Dynamic and fatigue performance detection device and method for steel rail assembling fastener system

A technology of fatigue performance and detection device, which is applied in the direction of measurement device, machine/structural component test, vibration test, etc., can solve the problem of inability to accurately and comprehensively predict the dynamics and fatigue mechanics of the fastener system, and achieves easy operation and low cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

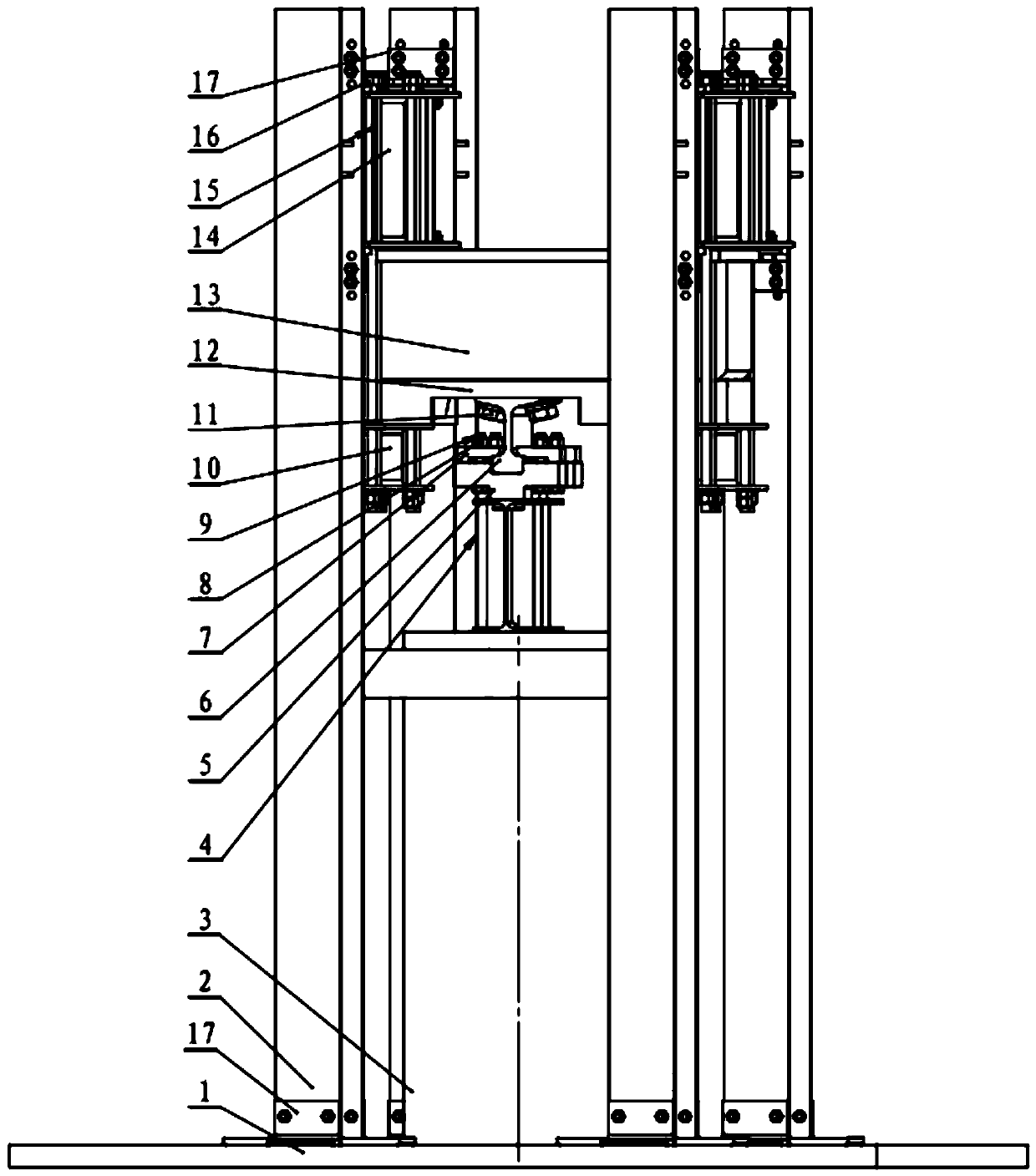

