Sodium hyaluronate gel lubricating liquid, filling agent and preparation method and application of sodium hyaluronate gel lubricating liquid and filling agent

A technology of sodium hyaluronate and lubricating fluid, which is used in pharmaceutical formulations, prostheses, drug delivery, etc., to simplify the preparation process, facilitate injection, and reduce pushing force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The compounding comprises the following steps: uniformly centrifuging and mixing the sodium hyaluronate gel particles and the lubricating liquid at a centrifugal speed of 5000 rpm to obtain the sodium hyaluronate gel filler.

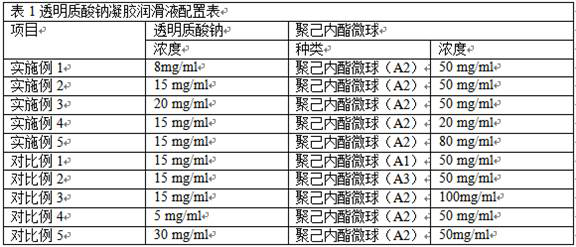

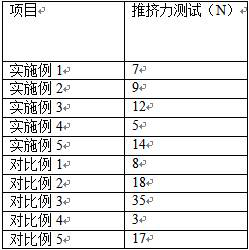

[0056] The sodium hyaluronate gel fillers prepared from the lubricating solutions in Examples 1-10 and Comparative Examples 1-5 were tested.

[0057] 【test analysis】

[0058] 【Test Results】

[0059] Table 2

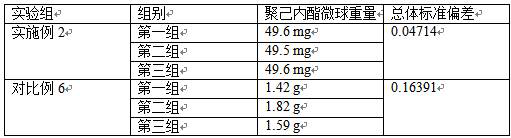

[0060] 2. Polycaprolactone homogeneity test

[0061] The calculation formula for calculating the population standard deviation is as follows: .

Embodiment 1

Embodiment 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com