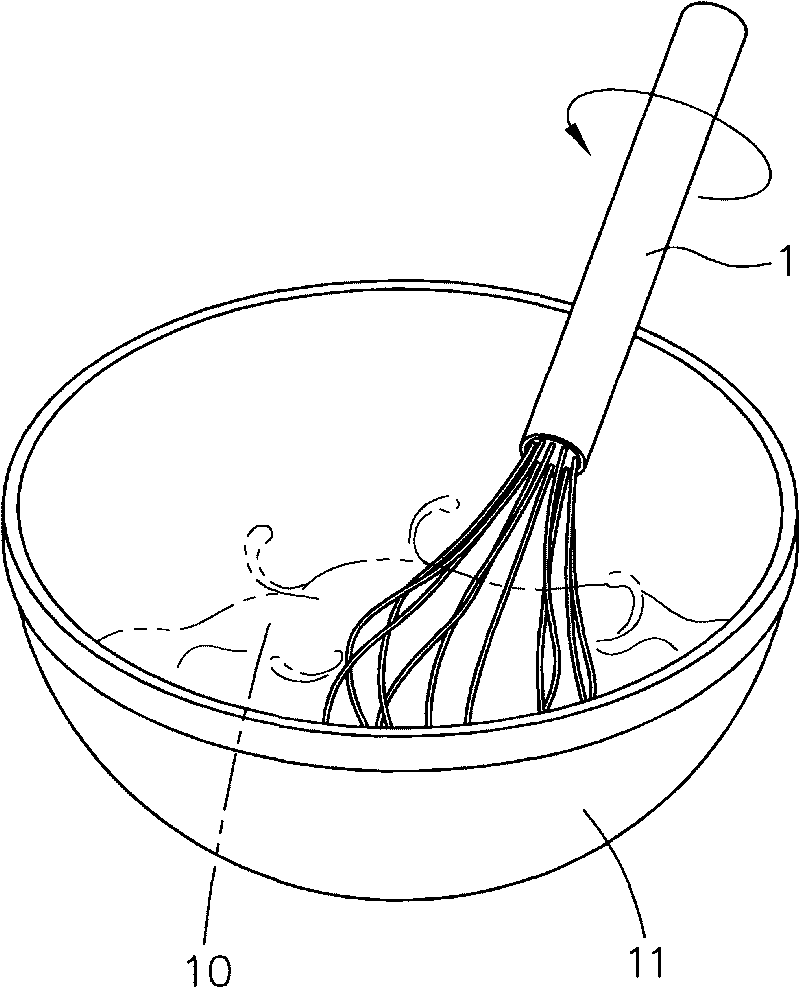

Egg beater

An egg beater and stirring piece technology, applied in the field of egg beaters, can solve the problems of unsatisfactory use, consuming a lot of time and effort, not meeting economic benefits and the like, and achieving the effect of not easy to splash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

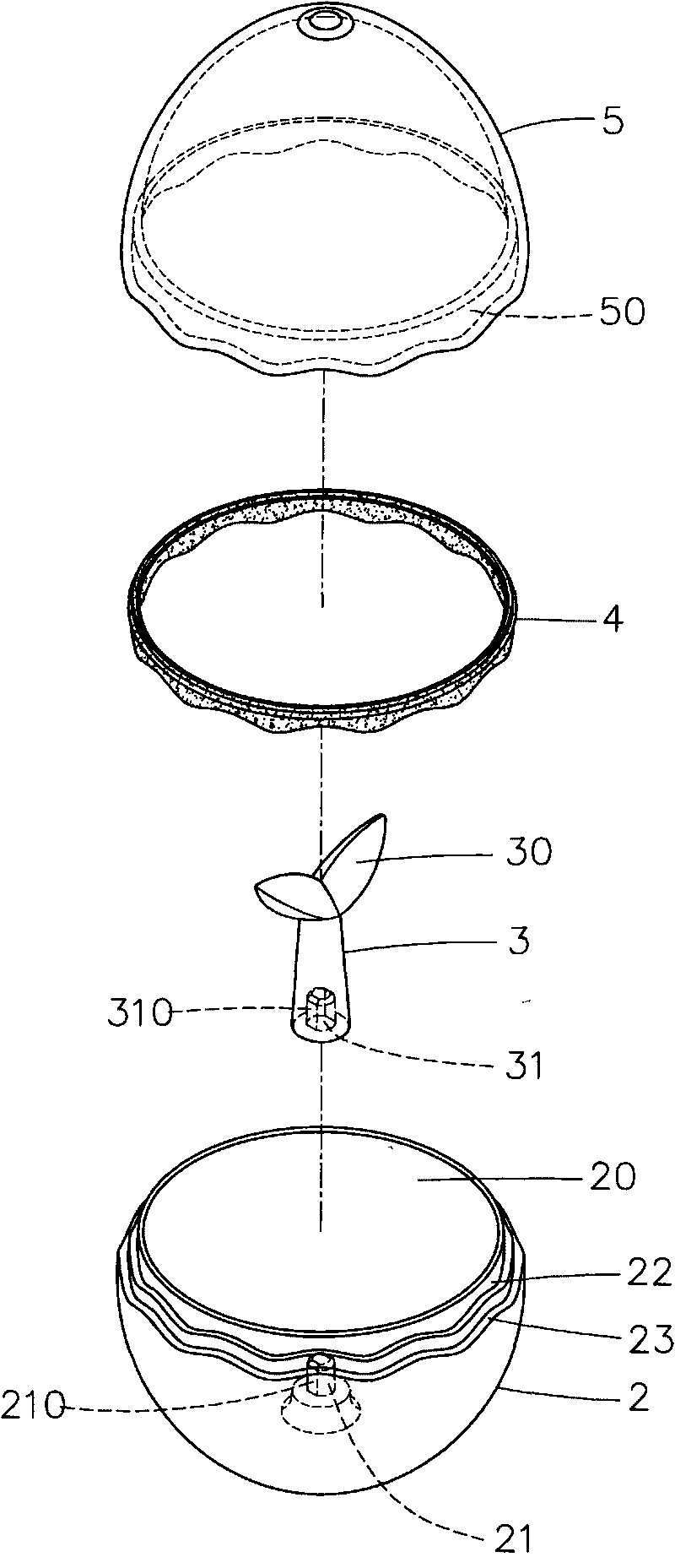

[0016] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0017] For an embodiment of the invention, please refer first to figure 2 As shown, it is mainly provided with a base 2, the base 2 is provided with a chamber 20, and a positioning boss 21 is arranged in the chamber 20, and the wall surface of the positioning boss 21 is provided with a cut surface 210 opposite to each other. The top edge of the outer wall surface of the base 2 is provided with a caulking groove 22, and the below of the caulking groove 22 is provided with an annular groove 23; A stirring member 3 is located in the chamber 20 of the base 2, and the top of the stirring member 3 is set as The leaf-shaped stirring part 30 is provided with a slot 31 at the bottom of the stirring part 3, and a cut surface 310 is provided on the wall of the slot 31; a waterproof gasket 4 is located on the socket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com