Patents

Literature

31results about How to "Hold time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

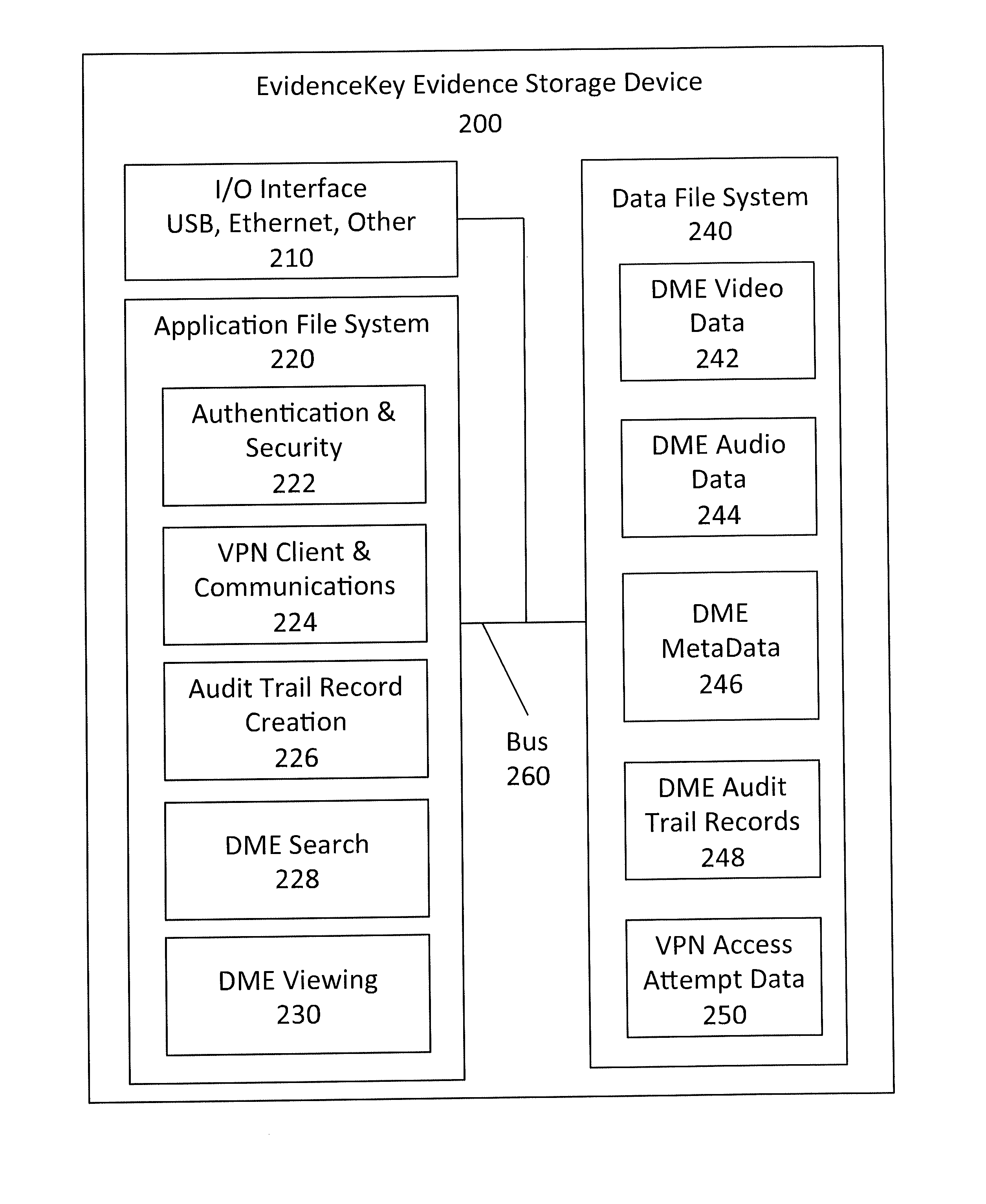

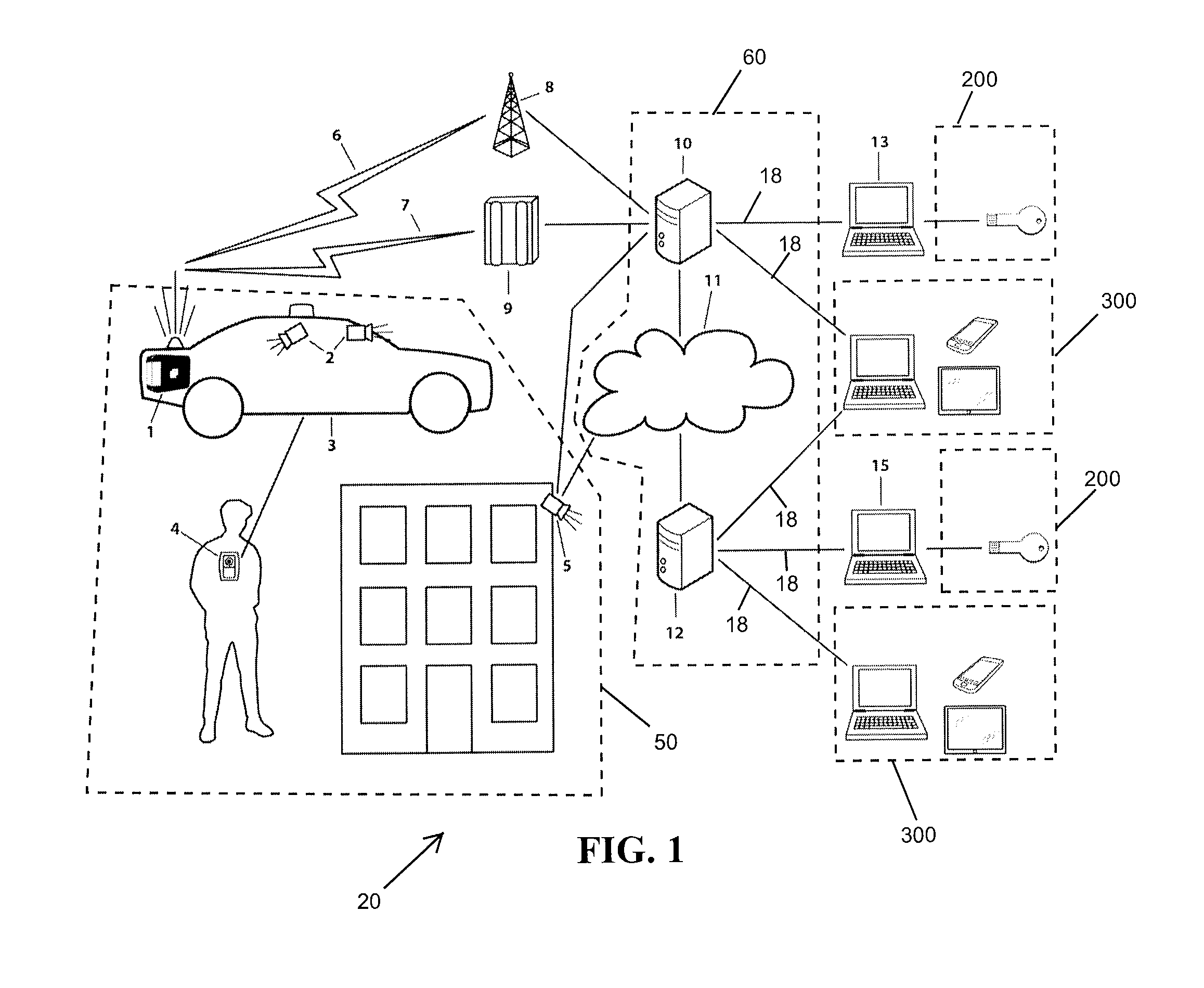

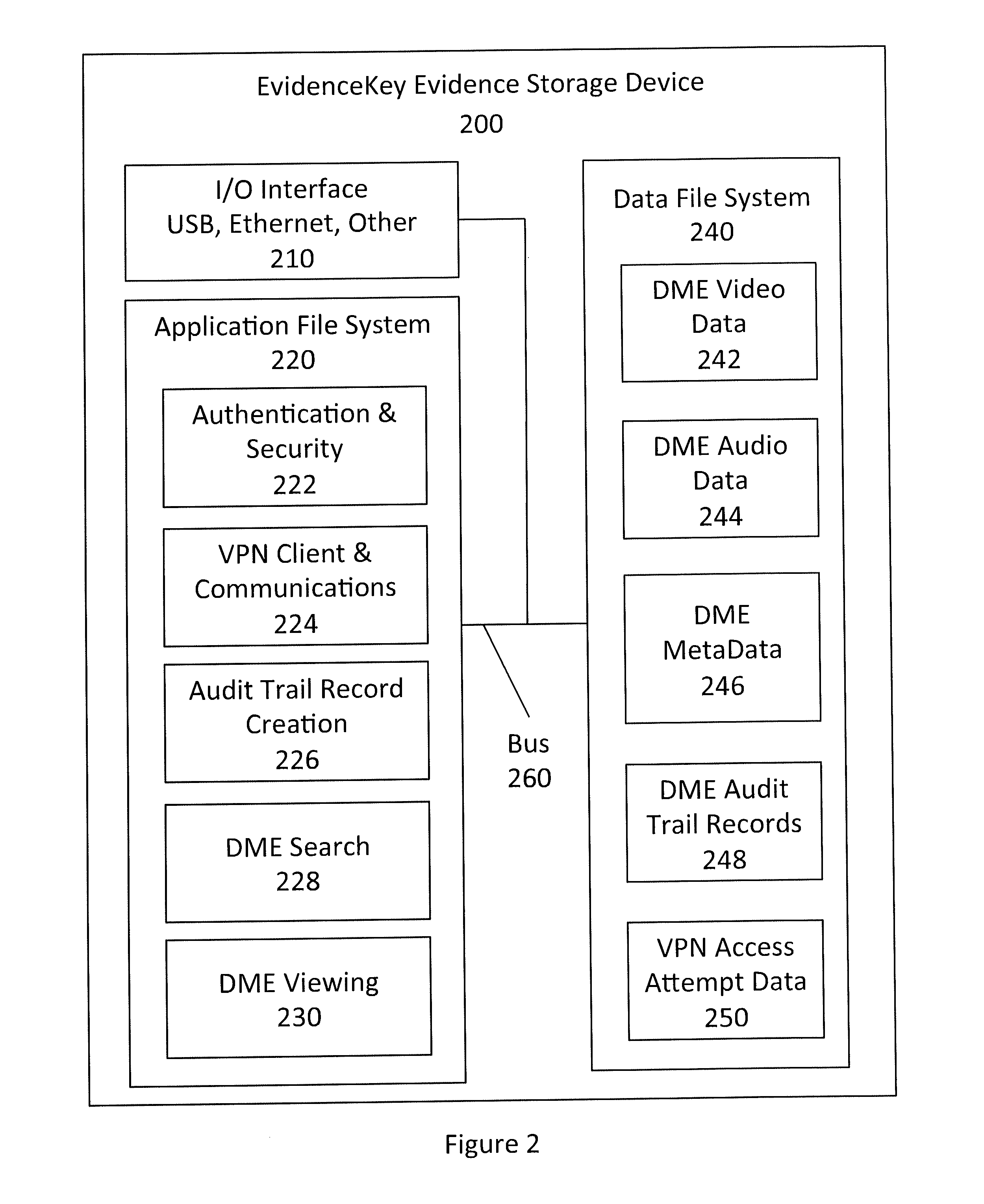

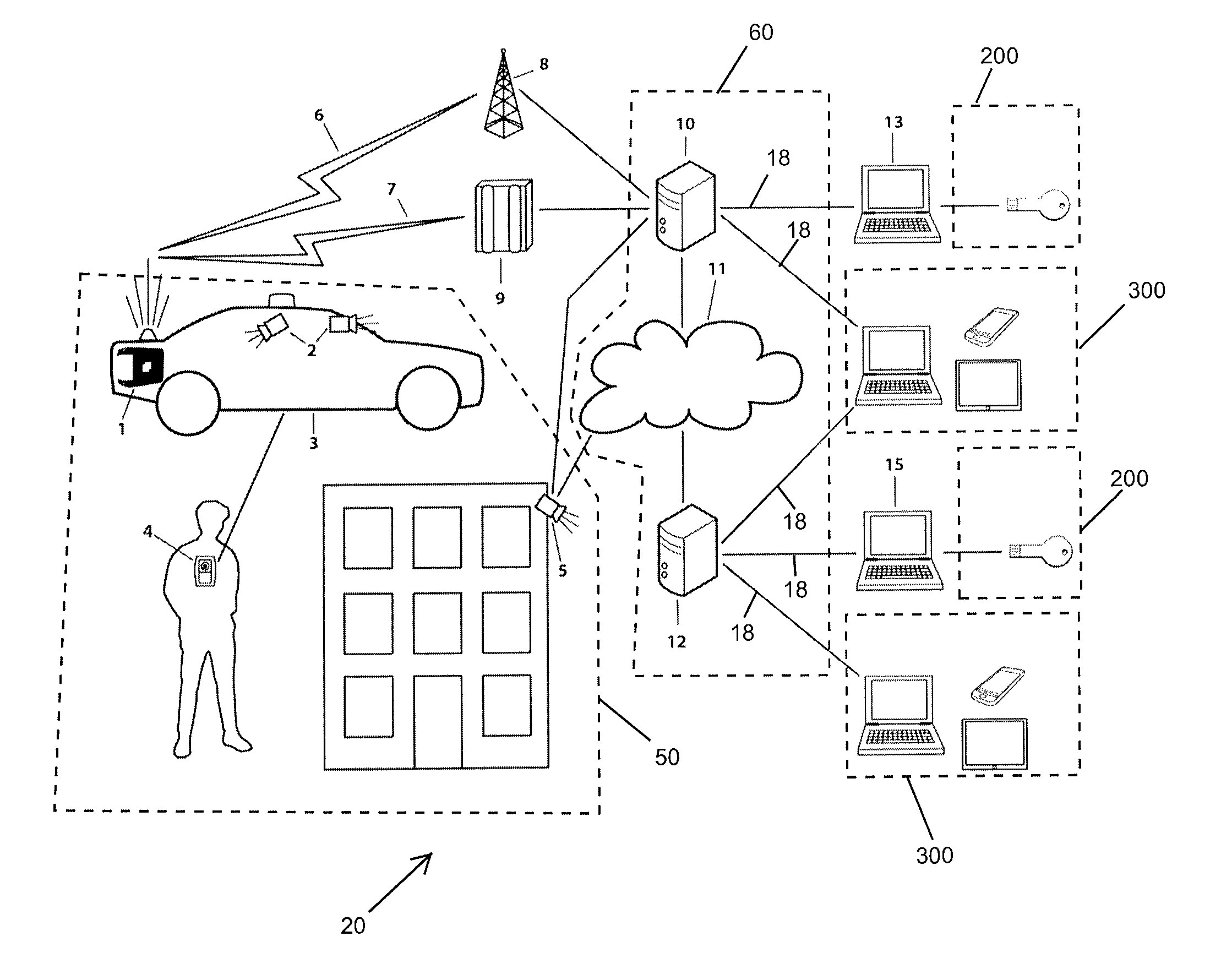

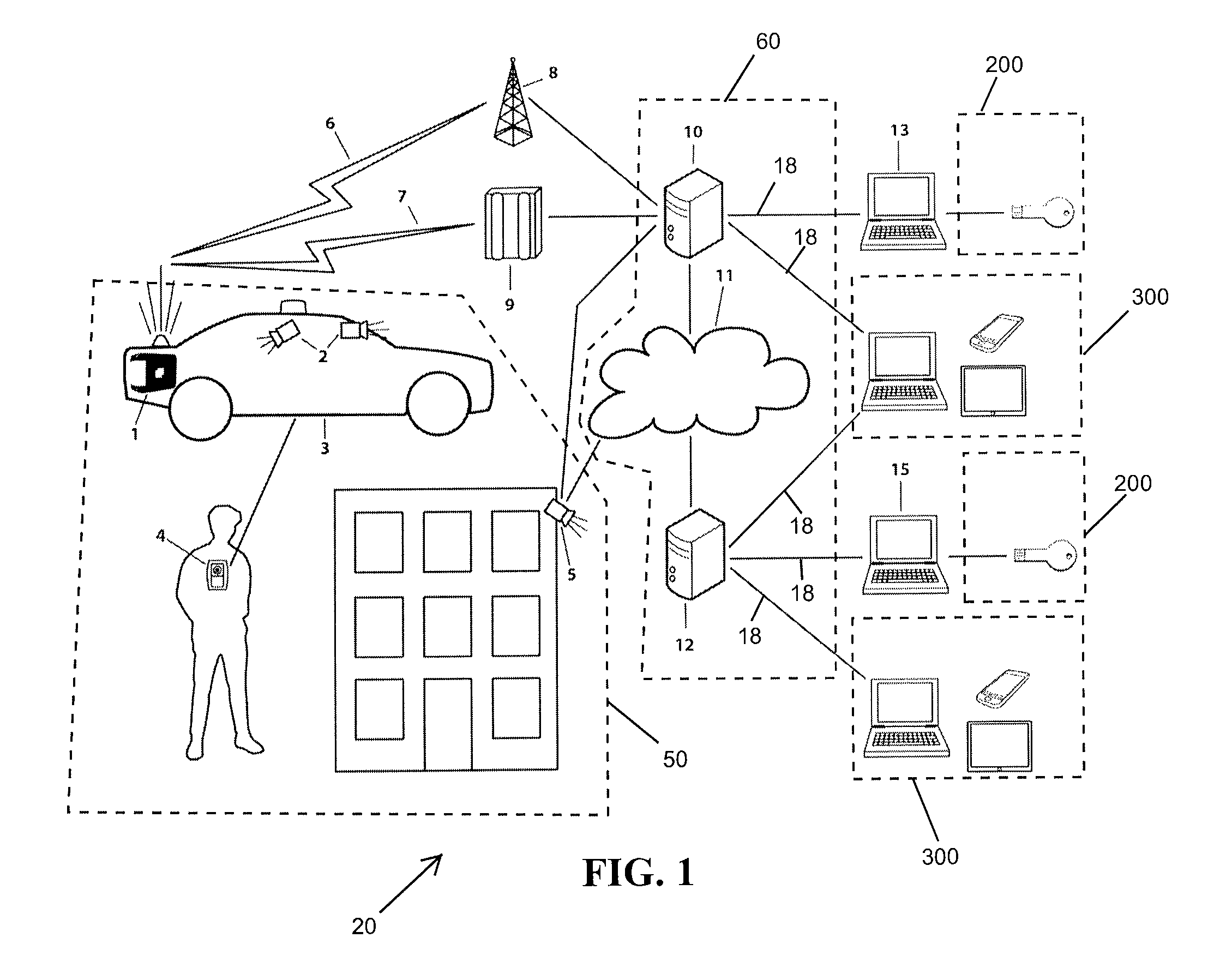

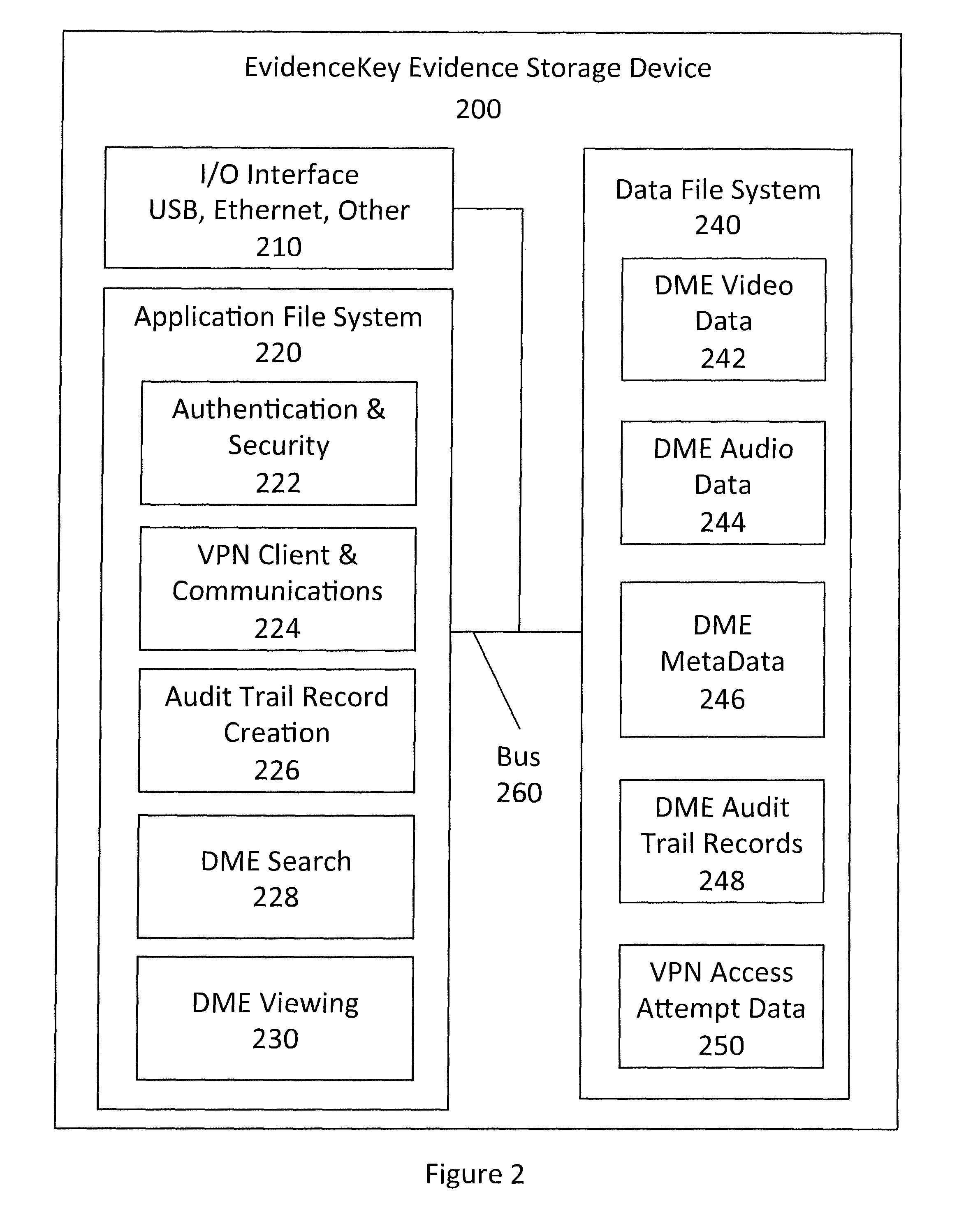

System and Method for Securely Distributing Legal Evidence

ActiveUS20140143545A1Shorten the timeReliable controlDigital data processing detailsUser identity/authority verificationLibrary scienceChain of custody

This invention provides a system and method to search for and securely download Digital MultiMedia Evidence (DME) data from a central DME repository to portable USB, smart phone, tablet, laptop, desktop, or other data storage devices, with a clear chain of custody and access control audit trail reporting, so the DME can be used to prepare for and conduct legal proceedings.

Owner:UTILITY ASSOCS

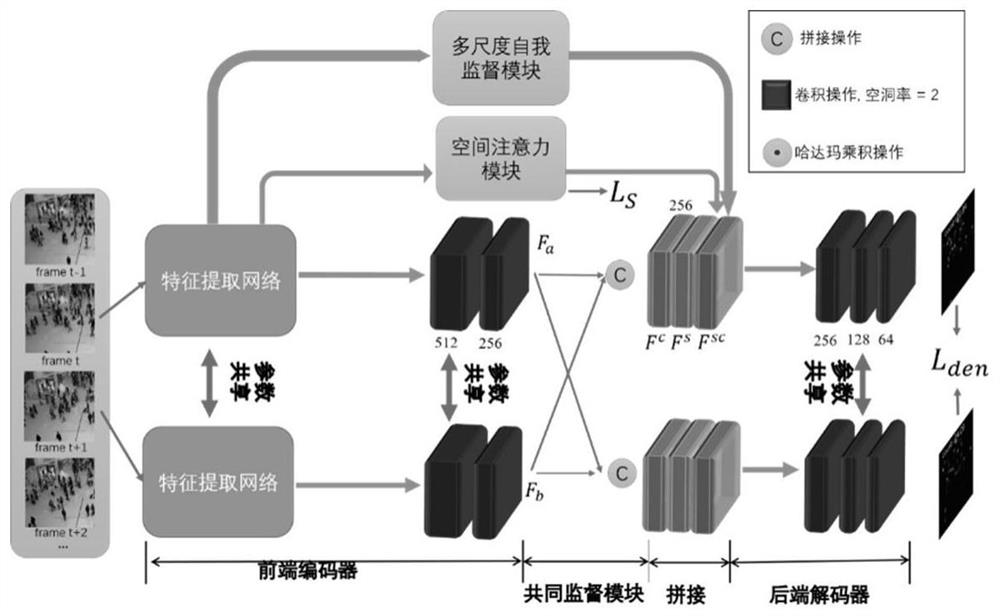

Video crowd counting system and method

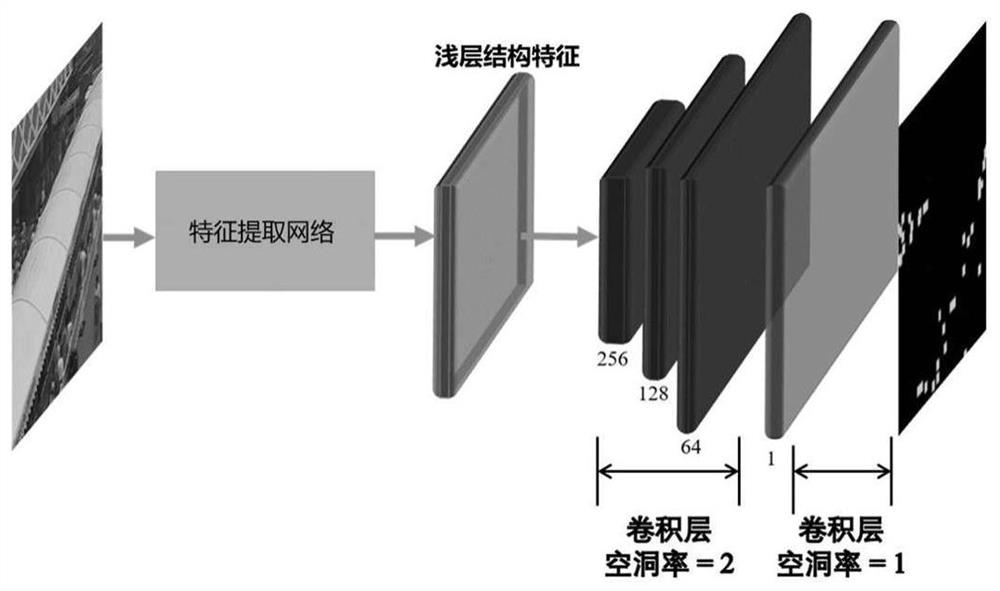

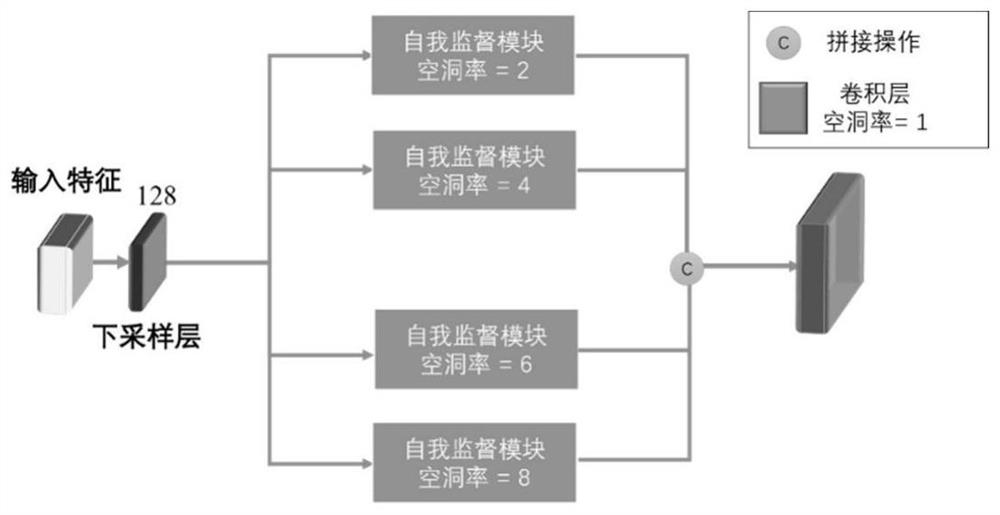

PendingCN111860162ARich correlationHold timeCharacter and pattern recognitionNeural architecturesCrowding inFeature fusion

The invention discloses a video crowd counting system and method. A front-end encoder performs feature extraction on a frame of image in a given video sequence; the common supervision module suppresses interference of a fixed background in a scene by utilizing related characteristics between a previous frame and a to-be-detected frame in a video sequence; the spatial attention module selects an attention area by utilizing shallow structure characteristics, and guides the system to distinguish foreground crowds from background interference; the multi-scale self-supervision module extracts different scale features of the crowd in the image through a multi-branch structure by using deep semantic features, adaptively integrates context feature information through a self-attention mechanism, and autonomously selects the most suitable scale branch feature; and the rear-end decoder is used for fusing the features extracted by the three modules and outputting a predicted crowd density map so as to calculate the number of people contained in the to-be-detected video frame. According to the invention, crowd number estimation is carried out on each contained frame of image according to the video sequence, and dense crowd counting for the video sequence is realized.

Owner:SHANGHAI JIAO TONG UNIV

System and method for securely distributing legal evidence

ActiveUS9246898B2Hold timeDigital data processing detailsTransmissionTablet computerChain of custody

This invention provides a system and method to search for and securely download Digital MultiMedia Evidence (DME) data from a central DME repository to portable USB, smart phone, tablet, laptop, desktop, or other data storage devices, with a clear chain of custody and access control audit trail reporting, so the DME can be used to prepare for and conduct legal proceedings.

