Soft high-efficiency light-emitting diode (LED) surface light source

A technology of LED surface light source and LED light source, which is applied in the field of soft and high-efficiency LED surface light source, can solve the problems of low light energy utilization efficiency, low light energy utilization efficiency, and low luminous efficiency, etc., so as to improve light energy utilization efficiency and reduce loss , Improve the effect of transmission ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

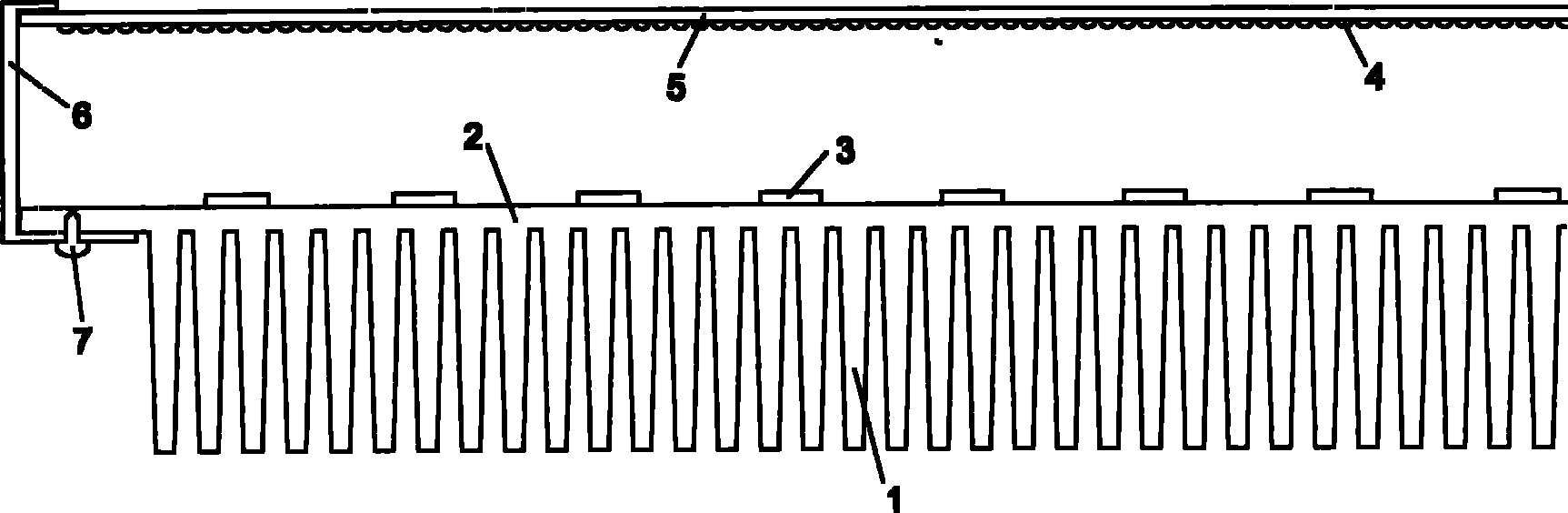

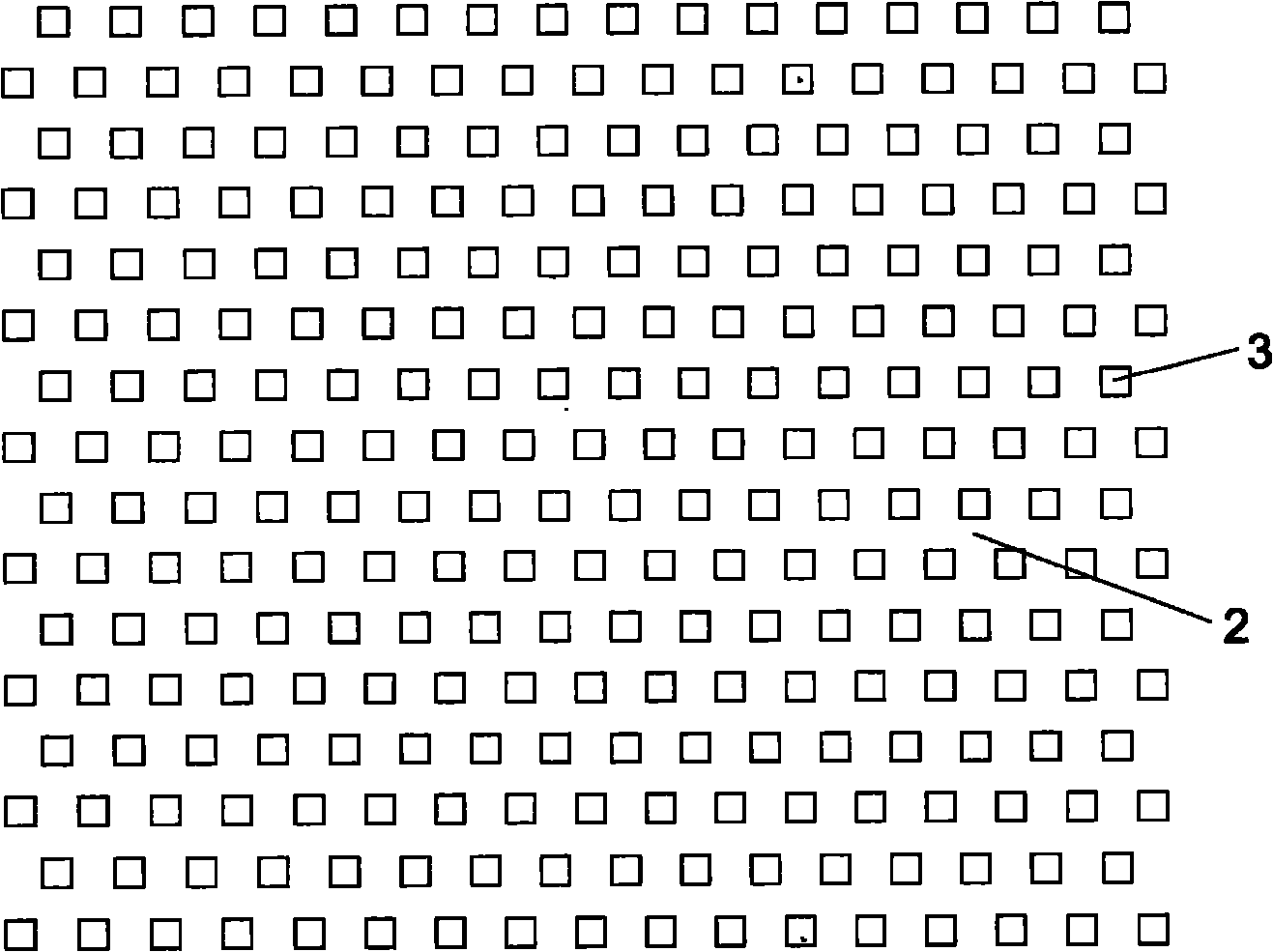

[0021] The structure of the surface light source of the present invention is as figure 1 As shown, it is mainly composed of a radiator 1, a light source 3, a light guide plate 5, a housing 6 and a power supply (not shown in the figure). The radiator 1 is locked on the casing 6 by screws 7 , the metal substrate 2 is placed on the radiator 1 , and a copper-clad circuit is made on the upper surface of the substrate 2 . The positions of the pads of the circuit are in an equilateral triangular array, so when the light sources 3 are mounted on it, they can be arranged in an equilateral triangular array, and the light emitting direction of the light sources 3 faces upward. A light guide plate 5 is installed on the heat sink 1 and the light source 3, and the light guide plate is glued on the housing with AB glue. The distance between the light guide plate 5 and the plane where the light source 3 is located is equal to the product of the cotangent of the 70% light intensity angle of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com