Alignment mark and defect detection method

A technology for alignment marks and defect detection, which is applied in the field of defect detection and can solve problems such as numerical offsets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

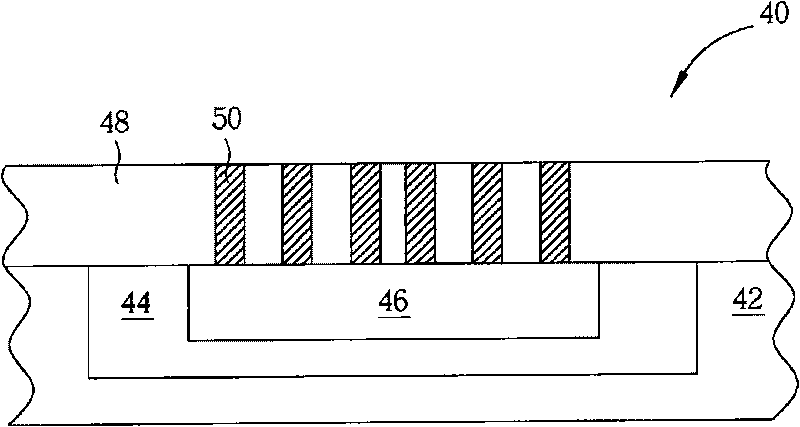

[0020] Please refer to figure 1 , figure 1 It is a schematic cross-sectional view of an alignment mark 40 in a preferred embodiment of the present invention. Such as figure 1 As shown, first a semiconductor substrate 42, such as a silicon wafer, is provided. An ion implantation process is then performed to implant N-type dopants into the semiconductor substrate 42 to form an N-type well (N-well) 44 . Then another ion implantation process is performed to implant P-type dopants into the formed N-type well 44 to form a shallower P+ doped region 46 in the N-type well 44 .

[0021] Then a dielectric layer 48 is formed on the semiconductor substrate 42 and covers the N − -type well 44 and the P+ doped region 46 . In this embodiment, the dielectric layer 48 may be made of dielectric materials such as oxides, carbides or nitrides, or low dielectric constant materials, or any combination thereof. Then form a patterned photoresist layer (not shown) on the dielectric layer 48, and u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com