Owner:UTILITY ASSOCS

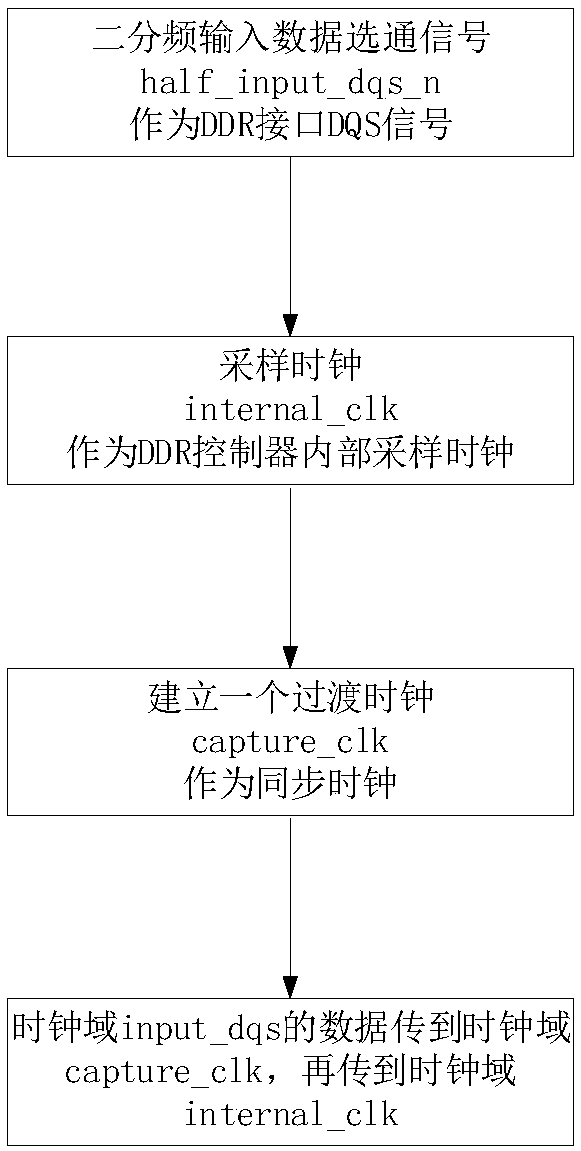

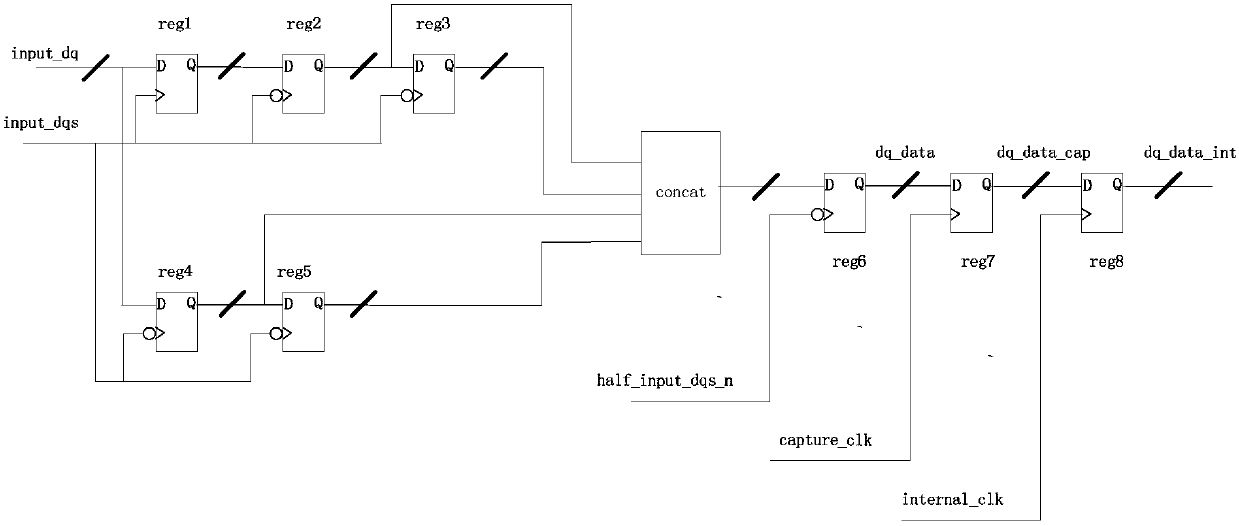

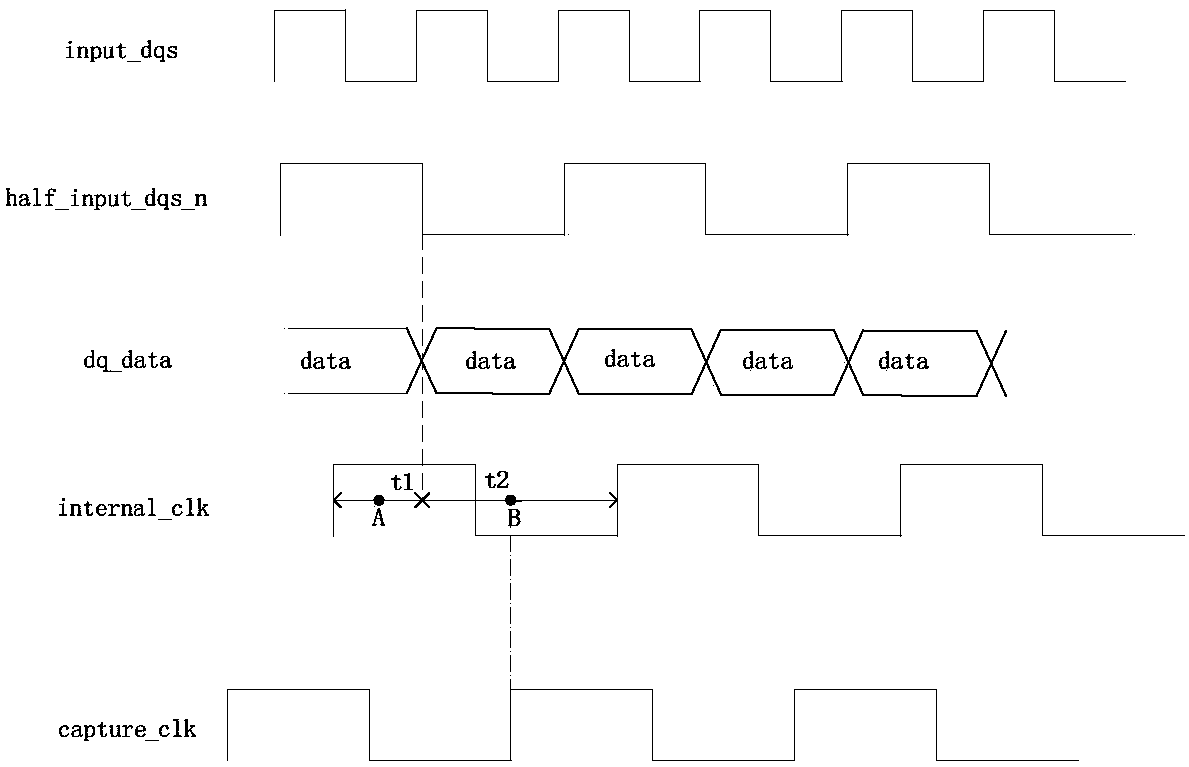

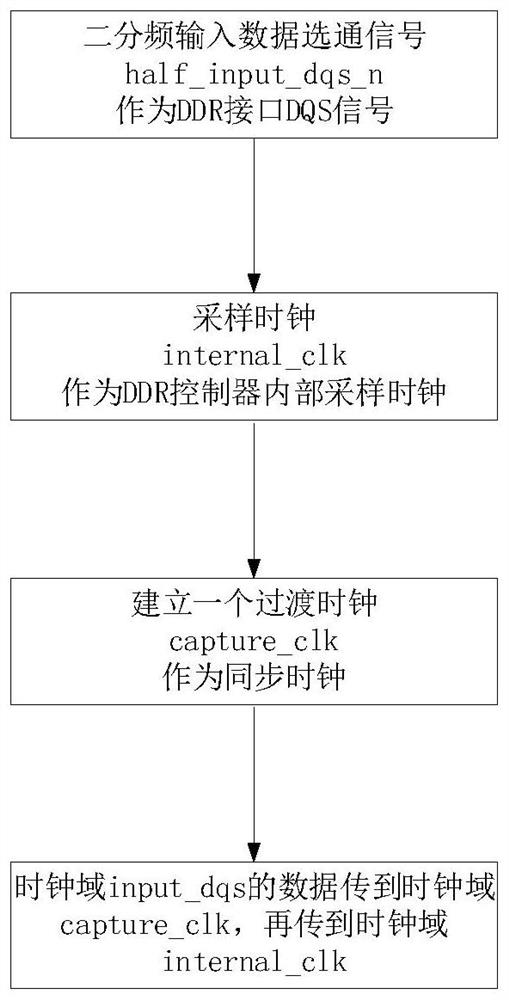

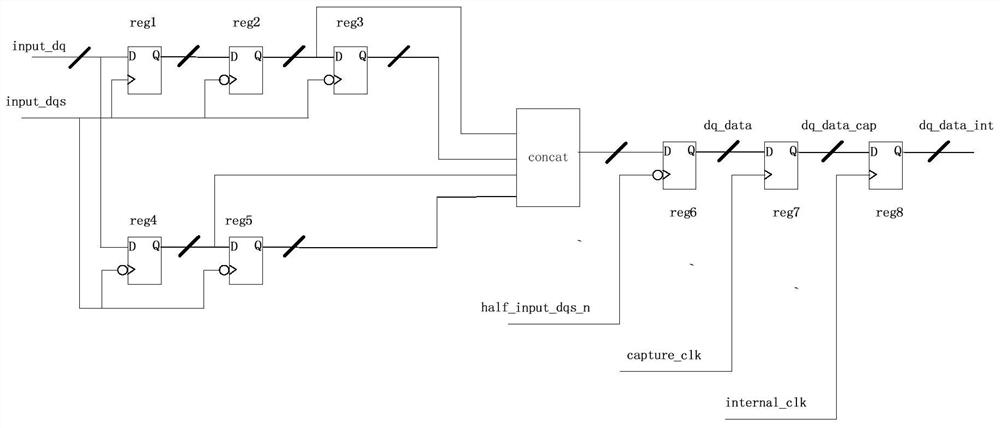

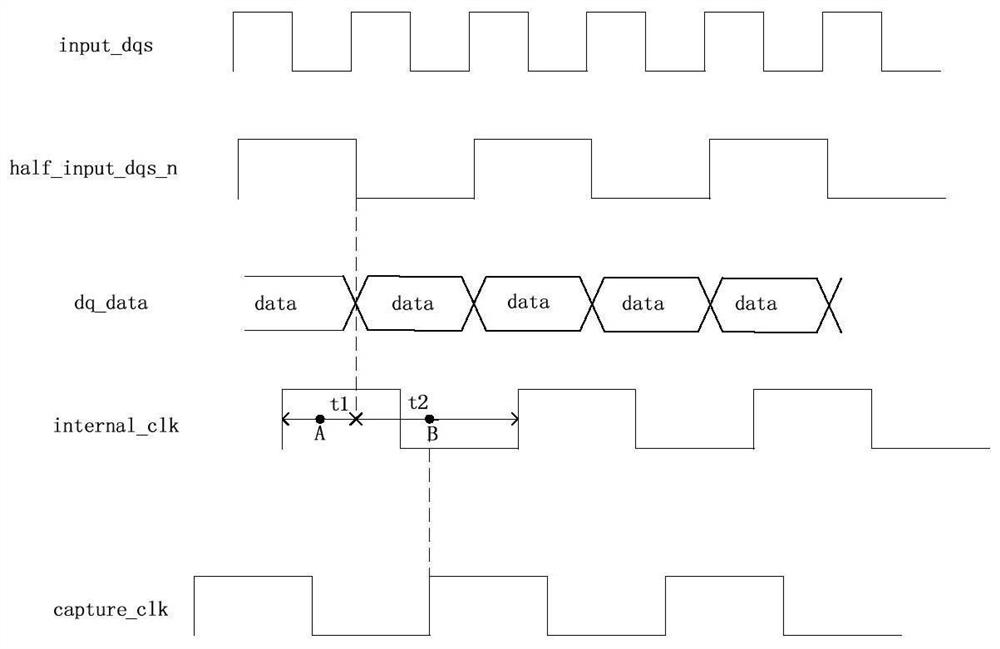

DDR-based reading data synchronization method and system

ActiveCN108038068AEliminate bottlenecksResolve synchronizationElectric digital data processingData synchronizationRetention time

The invention discloses a DDR-based reading data synchronization method and system. The method uses a frequency divider to input a data strobe signal half-inpu-dqs-n as a DDR interface DQS signal, a sampling clock internal-clk serves as a sampling clock in a DDR controller, a transition clock is set up as a synchronous clock between the DDR interface DQS signal and the sampling clock in the DDR controller, and the synchronous clock achieves the synchronization of the sampling clock in the DDR controller and an input color outside the DDR and achieves asynchronous transmission of DDR interfaceDQS domain data and domain data of the sampling color in the DDR controller. According to the method and the system, the building time and the retention time of a DQS domain and a sampling color domain in the DDR controller can be satisfied to the maximum extent, the synchronization problem of the DDR reading data is solved with a very small delay, and the method and the system no longer rely on the FIFO technology.

Owner:灿芯创智微电子技术(北京)有限公司

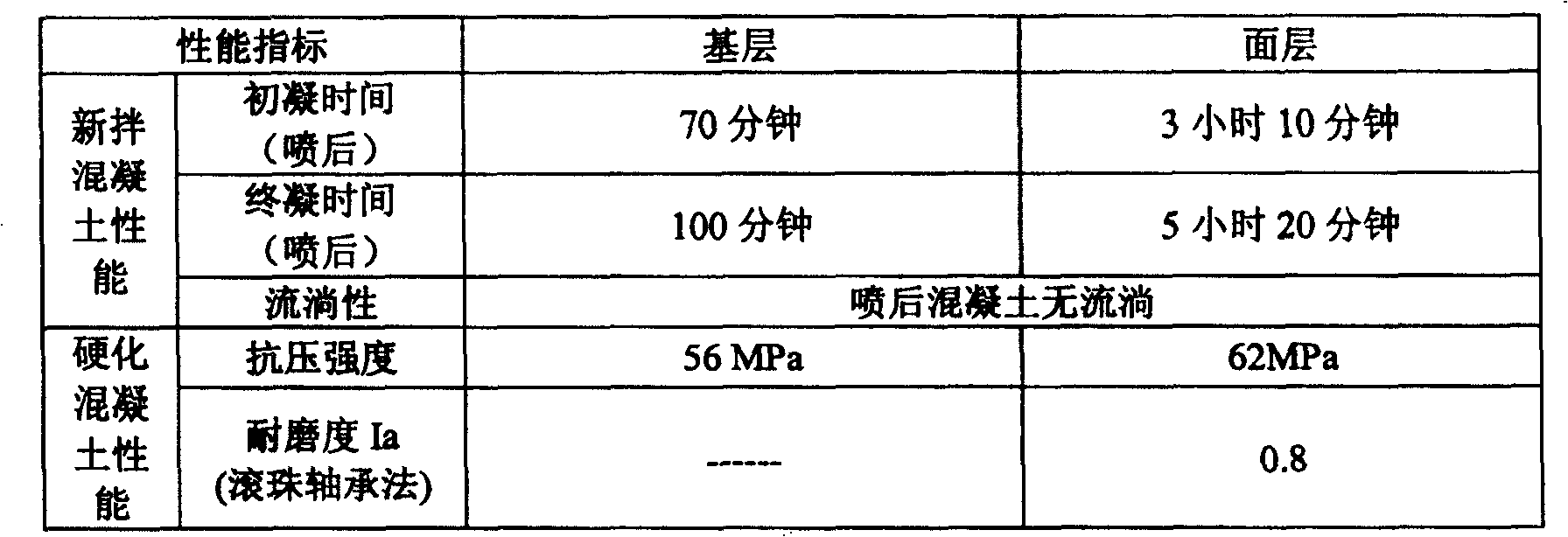

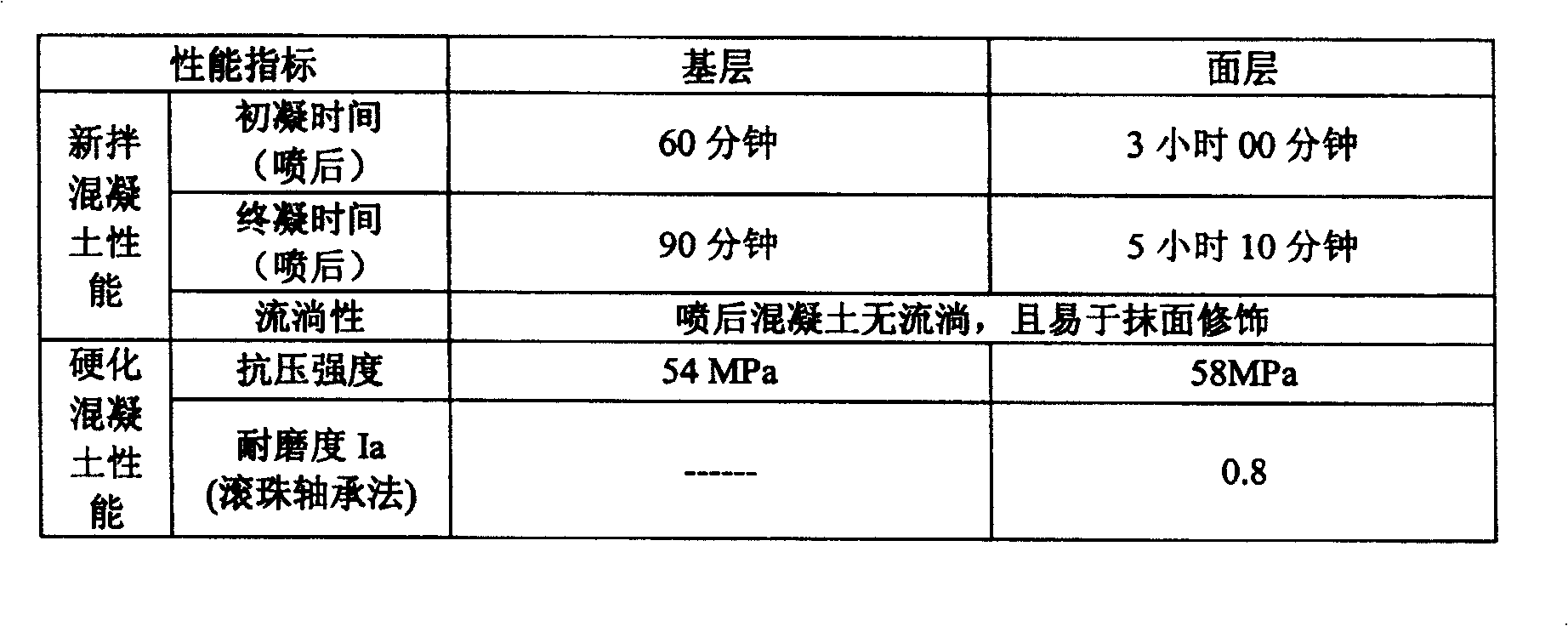

High compact bidirectionally adjustable concrete and its uses

InactiveCN101007722AHold timeGuaranteed not to flowSolid waste managementCeramic shaping apparatusCrushed stoneWollastonite

The invention discloses a high-compact bidirectional adjustable concrete and application, which comprises the following parts: 1% PII 52.5, 0.20-0.35% II-grade low-calcium coal ash, 0.05-0.08% wollastonite, 0.015-0.020% high-property polycarboxylic acid additive, 0.0012-0.0020% polypropylene fiber, 2.00-0.32% medium sand, 1.40-1.70% crushed stone, 0.38-0.45% water and 0-0.016% concrete accelerator. The invention is fit for spraying and casting on the large-smooth curve, which satisfies quality standard.

Owner:上海市建筑构件制品有限公司

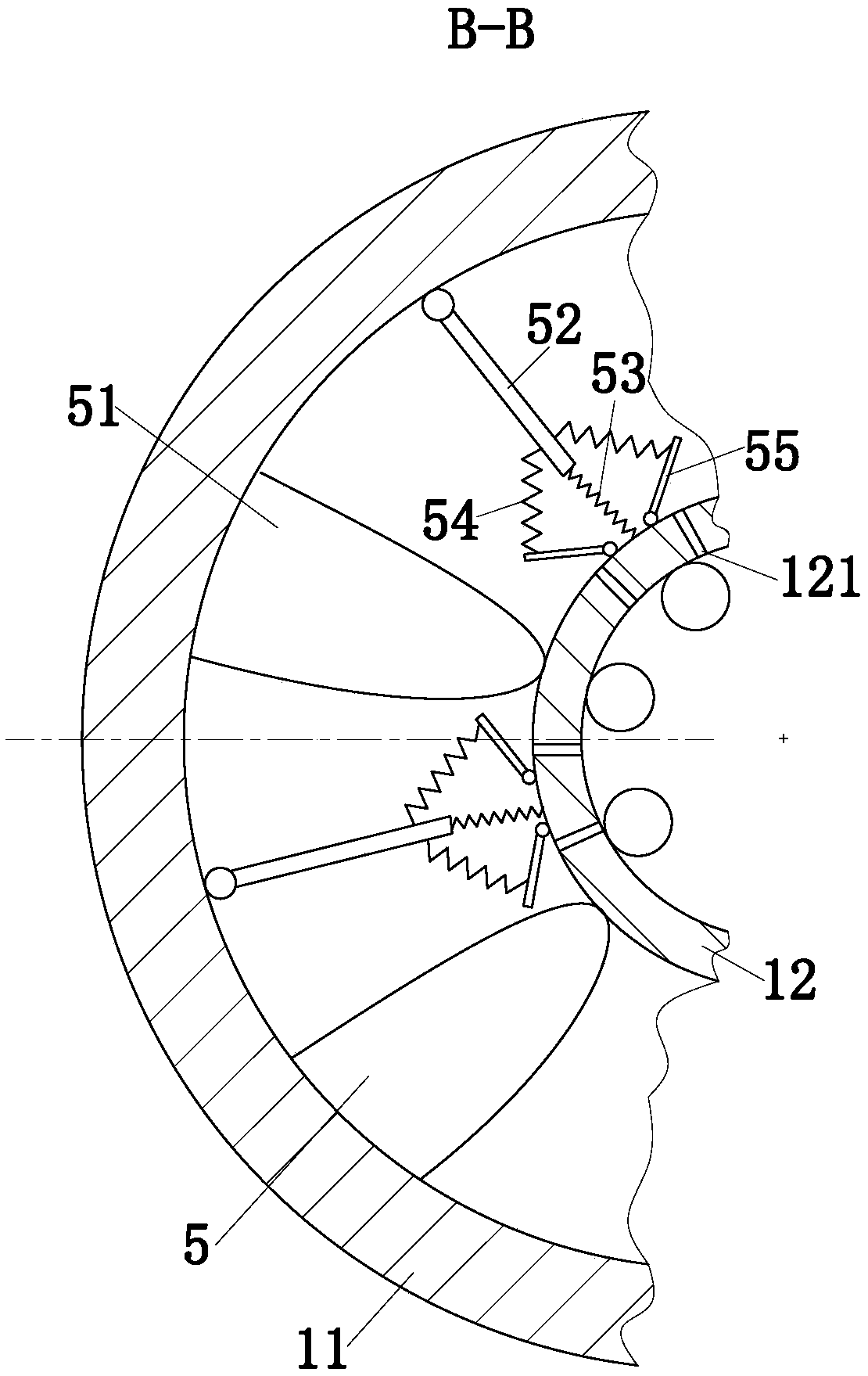

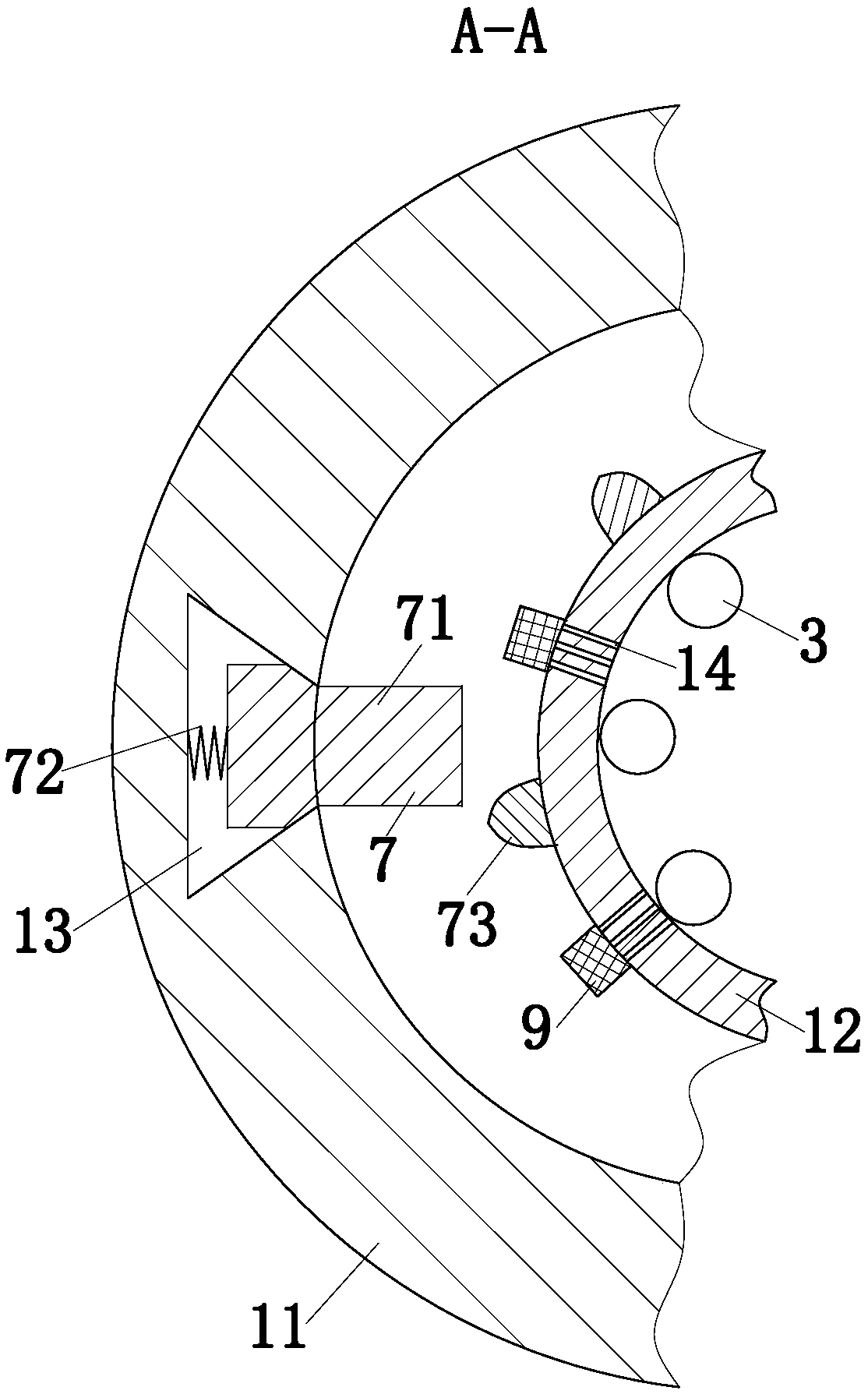

Self-lubricating bearing

ActiveCN108757743AImprove sealingImprove efficiencyBearing componentsMechanical engineeringEngineering

The invention belongs to the field of bearings, in particular to a self-lubricating bearing. The self-lubricating bearing comprises an outer race, an inner race, rolling elements, a retainer, a sealing strip, a lubricating unit and a sealing unit, wherein the outer race consists of an outer ring and an inner ring which are respectively in a cylinder shape; the outer ring and the inner ring are concentrically arranged, and are connected by a connecting unit; the inner race is in a cylinder shape, and is arranged at the inner side of the inner ring; the rolling elements are arranged between theinner ring and the inner race; the retainer is arranged between the adjacent rolling elements; the sealing strip is arranged between the outer ring and the inner ring; the lubricating unit is used forlubricating the bearing self; the sealing unit is used for sealing the interior of the bearing self. The self-lubricating bearing has the advantages that when the self-lubricating bearing works, theinner race drives the inner ring of the outer race to rotate through the rolling elements, the self-lubricating bearing is filled with the lubricating oil, the lubricating oil enters the part betweenthe outer ring and the inner ring under the function of the lubricating unit, and the lubricating function is realized between the inner ring and the inner race, so that the use effect of the bearingis improved.

