Full-automatic cutting apparatus for adhesive tape

A fully automatic, adhesive tape technology, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., to save manpower, reduce time costs, and improve the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation and examples of the device of the present invention will be described in detail below in conjunction with the accompanying drawings.

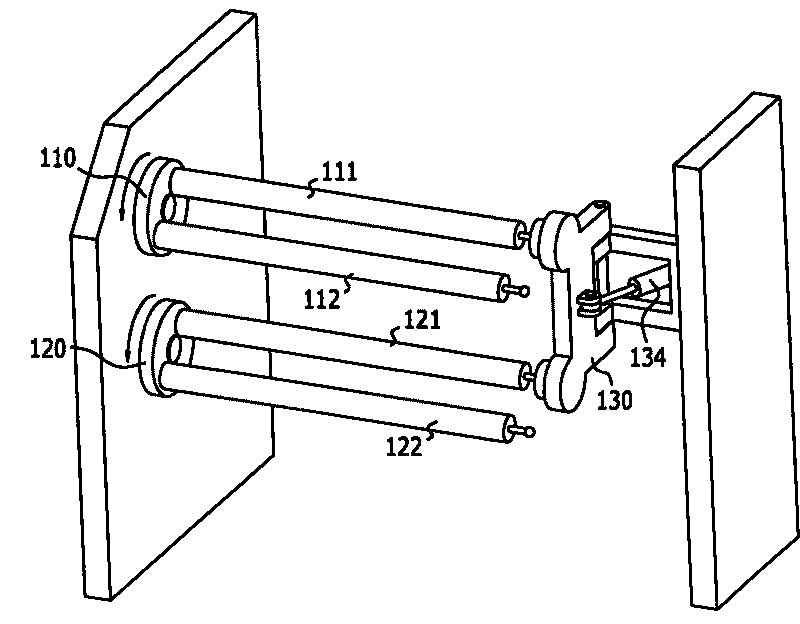

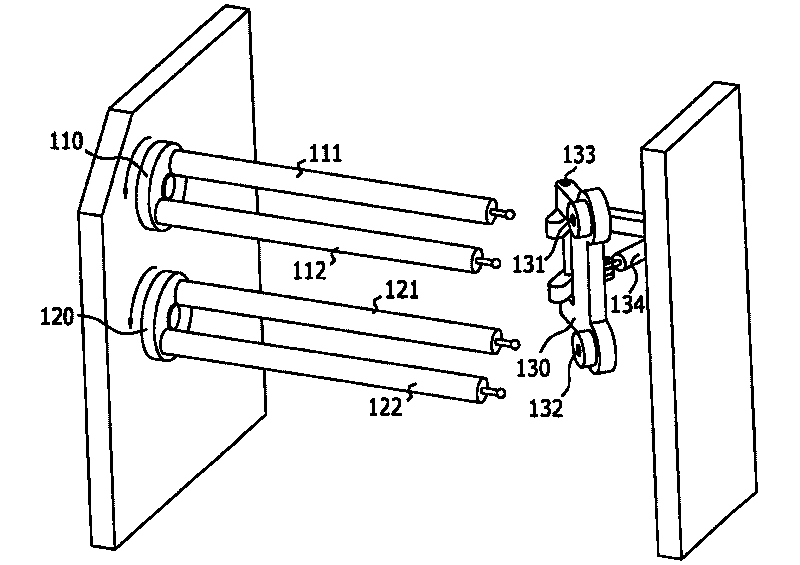

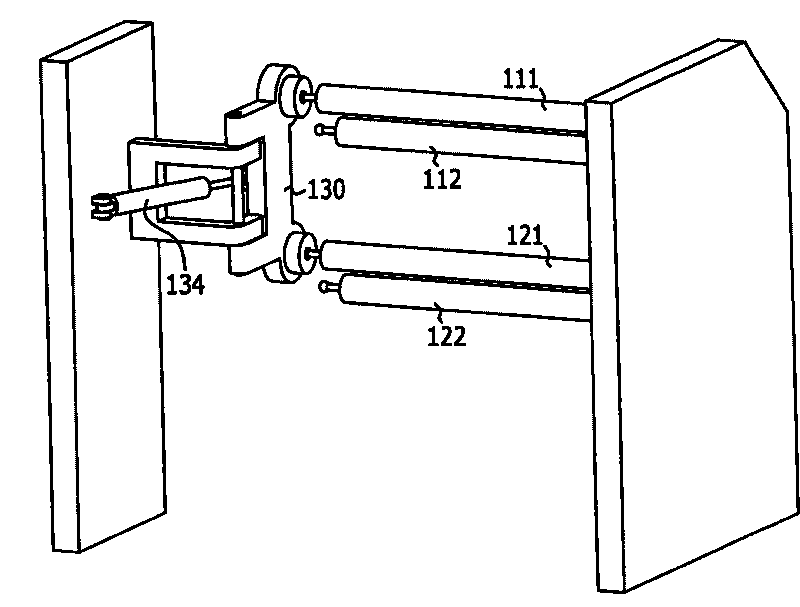

[0028] A fully automatic cutting equipment for adhesive tape of the present invention, one of its specific implementations, as attached figure 1 and 3 As shown, it includes at least one turntable 110 and 120 for changing stations; Under the rotation of the turntable 110 (or 120), the roller shafts 111 and 112 (or 121 and 122) on the same turntable 110 (or 120) are alternately in the winding station (such as the roller shaft 111 or 121) and Loading and unloading station (such as the roller shaft 112 or 122); wherein, one end of the roller shaft 111, 112 (and 121, 122) is fixedly connected to the respective turntable 110 (and 120); The other end of the roller shaft 111 (and 121) on the position is supported on a movable support 130 for automatic winding; the other end of the roller shaft 112 (and 122) on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com