Frame structure of scooter type locomotive

A technology of frame structure and scooter, which is applied in the directions of motor vehicles, bicycle frames, bicycles, etc., can solve the problems of complicated assembly of the frame structure 40, unfavorable assembly or production efficiency, and improvement, and achieves controllability and safety. Improve, improve assembly efficiency, the effect of strong force structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

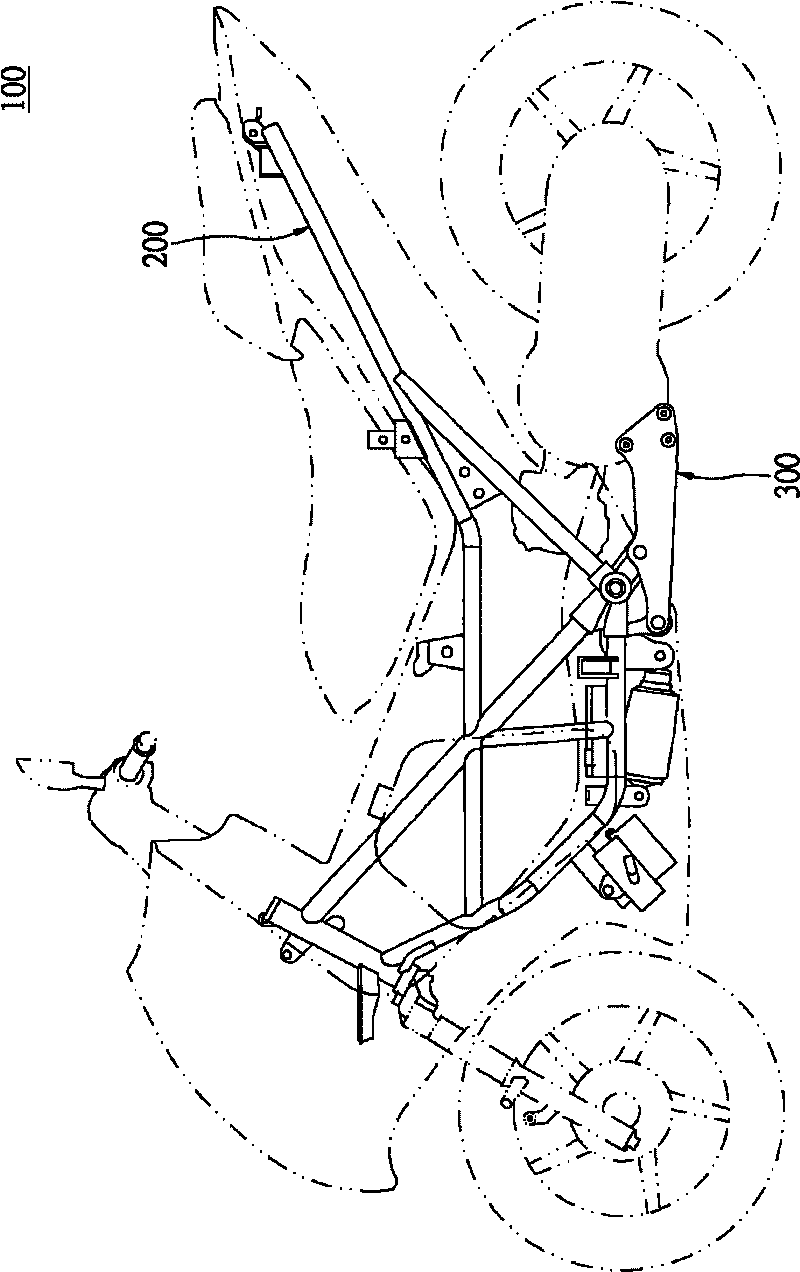

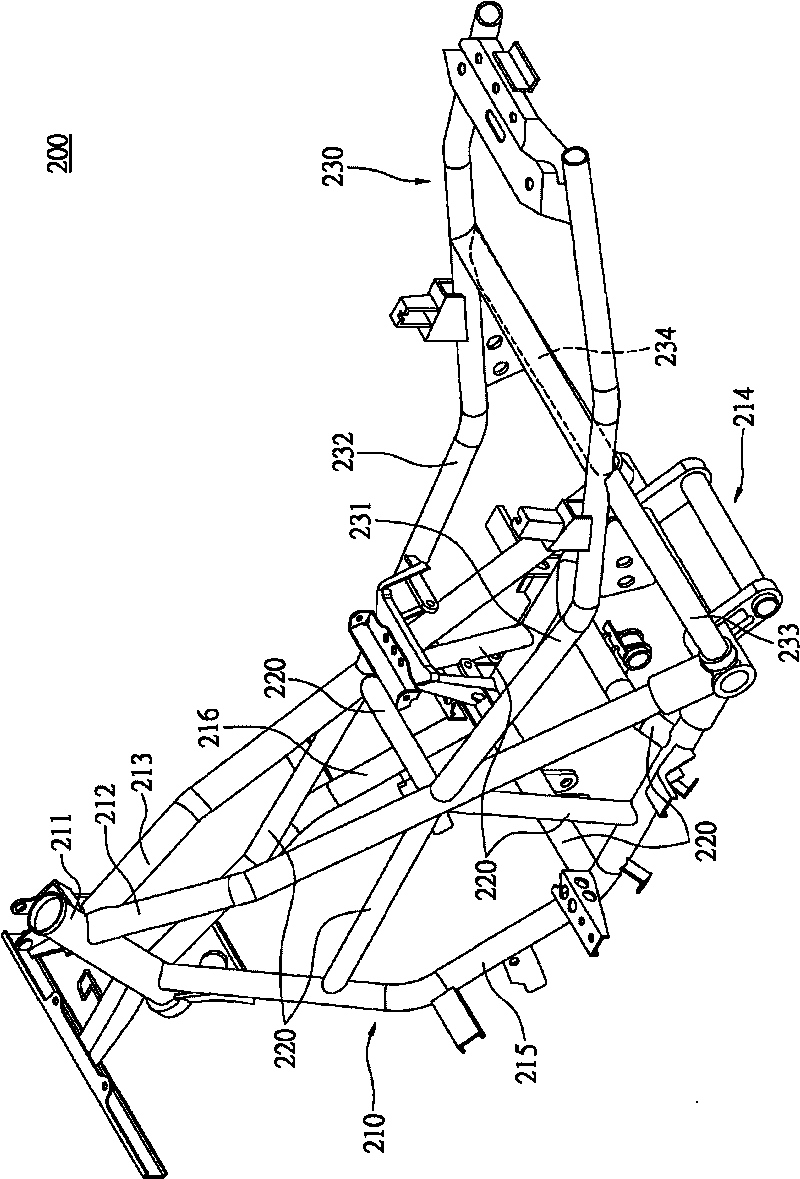

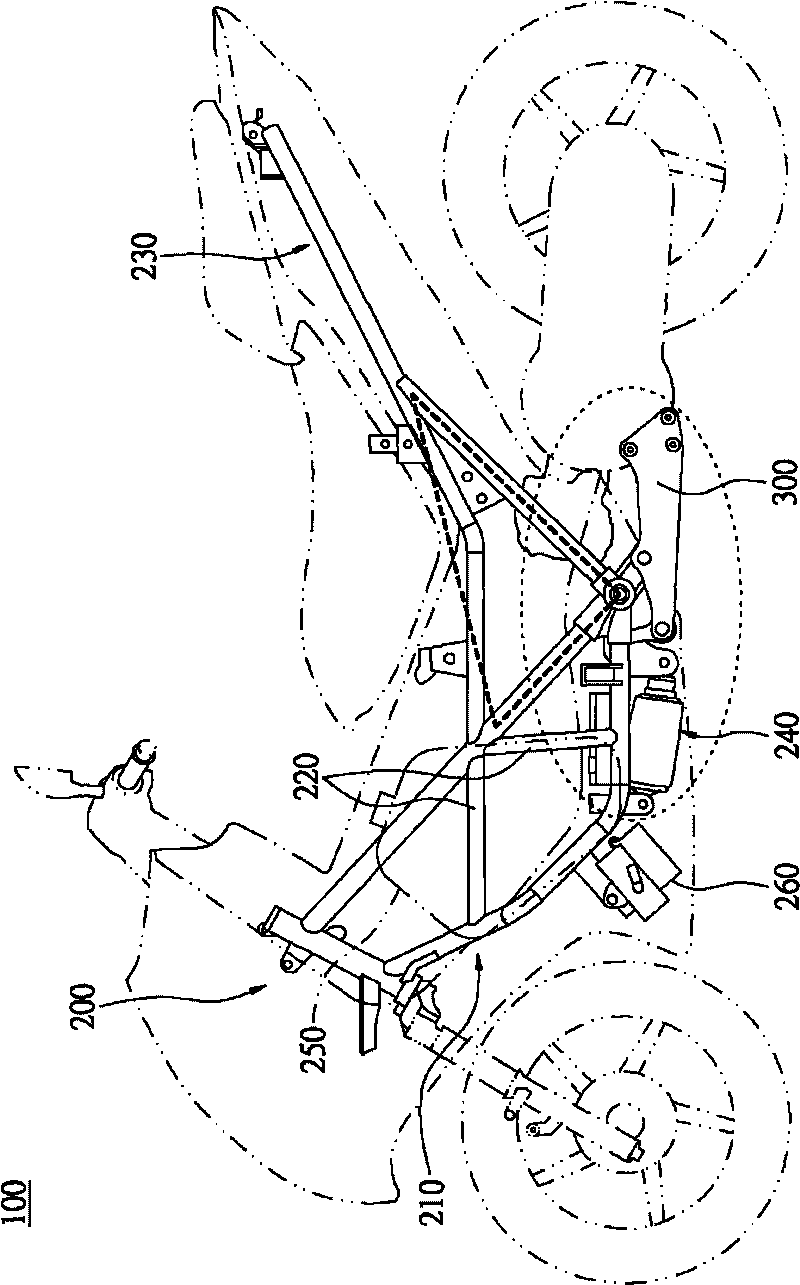

[0073] see figure 1 As shown, an embodiment of the frame structure of the scooter-type locomotive of the present invention, wherein a scooter-type locomotive 100 is shown, and a scooter-type locomotive frame structure 200 is included. see figure 2 and image 3 Shown is a three-dimensional schematic view and a schematic plan view according to an embodiment of the present invention. The frame structure 200 of the scooter locomotive is connected to an engine bracket 300, and includes a first frame 210, a plurality of auxiliary pipes 220, a first Two vehicle frames 230 , a horizontally mounted rear suspension unit 240 , a fuel tank 250 and a radiator 260 .

[0074] see Figure 4As shown, the first vehicle frame 210 is assembled in front of the scooter 100, and includes a head tube 211, a left upper tube 212, a right upper tube 213, a connecting assembly 214, a left lower tube 215 and a right The lower tube 216 , the left upper tube 212 and the right upper tube 213 are fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com