Owner:台州椒星传动设备有限公司

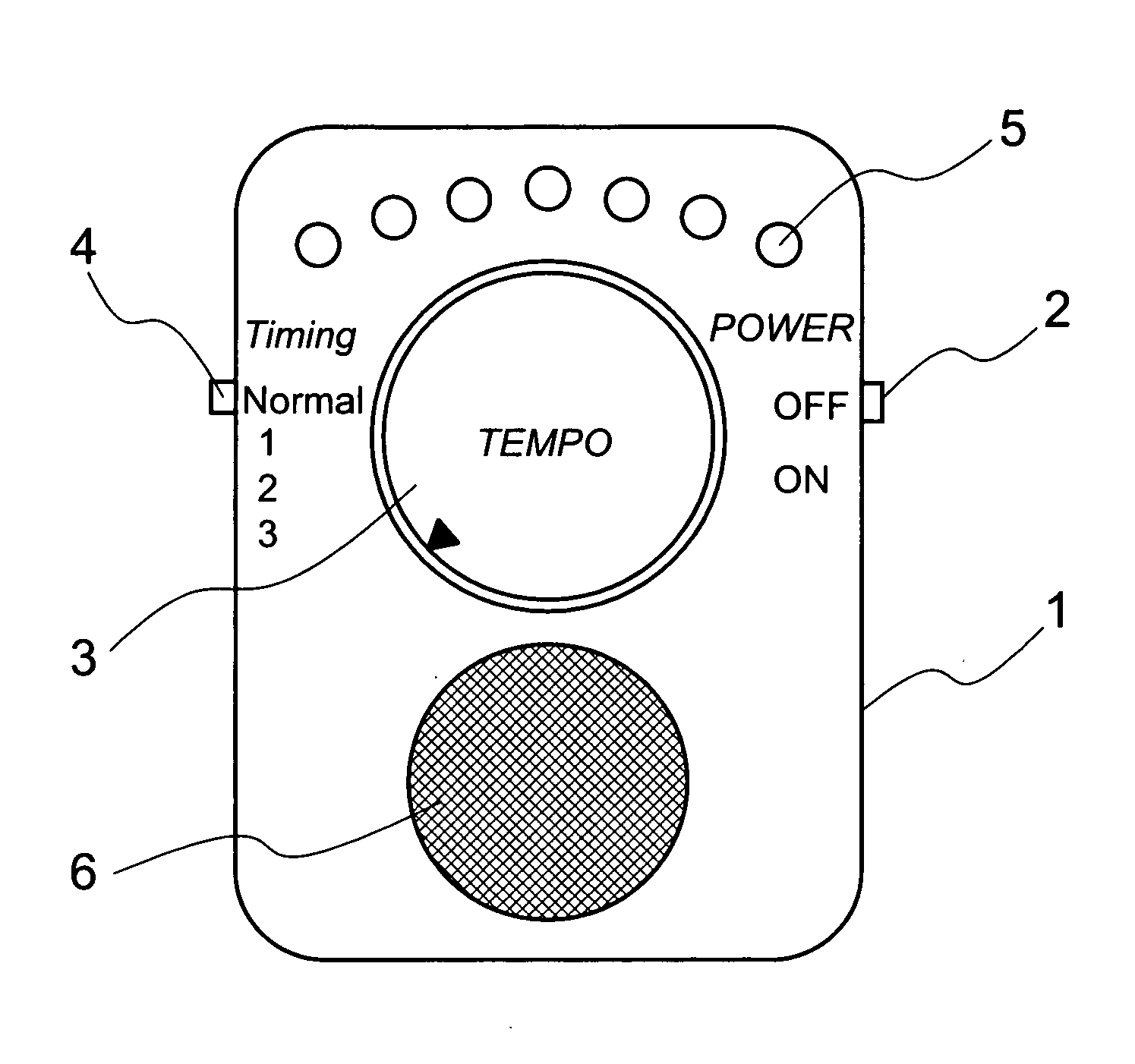

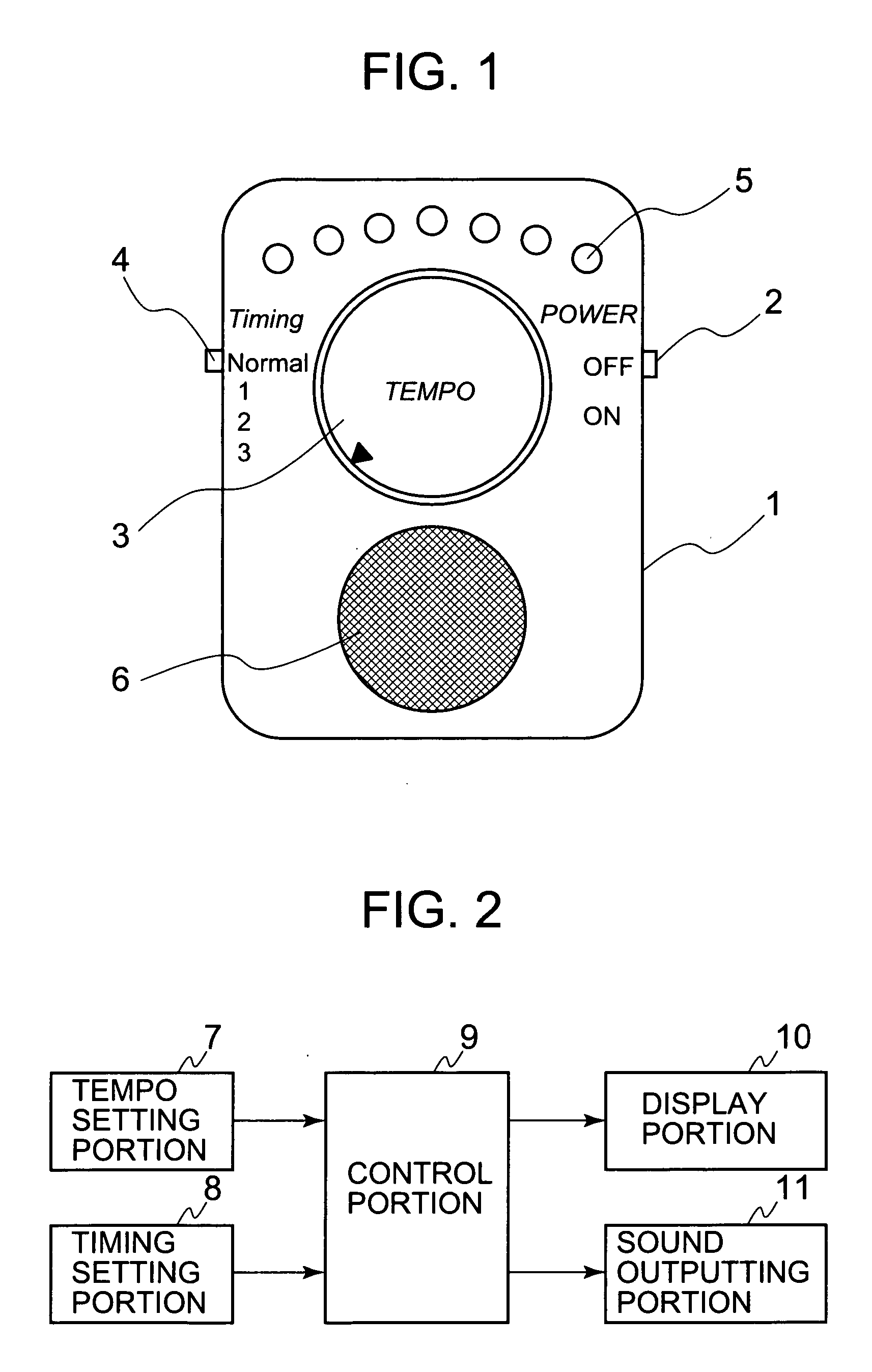

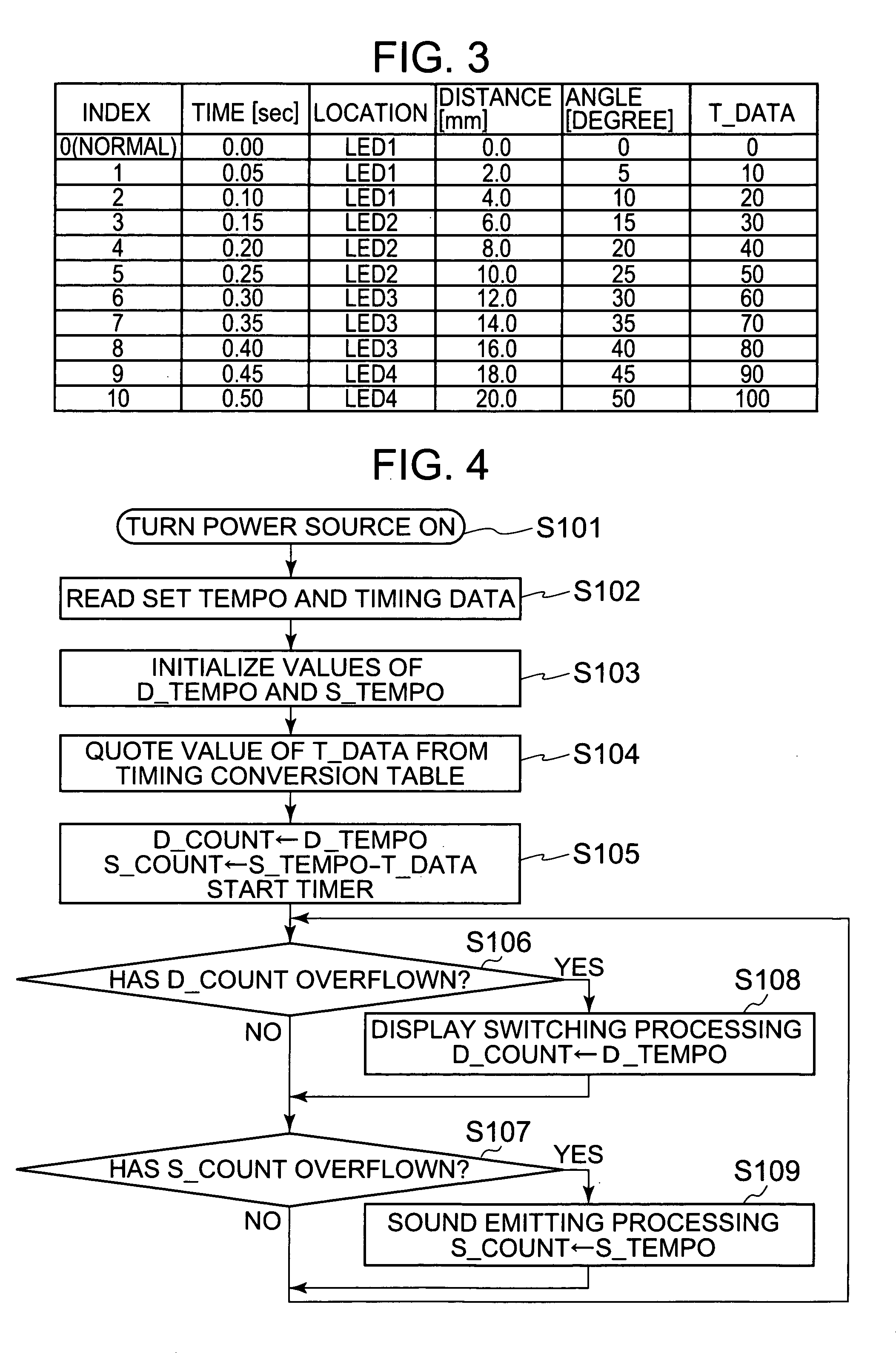

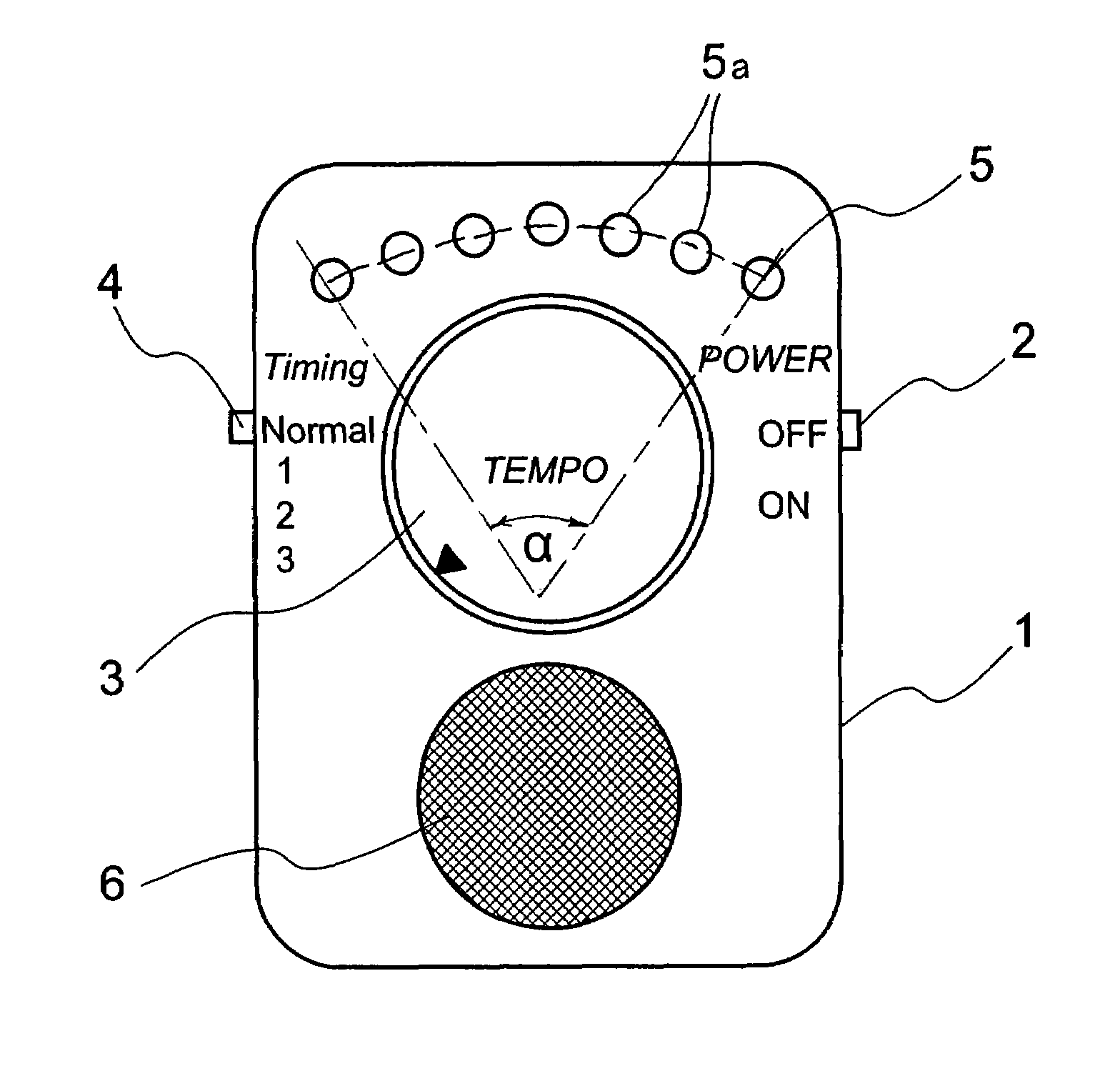

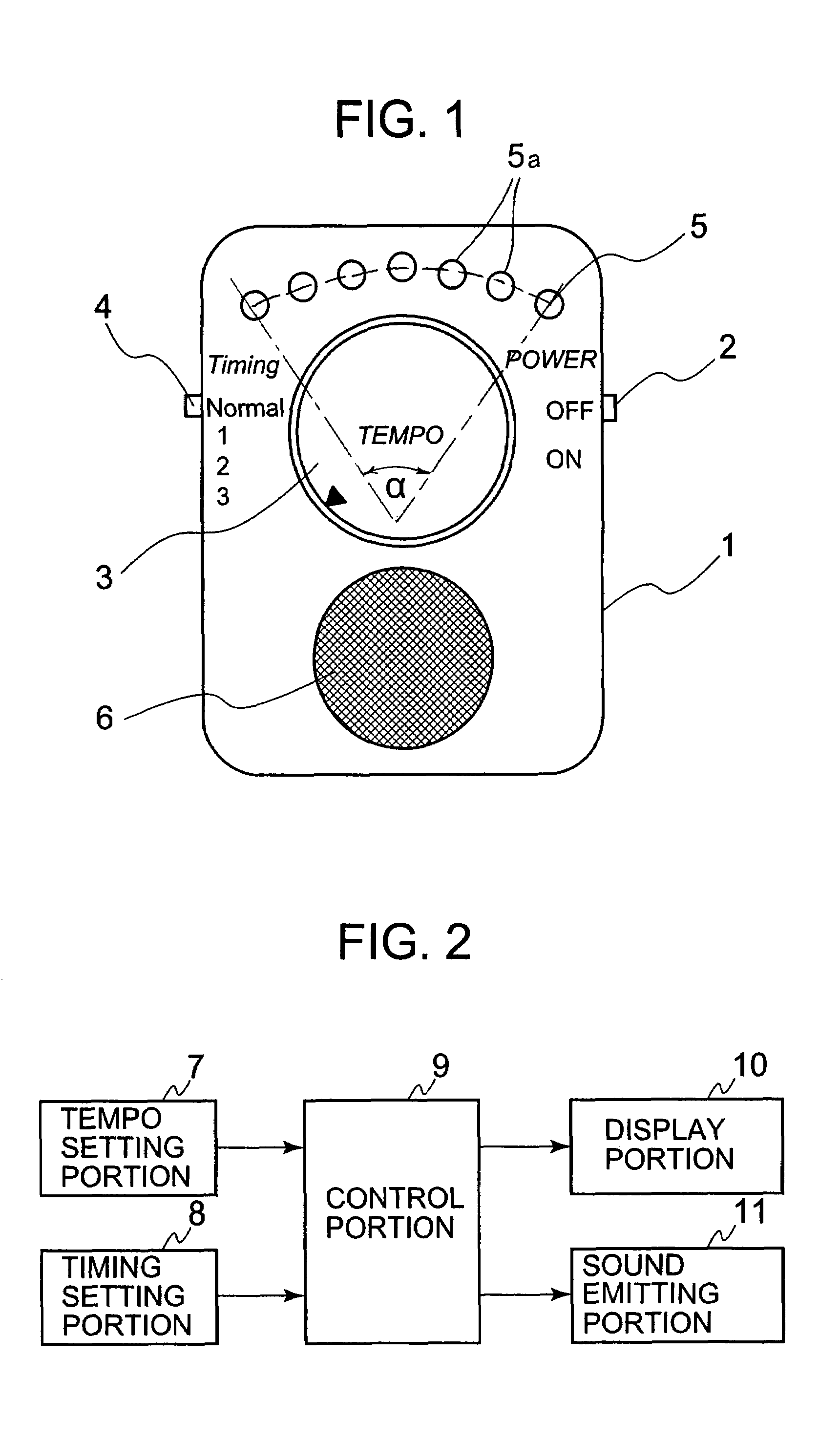

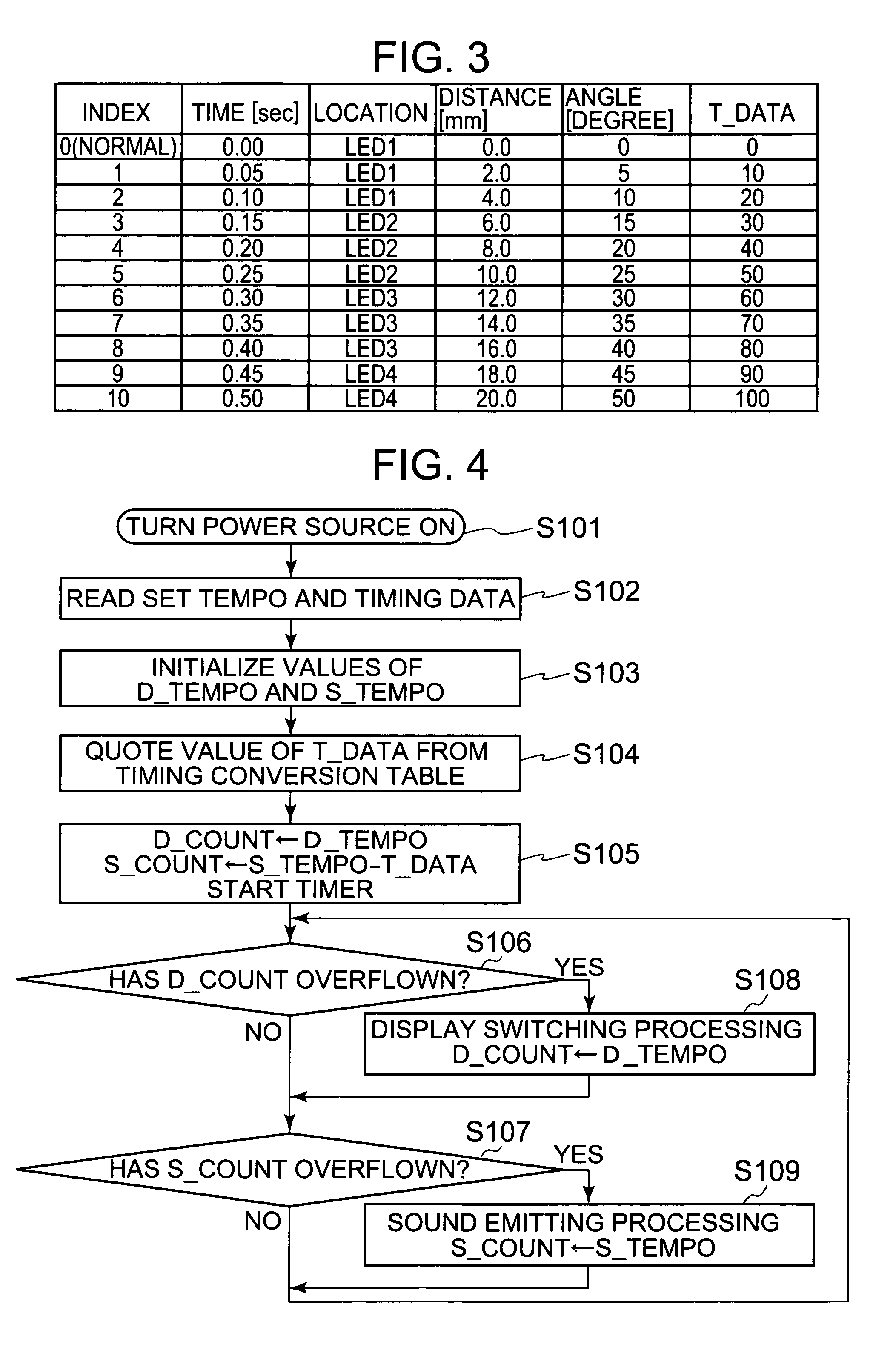

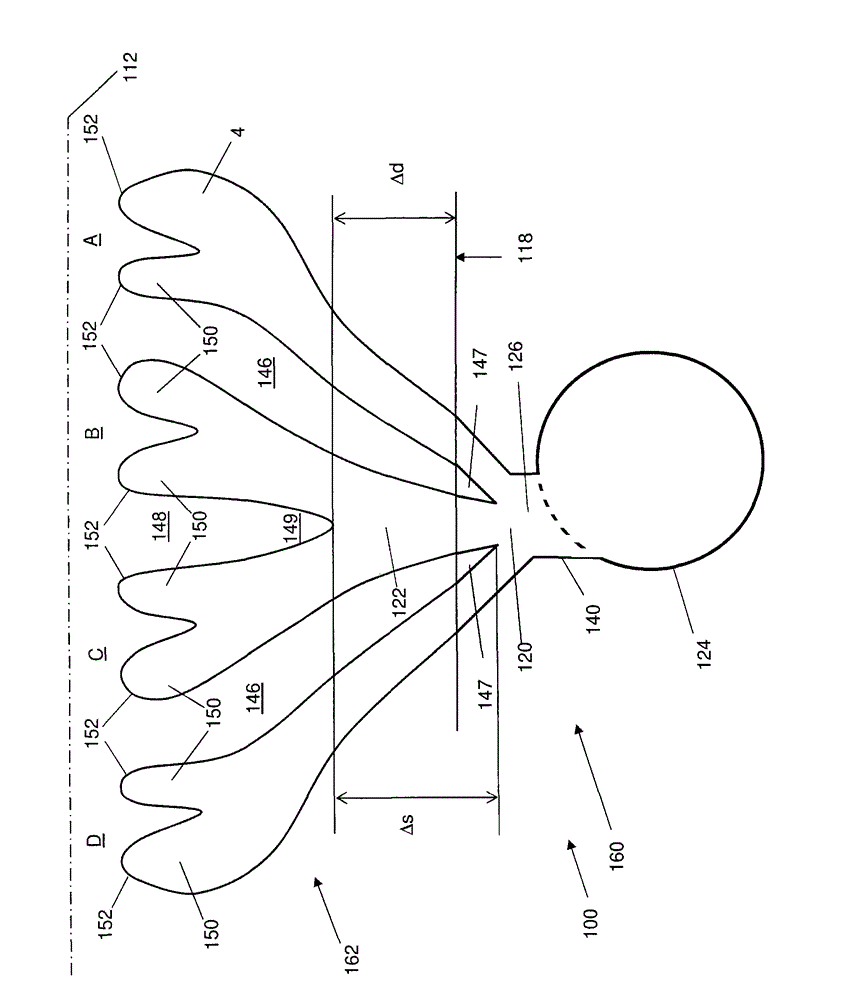

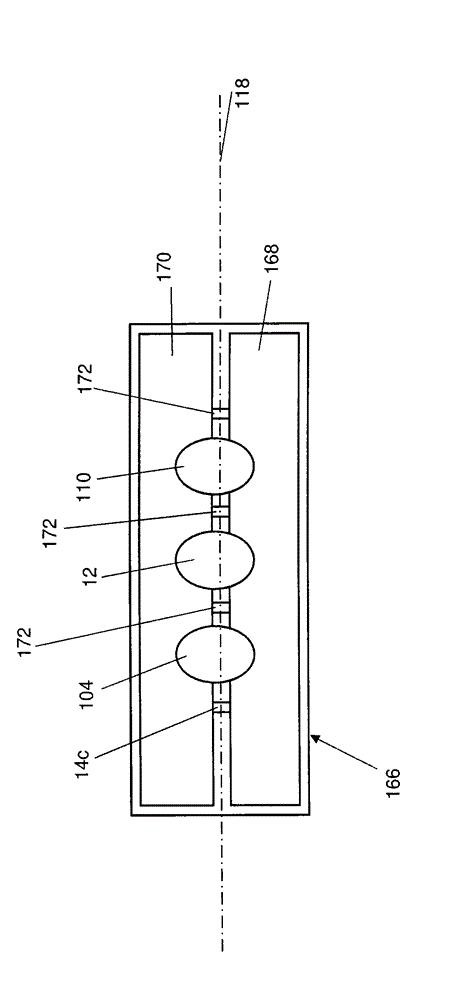

Electronic metronome and method of indicating tempo of electronic metronome

InactiveUS20050211073A1Time offsetHold timeElectrophonic musical instrumentsMetronomesLiquid-crystal displayMetronome

To provide an electronic metronome making a display similar to the movement of a mechanical metronome or a parabolic movement, an electronic metronome of the present invention includes a timing setting portion for setting a timing for emitting a sound, a control portion that outputs pieces of tempo indication data and a tempo sound signal, which are based on a piece of data on a set tempo, respectively at timings based on a piece of sound emission timing information set by the timing setting portion, a display portion that is constructed of a plurality of light emitting elements or liquid crystal display segments and visually displays a tempo by sequentially displaying the pieces of tempo indication data outputted from the control portion, and a sound emitting portion that emits a sound through amplification of the tempo sound signal outputted from the control portion.

Owner:SEIKO INSTR INC

Electronic metronome and method of indicating tempo of electronic metronome

InactiveUS7531734B2Hold timeElectrophonic musical instrumentsMetronomesLiquid-crystal displayDisplay device

To provide an electronic metronome making a display similar to the movement of a mechanical metronome or a parabolic movement, an electronic metronome of the present invention includes a timing setting portion for setting a timing for emitting a sound, a control portion that outputs pieces of tempo indication data and a tempo sound signal, which are based on a piece of data on a set tempo, respectively at timings based on a piece of sound emission timing information set by the timing setting portion, a display portion that is constructed of a plurality of light emitting elements or liquid crystal display segments and visually displays a tempo by sequentially displaying the pieces of tempo indication data outputted from the control portion, and a sound emitting portion that emits a sound through amplification of the tempo sound signal outputted from the control portion.