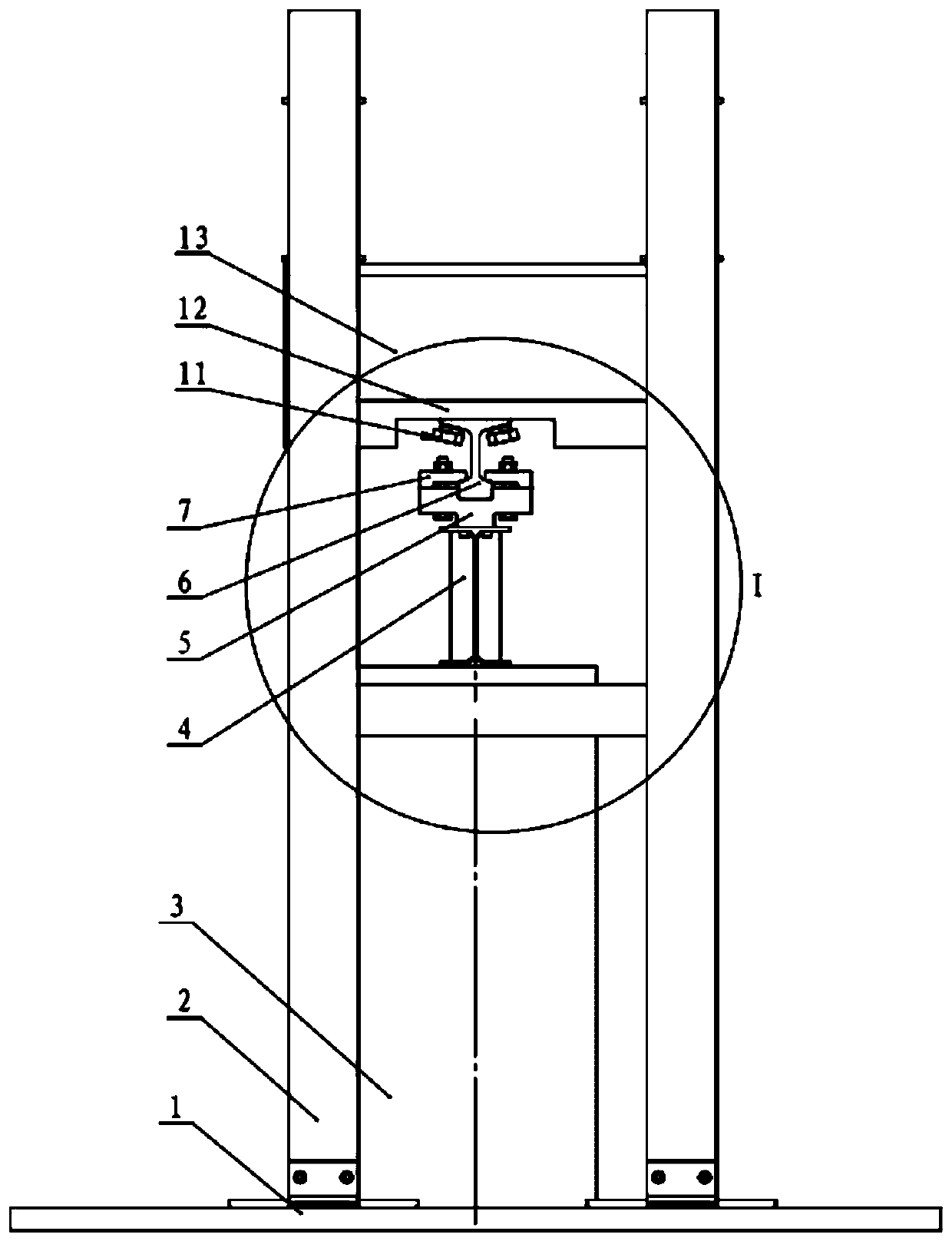

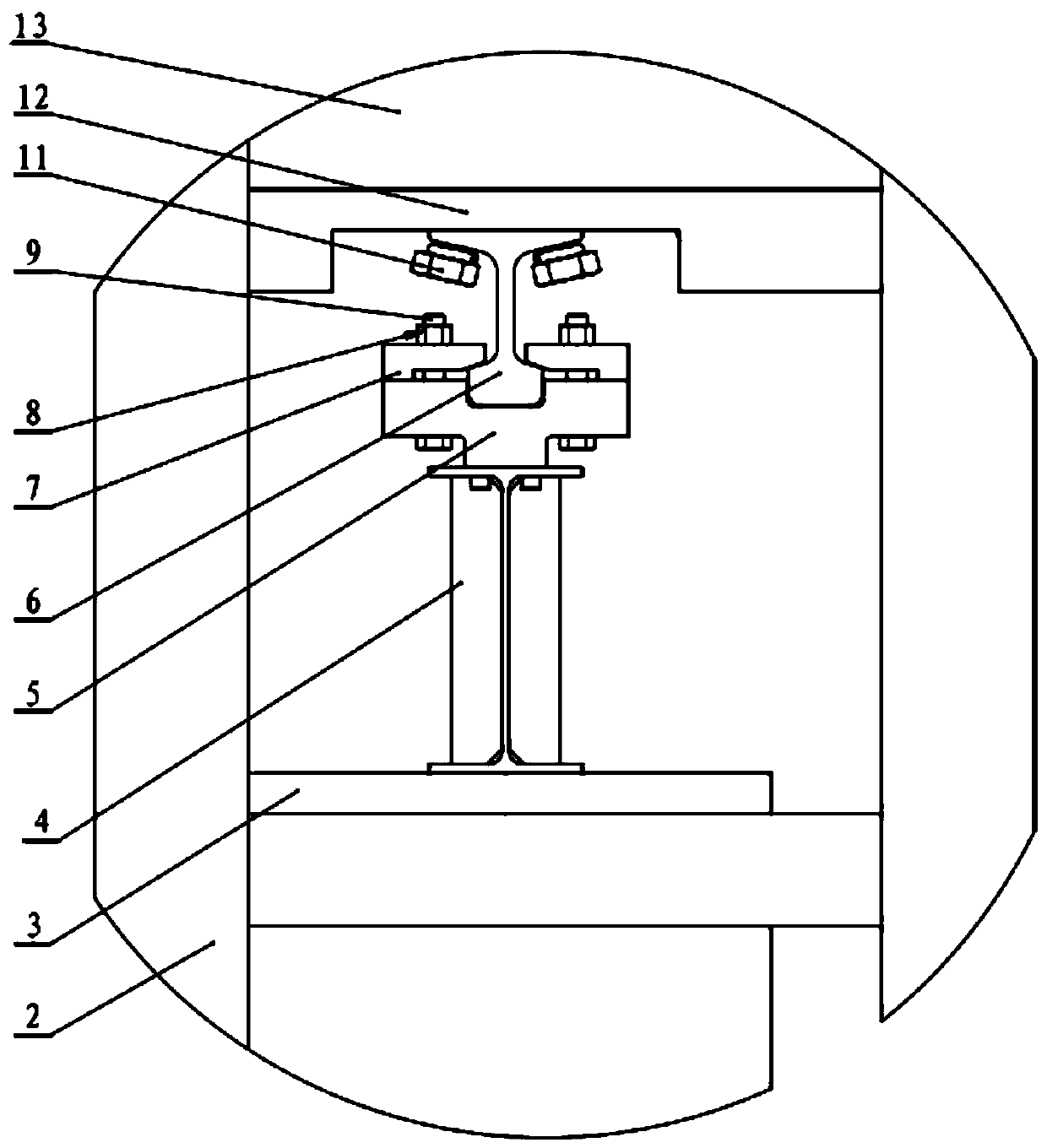

[0026] refer to Figure 1-Figure 3 , a dynamic and fatigue performance detection device of a rail assembly fastener system, used for dynamic mechanical behavior detection and fatigue performance detection of the rail assembly fastener system, the rail assembly fastener system includes rails 6, sleepers 13 and connected to The buckling element 11 between the rail 6 and the sleeper 13, the detection device includes a bottom plate 1, a vertical column 2, a vibrator 3, an actuating head 4, a transition slider 5, a tongue plate 7, an auxiliary beam 10, and a box body 12 and the upper beam 14, the vertical column 2 is fixedly connected to the base plate 1, the auxiliary beam 10 and the upper beam 14 are respectively connected to the vertical column 2, and the box 12 is located between the auxiliary beam 10 and the upper beam 14 Between, the box 12 is used to fix the sleeper 13, the vibrator 3 is fixed on the bottom plate 1, the actuating head 4 of the vibrator 3 is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com