High-barrier-property polyethylene composition, preparation method, film and application

A polyethylene film, high-barrier technology, used in flexible covering, transportation and packaging, packaging, etc., can solve the problems of unsuitable film, low melting point, poor transparency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

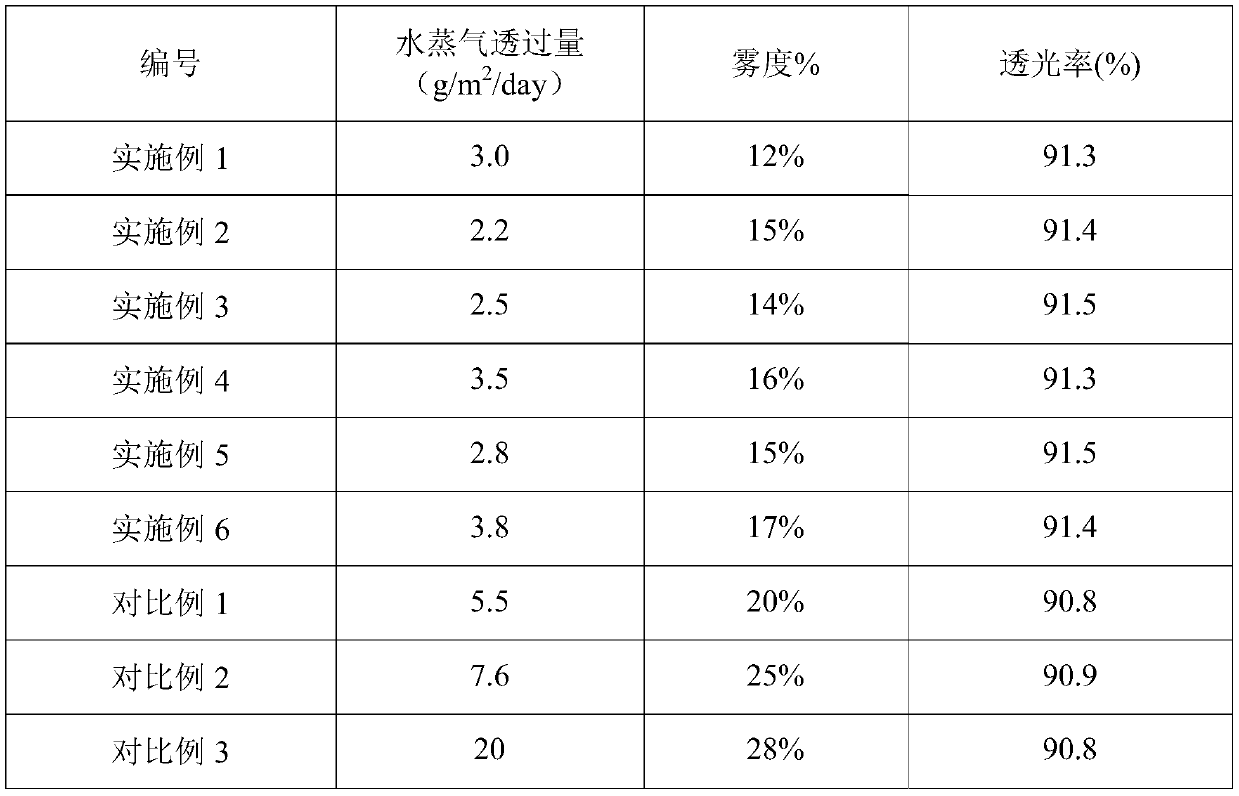

Examples

Embodiment approach

[0021] According to a preferred embodiment of the present invention, the ethylene / 4-methyl-1-pentene copolymer is prepared by a method comprising the following steps:

[0022] Vacuumize and flush the fully dried polymerization device three times. Then vacuumize again, controlled by solenoid valve, fill in ethylene, add reaction solvent toluene, 4-methyl-1-pentene, add methylaluminoxane toluene solution (containing MAO), heat up to 60-80°C, add Metallocene catalyst (such as vinyl bridged bis-indenyl zirconium dichloride) toluene solution, start timing. After 10-20 minutes, turn off ethylene, add acidified ethanol to the reaction solution, stir for more than 6 hours, and filter to obtain a copolymer.

[0023] According to the present invention, it is preferred to select linear low-density polyethylene with the following characteristics: the melt index of the linear low-density polyethylene at 190°C under a load of 2.16kg is 0.1-5g / 10min, preferably 0.2-4g / 10min; 0.90-0.94g / cm ...

Embodiment 1

[0039] This example is used to illustrate the preparation of the polyethylene composition and polyethylene film provided by the present invention.

[0040] 1) Synthesis of ethylene / 4-methyl-1-pentene copolymer.

[0041]Vacuumize and flush the fully dried polymerization device three times. Carry out vacuum again then, solenoid valve control, be filled with the ethene of 1 standard atmospheric pressure, add 19.0 milliliters of reaction solvent toluene, add 1.0 milliliters of 4-methyl-1-pentene, add 9.0 milliliters of methylalumoxane toluene solution (containing MAO 15.0 mmol), the temperature was raised to 70° C., 1.0 ml of toluene solution containing 10.0 micromol of racemic vinyl bridged indenyl zirconium dichloride was added, and timing was started. After 15 minutes, turn off ethylene, add acidified ethanol to the reaction solution, stir for more than 6 hours, filter to obtain the copolymer, dry it in vacuum for 24 hours, and weigh to obtain 2.47 grams of copolymer. The mol...

Embodiment 2

[0046] This example is used to illustrate the preparation of the polyethylene composition and polyethylene film provided by the present invention.

[0047] 1) Synthesis of ethylene and 4-methyl-1-pentene copolymer.

[0048] Vacuumize and flush the fully dried polymerization device three times. Carry out vacuum again then, solenoid valve control, be filled with the ethene of 1 standard atmospheric pressure, add 19.0 milliliters of reaction solvent toluene, add 1.0 milliliters of 4-methyl-1-pentene, add 9.0 milliliters of methylalumoxane toluene solution (containing MAO 15.0 mmol), the temperature was raised to 70° C., 1.0 ml of toluene solution containing 10.0 micromol of racemic vinyl bridged indenyl zirconium dichloride was added, and timing was started. After 15 minutes, turn off ethylene, add acidified ethanol to the reaction solution, stir for more than 6 hours, filter to obtain the copolymer, dry it in vacuum for 24 hours, and weigh to obtain 2.47 grams of copolymer. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com