Owner:SEIKO INSTR INC

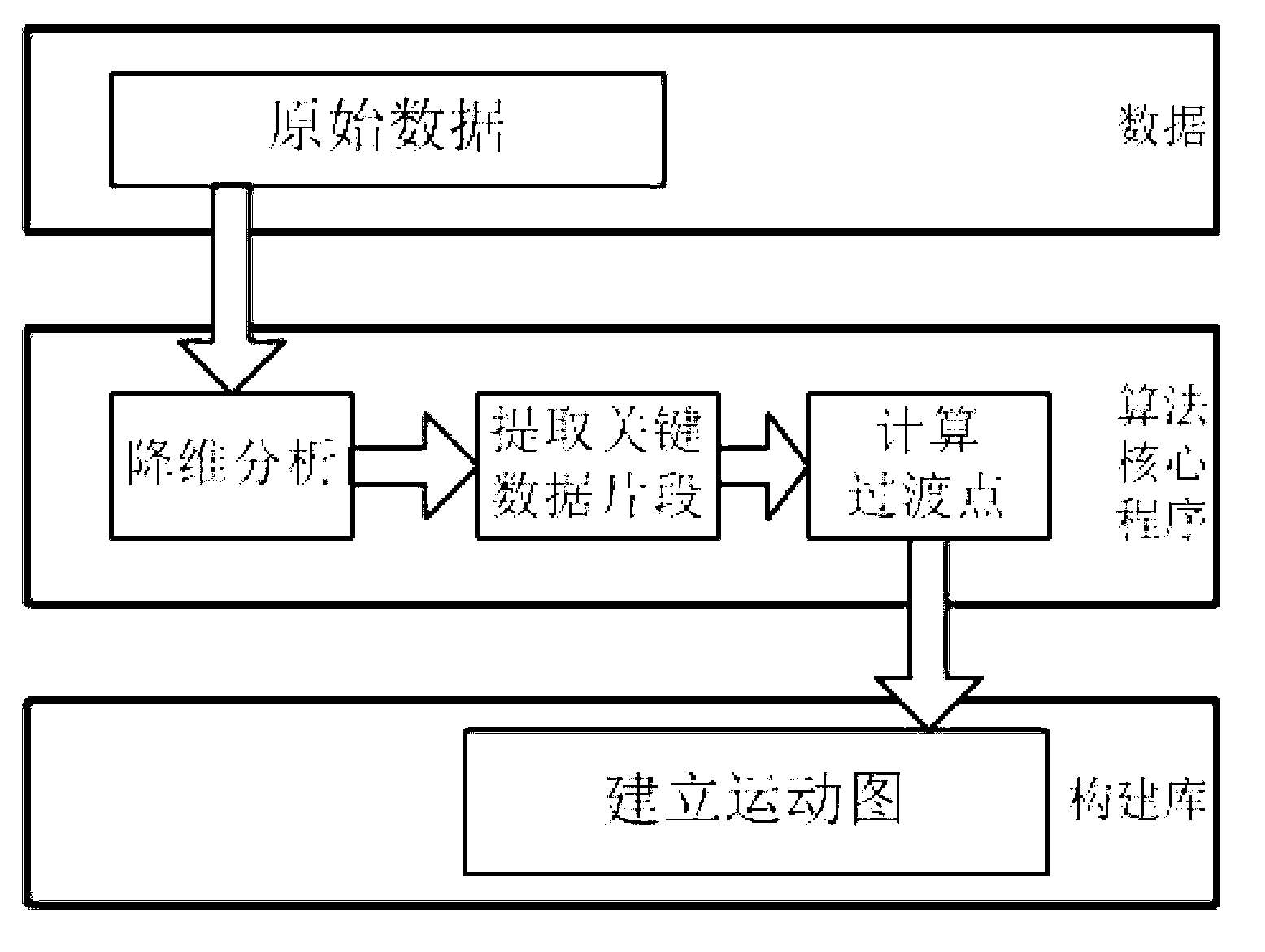

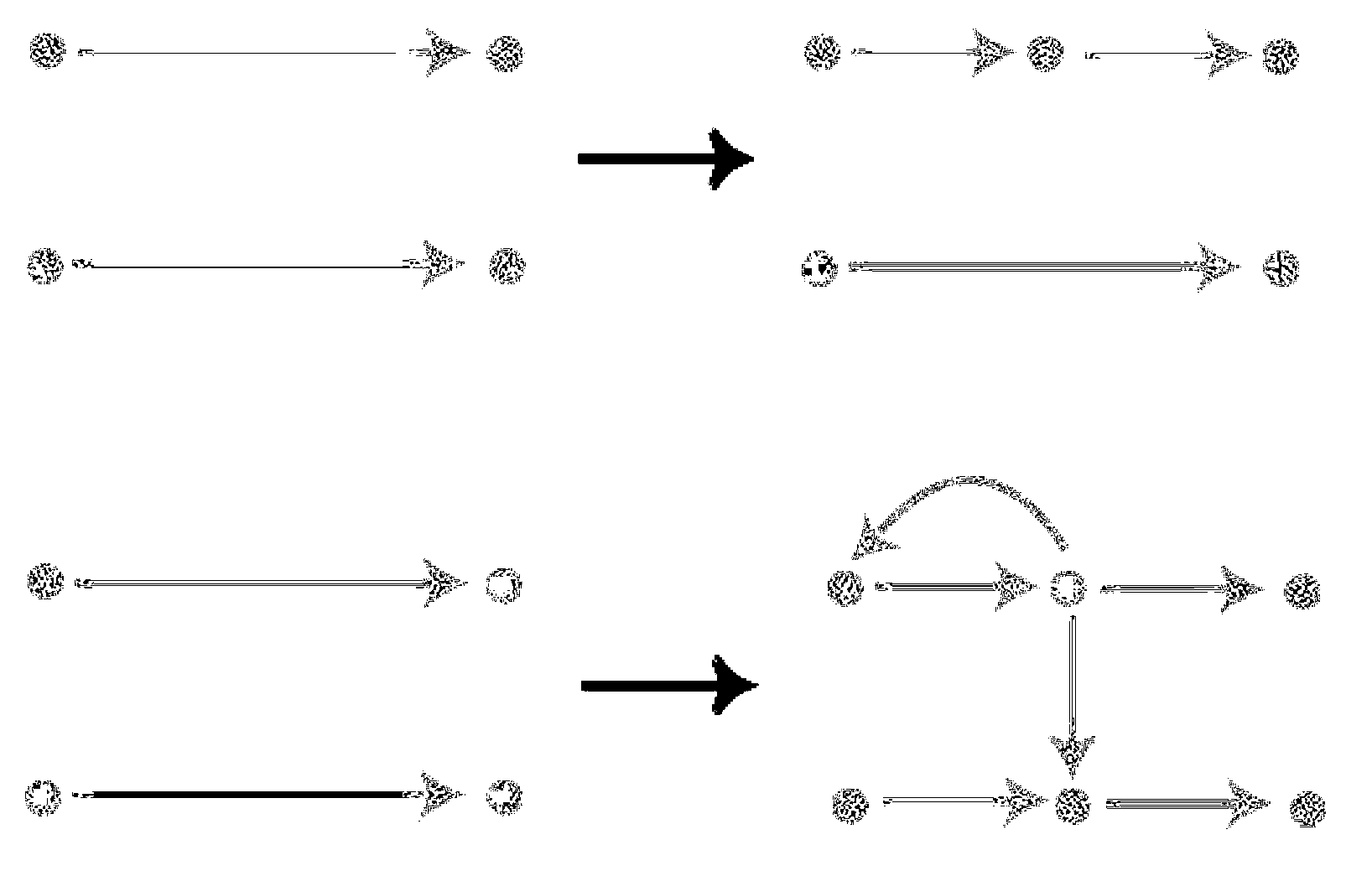

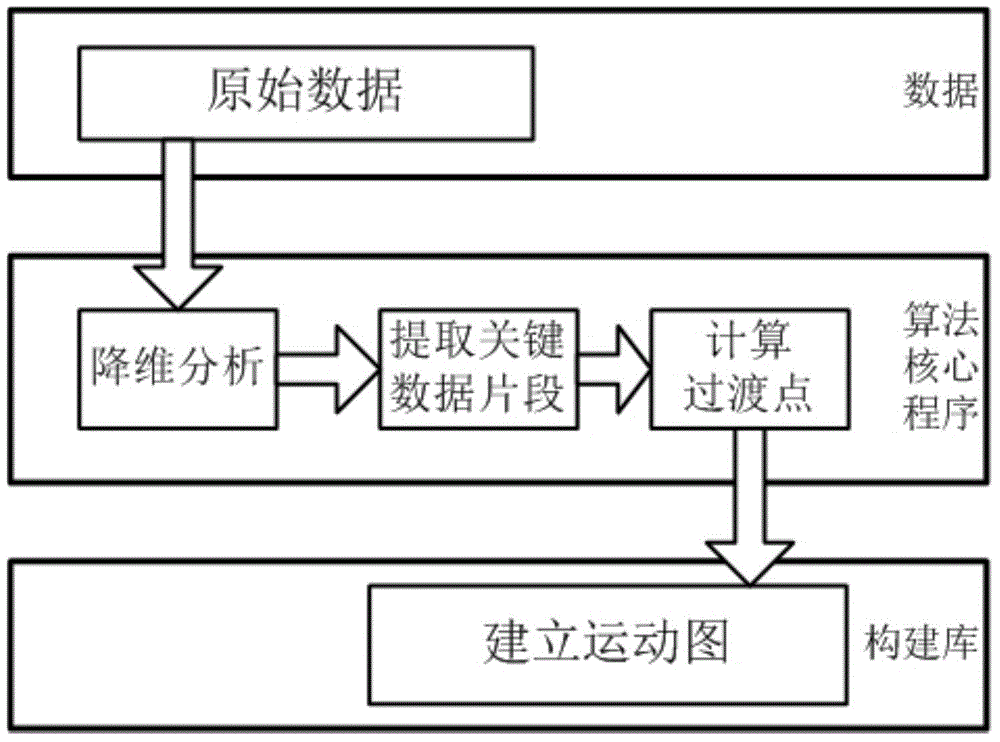

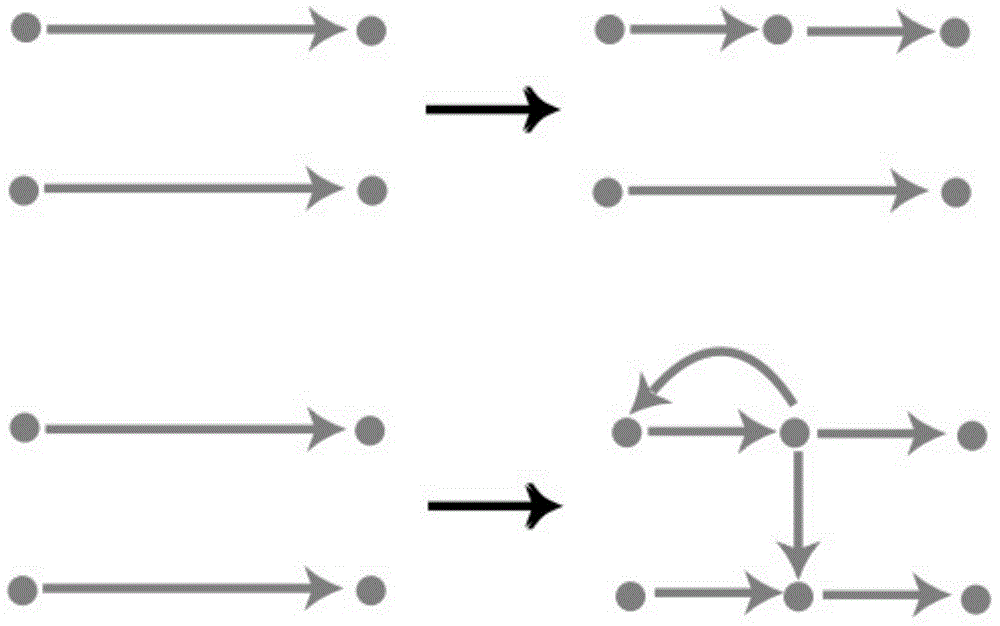

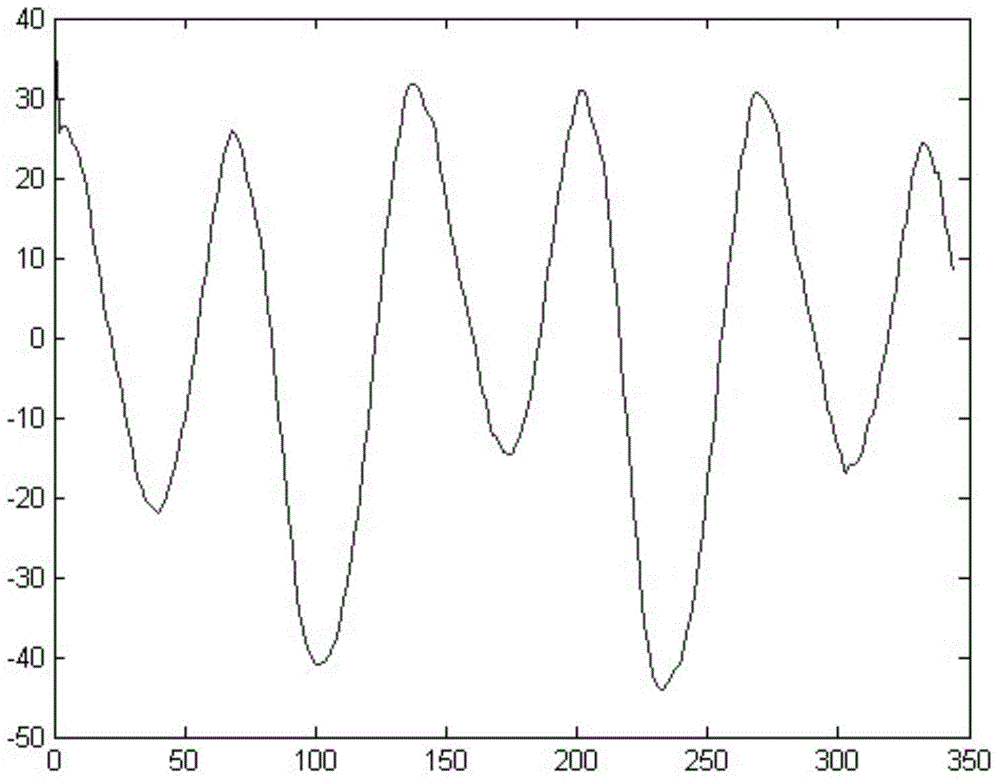

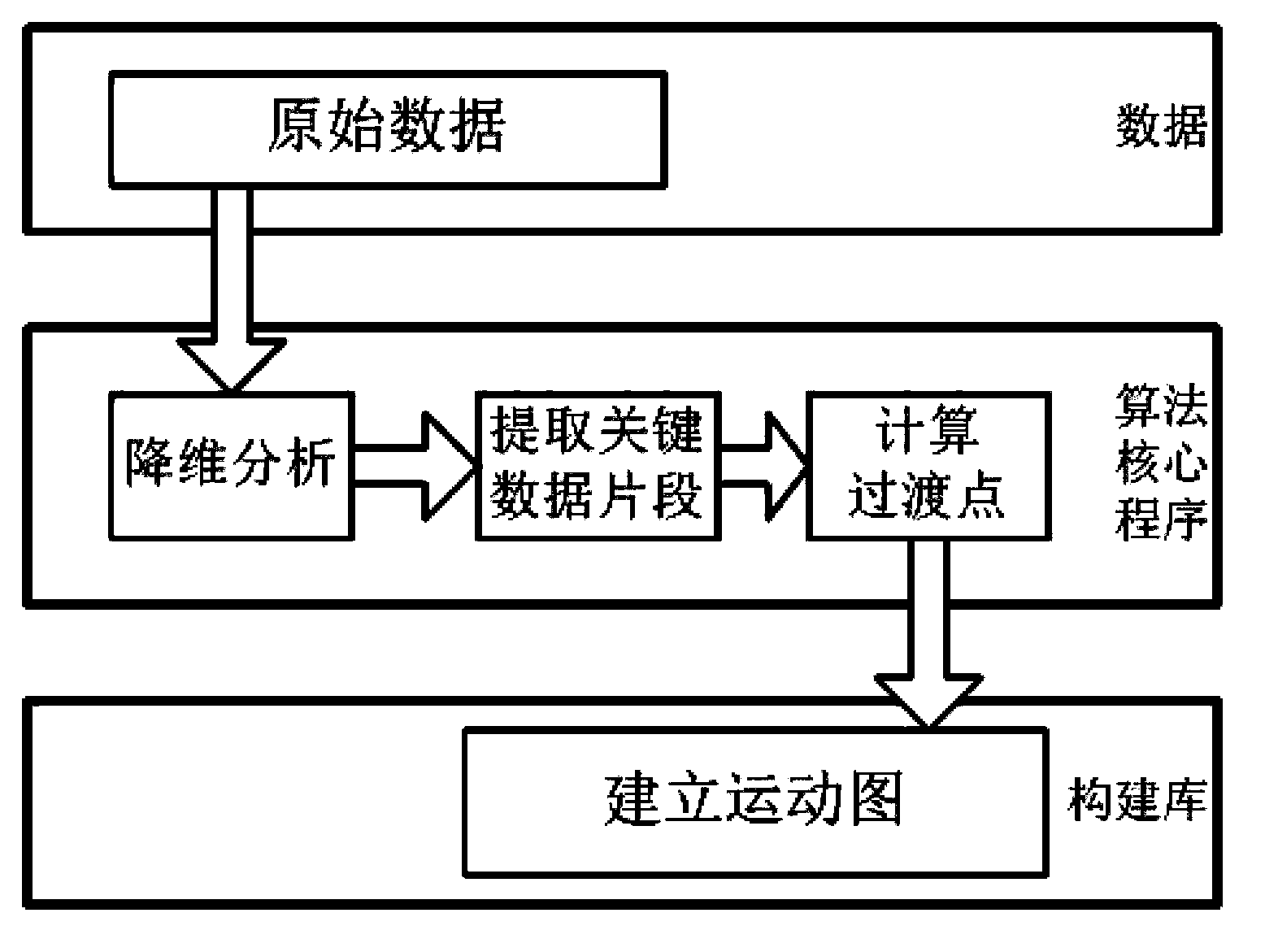

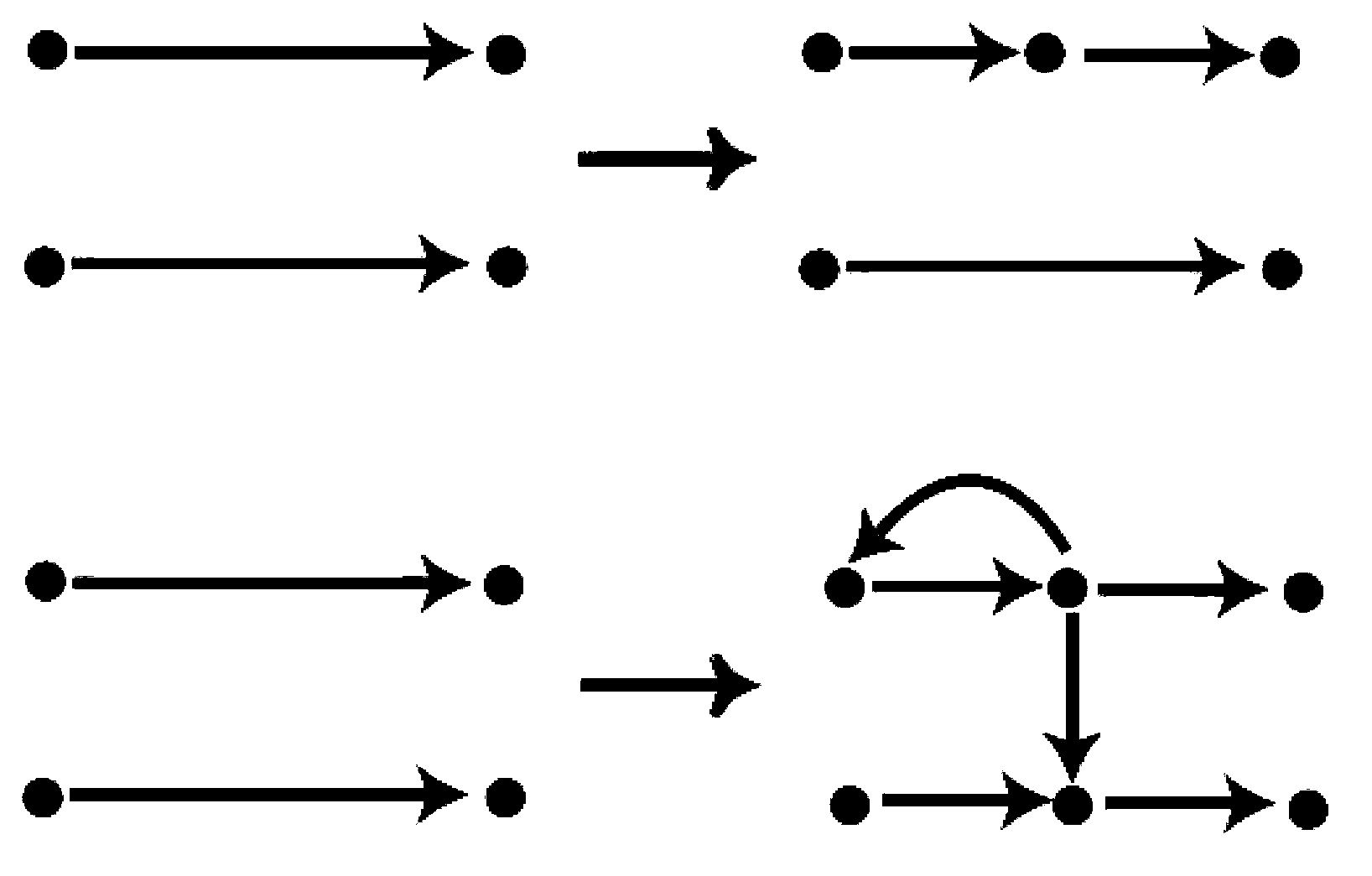

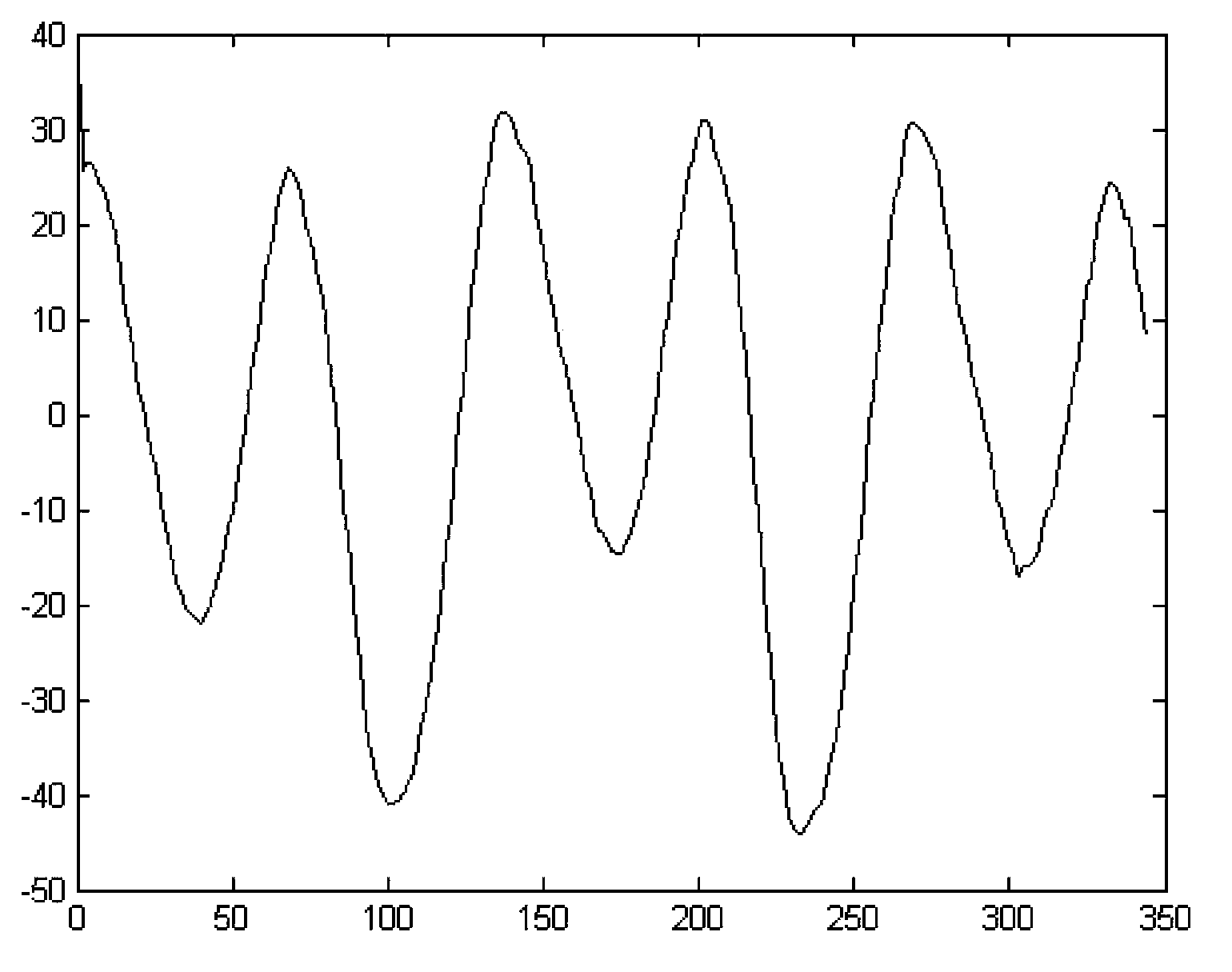

Motion diagram transition point selecting method based on nonlinearity manifold learning

ActiveCN103021009AExcellent time and efficiencyImprove accuracyAnimationData segmentDimensionality reduction

The invention discloses a motion diagram transition point selecting method based on nonlinearity manifold learning and belongs to the technical field of computer image processing. The method includes the steps of dimensionality reduction analysis of high dimensional data, extraction of key data segments, calculation of key data segment interframe similarity and construction of motion diagrams.

Owner:DALIAN UNIV

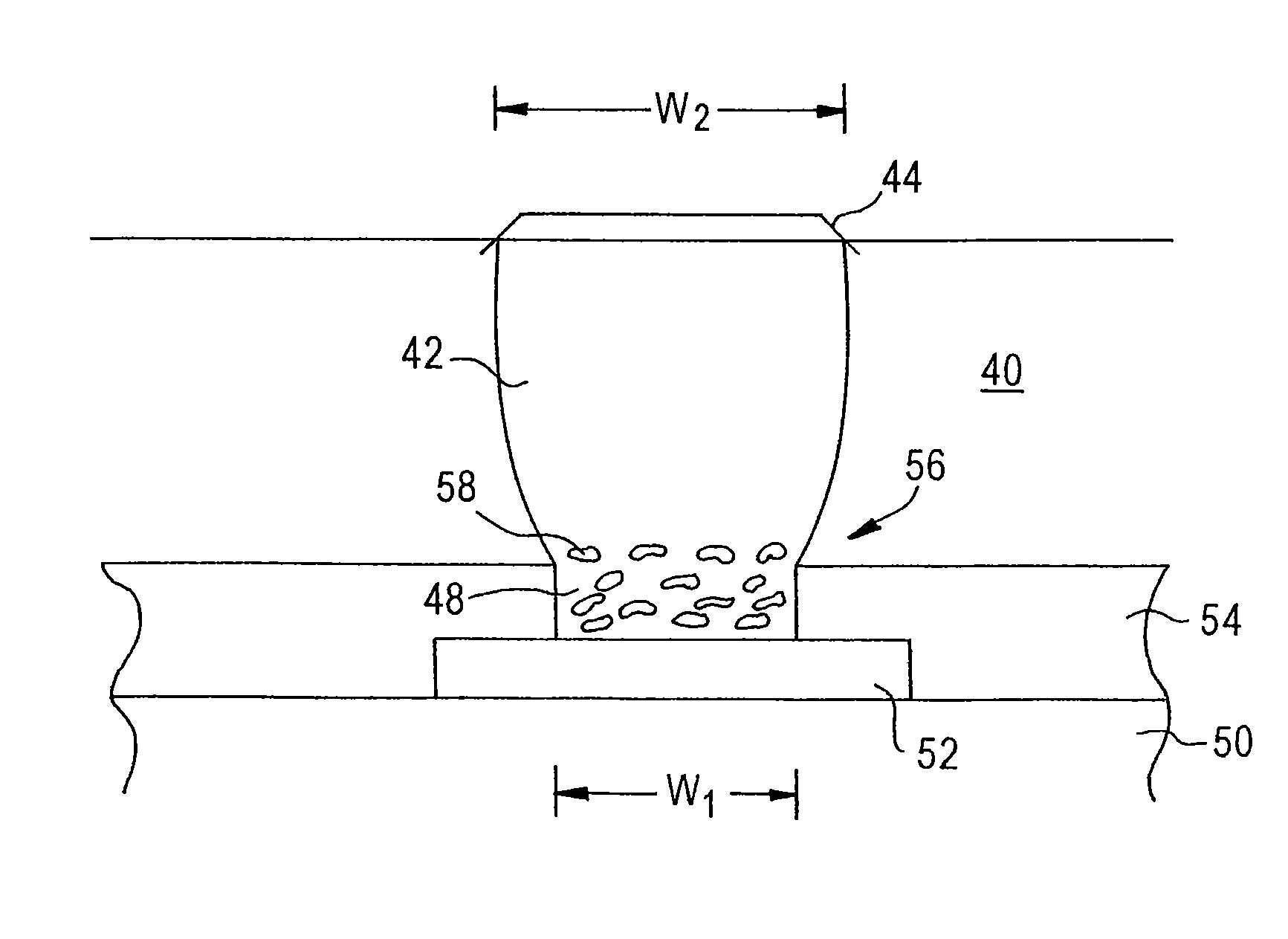

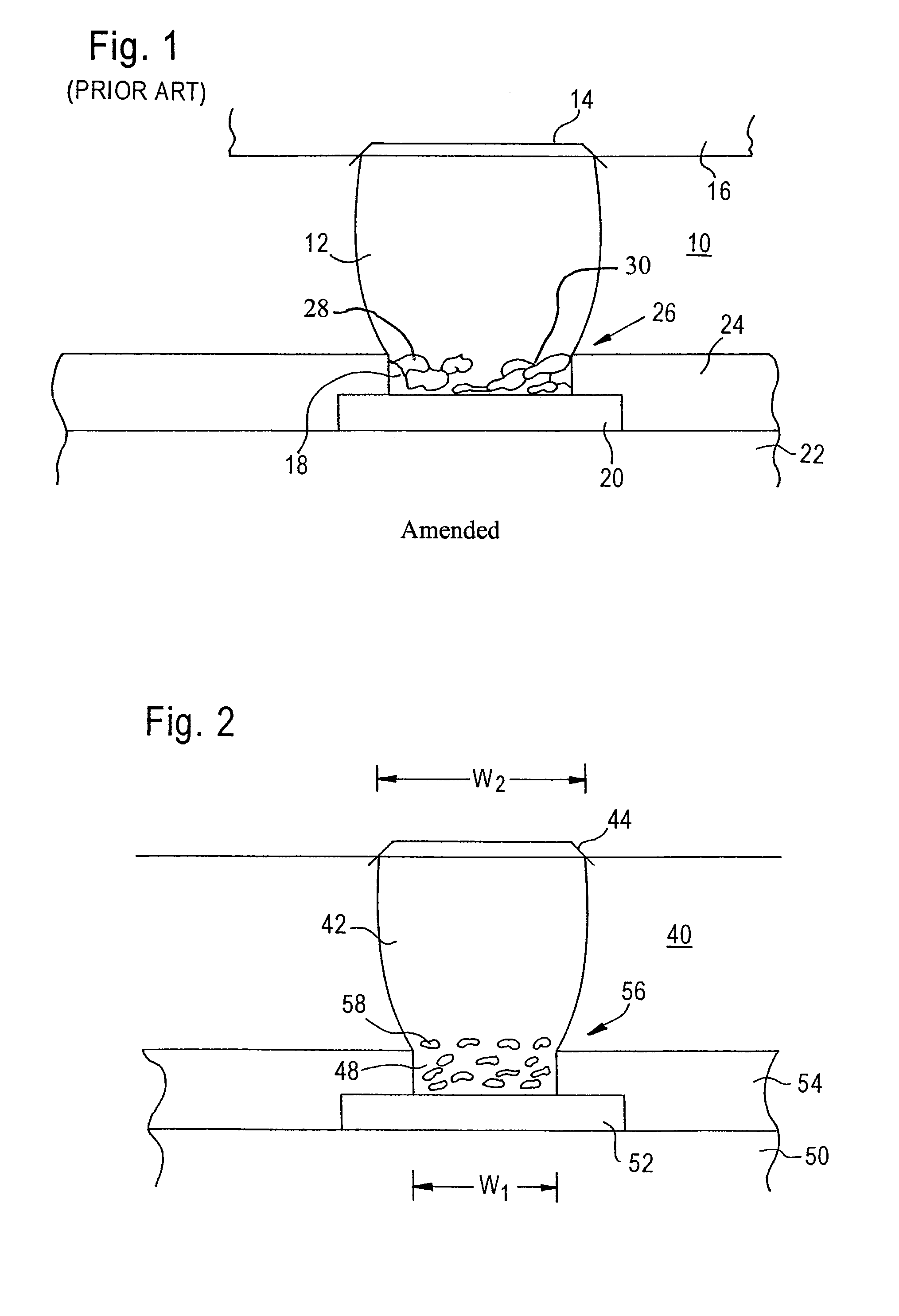

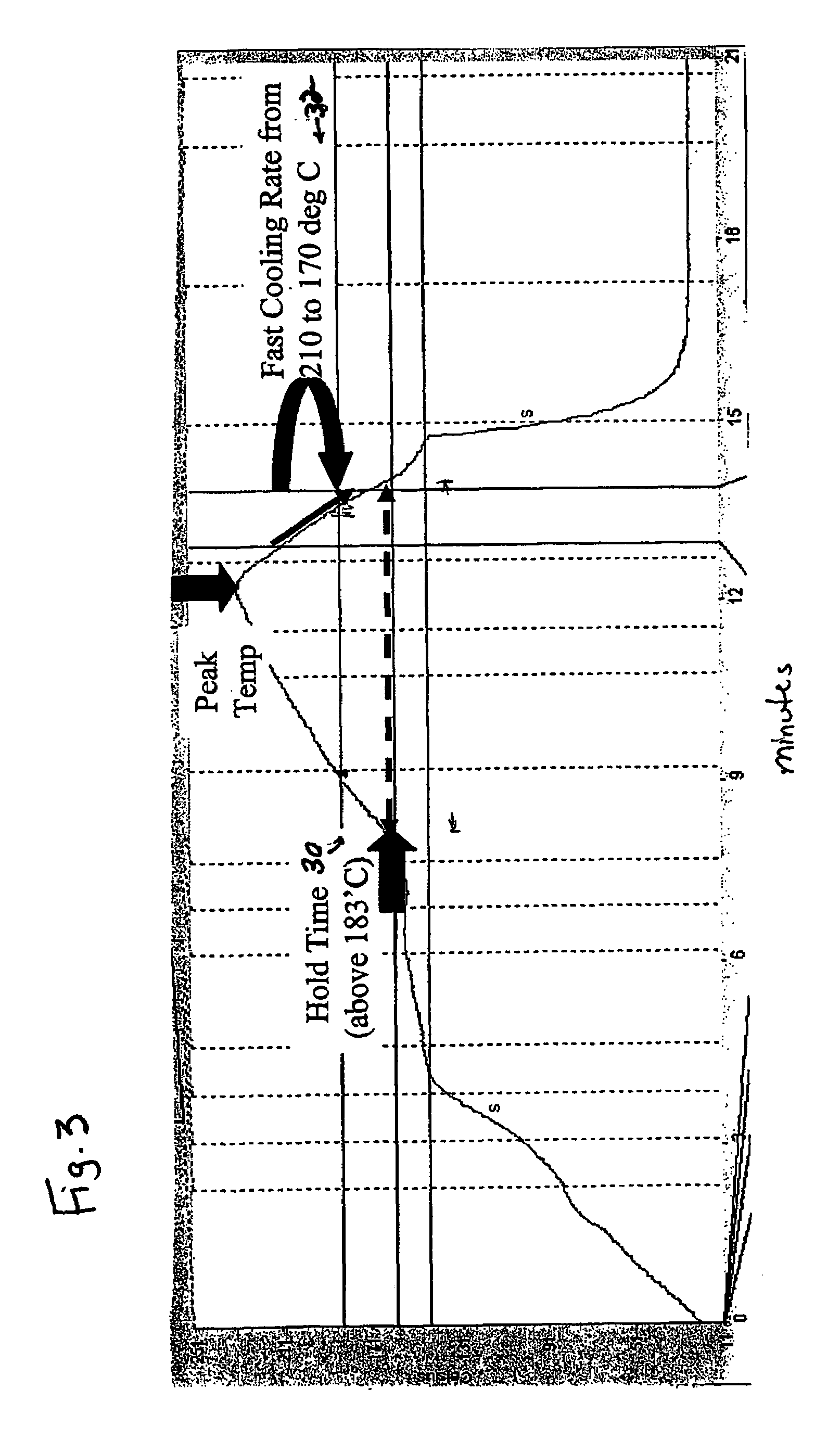

Method for forming solder joints for a flip chip assembly

InactiveUS7601612B1Improve fatigue lifeImprove distributionFinal product manufactureSemiconductor/solid-state device detailsSolder maskUnder bump metallurgy

A method for forming a solder joint for a package arrangement with a dispersed Sn microstructure provides a flip chip on a package, with a flip chip having solder bumps to be connected by eutectic solder joints to pads on the package. The eutectic solder is reflowed at a solder bump / pad interface with a eutectic reflow profile that is configured to achieve eutectic solder joints having substantially evenly distributed Sn grains. The eutectic reflow profile includes an increased cooling rate and decreased hold time with a higher peak temperature. A defined ratio of the pad openings in the solder mask to the under bump metallurgy is provided. The eutectic reflow profile and the defined ratio prolong fatigue life in the package arrangement.

Owner:GLOBALFOUNDRIES US INC

Multi-cylinder internal combustion engine and method for operating such a multi-cylinder internal combustion engine

ActiveCN103184950AModerate the problem of interplay of inflation changesHold timeExhaust apparatusCylinder headsCylinder headExternal combustion engine

A linearly aligned four-cylinder internal combustion engine system operated in a 1-3-4-2 sequence, comprising a cylinder head connected with a cylinder block wherein each cylinder has at least one exhaust port to discharge exhaust gasses via an exhaust gas discharge system, for which an exhaust gas pipe is connected at each exhaust port; wherein the exhaust gas pipes of the cylinders that merge in stages into a common exhaust gas pipe and the exhaust gas discharge system emerges outside of the cylinder head. Thus exhaust gas from consecutive ignitions in adjacent cylinders is separated for a distance throughout the engine head to reduce mutual influencing in adjacent cylinders with consecutive ignitions.

