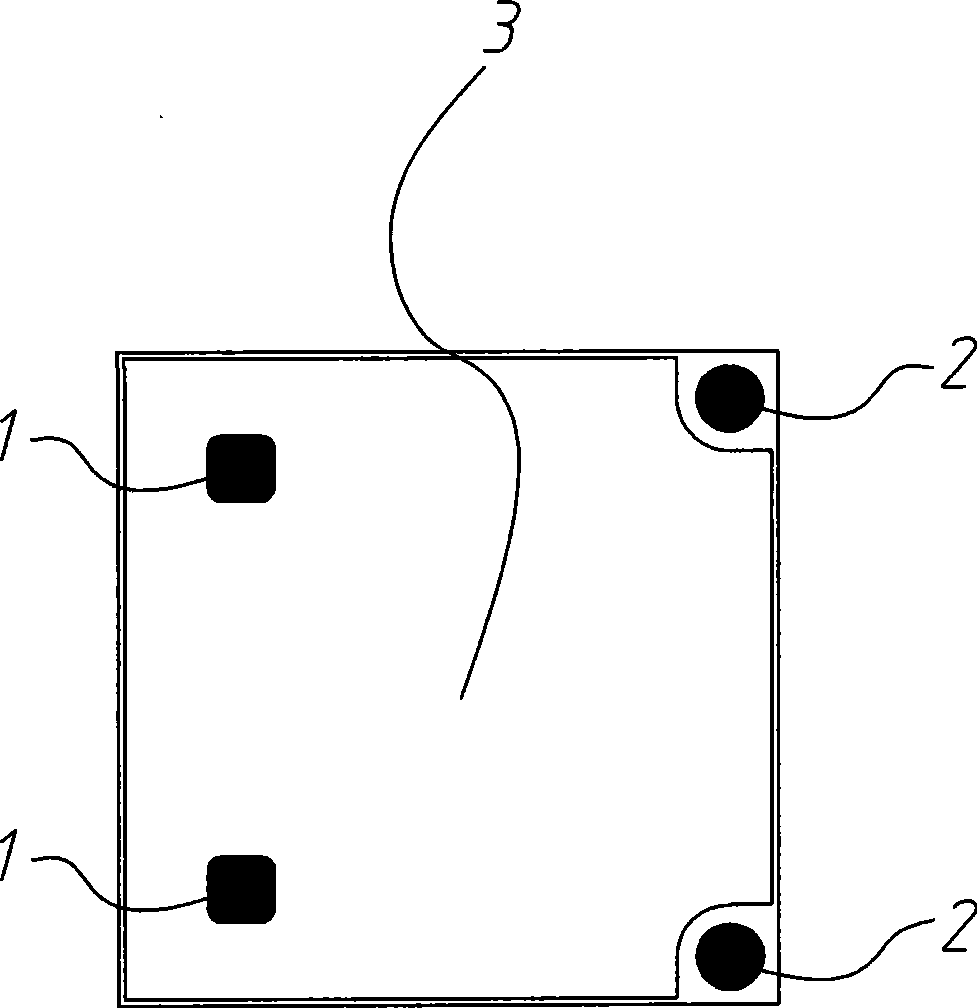

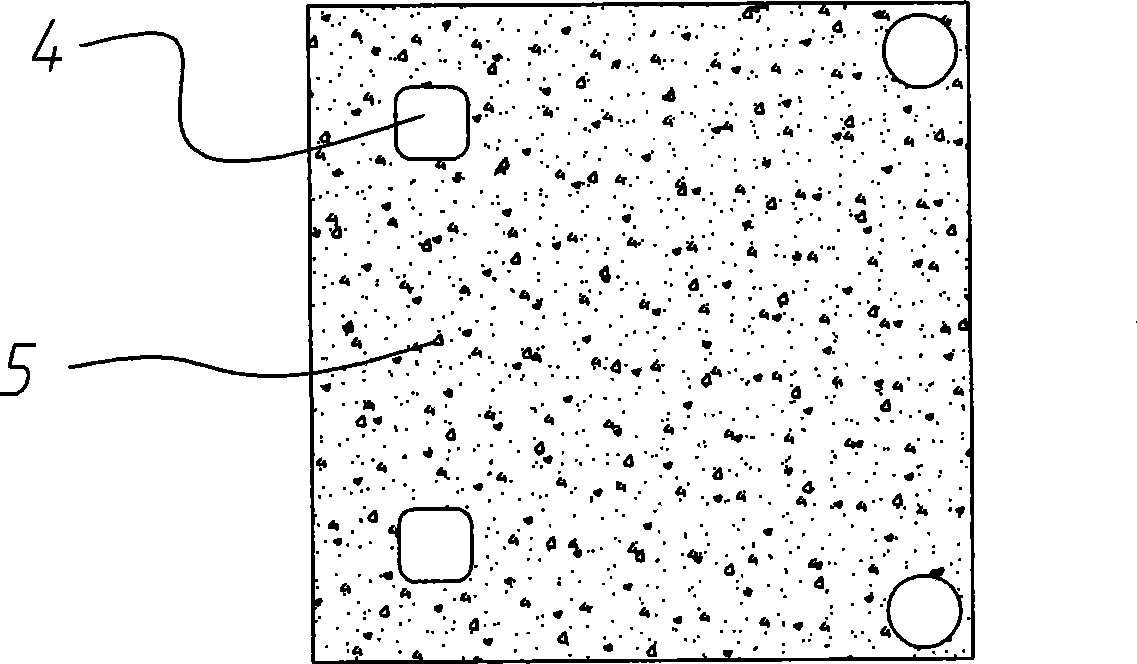

[0028] first as image 3 As shown, the columnar hole membrane structure permeable membrane 5 obtained by using polycarbonate or polyester materials through the nuclear etching method is punched 4 according to the position of the positive and negative electrodes PAD1 and 2 of the LED chip 3 gold wire bonding; the hole 4 is punched The permeable membrane 5 is cut according to the size of the LED wafer 3; Figure 4 , Figure 5 As shown, the permeable membrane 5 that has been punched and cut is placed on the top of the LED chip 3; Figure 6 As shown, use a dispensing machine to mix phosphor powder and silica gel at a mass ratio of 1:1.25 to 1:1000. Put 6 spots of the phosphor powder mixture on the above-mentioned permeable membrane 5; Figure 7 As shown, the above phosphor powder mixture 6 is cured and the permeable membrane 5 is peeled off, leavi...

Embodiment 2

[0030] The LED fluorescent powder coating process method of the present invention is carried out according to the following steps:

[0031] first as image 3 As shown, the columnar hole membrane structure permeable membrane 5 obtained by using polycarbonate or polyester materials through the nuclear etching method is punched 4 according to the position of the positive and negative electrodes PAD1 and 2 of the LED chip 3 gold wire bonding; the hole 4 is punched The permeable membrane 5 is cut according to the size of the LED wafer 3; Figure 4 , Figure 5 As shown, the permeable membrane 5 that has been punched and cut is placed on the top of the LED chip 3; Figure 6 As shown, use a dispensing machine to mix phosphor powder and epoxy resin at a mass ratio of 1:1.25 to 1:1000, and put 6 spots of the phosphor powder mixture on the above-mentioned permeable membrane 5; Figure 7 As shown, the above phosphor powder mixture 6 is cured and the permeable membrane 5 is peeled off, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com