Long-persistence luminous enameled plate and preparation method thereof

A technology of long afterglow luminescence and long afterglow luminescence powder, which is applied in the field of long afterglow luminescence enamel plate and its preparation, can solve the problems of short afterglow luminescence time, poor gloss of glaze surface, low transparency of enamel, etc., and achieve improved absorption function, The effect of lowering the firing temperature and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

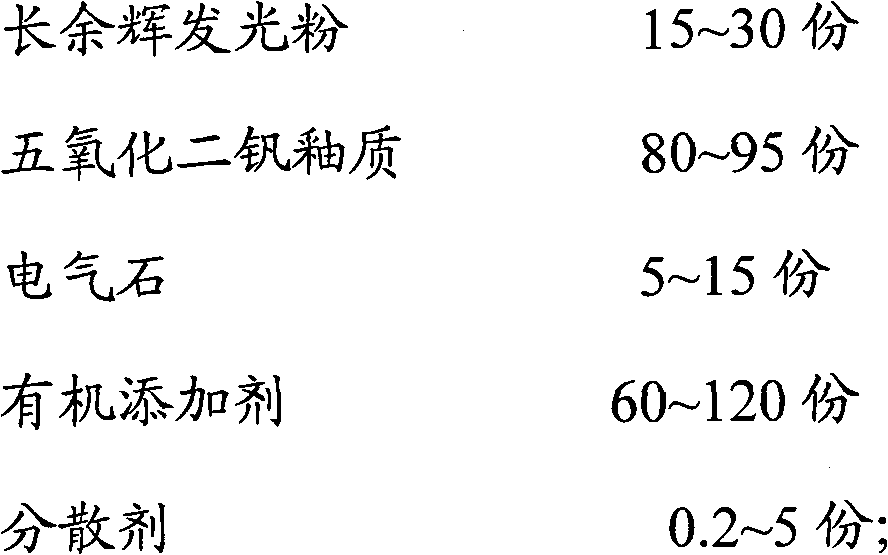

Method used

Image

Examples

Embodiment 1

[0042] Used in Example 1 (Ca 0.2 Sr 0.8 )Al 4 o 7 :0.04Eu 2+ , 0.01Dy 3+ , used in Example 3 (Ga 0.1 Y 0.9 ) 2 o 2 S:0.01Eu, 0.04Ti, 0.08Mg, used in embodiment 4 (Ba 0.2 Sr 0.8 ) 3 MgSi 2 o 8 :0.01Eu, 0.05Mn), can be prepared according to a similar method.

[0043] Example 1:

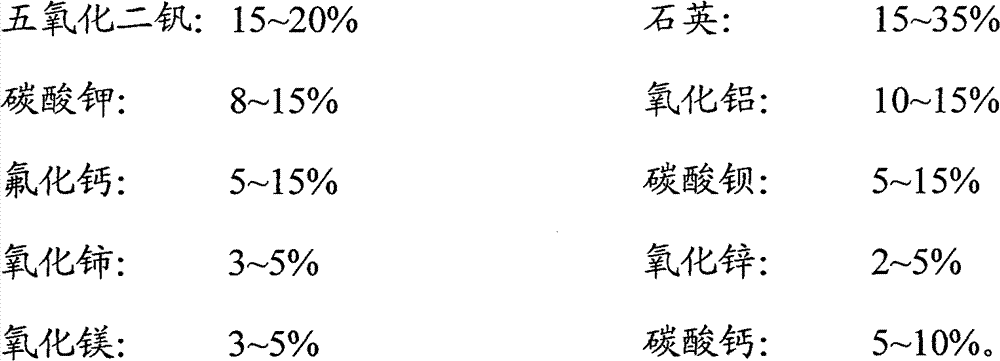

[0044] The mass composition of vanadium pentoxide enamel is as follows:

[0045] Vanadium pentoxide: 15%

[0046] Quartz: 20%

[0047] Potassium Carbonate: 11%

[0048] Aluminum Oxide: 12%

[0049] Calcium Fluoride: 14%

[0050] Barium carbonate: 10%

[0051] Cerium Oxide: 3%

[0052] Zinc Oxide: 3%

[0053] Magnesium Oxide: 4%

[0054] Calcium Carbonate: 8%

[0055] Accurately weigh the above-mentioned raw materials, put them into a corundum crucible after uniform mixing, place them in a furnace at 1200°C for sintering for 60 minutes, and then quench in water to obtain a low-temperature high-transparency vanadium pentoxide enamel substrate.

[0056] Take by weighing 70 grams of...

Embodiment 2

[0059] The mass composition of vanadium pentoxide enamel is as follows:

[0060] Vanadium pentoxide: 20%

[0061] Quartz: 18%

[0062] Potassium Carbonate: 8%

[0063] Aluminum Oxide: 12%

[0064] Calcium Fluoride: 14%

[0065] Barium carbonate: 12%

[0066] Cerium Oxide: 3%

[0067] Zinc Oxide: 3%

[0068] Magnesium Oxide: 4%

[0069] Calcium Carbonate: 6%

[0070] Accurately weigh the above-mentioned raw materials, put them into a corundum crucible after uniform mixing, place them in a furnace at 1200°C for sintering for 60 minutes, and then quench in water to obtain a low-temperature and highly transparent vanadium pentoxide enamel substrate.

[0071] Take by weighing 70 grams of vanadium pentoxide enamel and the long afterglow luminescent powder ((Ga 0.3 Y 0.7 ) 2 o 2 S: 0.08Eu, 0.5Ti, 0.10Mg), the weight is the ethanol additive of 10g tourmaline and 60ml, after ball milling 5h mixing in the ball mill, then add 2g triethanolamine, then ball milling 1h mix, make...

Embodiment 3

[0074] The mass composition of vanadium pentoxide enamel is as follows:

[0075] Vanadium pentoxide: 18%

[0076] Quartz: 22%

[0077] Potassium Carbonate: 10%

[0078] Aluminum Oxide: 12%

[0079] Calcium Fluoride: 14%

[0080] Barium carbonate: 8%

[0081] Cerium Oxide: 3%

[0082] Zinc Oxide: 3%

[0083] Magnesium Oxide: 4%

[0084] Calcium Carbonate: 6%

[0085] Accurately weigh the above-mentioned raw materials, put them into a corundum crucible after uniform mixing, place them in a furnace at 1000°C for sintering for 120 minutes, and then quench in water to obtain a low-temperature and highly transparent vanadium pentoxide enamel substrate.

[0086] Take by weighing 80g vanadium pentoxide enamel and the long afterglow luminescent powder ((Ga 0.1 Y 0.9 ) 2 o 2 S: 0.01Eu, 0.04Ti, 0.08Mg), weight is 15g of tourmaline and 100ml of methyl ethanol additive, after ball milling in a ball mill for 5h and mixing, then add 2g of toluene diphenyl phosphate, and then ball...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com