Owner:FORD GLOBAL TECH LLC

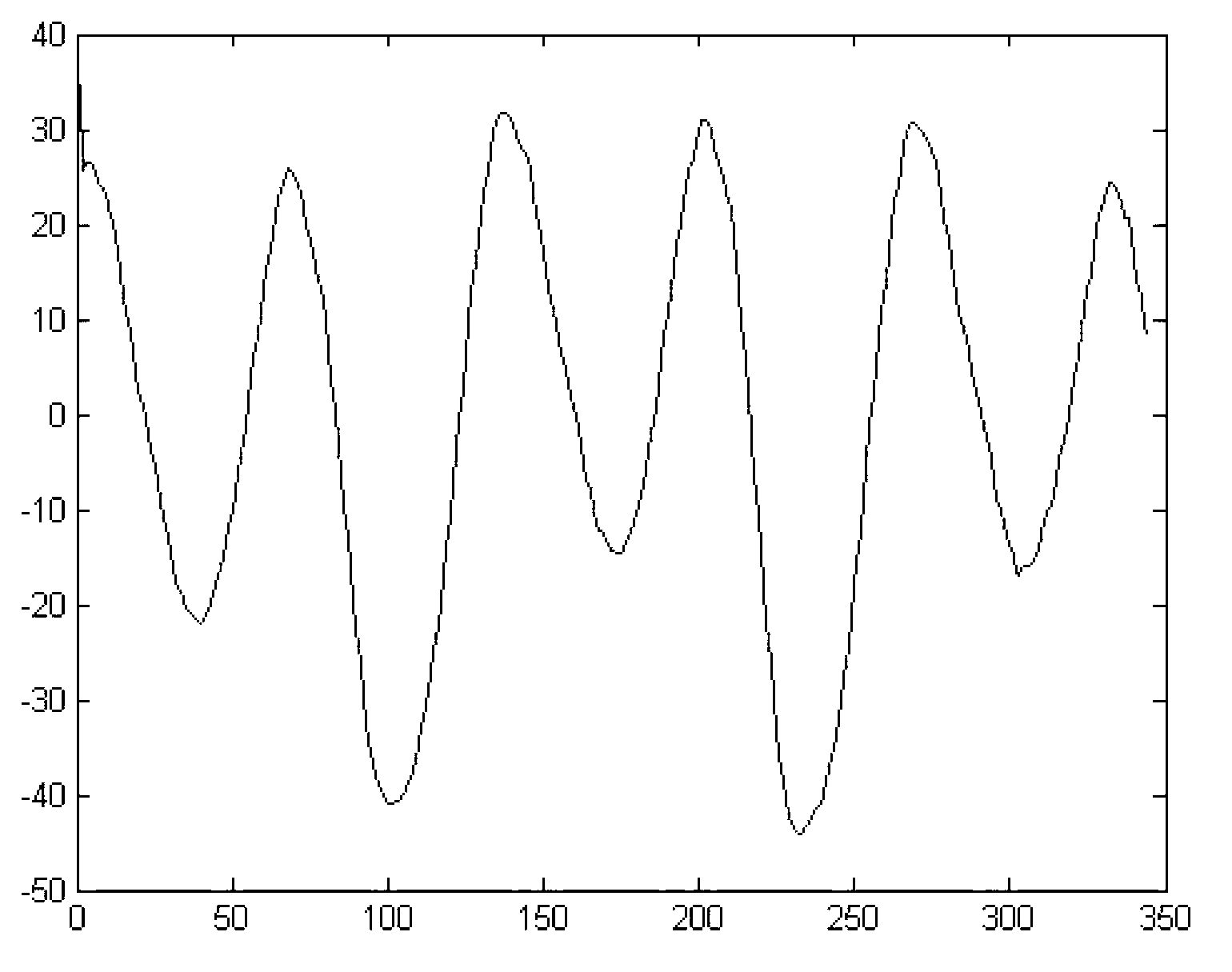

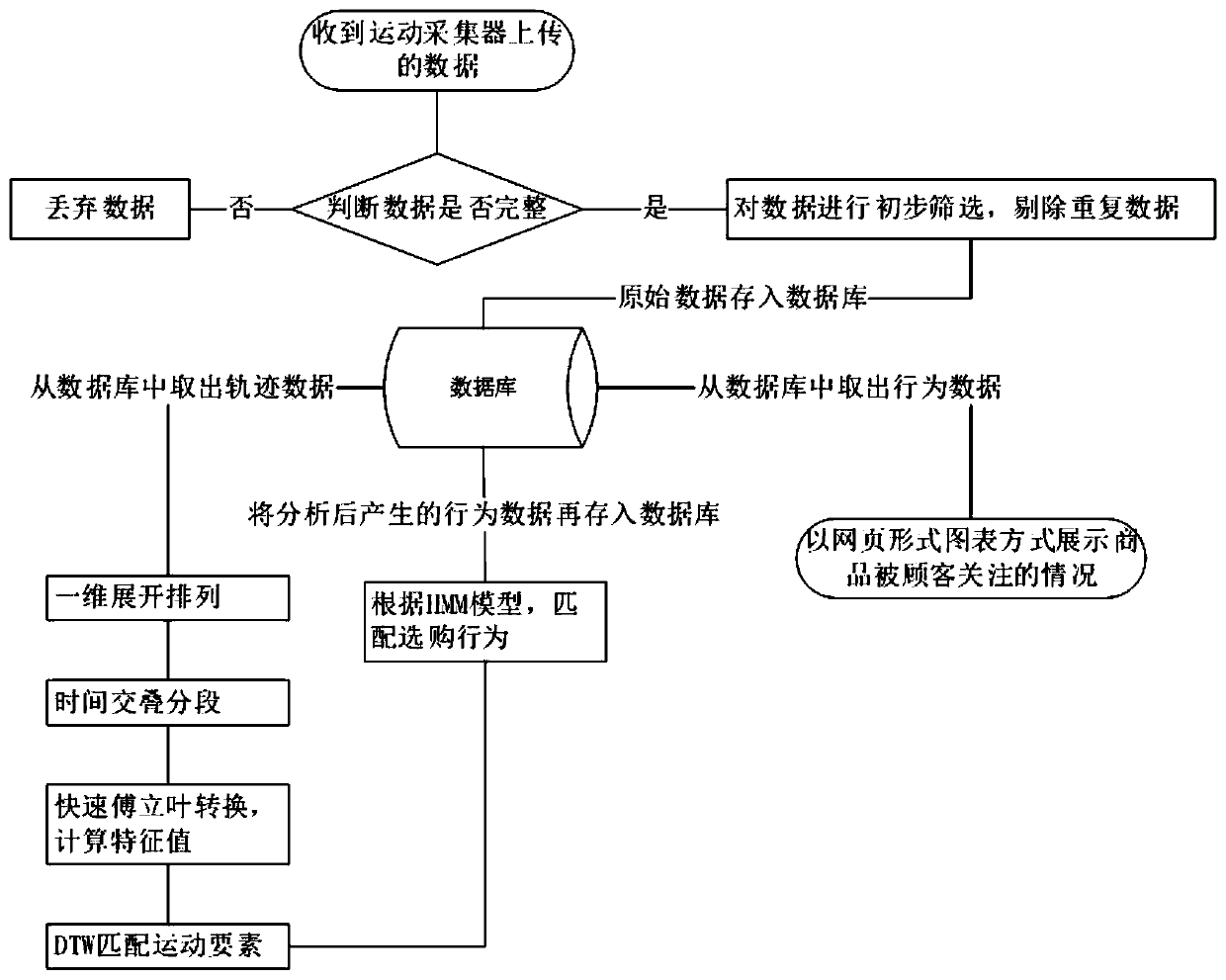

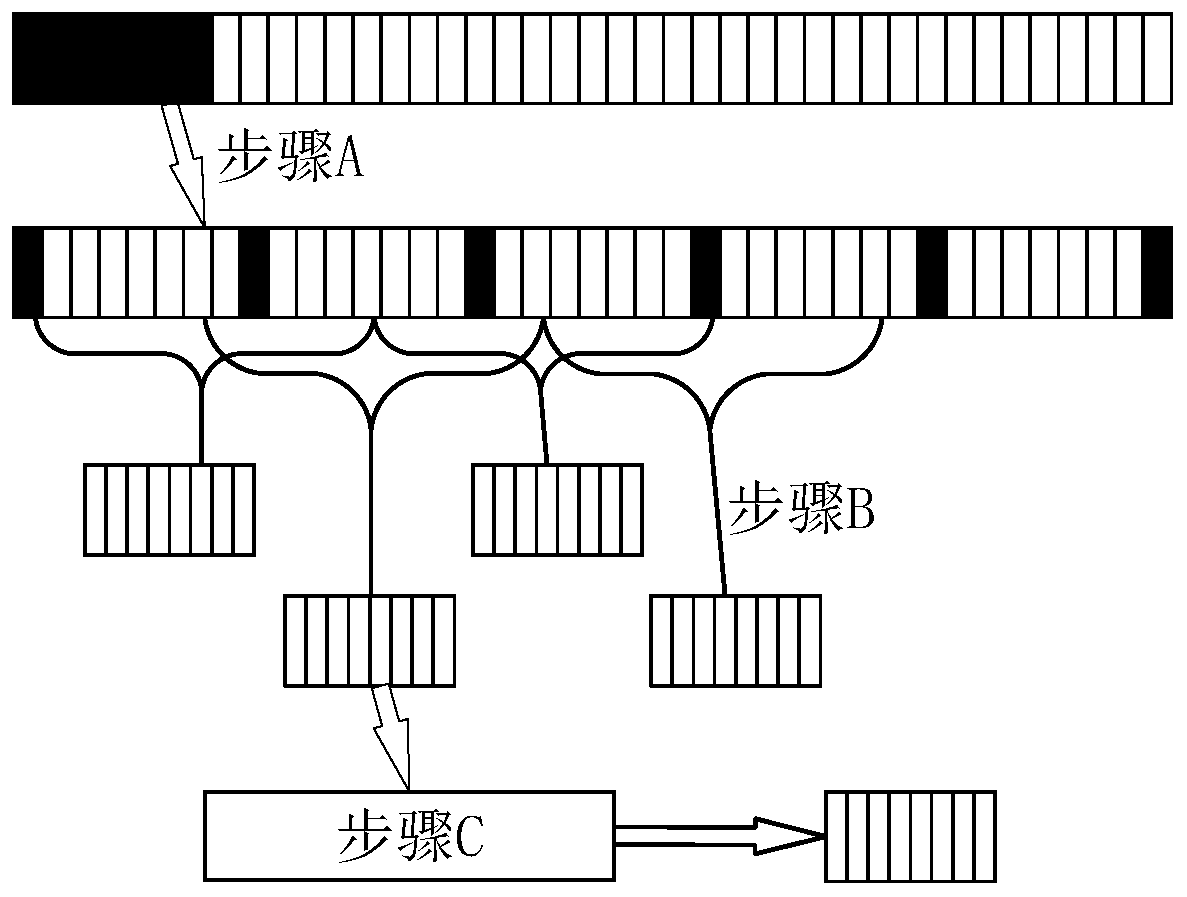

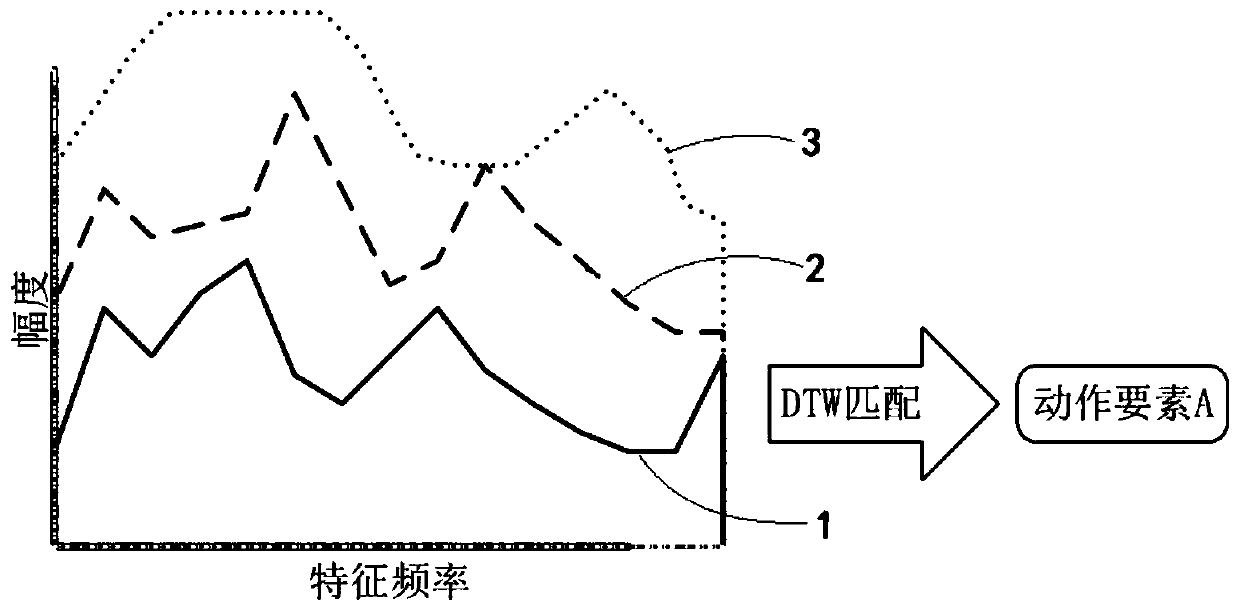

Method for identifying action types

ActiveCN110680337AReduce computing costExpand the scope of recognitionDiagnostic recording/measuringSensorsPattern recognitionData segment

The invention provides a method for identifying action types. The method comprises the following steps: collecting motion data; processing the motion data into a plurality of data segments; respectively performing Fourier transform on the plurality of data segments to obtain frequency domain features of the plurality of data segments; respectively matching the frequency domain features of the plurality of data segments with the frequency domain features of the action elements to obtain action elements corresponding to the plurality of data segments; connecting the action elements correspondingto the plurality of data segments to obtain continuous action elements; and matching a continuous action model by using the continuous action elements, and identifying the type of the action. By adopting the method provided by the invention, complex continuous actions can be identified, and the calculation cost is low.

Owner:无锡慧眼人工智能科技有限公司

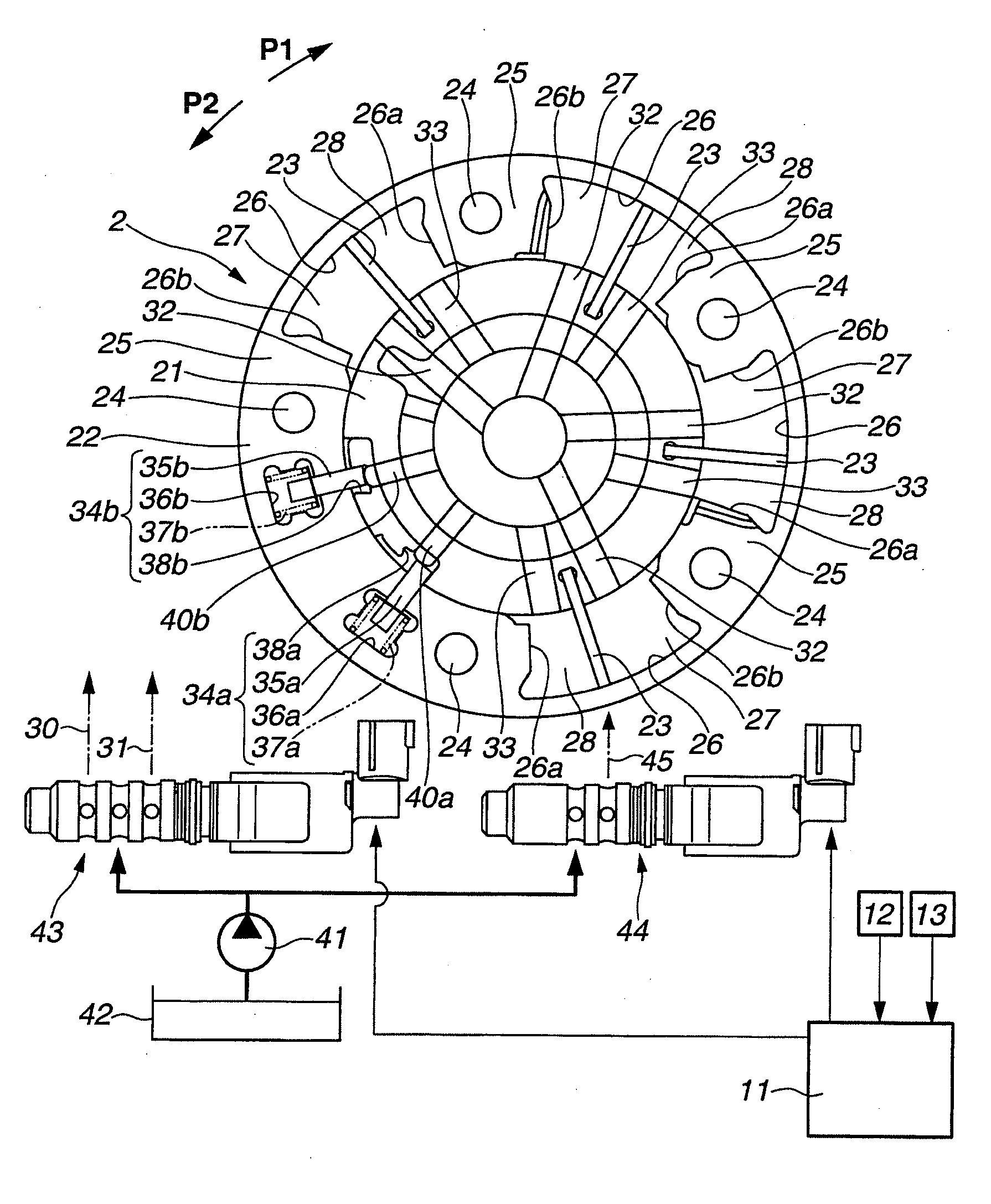

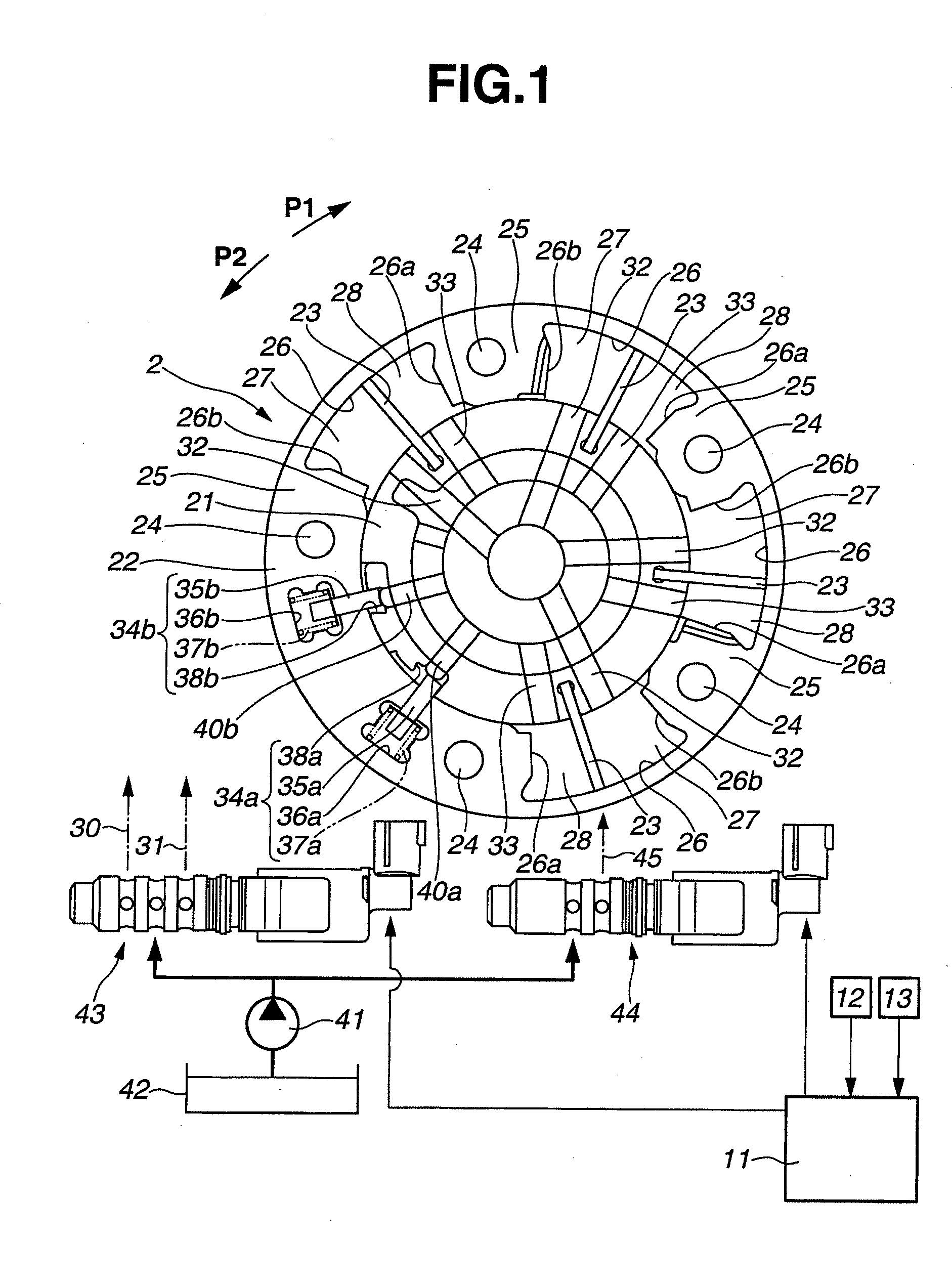

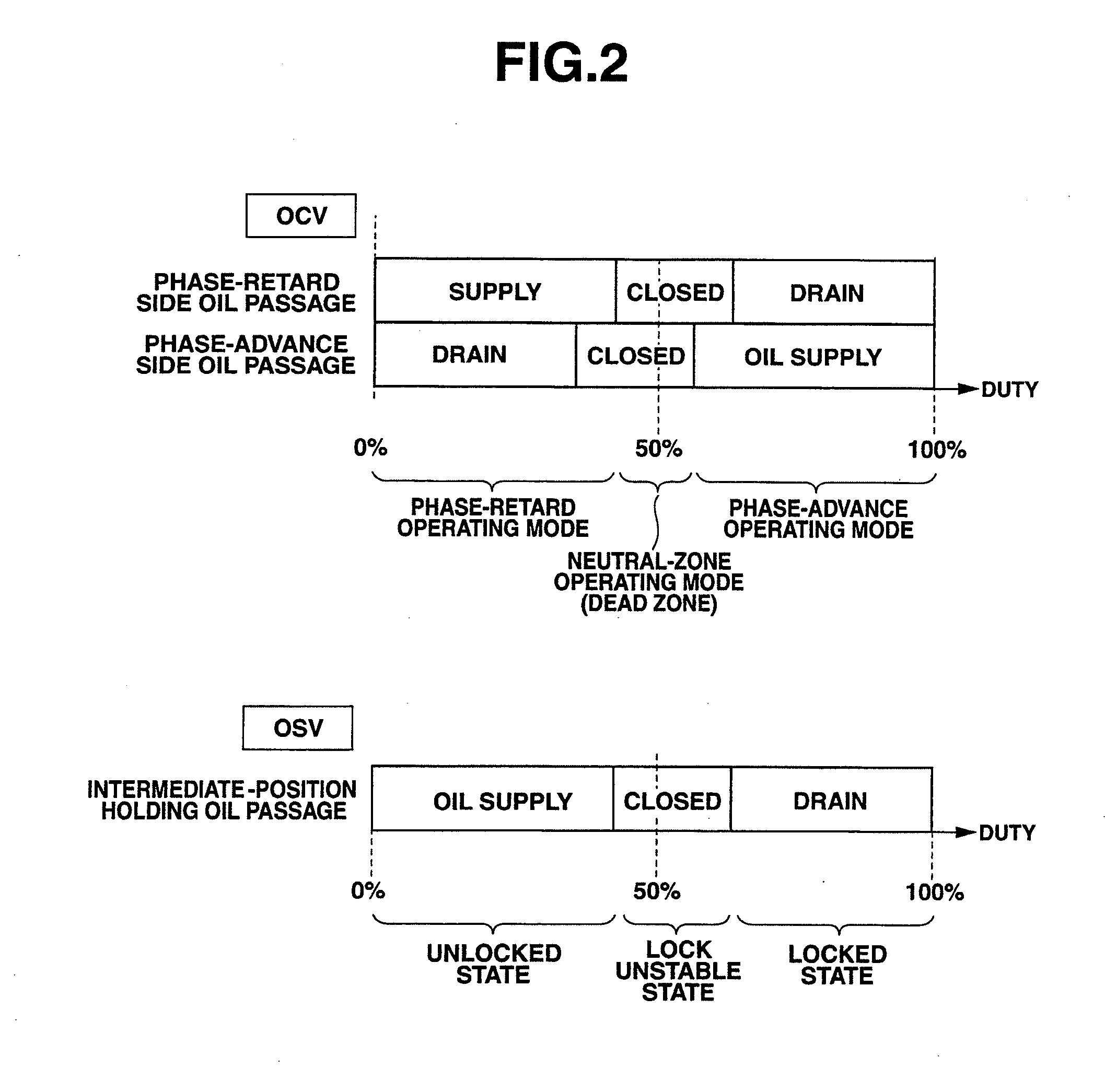

Variable valve timing control device for internal combustion engine

ActiveUS20150013626A1Hold timeValve arrangementsElectrical controlVariable valve timingInternal combustion engine

Intermediate position feedback control is executed when valve timing of an intake valve is at an intermediate lock position, an intermediate lock is needed, and an engine revolution speed is greater than a first engine revolution speed R1. Forced lock control is executed when the valve timing of the intake valve is at the intermediate lock position, the intermediate lock is needed, the engine revolution speed is less than the first engine revolution speed R1, and the intermediate position feedback control is not being executed. As a result, even when the engine revolution speed increases in the presence of a demand that the valve timing needs to be in the intermediate lock position, it is possible to maintain the valve timing at the intermediate lock position.

Owner:NISSAN MOTOR CO LTD

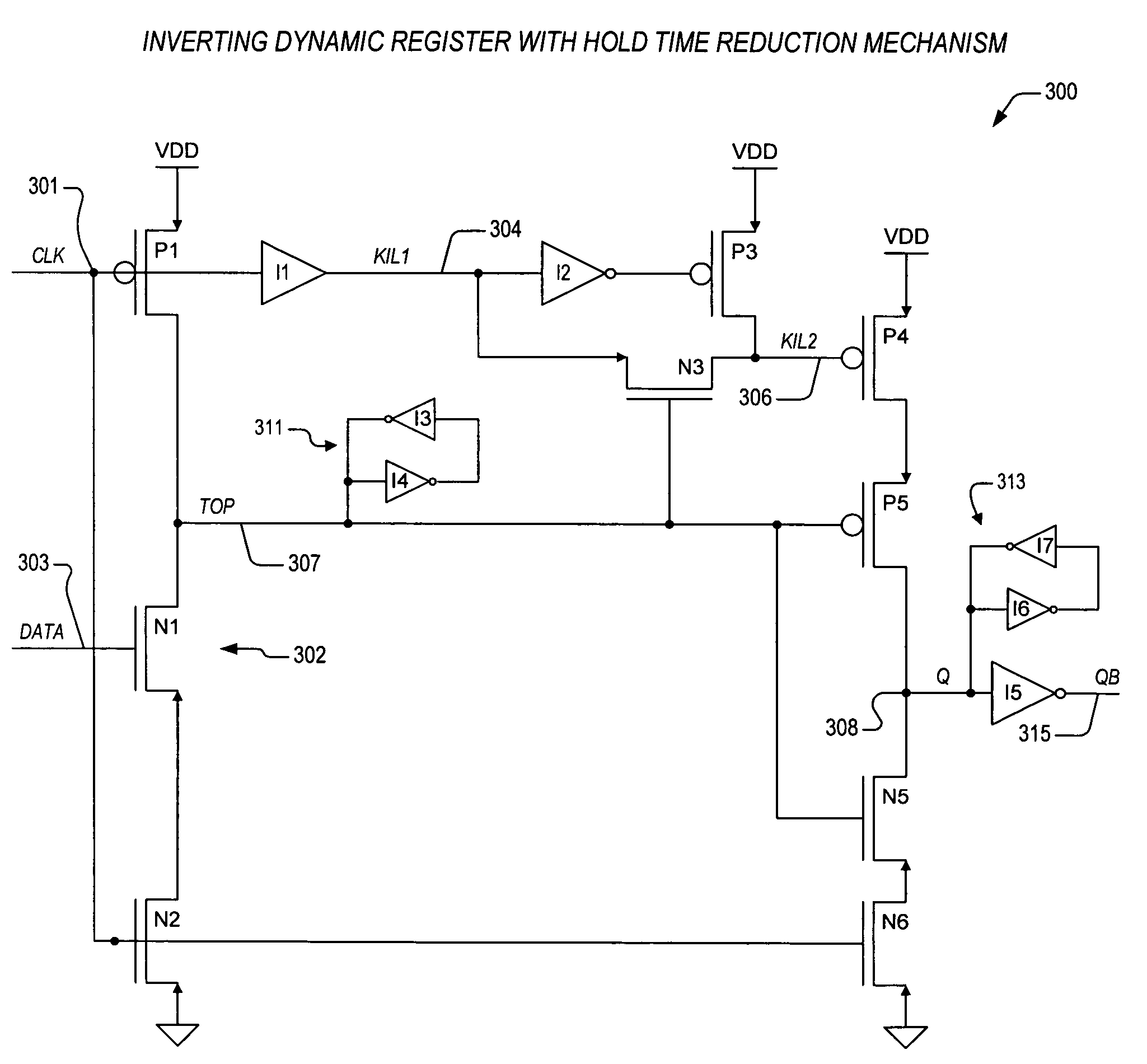

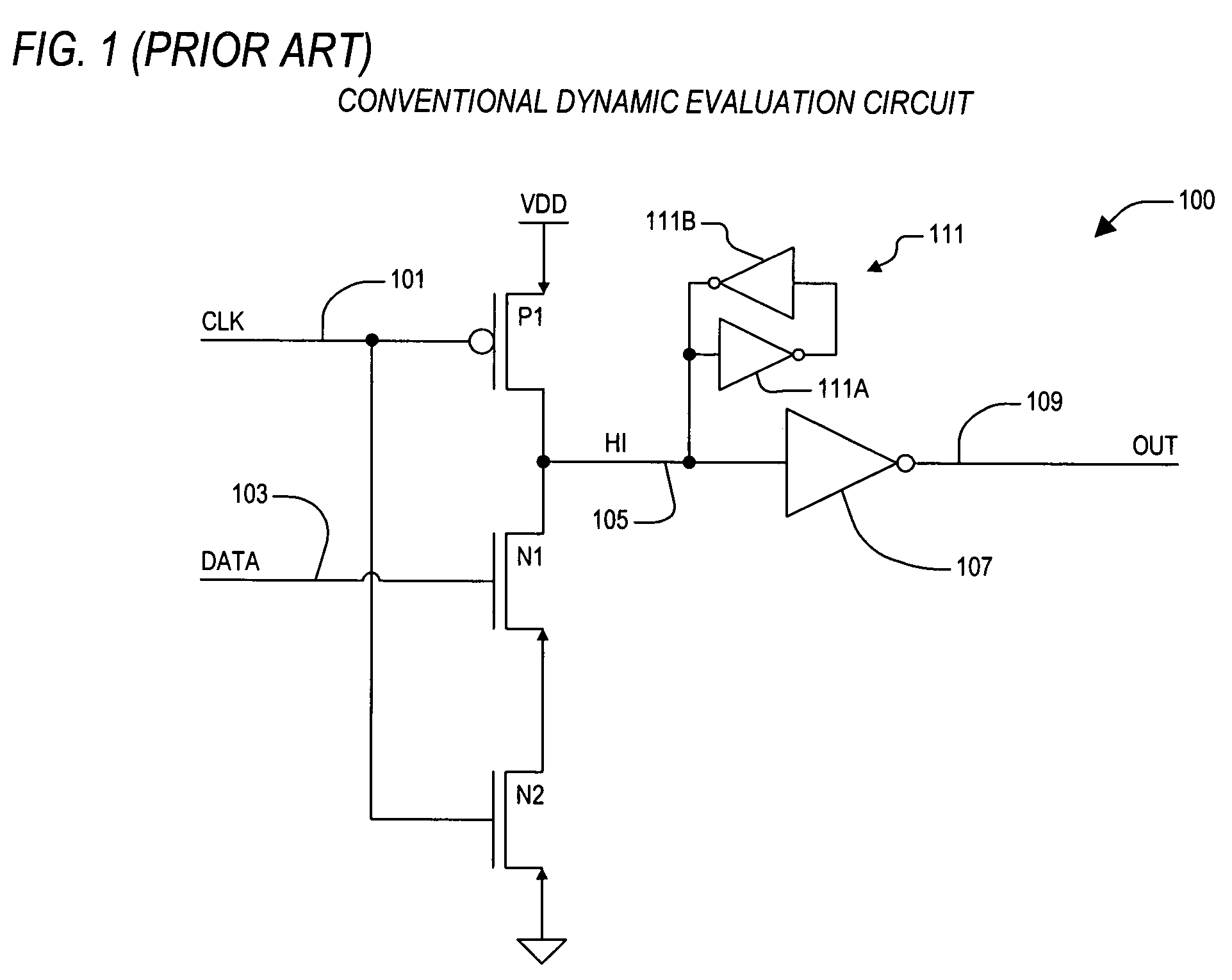

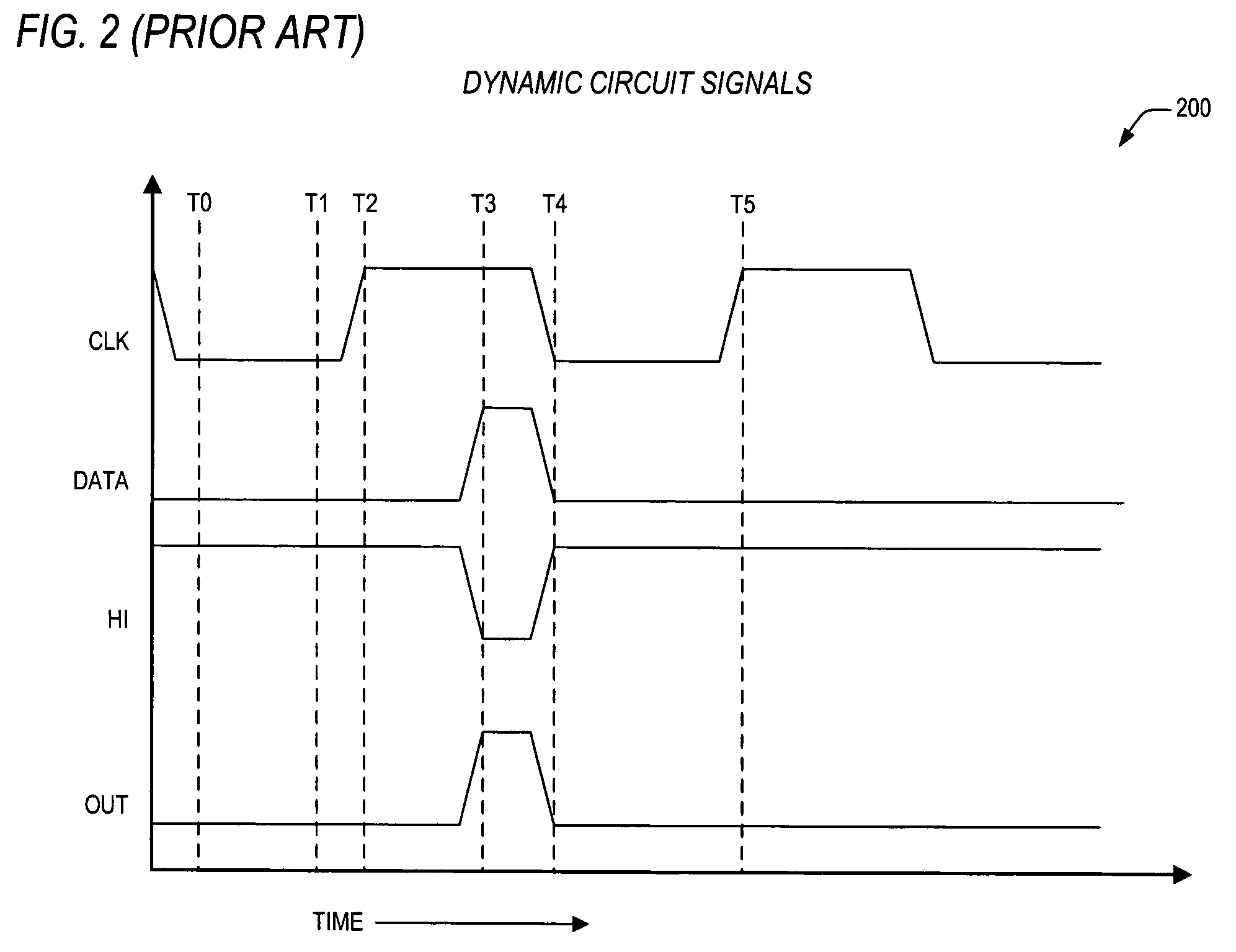

Inverting dynamic register with data-dependent hold time reduction mechanism

ActiveUS7358775B2Superior techniqueReduced time requirementsLogic circuitsProcessor registerPre-charge

Dynamic logic register including evaluation logic, delay logic, latching logic, and a keeper circuit. The evaluation logic evaluates a logic function based on data input. The logic function evaluates to either a first state or a second state. The delay logic generates a kill signal, where the kill signal is a delayed version of a clock signal, and where the delay between the clock and kill signals comprises a hold time, and where the hold time is shortened when the logic function evaluates to the first state. The latching logic is responsive to the clock and kill signals and the state of pre-charged node, and controls the state of an output node based on the state of a pre-charged node during an evaluation period between an operative edge of the clock signal and the next edge of the kill signal, and otherwise presents a tri-state condition to said output node.

Owner:VIA TECH INC

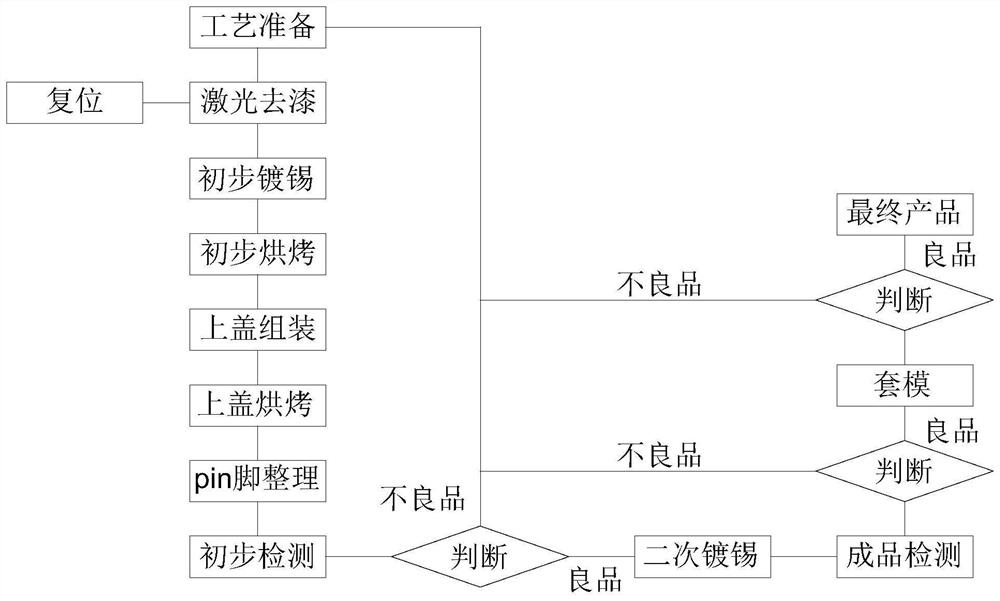

Double in-line package process

ActiveCN112670072AEvenly heatedAvoid WeldingTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureProcess engineeringIndustrial engineering

The invention belongs to the technical field of network transformer manufacturing, and discloses a double in-line package process. The method comprises the following steps: performing primary tinning; performing preliminary baking; baking the upper cover; performing secondary tinning; detecting a finished product, wherein in the steps of preliminary baking and upper cover baking, preliminary baking and upper cover baking are completed through a circulating baking oven, the baking temperature is 115-125 DEG C, and the baking time is 18-22 min. According to the invention, the network transformer is circularly baked at a proper temperature for a proper time, so the use stability of the network transformer is improved, and the requirement on the yield is met on the basis.

Owner:DEYANG BOTHHAND ELECTRONICS

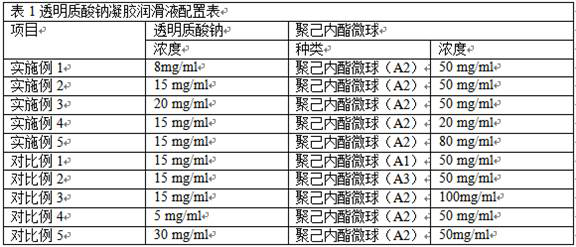

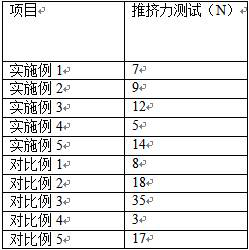

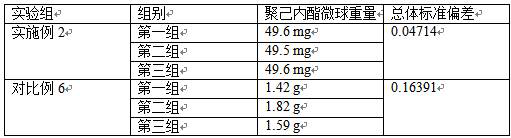

Sodium hyaluronate gel lubricating liquid, filling agent and preparation method and application of sodium hyaluronate gel lubricating liquid and filling agent

InactiveCN114601966AConcentration controllableHold timePharmaceutical delivery mechanismProsthesisMicrosphereBiology

Owner:ZHEJIANG JINGJIA MEDICAL TECH CO LTD

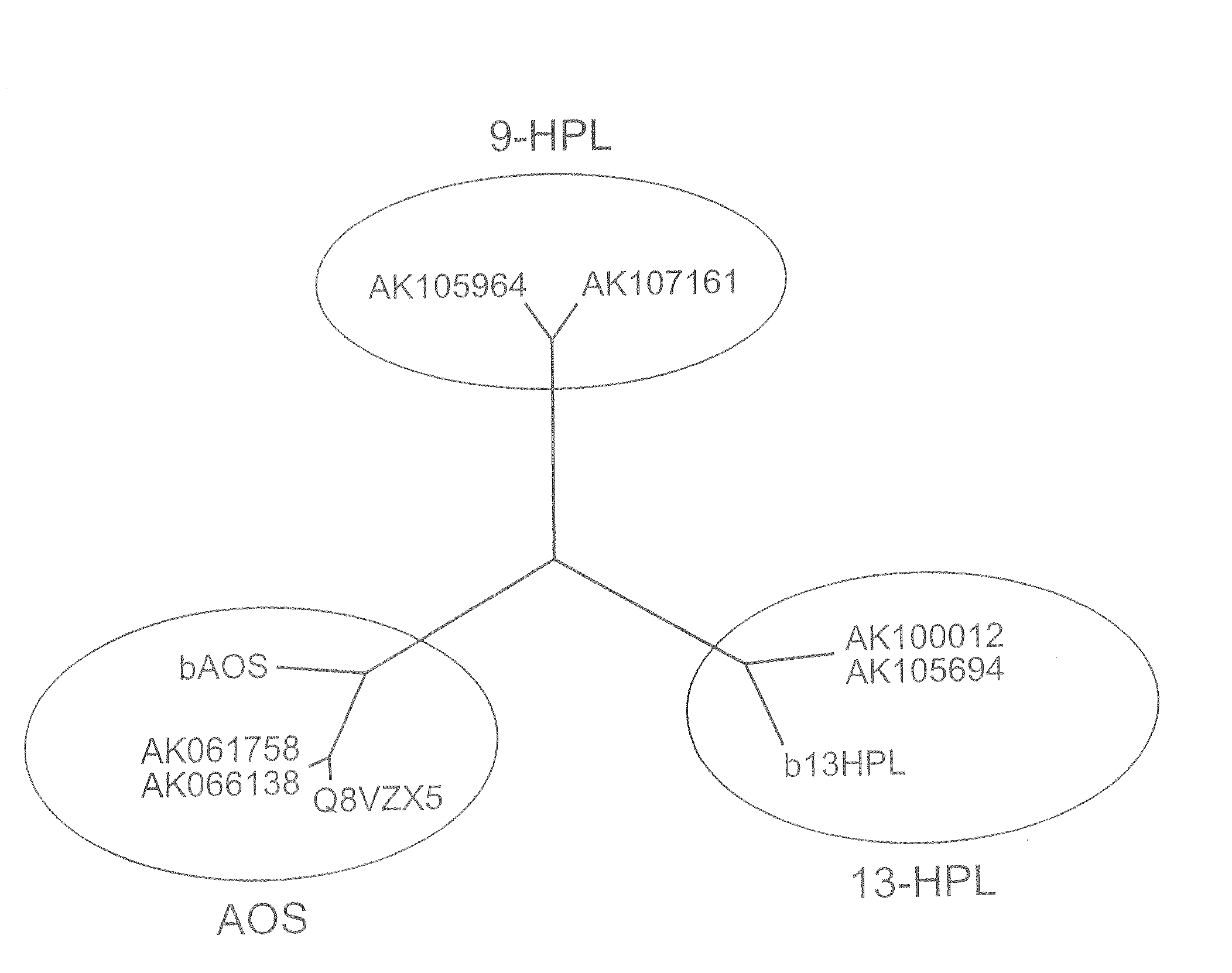

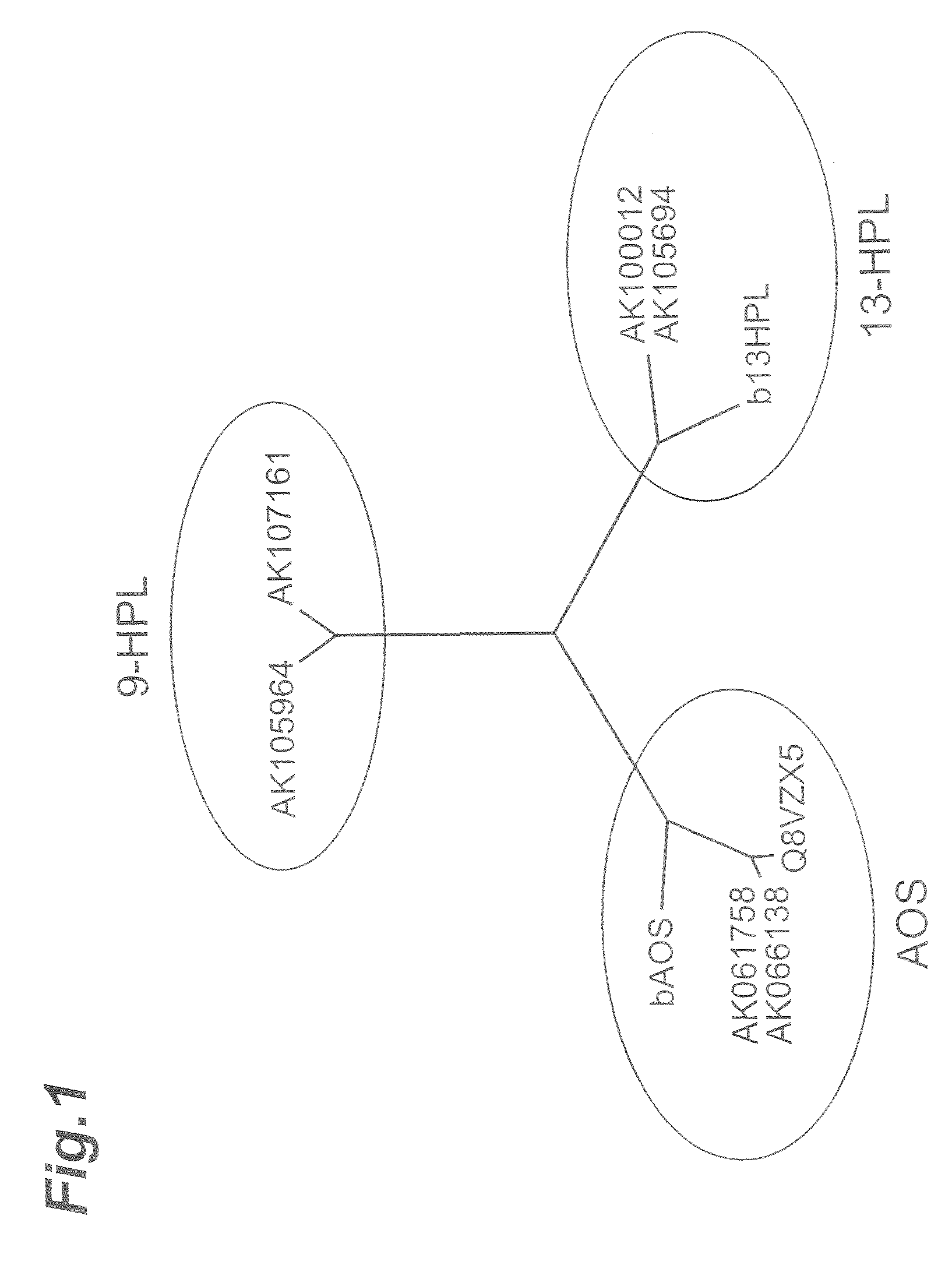

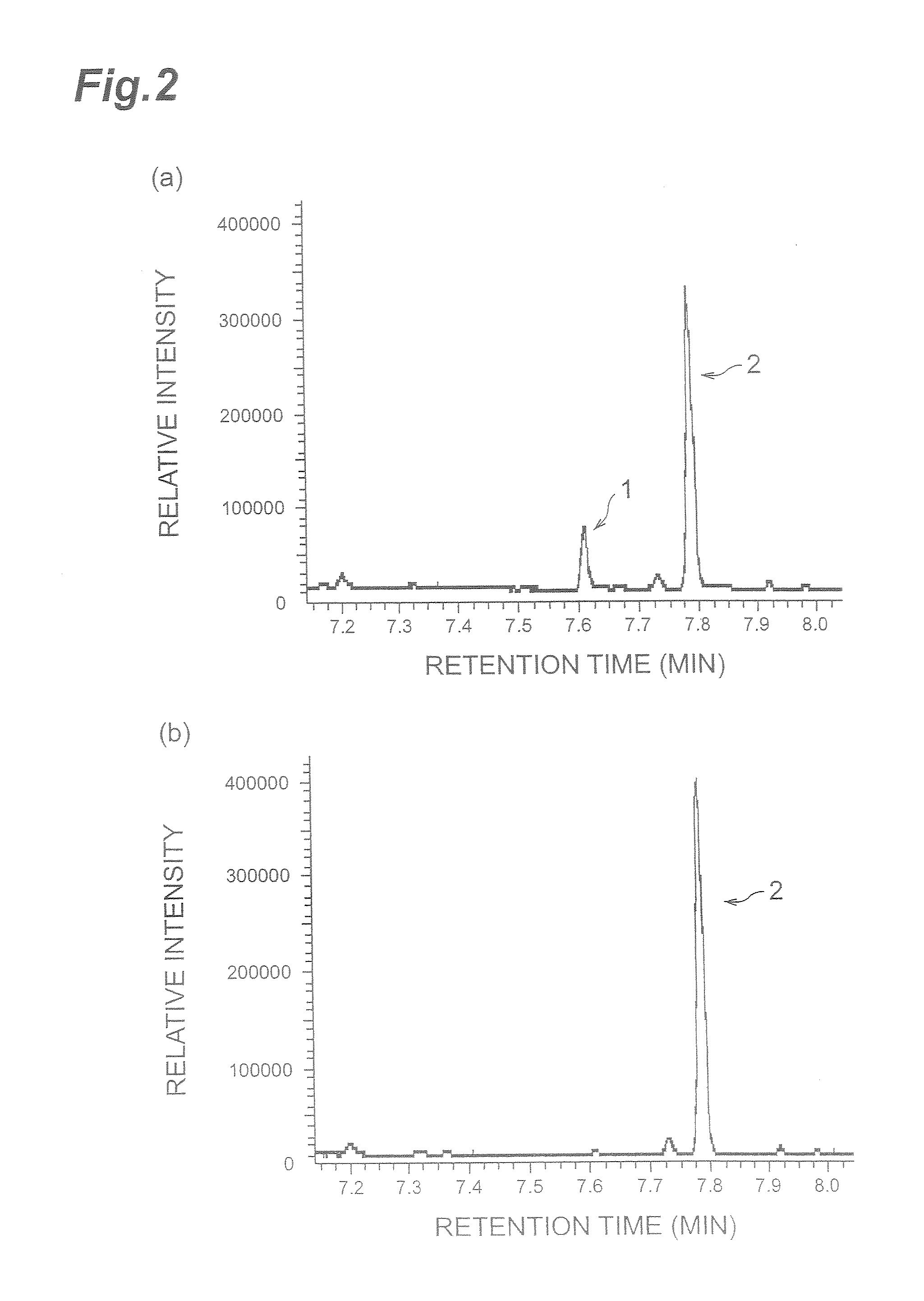

9-Fatty Acid Hydroperoxide Lyase Genes

InactiveUS20080200662A1Reduced activitySolve the stability is not highSugar derivativesLyasesNucleotideNucleotide sequencing

A 9-fatty acid hydroperoxide lyase gene consisting of the nucleotide sequence as set forth in SEQ ID No: 1, and a 9-fatty acid hydroperoxide lyase gene consisting of the nucleotide sequence as set forth in SEQ ID No: 5.

Owner:SAPPORO BREWERIES

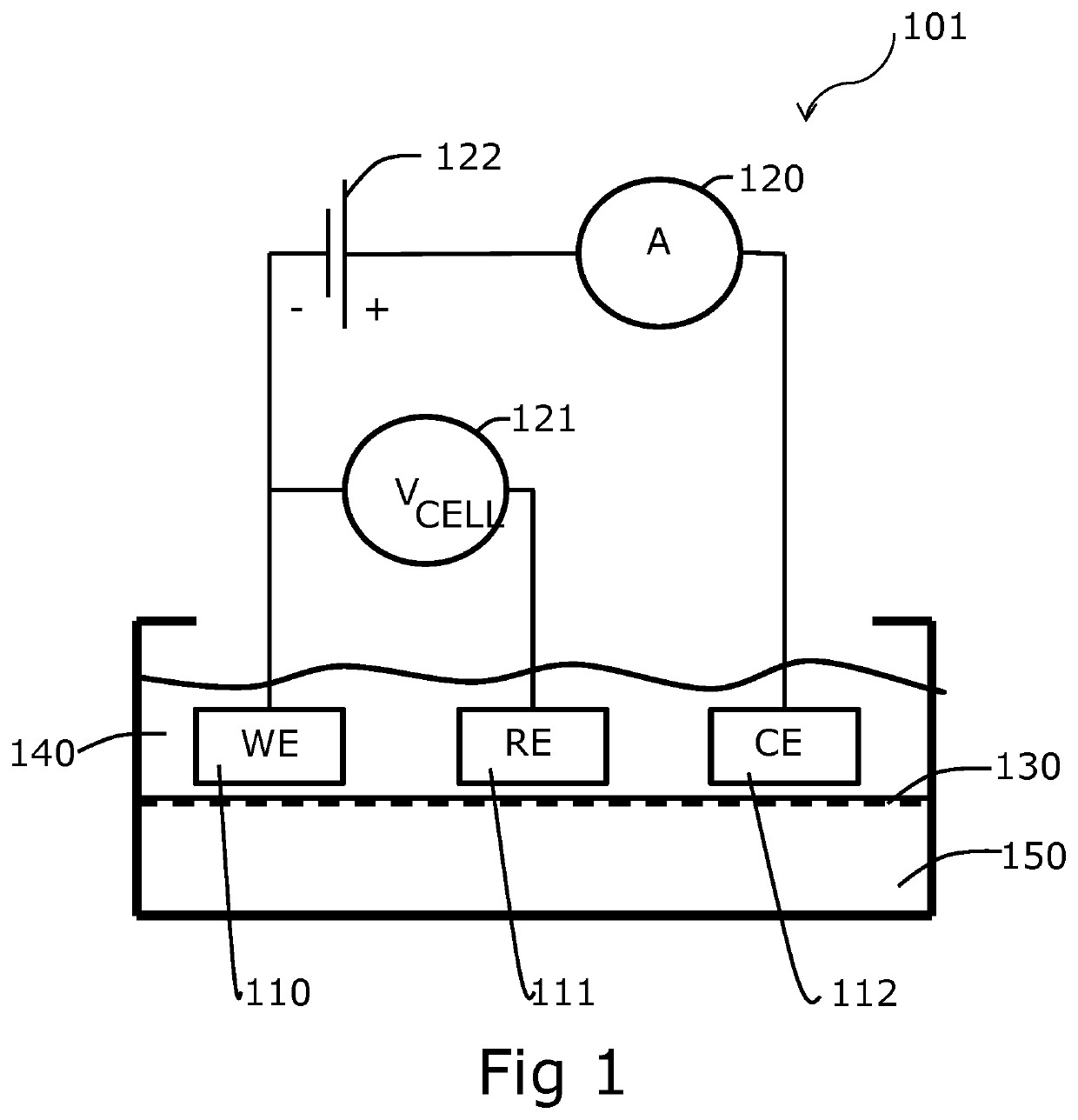

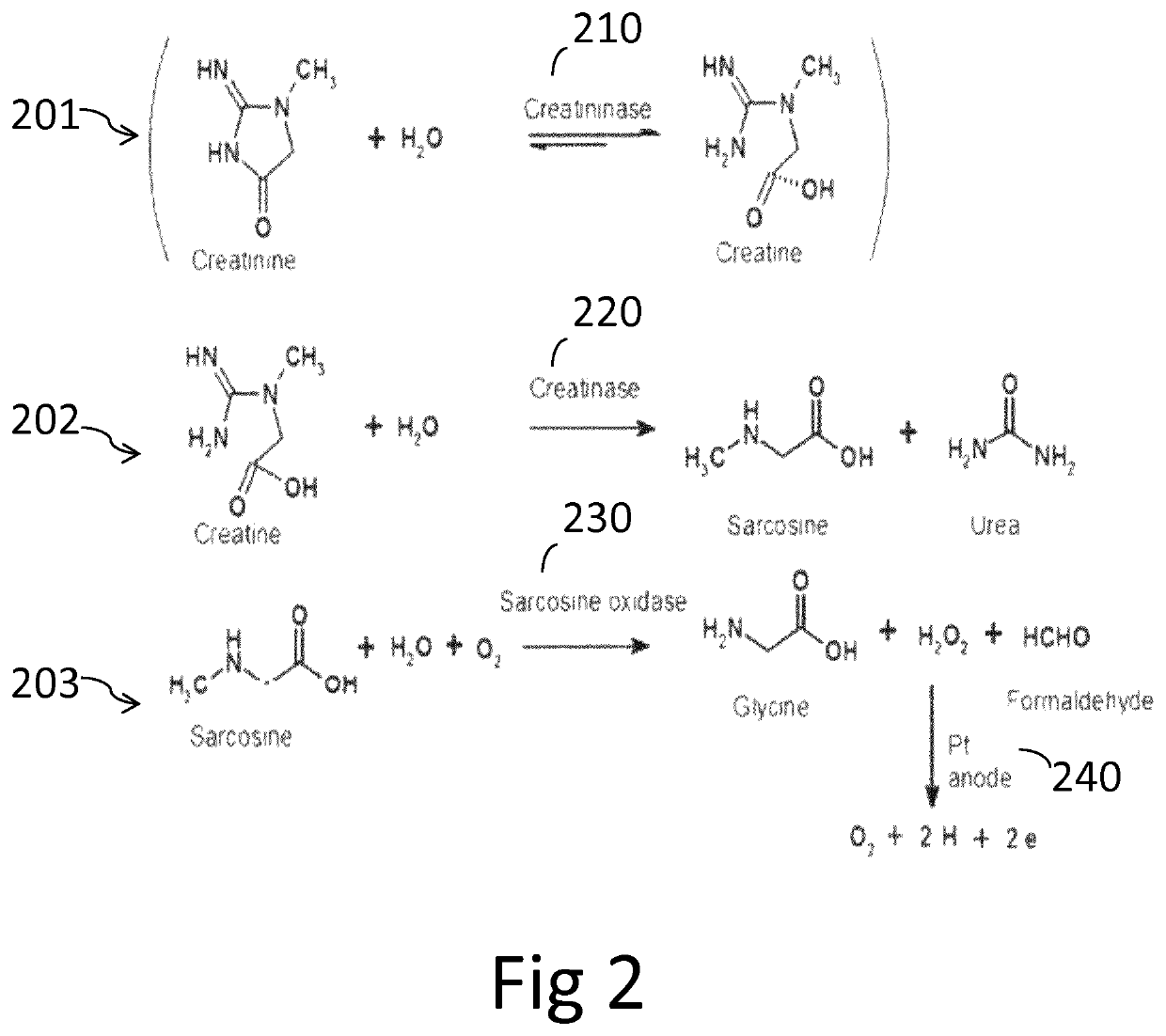

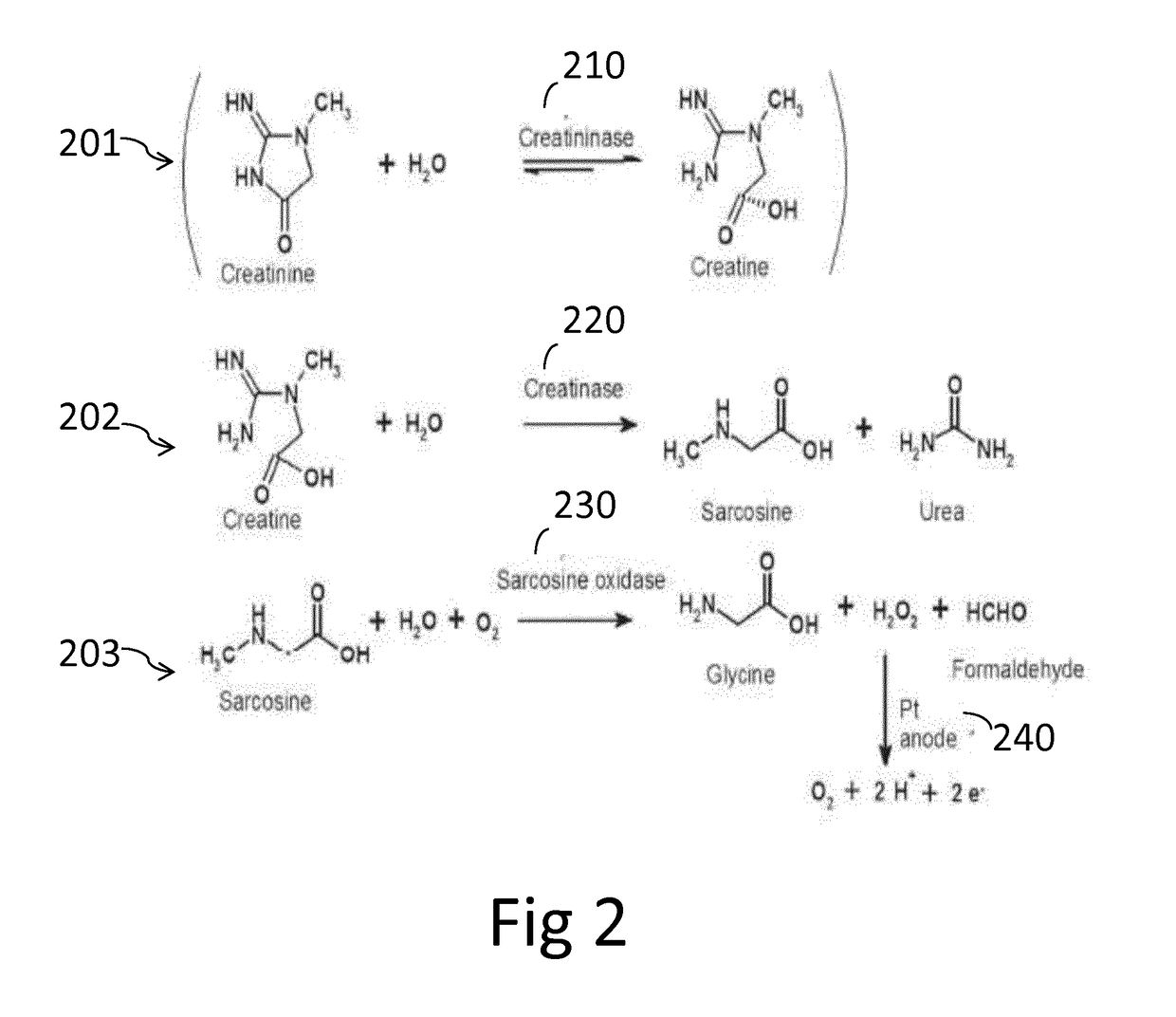

Method for correcting Crea sensor for calcium inhibition

ActiveUS10969358B2The result is accurateIncrease the number ofHydrolasesMicrobiological testing/measurementChemical physicsElevated creatinine

Owner:RADIOMETER AS

High compact bidirectionally adjustable concrete and its uses

InactiveCN100424031CHold timeGuaranteed not to flowSolid waste managementCeramic shaping apparatusCrushed stoneWollastonite

The invention discloses a high-compact bidirectional adjustable concrete and application, which comprises the following parts: 1% PII 52.5, 0.20-0.35% II-grade low-calcium coal ash, 0.05-0.08% wollastonite, 0.015-0.020% high-property polycarboxylic acid additive, 0.0012-0.0020% polypropylene fiber, 2.00-0.32% medium sand, 1.40-1.70% crushed stone, 0.38-0.45% water and 0-0.016% concrete accelerator. The invention is fit for spraying and casting on the large-smooth curve, which satisfies quality standard.

Owner:上海市建筑构件制品有限公司

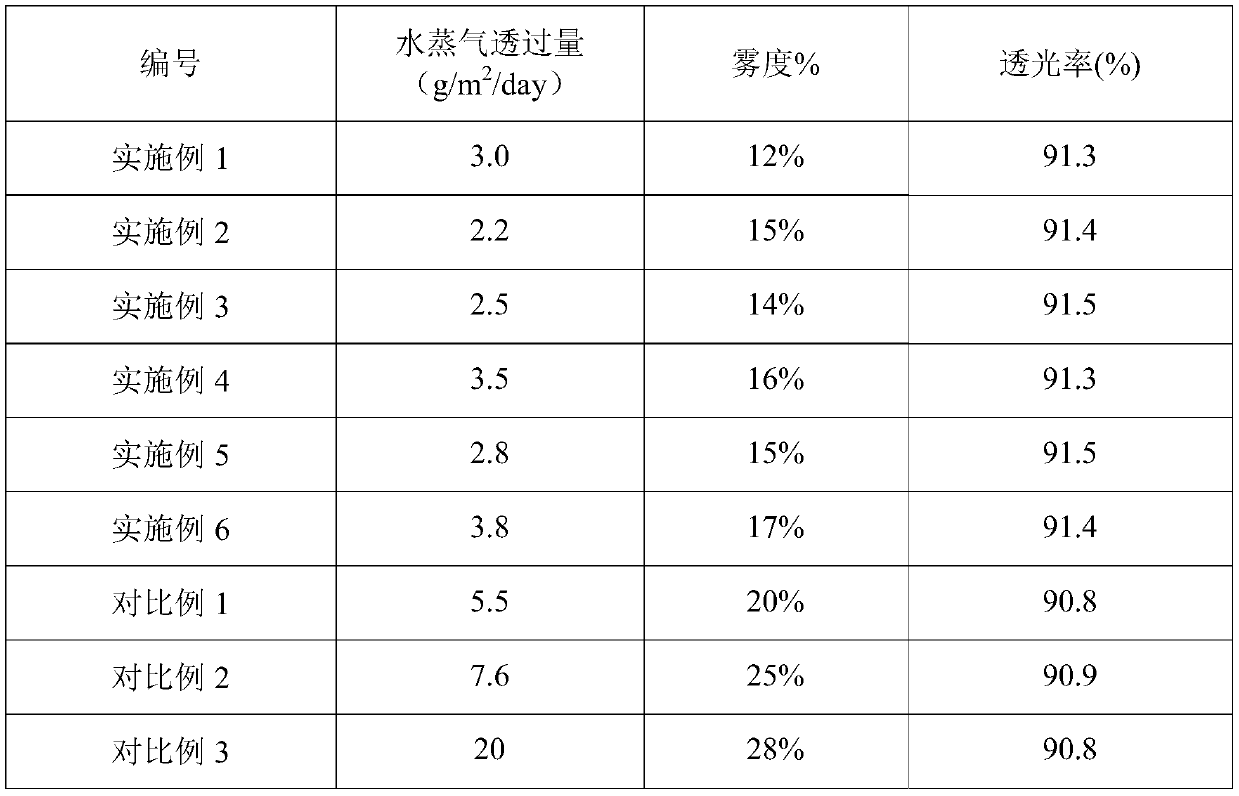

High-barrier-property polyethylene composition, preparation method, film and application

ActiveCN111269484AReduce transpirationGuaranteed freshnessFlexible coversWrappersLinear low-density polyethylenePolymer science

The invention belongs to the field of films, and relates to a high-barrier-property polyethylene composition, a preparation method, a film and application. The polyethylene composition is prepared byblending the following raw materials in parts by weight: 70-99.5 parts of linear low density polyethylene and 0.5 to 30 parts of an ethylene / 4-methyl-1-pentene copolymer; wherein the content of the 4-methyl-1-pentene in the ethylene / 4-methyl-1-pentene copolymer is 0.1-10 mol%, and the melting point of the ethylene / 4-methyl-1-pentene copolymer is 105 DEG C to 130 DEG C. The polyethylene film disclosed by the invention has the advantages of obviously reduced water vapor transmission amount, lower haze and higher light transmittance, and is particularly suitable for transparent packaging of fruits, vegetables and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

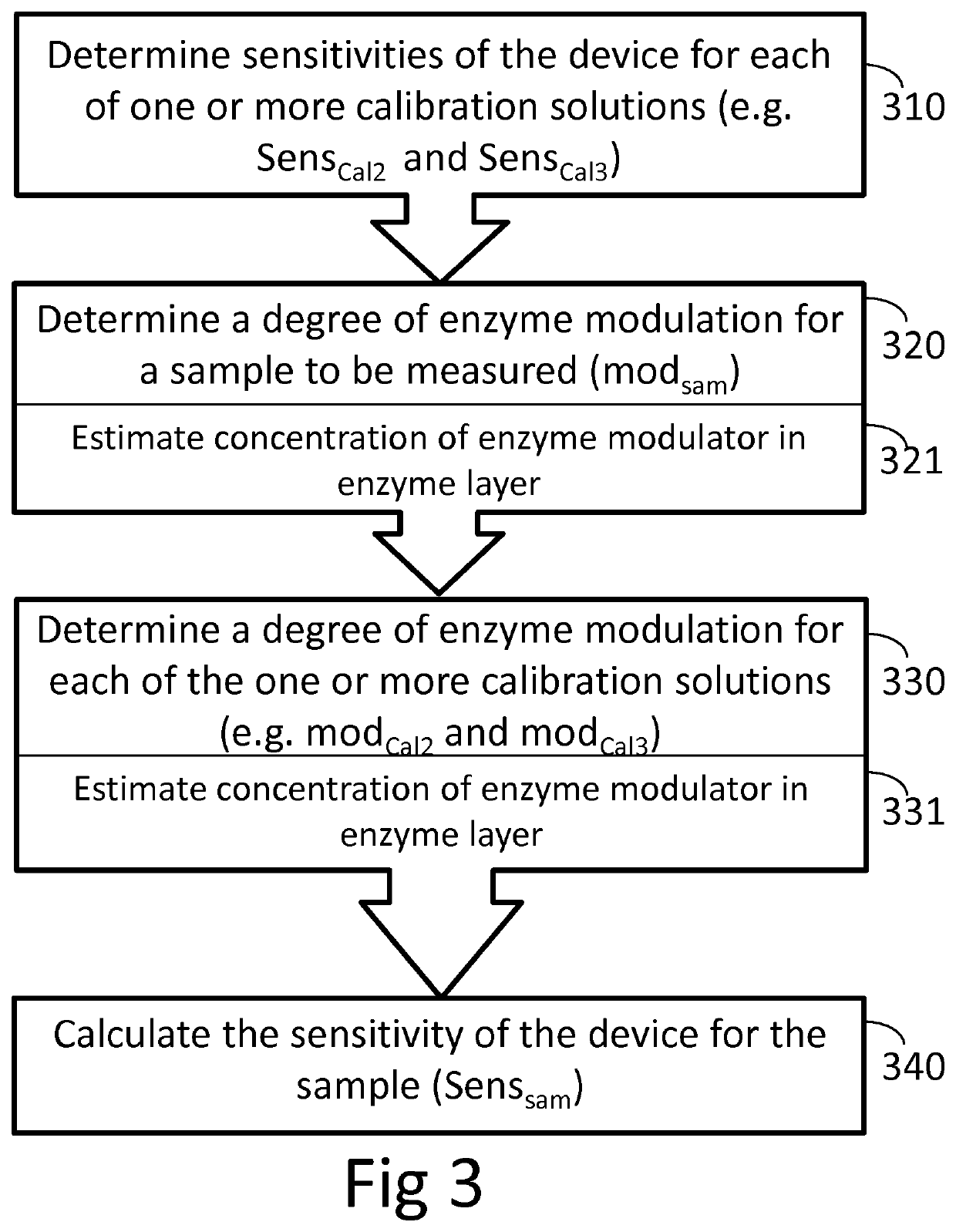

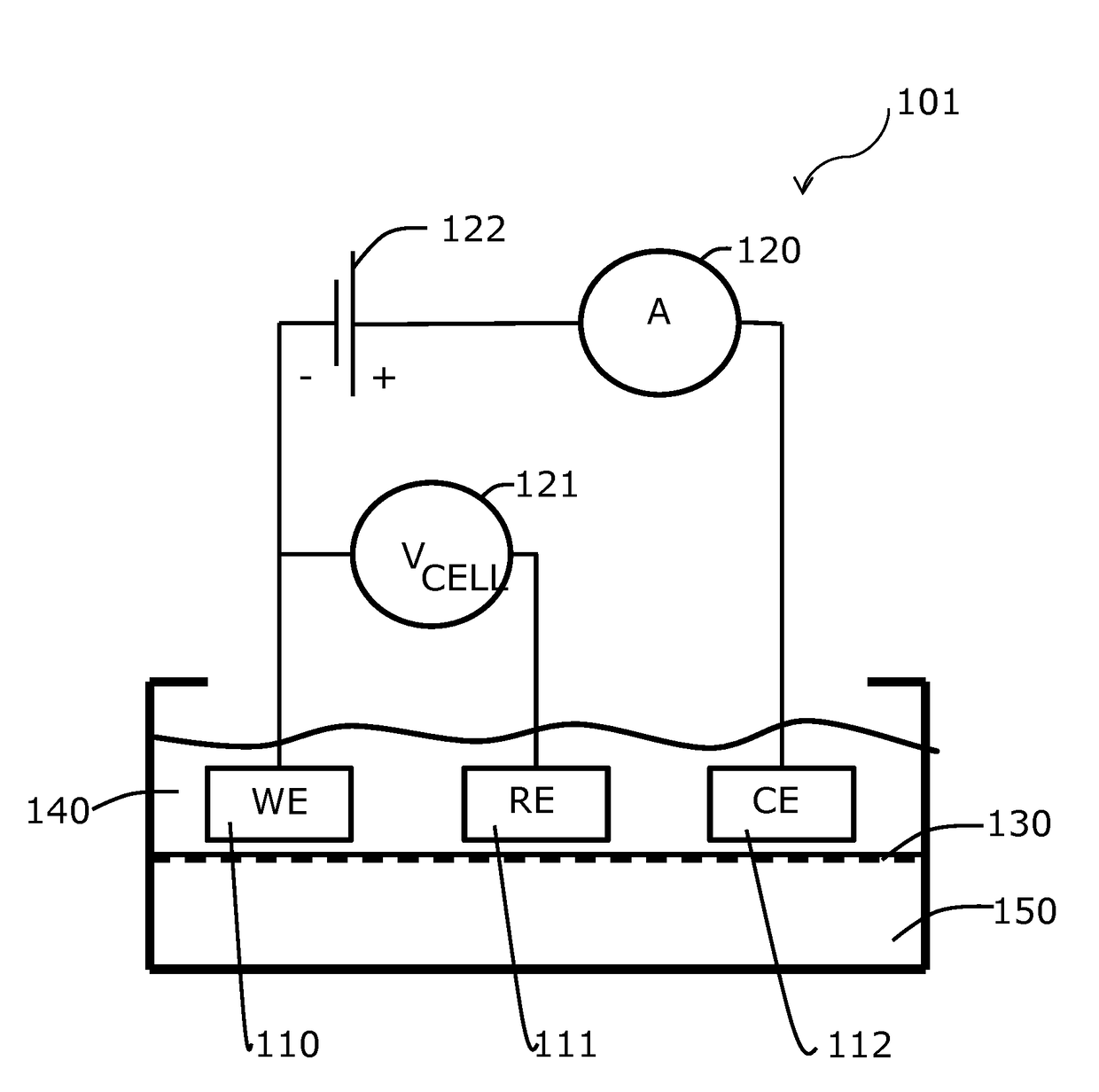

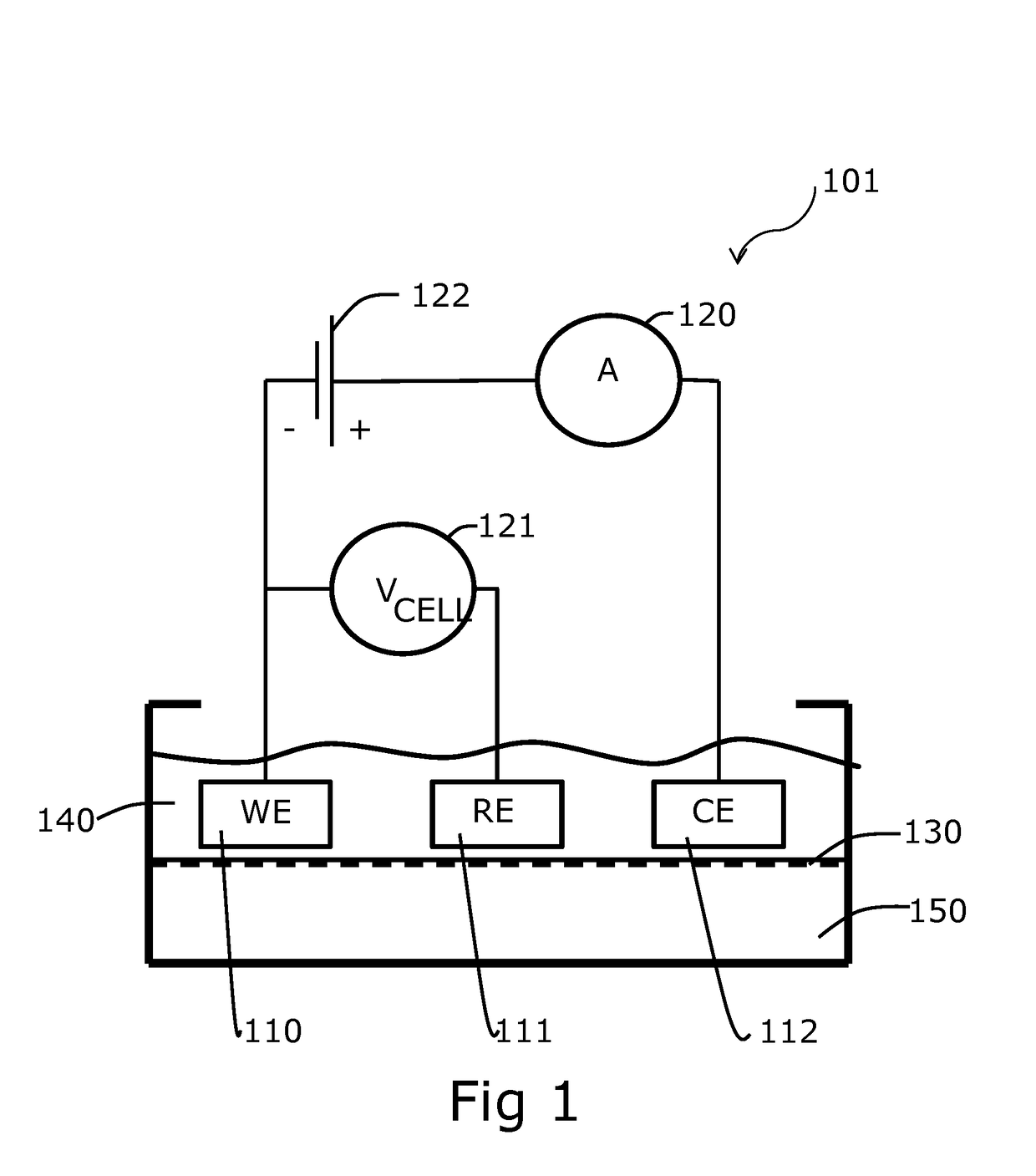

Method for correcting crea sensor for calcium inhibition

ActiveUS20180202963A1Accurately measureIncrease number of sampleHydrolasesMicrobiological testing/measurementPhysicsEnzyme modulator

A method of calibrating a device for measuring the concentration of creatinine in a sample including one or more enzyme modulators, the device comprising an enzyme layer, the method comprising: determining sensitivities of the device for each of one or more calibration solutions; determining a degree of modulation for the sample to be measured, determining a degree of modulation for each calibration solution; wherein said determining of each of the degrees of modulation comprises estimating the concentration of an enzyme modulator in the enzyme layer of the device; and calculating the sensitivity of the device for the sample, wherein the said calculating comprises adjusting the sensitivity of the device for each calibration solution by a factor comprising the determined degrees of modulation of the sample and the calibration solution.

Owner:RADIOMETER AS

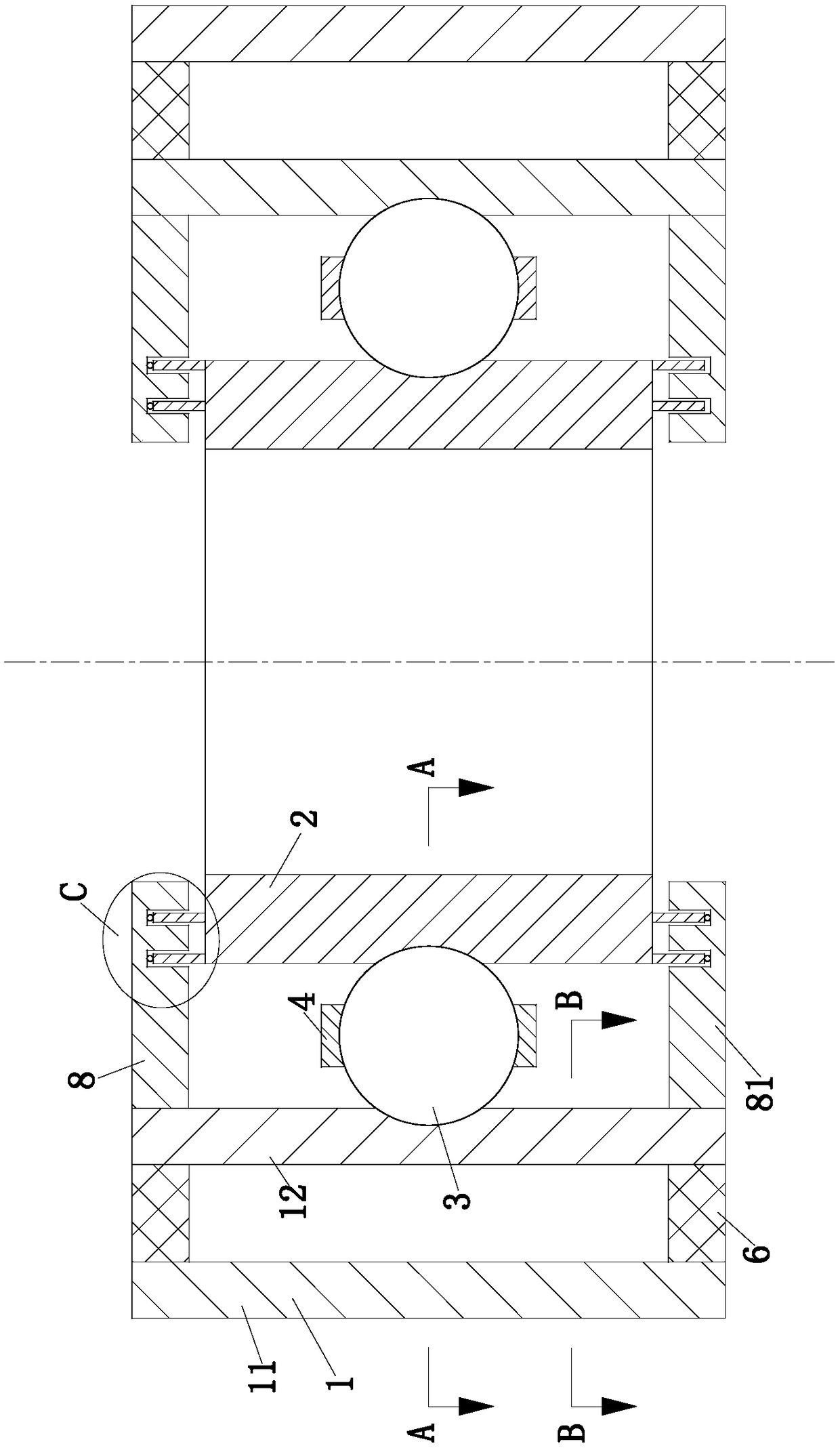

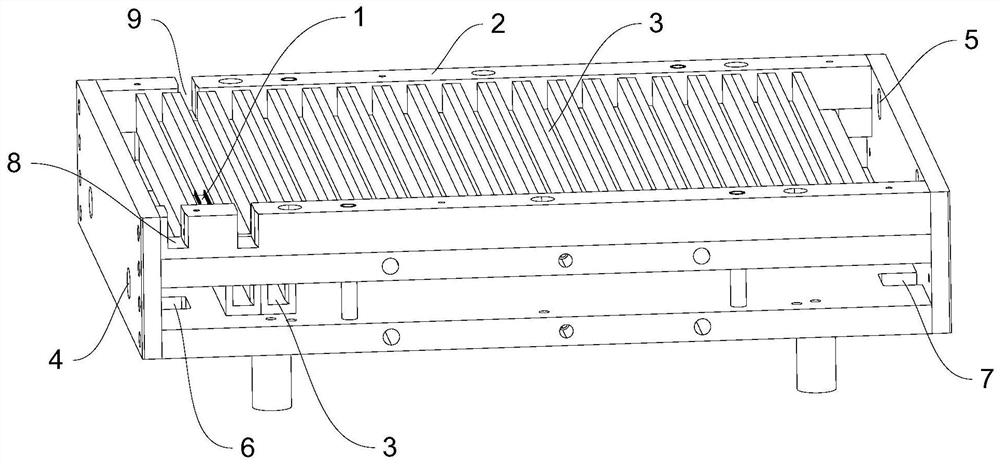

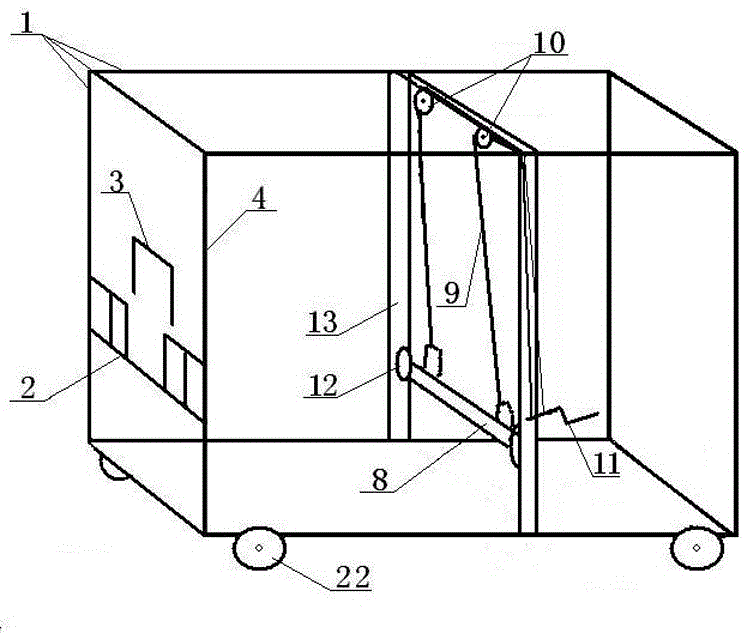

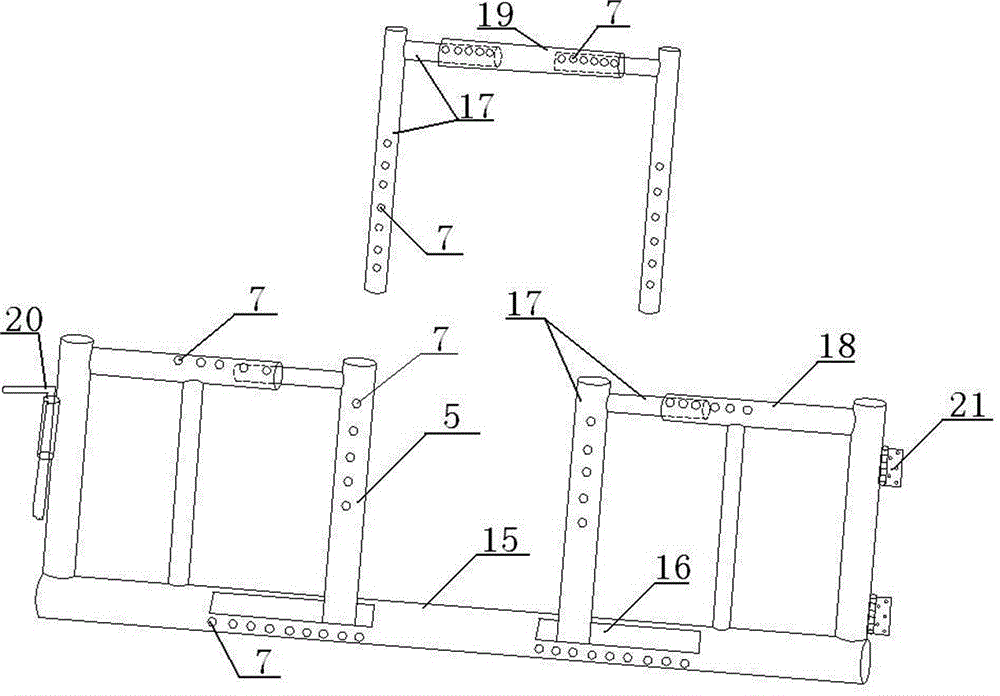

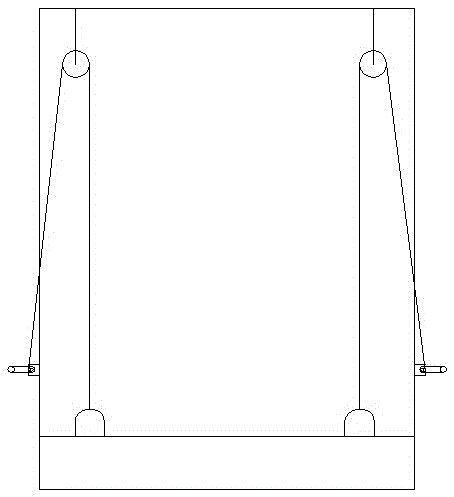

A device for artificial insemination of livestock

The invention discloses a device for artificial insemination of livestock, which is composed of a neck holding mechanism and a rear leg tail holding mechanism. The invention fixes the livestock so that it does not move around, and facilitates the operation of semen injection and fertilization; the width and height of the U-shaped frame can be adjusted, which is suitable for the artificial insemination of animals such as sheep and cattle; the hind hips of the animals are lifted, and the semen does not flow backwards. Keep the semen retention time equivalent to the natural mating time to reduce the chance of infertility; the removable design is convenient for fixed operations in different places; the soft cushion and anti-collision arc are humanized designs to ensure that animals feel comfortable during artificial insemination. Injured, fertilized in good condition, more likely to produce healthy offspring.

Owner:天祝藏族自治县三洋盛生物工程有限公司

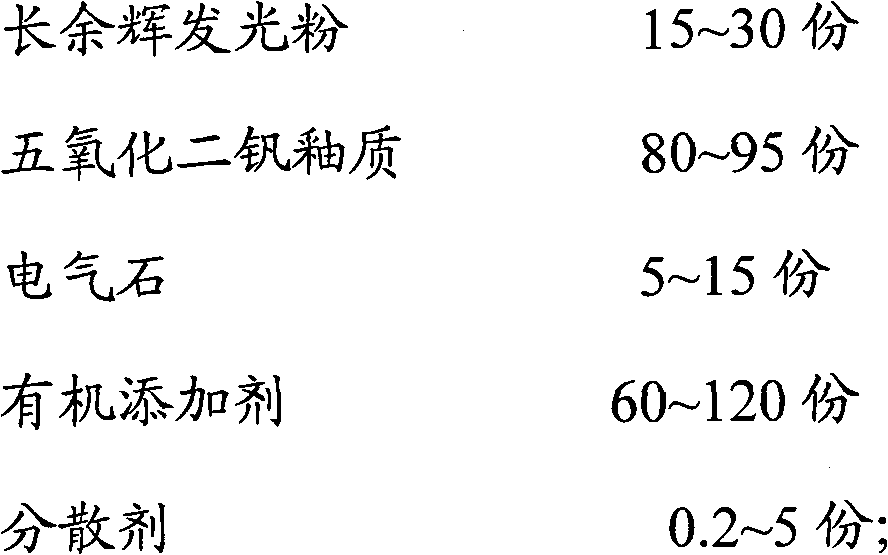

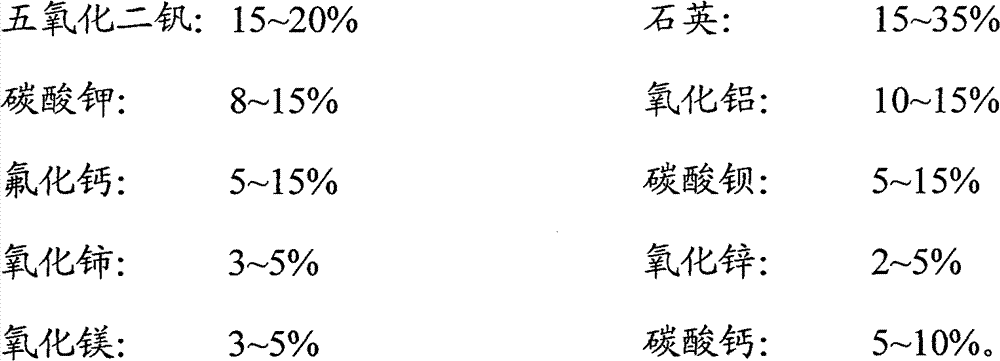

Long-persistence luminous enameled plate and preparation method thereof

Owner:ZHEJIANG KAIER IND +1

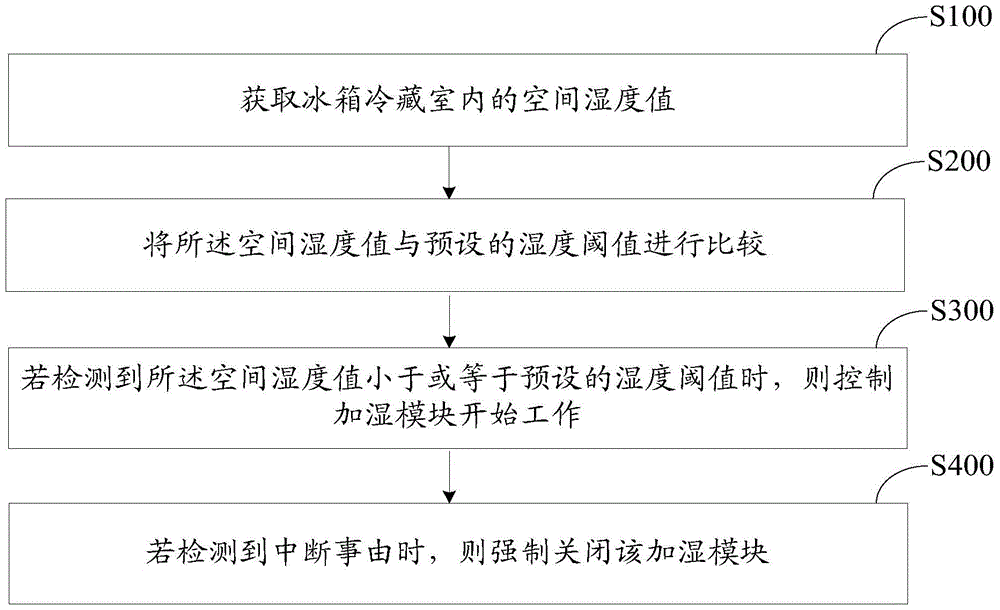

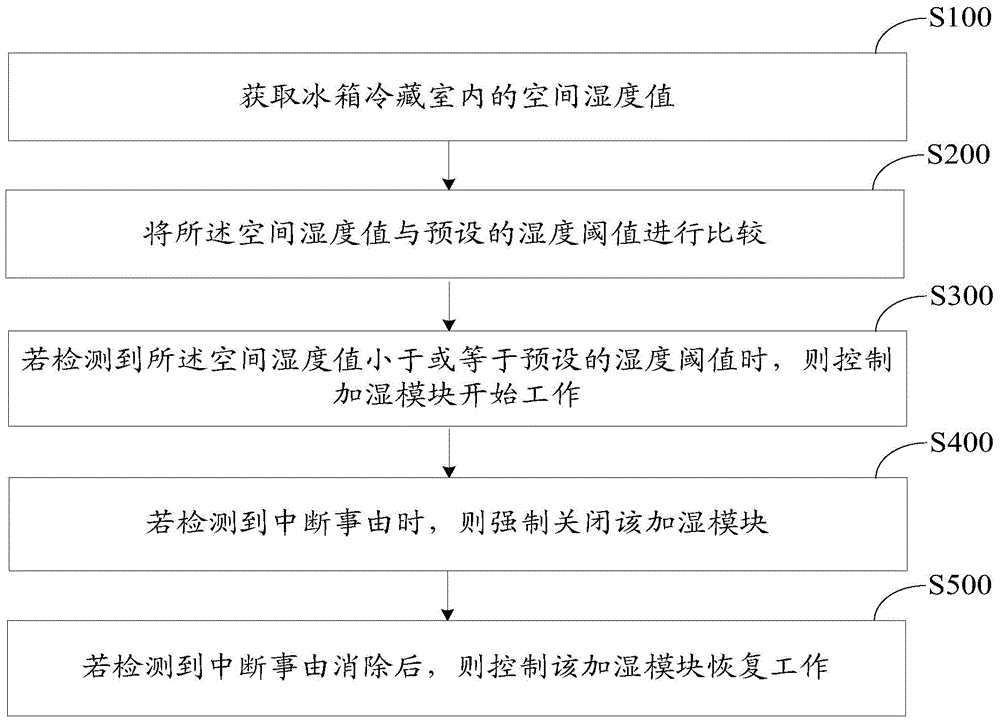

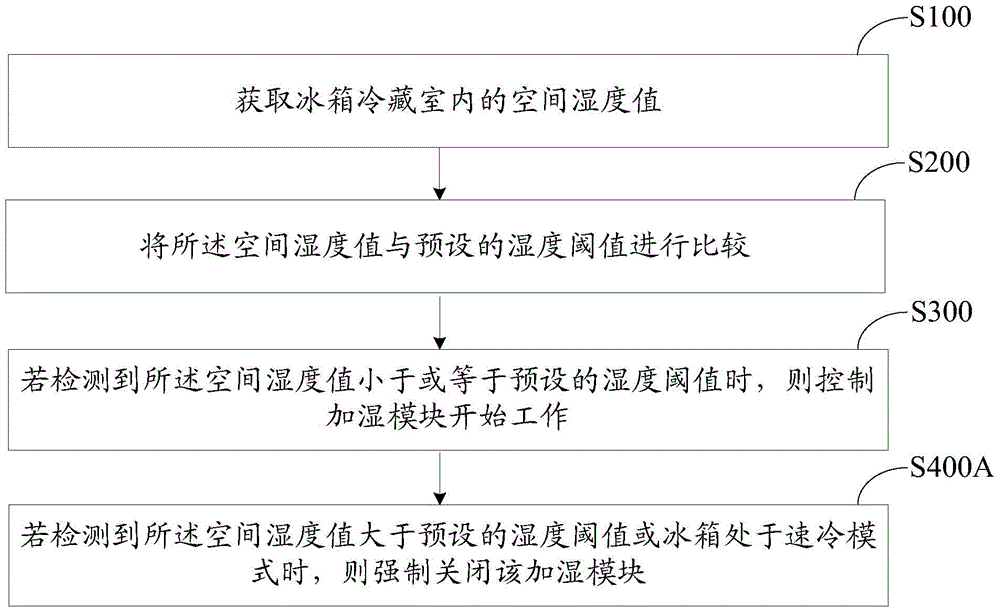

Humidity control method, device and refrigerator

ActiveCN104359284BHold timeKeep freshLighting and heating apparatusCooling fluid circulationTemperature controlHigh humidity

The invention discloses a temperature control method. The method comprises the steps of acquiring a space humidity value in a refrigerator refrigerating chamber; comparing the space humidity value with a preset humidity threshold value; controlling a humidifying module to begin to work when the detected space humidity value is smaller than or equal to the preset humidity threshold value; forcedly closing the humidifying module when an interruption event is detected. The invention also discloses a temperature control device and a refrigerator. By adopting the temperature control method and device and the refrigerator, the refrigerator refrigerating chamber space is enabled to stay at a constant high-humidity state, so that the cold storage time and freshness of food can be maintained, and the user experience can be enhanced.

Owner:HEFEI HUALING CO LTD

Selection method of transition point of motion diagram based on non-linear manifold learning

InactiveCN104658023AExcellent time and efficiencyImprove accuracyAnimationData segmentDimensionality reduction

The invention discloses a selection method of a transition point of a motion diagram based on non-linear manifold learning, and belongs to the technical field of computer image processing. The method comprises the steps of performing dimensionality reduction analysis of high dimensional data, extracting key data segments, computing interframe similarity of the key data segments, and constructing the motion diagram.

Owner:DALIAN YOUJIA SOFTWARE TECH

Keratin softening patch

InactiveCN107872970AImprove witheringHold timeCosmetic preparationsToilet preparationsIrritationMedicine

The present invention relates to a cataplasma, a patch and a kit, all of which are for keratin care. According to the present invention, the kit has less chemical or physical irritation when used, anexcellent keratin removal effect, an easy method of use and even an excellent moisturizing effect.

Owner:宇信乐宝贴剂

A method and system for synchronizing read data based on ddr

ActiveCN108038068BEliminate bottlenecksResolve synchronizationElectric digital data processingComputer hardwareData synchronization

Owner:灿芯创智微电子技术(北京)有限公司

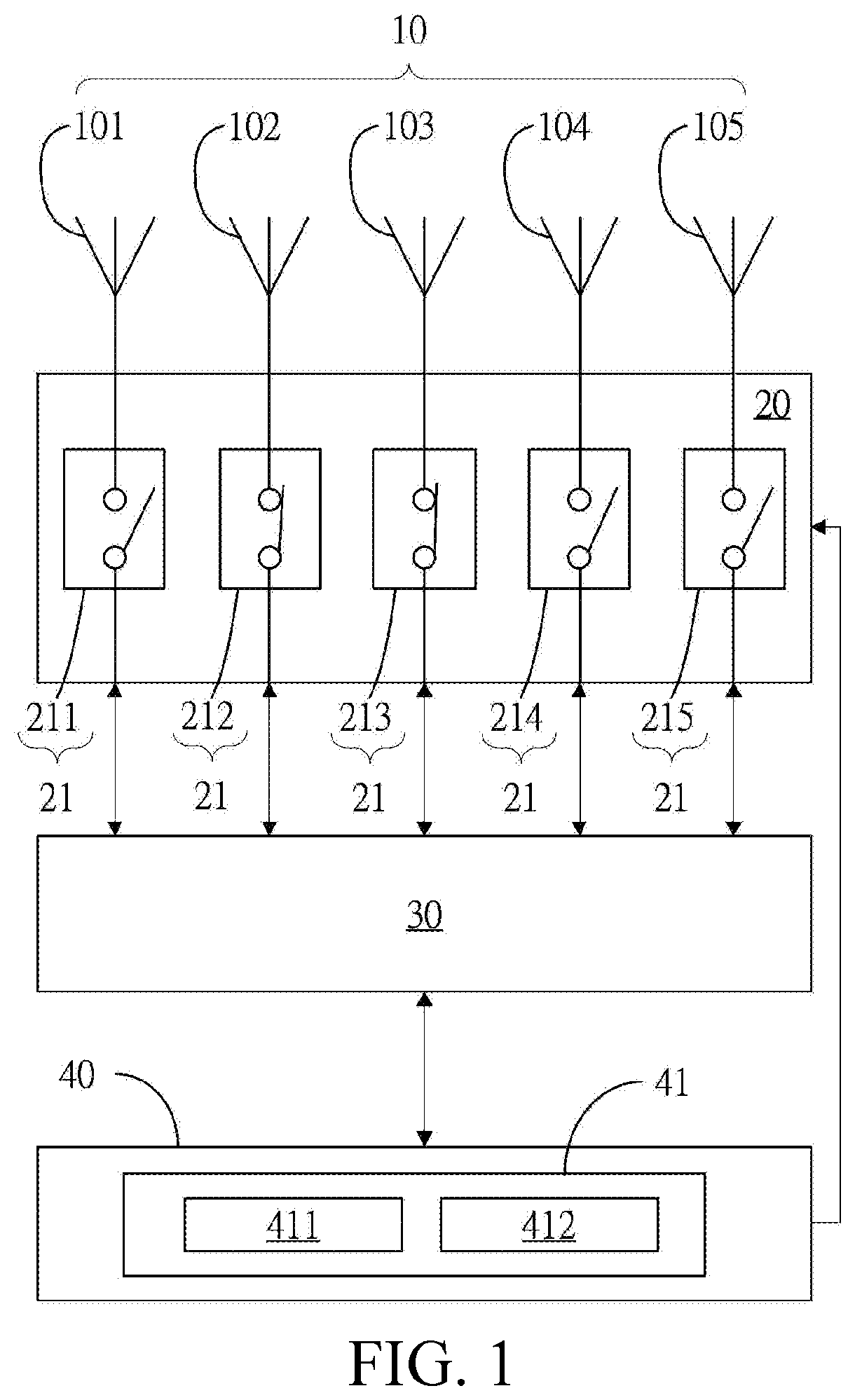

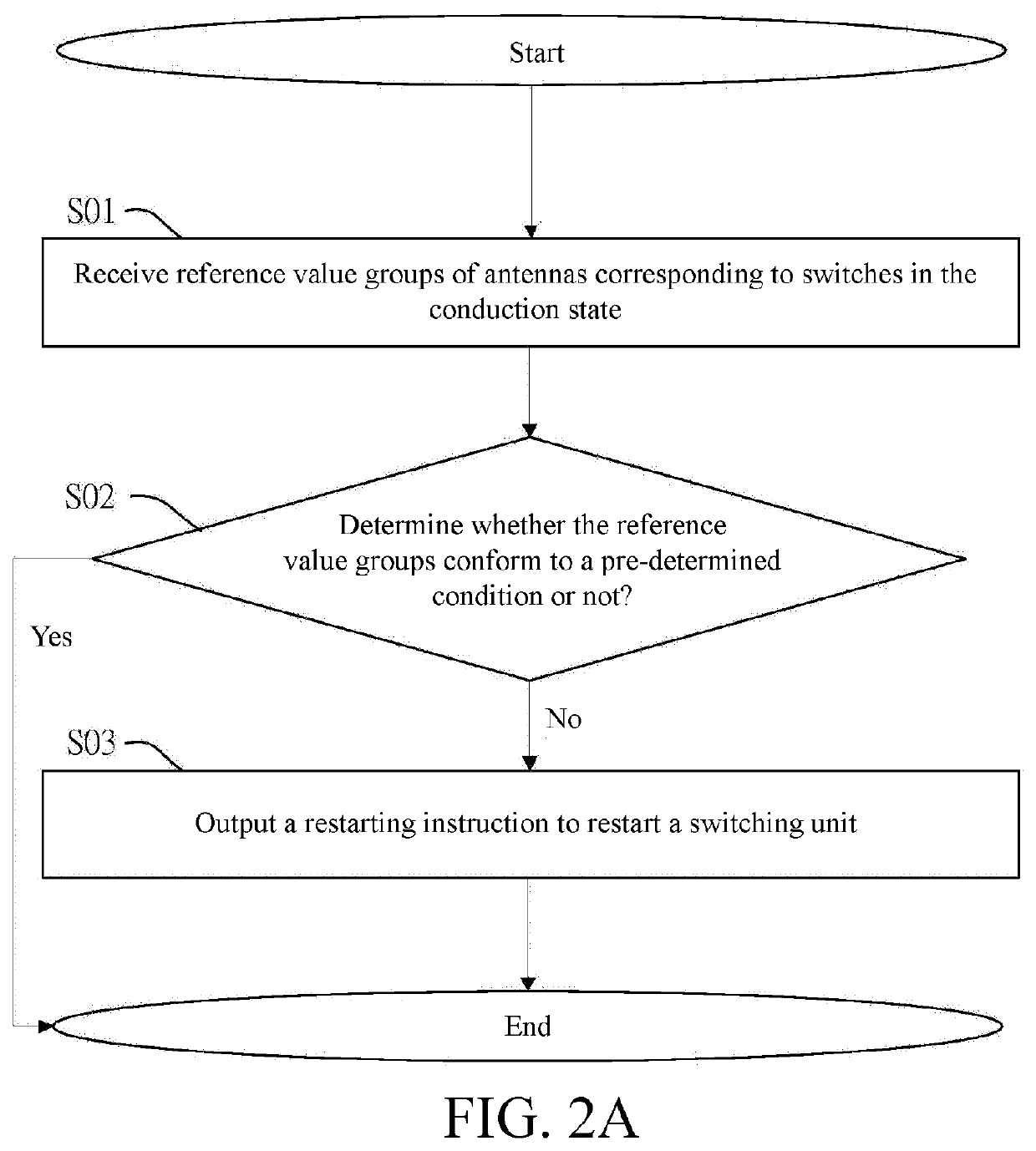

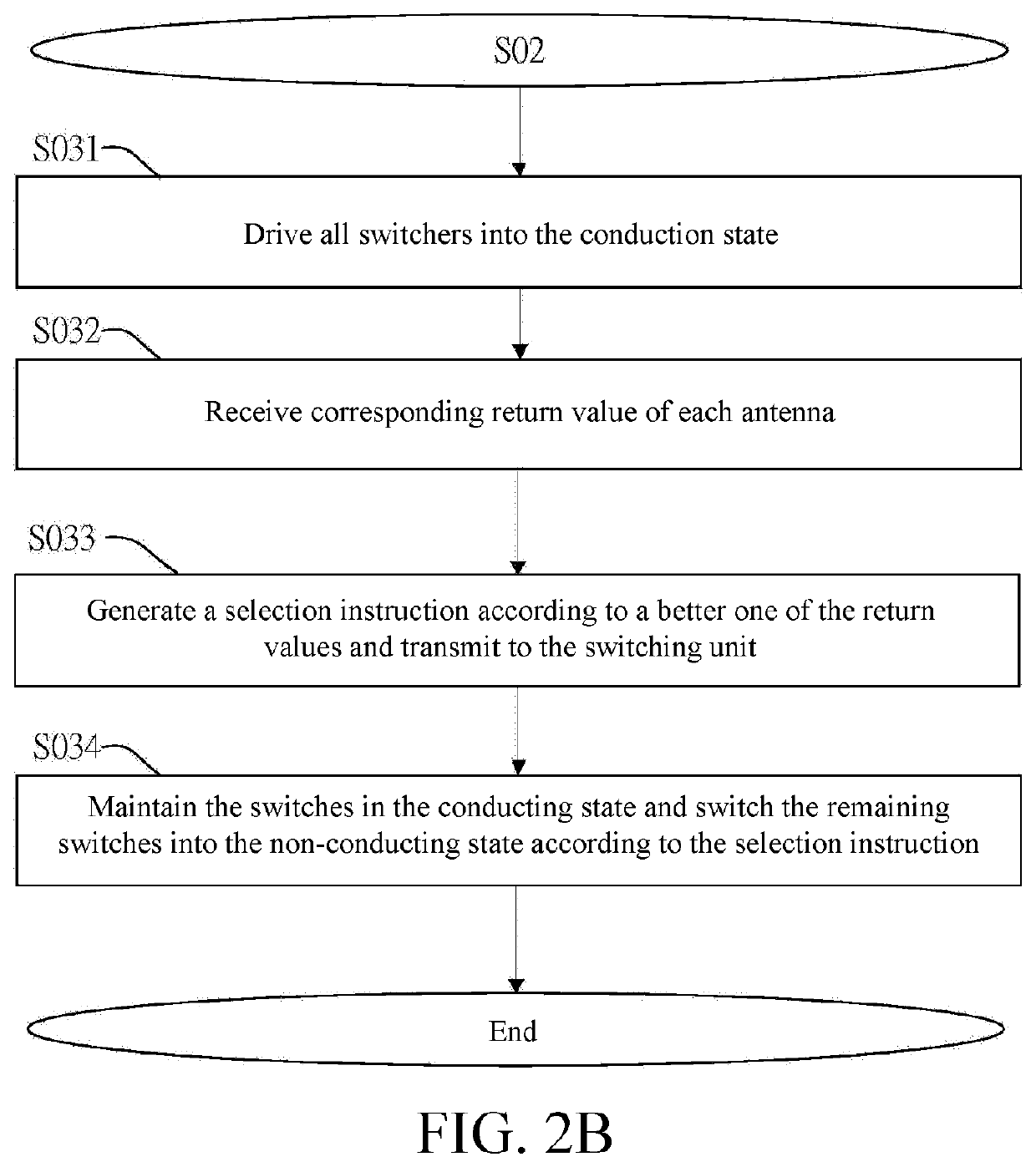

Antenna system and restarting method thereof

ActiveUS20190364572A1Good wireless transmission qualityHold timeRadio transmissionDifferential interacting antenna combinationsEngineeringElectrical and Electronics engineering

An antenna system includes: a plurality of antennas; a switching unit, having a plurality of switches, wherein each of the plurality of switches and the corresponding antenna are in a conducting state or in a non-conducting state; a communication unit, connected with each of the plurality of switches of the switching unit, and coupled with the antennas, wherein the communication unit receives a reference value group of the corresponding antenna from the switch in the conducting state; and a control unit, connected with the switching unit and the communication unit, wherein the control unit receives the reference value group from the communication unit, and compares the reference value group with an threshold, to determine whether the reference value group conforms to a pre-determined condition or not, and outputs a restarting instruction to restart the switching unit when the reference value group does not satisfy the pre-determined condition.

Owner:ASUSTEK COMPUTER INC

Motion diagram transition point selecting method based on nonlinear manifold learning

The invention discloses a motion diagram transition point selecting method based on nonlinearity manifold learning and belongs to the technical field of computer image processing. The method includes the steps of dimensionality reduction analysis of high dimensional data, extraction of key data segments, calculation of key data segment interframe similarity and construction of motion diagrams.

Owner:DALIAN UNIV

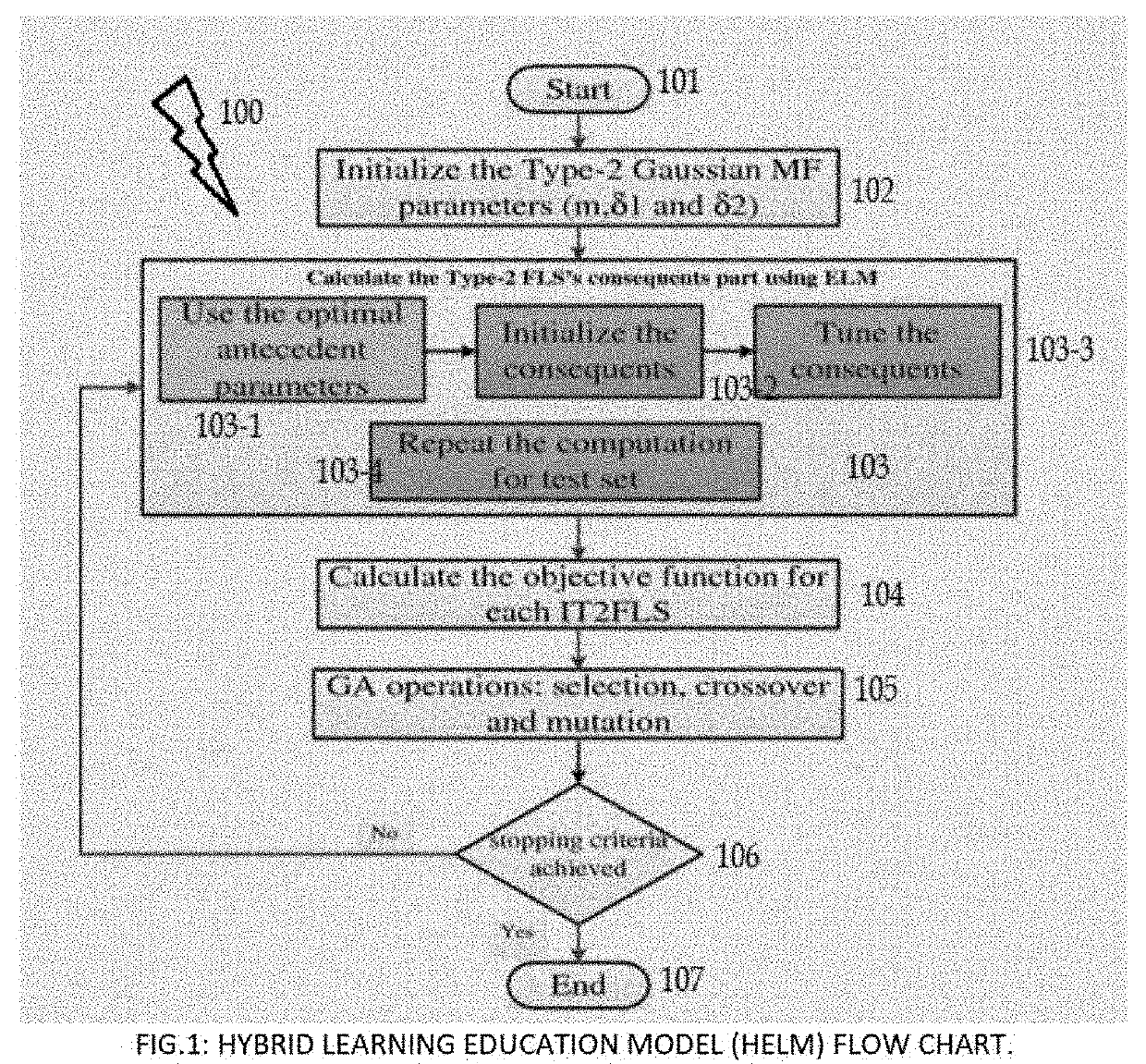

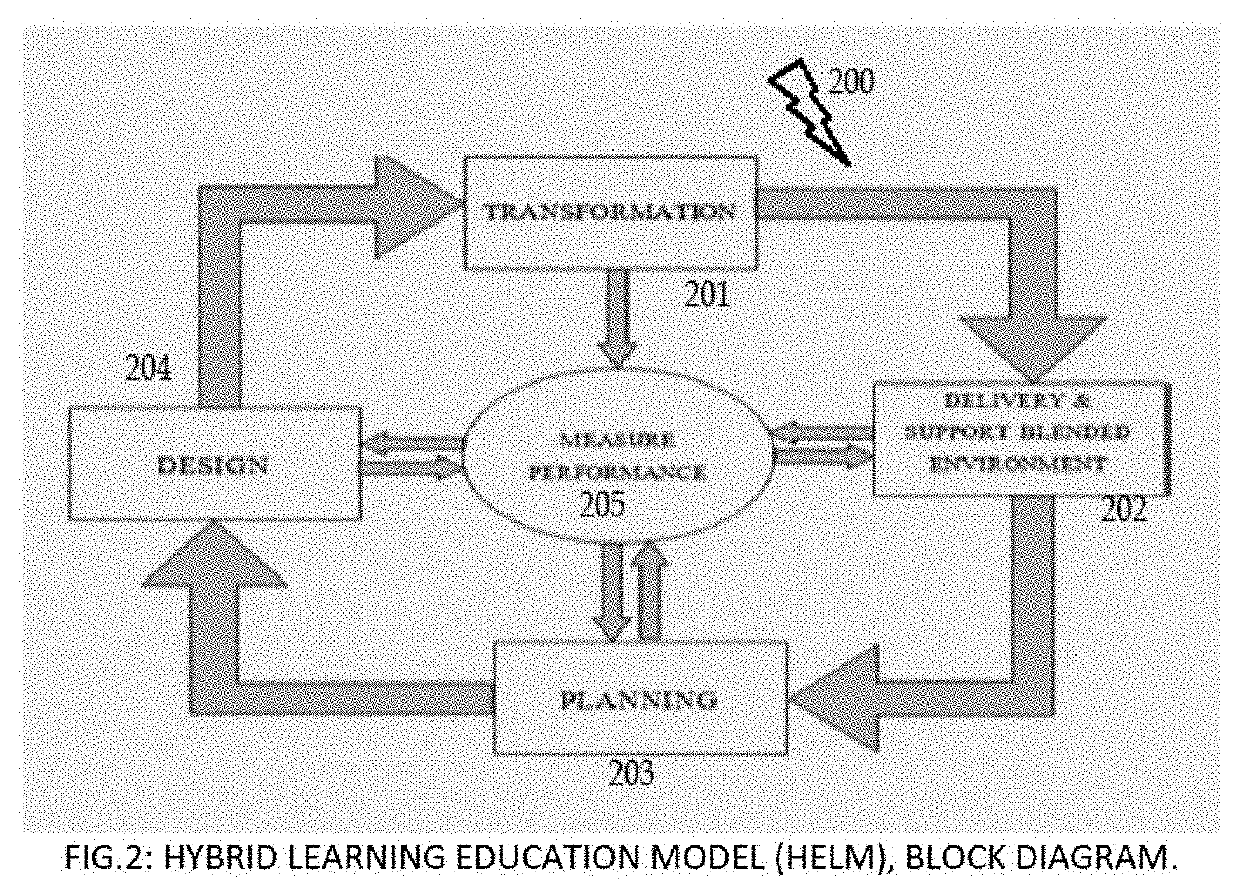

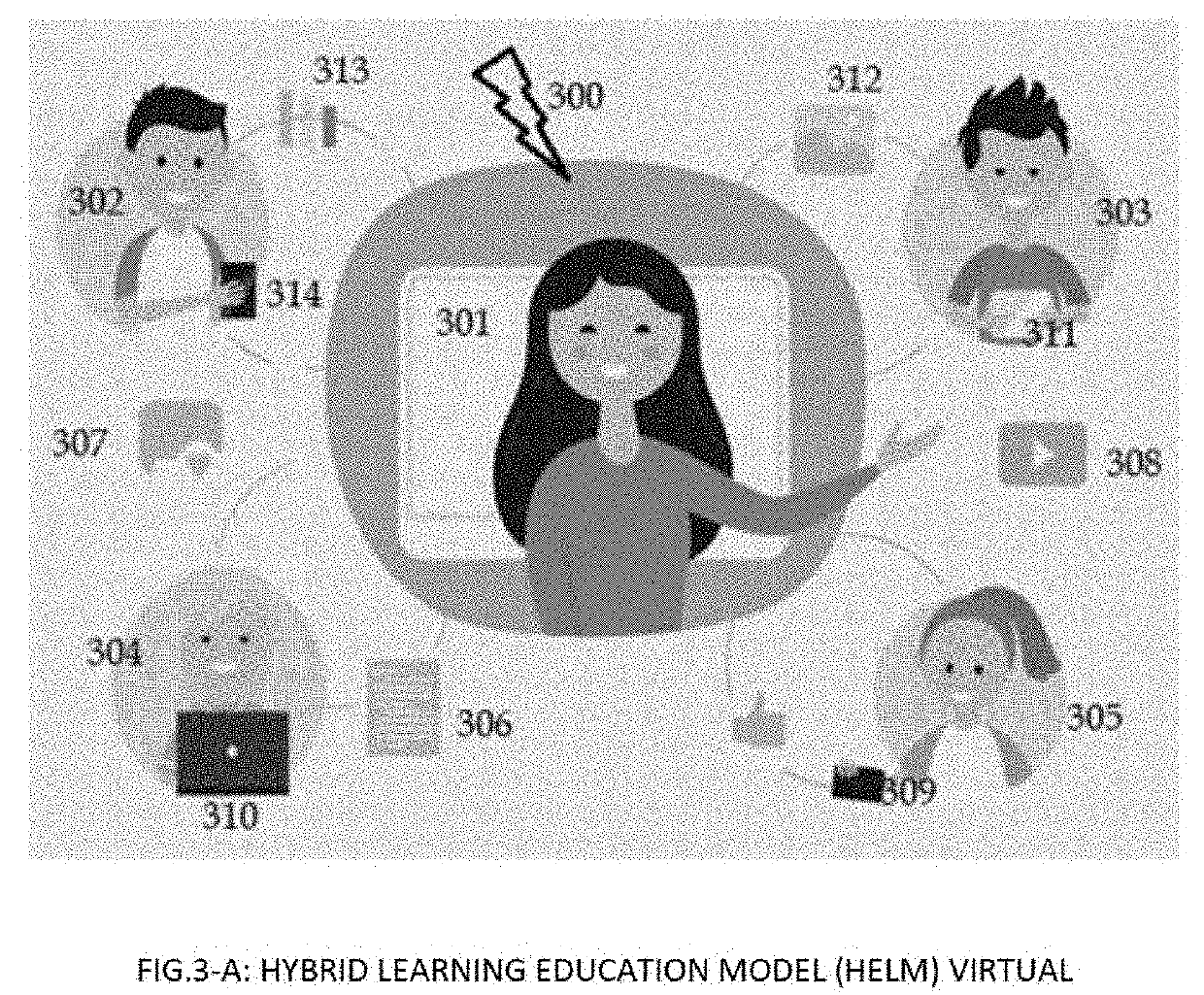

Hybrid learning education model (HLEM)

InactiveUS20210407026A1Enhance numerous answerHold timeData processing applicationsElectrical appliancesEngineeringKnowledge management

The Hybrid Learning Education Model (HLEM) is provided with an objective to ensure that learning is accessible, affordable, inclusive, developmental to educate learners beyond boundaries. Over many decades, teaching and learning was largely restricted to physical schools purely through face-to-face learning. The COVID-19 pandemic & subsequent lockdowns totally disrupted teaching & learning due to school closures announced by all countries globally. Technology in classroom was seen as one of the supplementary learning tools in education. Physical Schools and educational institutions held governance of student teaching & learning. Home schooling was seen in the dim light of educational progress towards sustenance. While Design Learning (DL) and outcome-based approach gained prominence, the Design Learning (DL) methods have been comprehensively used in various regions, there by assisting in teaching, learning, evaluation, and outcome-based assessment. In this advancement, we present an outline of the HLEM through Parent campus and Home Campuses, essentially looking at it from a origin, initiation, screening and assessment perspectives.

Owner:CHOWALLOOR FRANCIS JOSEPH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com